Rapid and automatic detection method and controller for shaft sleeve crack of mechanical sealing element

A mechanical seal, automatic detection technology, used in the use of liquid/vacuum for liquid tightness measurement, instruments, by measuring the acceleration and deceleration rates of fluids, etc., can solve long detection time, high detection cost, and automation difficulties problem, to achieve the effect of high degree of automation, high detection efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

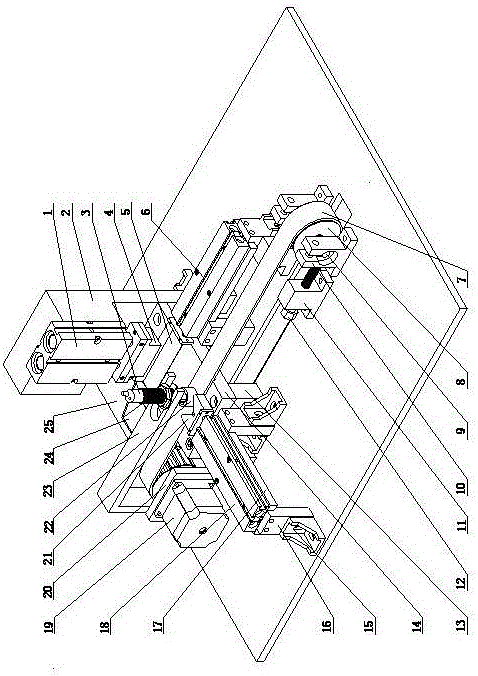

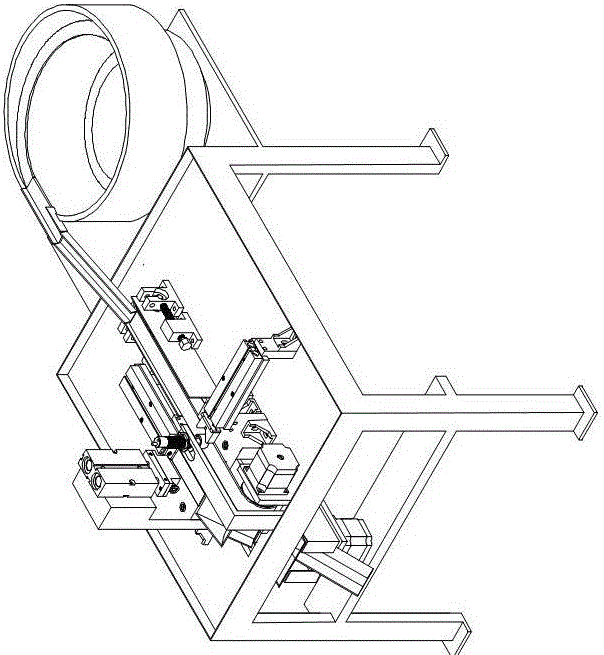

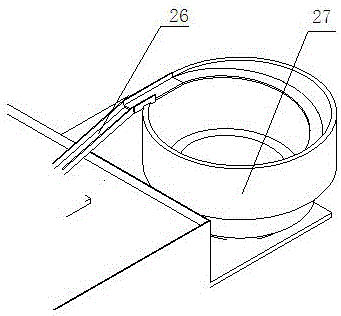

[0023] In order to better understand the present invention, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods, see Figure 1 to Figure 4 :

[0024] According to the method for fast and automatic detection of shaft sleeve cracks of mechanical seals implemented in the present invention, its measurement principle is as follows: after sealing the workpiece to be tested, inflate the inside of the workpiece, and after holding the pressure for a period of time, the qualified products without cracks leak slowly, and the internal The air pressure is stable, which is almost the same as the output air pressure of the external air source. There are cracks and unqualified products. When the air pressure reaches 0.4MPa, the air leakage is serious, so the air pressure is unstable or the value of the stabilized pressure is small. The digital electronic barometer collects the air pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com