Device and method for automatically detecting defects of cylinder liners by aid of X-rays

An automatic detection device and automatic detection technology, applied in the direction of material analysis using radiation, can solve problems such as inaccurate detection results, defects, and inaccurate images, and achieve the effect of avoiding the decline of image resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

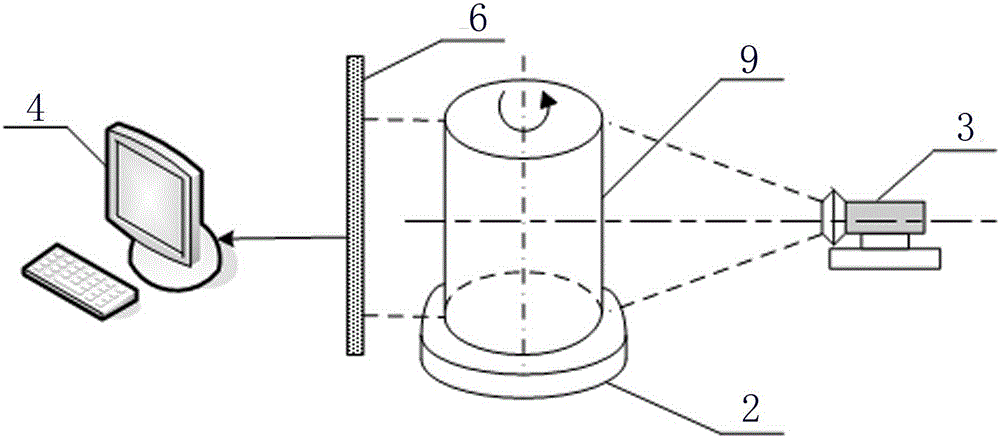

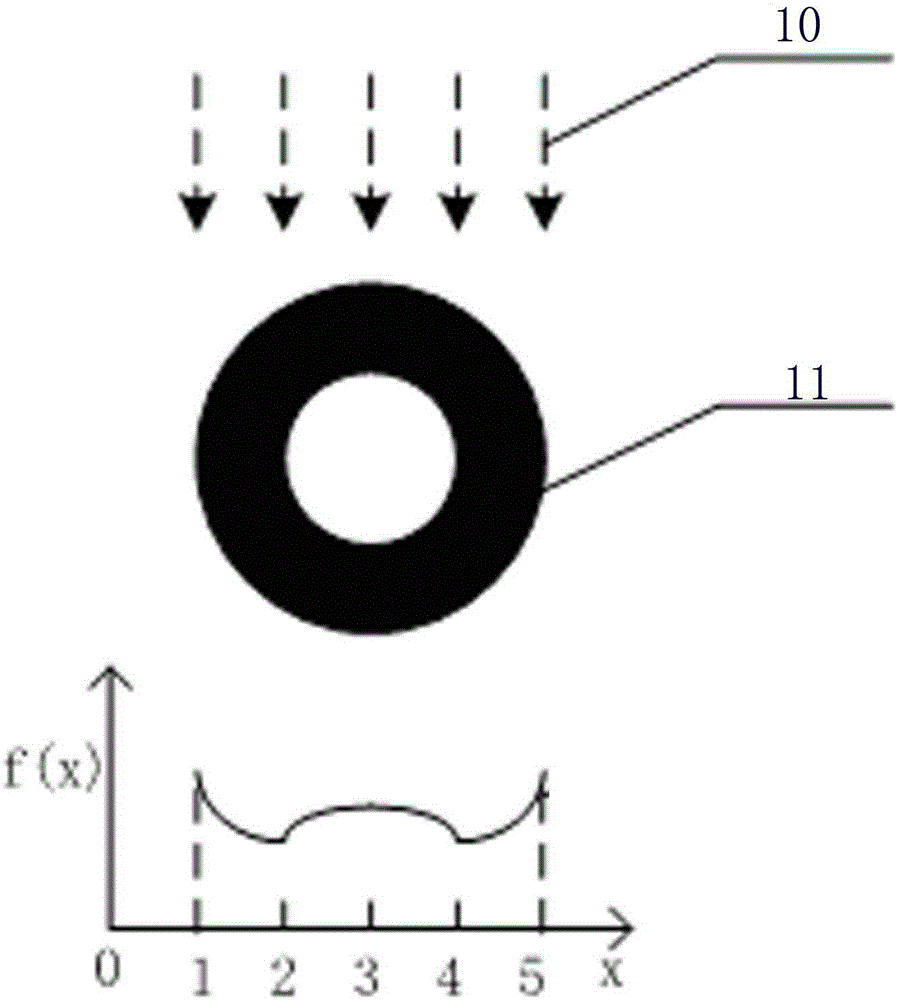

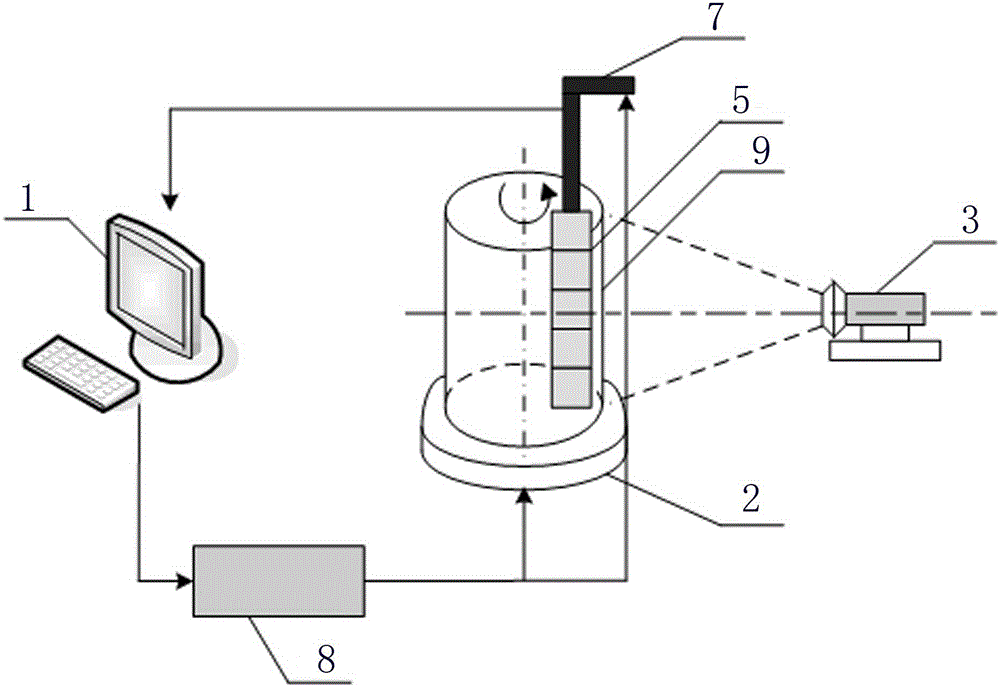

[0054] An automatic X-ray detection device for cylinder liner defects, including a computer control and image processing unit 1, a detection workbench 2, and an X-ray tube 3; it also includes a linear array imaging device 5 matched with the X-ray tube 3; The linear array imaging device 5 is supported by the detector support arm 7 and connected with the computer control and image processing unit 1; the detection workbench 2 can be lifted up and down and rotated freely at 360 degrees, and is used to lift the cylinder liner 9 into the line array The computer control and image processing unit 1 controls the movement of the detection table 2 and the detector support arm 7 through the electromechanical control module 8 around the periphery of the imaging device 5 .

[0055] The electromechanical control module 8 includes a feeding mechanism; the feeding mechanism sends batches of cylinder liner workpieces to the detection workbench in sequence; the feeding mechanism can be a large tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com