Mining NDIR gas sensor and concentration quantitative analysis temperature compensation method

A gas sensor and mine-used technology, which is applied to the analysis of materials, material analysis through optical means, instruments, etc., can solve the problems of inaccurate detection results and other problems, and achieve the goal of ensuring accuracy, eliminating errors, eliminating hardware fluctuations and system drift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

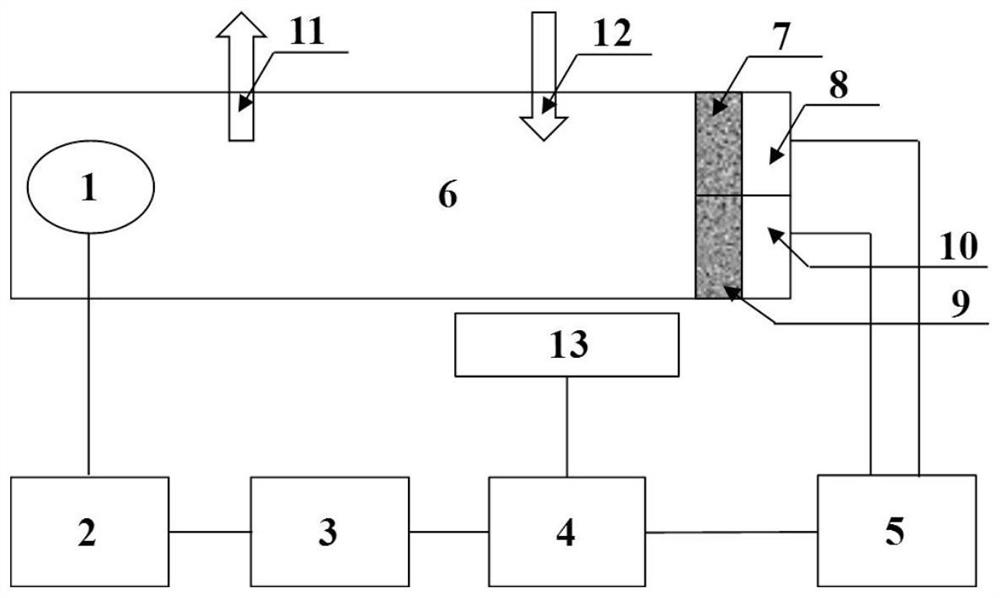

[0053] see figure 1 , a mine-used NDIR gas sensor, comprising an infrared modulation light source 1, a microprocessor 2, an A / D analog-to-digital converter 3, a multi-channel converter 4, an amplifier 5, a gas pool 6, an air outlet 11, and an air inlet 12 The infrared modulation light source (providing blackbody radiation light 1 is placed on one end of the gas pool 6, an air outlet and an air inlet are provided on the top of the gas pool 6, and the other end of the gas pool 6 is provided with a light filter 7 to be measured and a reference light filter 9, and a photodetector to be tested 8 and a reference photodetector 10 are respectively arranged at corresponding positions on the rear side of the photofilter to be tested 7 and the reference photofilter 9, and the infrared modulation light source 1 is respectively arranged on the The microprocessor 2, A / D analog-to-digital converter 3, multi-channel converter 4, and amplifier 5 outside the gas cell 6 are electrically connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com