Automatic pipeline-corrosion detecting device using concave phased array probe with adjustable curvature

An automatic detection device and curvature technology, which are applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of inability to realize automatic detection, low detection efficiency, and high detection cost, so as to reduce the detection cost, The effect of solving low efficiency and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

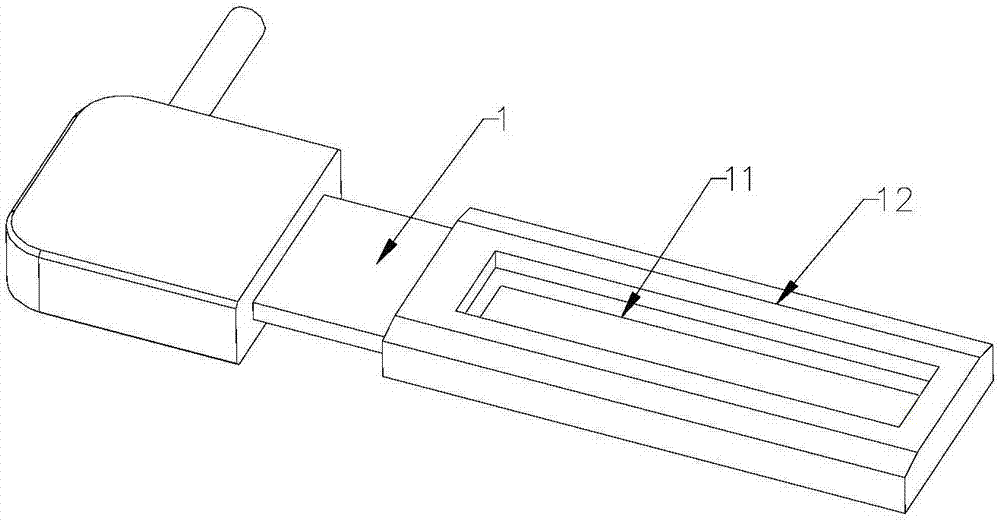

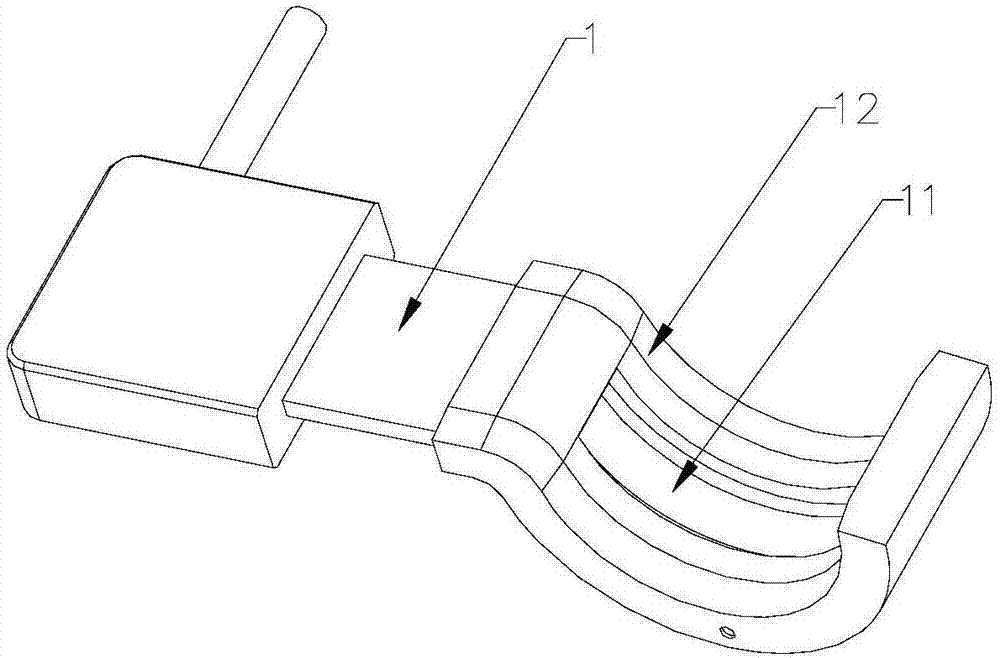

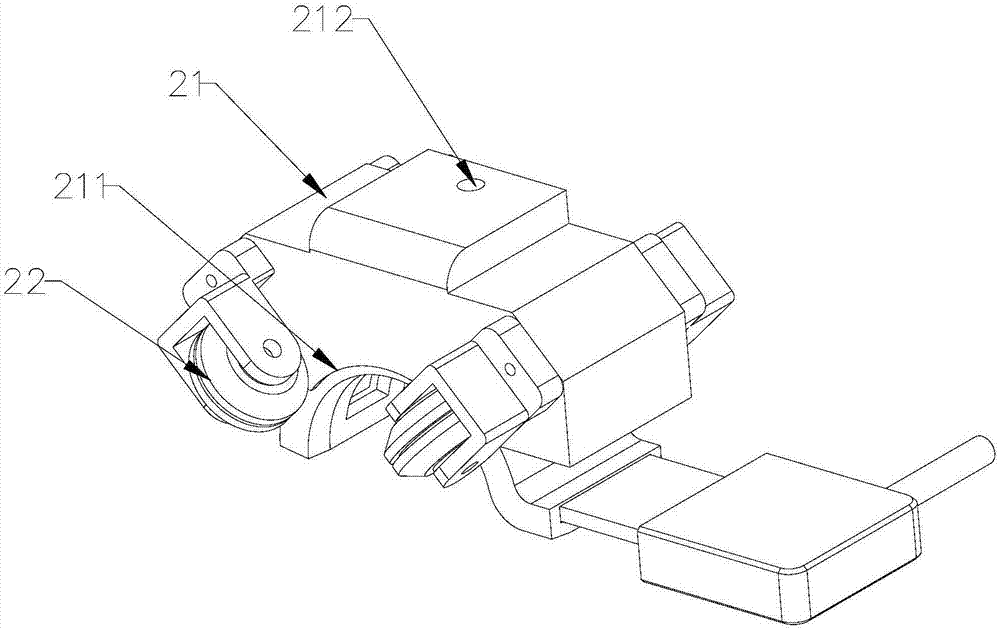

[0044] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , figure 1 It is a structural schematic diagram of the probe mechanism in the pipeline corrosion automatic detection device provided in this embodiment; figure 2It is a schematic diagram of the probe mechanism bent into a concave array probe in the pipeline corrosion automatic detection device provided in this embodiment; image 3 It is a structural schematic diagram of the pipeline corrosion automatic detection device provided in this embodiment; Figure 4 It is a structural schematic diagram of the pipeline corrosion automatic detection device provided in this embodiment; Figure 5 It is a schematic diagram of the pipeline corrosion automatic detection device provided in this embodiment being adsorbed on the pipeline to be detected.

[0045] The curvature-adjustable phased array concave array probe pipeline corrosion ultrasonic automatic detection device provided in this embodiment includes: probe m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com