Method for rapid characterization of segregation of bearing steel by using electronic probe

An electronic probe and bearing steel technology, applied in the field of detection, can solve problems such as errors and long characterization analysis time, achieve the effect of improving accuracy, solving inaccurate test results, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

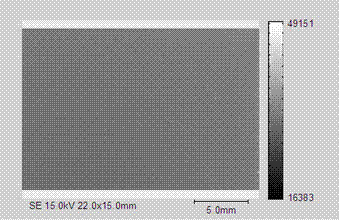

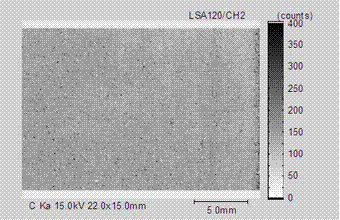

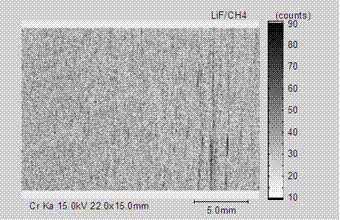

Image

Examples

Embodiment Construction

[0021] Below, the present invention is described further by embodiment.

[0022] Instrument used in the embodiment:

[0023] Electron Probe Analyzer:

[0024] SHIMADZU EPMA-1720 electron probe analyzer and its matching spectrometer (WDS).

[0025] (1) Sample preparation: Cut the steel plate to make a sample with a cross-section of 25×17mm. The length of the sample includes the edge and center of the steel plate. ) were smoothed with 180#, 600#, 800#, 1000# water sandpaper in turn, then polished with a polishing agent, corroded with 4% nitric acid alcohol (subject to the ability to distinguish the tissue), and analyzed by a metallographic microscope The area is defined, and the defined area is calibrated with a microhardness tester, and then the sample is ground and polished to ensure that the microhardness imprint can be observed. Ensure the absolute flatness of the observation surface, with a smoothness of 0.04μm.

[0026] (2) Analysis and calculation of samples:

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com