Work piece automatic welding method based on grating projection three-dimensional reconstruction

An automatic welding and grating projection technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that it is difficult to ensure the consistency and accuracy of processing, low welding efficiency, and difficult to ensure welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

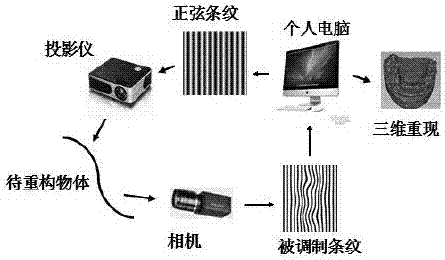

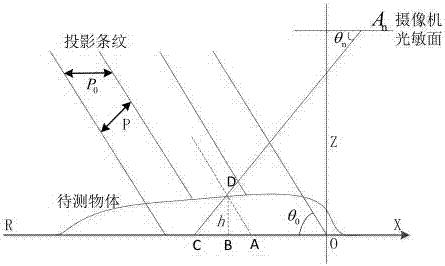

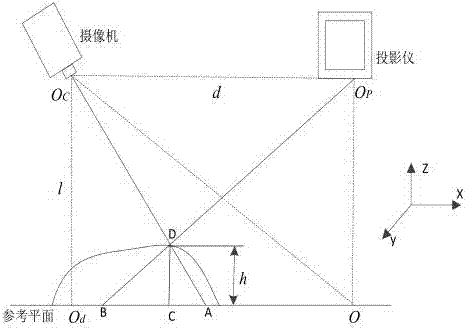

[0010] figure 1 Shown is a schematic diagram of the structure of the raster projection system. A set of three-dimensional reconstruction system based on digital raster projection mainly includes hardware such as computer, industrial computer, camera and projector. The sinusoidal grating stripes are generated by a computer programming control projector and projected onto the reference plane and the surface of the object, and the camera is used to capture images of the reference plane and the object carrying the deformed grating stripes. First, the digital projection device projects grating stripes with sinusoidal distribution of light intensity to the reference plane, and the camera captures and saves the image of the reference plane with grating stripes at the same time. Then, put the object to be measured, project the same grating image onto the surface of the object to be measured, use a camera to capture and save the grating image deformed by the surface modulation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com