Automatic detection system and method for spherical fuel element fuel-free section

A spherical fuel element, automatic detection technology, applied in the direction of using radiation for material analysis, sorting, etc., can solve the problems of non-traceability, decreased attention, long detection cycle, etc., to achieve low operation and maintenance costs, rapid automatic detection, The effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

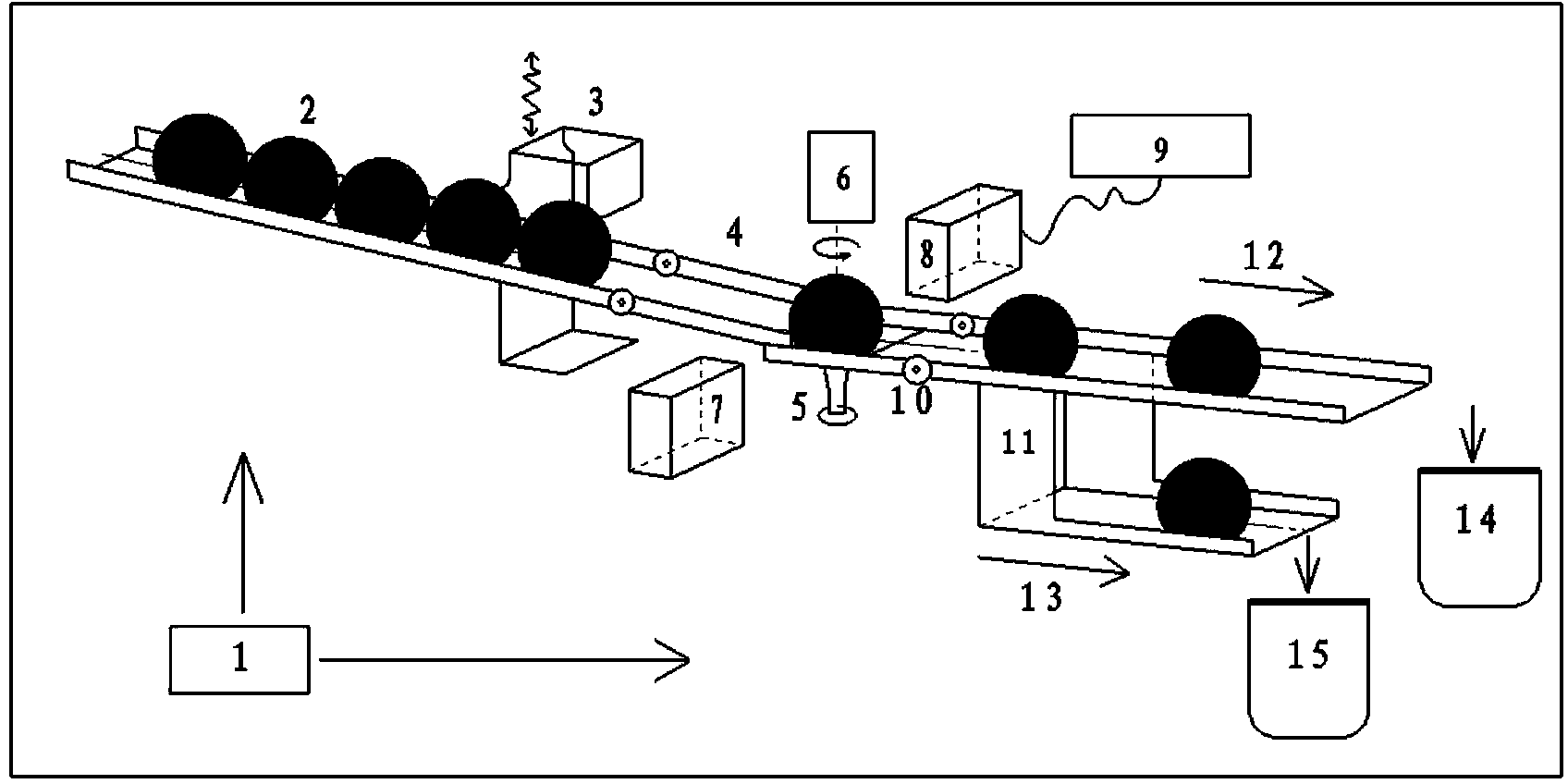

[0051] The embodiment of the present invention provides an automatic detection system for the fuel-free area of spherical fuel elements, see figure 1 , the system consists of:

[0052] Transmission components, including a transmission channel (2-4-12 or 2-4-13 according to the route) for transmitting spherical fuel elements, and an element queuer 3 for stopping the spherical fuel elements to be detected according to the queuing signal , and the channel selector 11 for making the detected spherical fuel element lead to the qualified product channel 12 or the unqualified product channel 13 according to the detection result signal;

[0053] The detection component includes a vacuum suction cup placed on the transmission channel that is started or stopped according to the detection and collection signal, a rotating device 6 that drives the vacuum suction cup to rotate horizontally according to the detection and collection signal, and X-ray emission devices placed oppositely on bot...

Embodiment 2

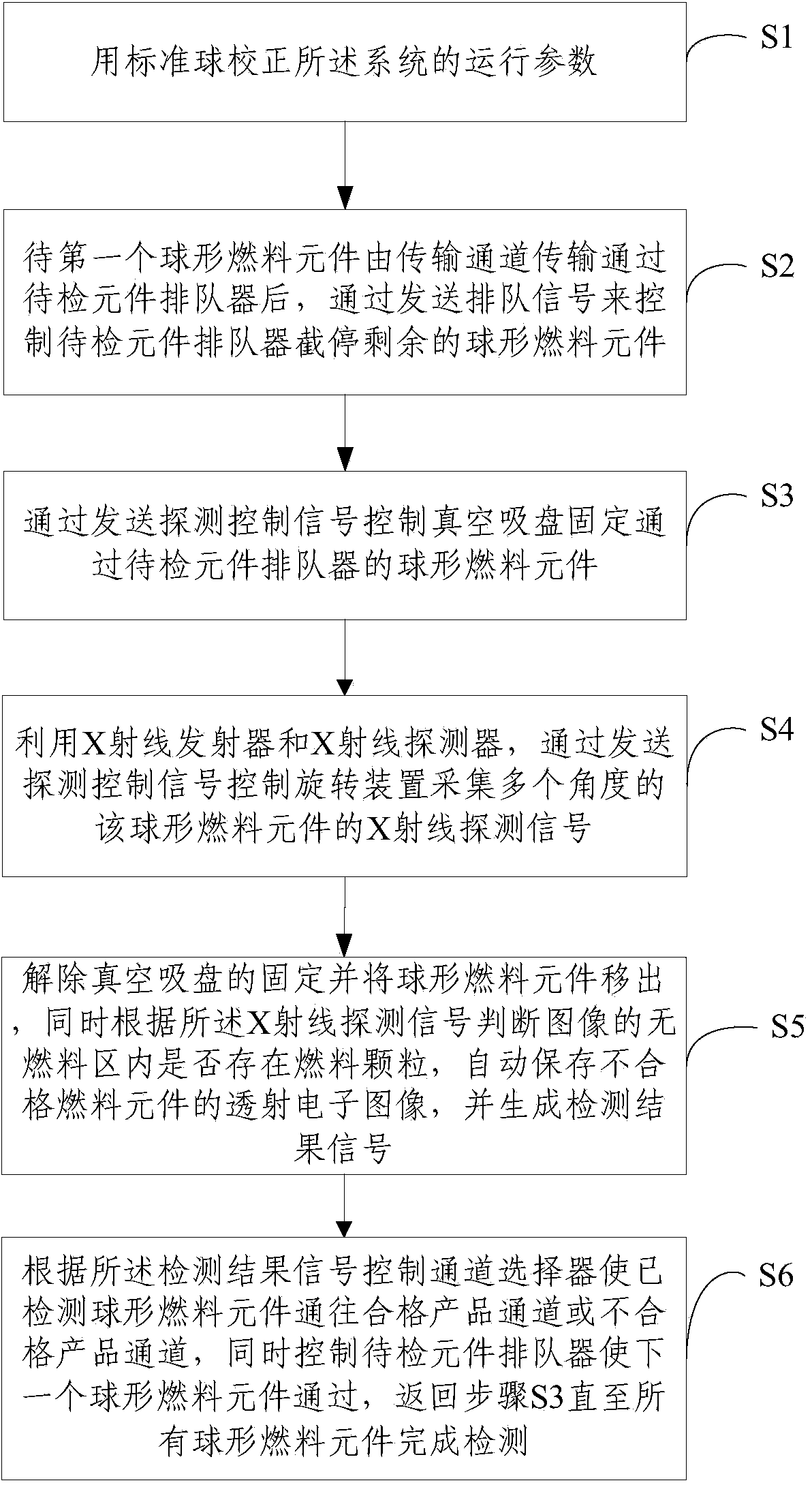

[0066] The embodiment of the present invention proposes an automatic detection method for the fuel-free area of the spherical fuel element using any system in embodiment 1, see figure 2 , the method includes:

[0067] Step S1: Calibrate the operating parameters of the system with a standard spherical fuel element sample;

[0068] Step S2: After the first spherical fuel element is transmitted through the transmission channel through the element queuer to be inspected, control the element queuer to stop the remaining spherical fuel elements by sending a queuing signal;

[0069] Step S3: controlling the vacuum chuck to fix the spherical fuel element passing through the queue of the element to be inspected by sending the detection and collection signal;

[0070] Step S4: using the X-ray emitter and the X-ray detector to collect the X-ray detection signals of the spherical fuel element at multiple angles by sending detection collection signals to control the rotating device;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com