Detecting mechanism of automatic assembling and detecting machine for door locks

A technology of automatic assembly and detection mechanism, applied in the direction of measuring devices, workpiece clamping devices, instruments, etc., can solve the problems of reducing production efficiency, detection data errors, etc., to improve production efficiency, reduce detection errors, and save labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

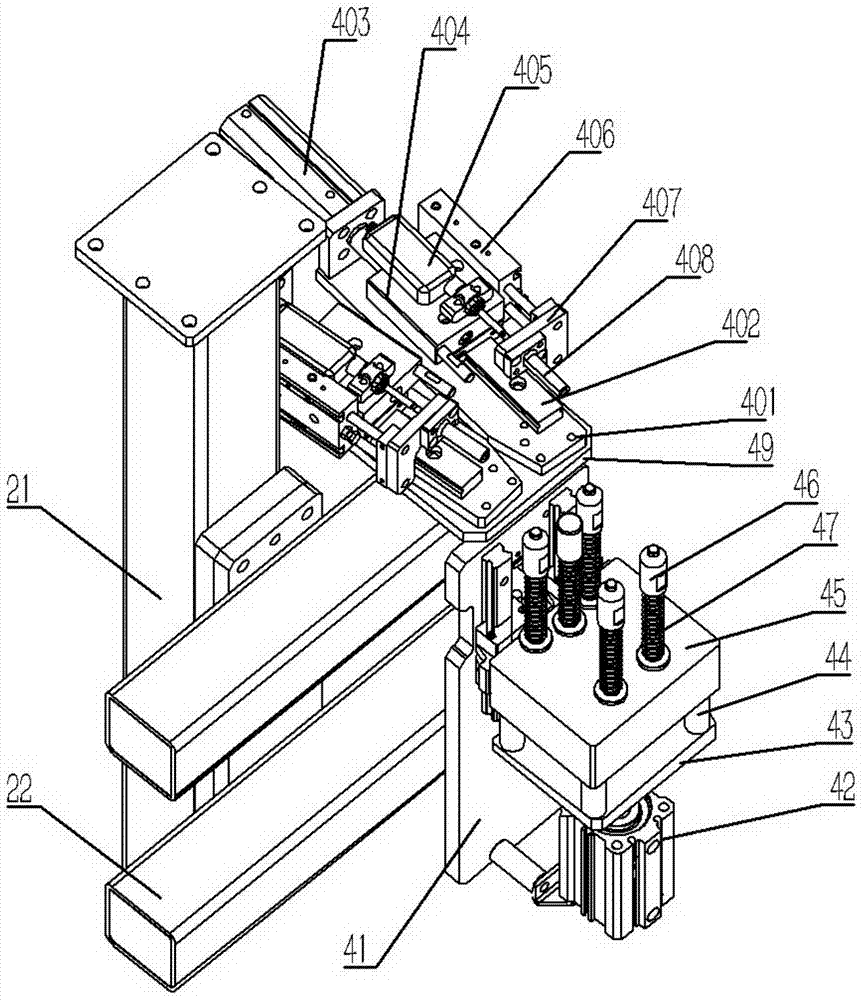

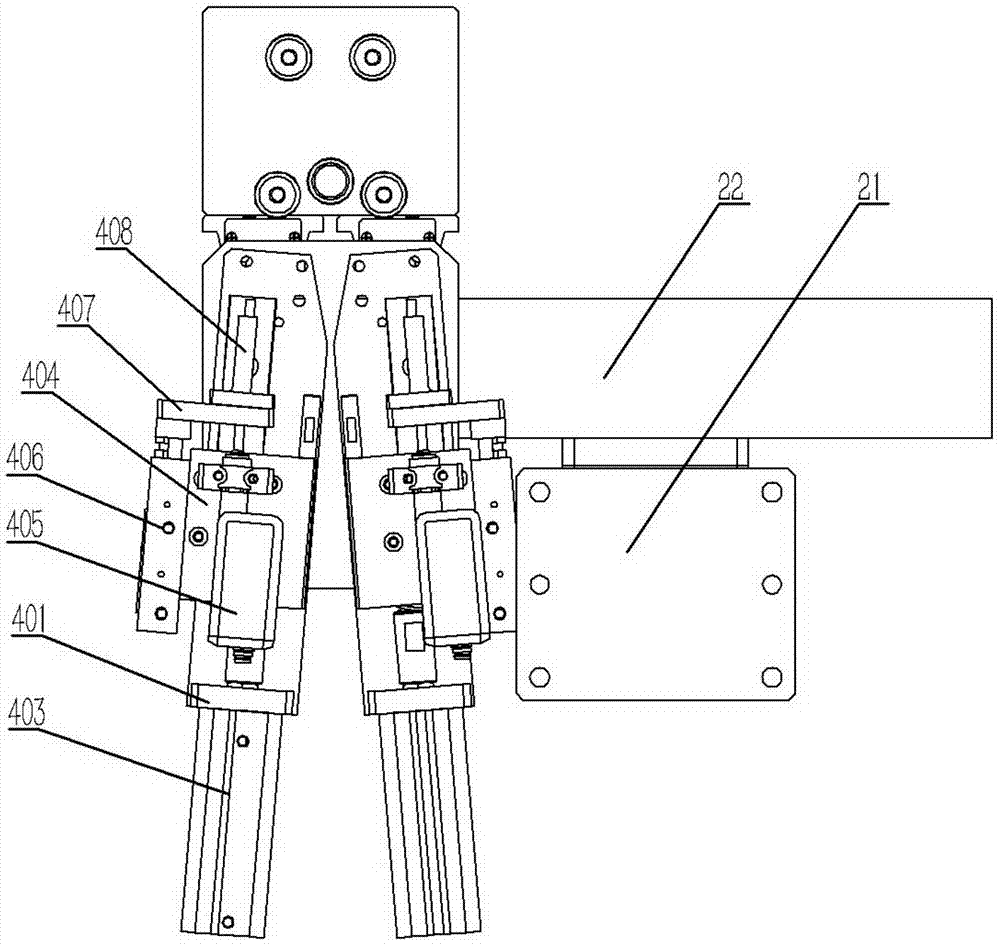

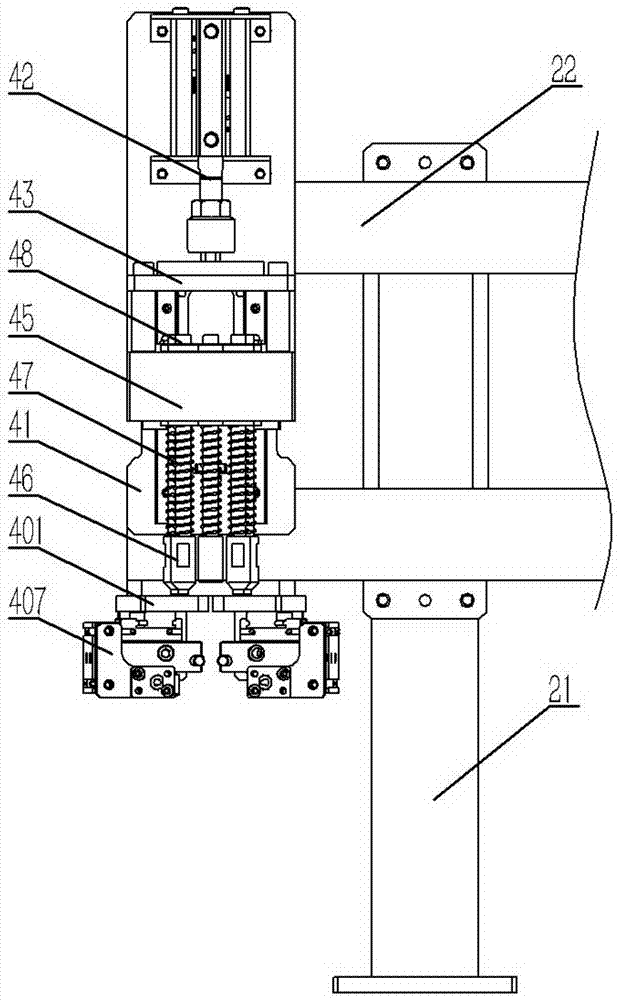

[0017] Example: see Figures 1 to 3 As shown, the detection mechanism of the door lock automatic assembly detection machine includes a vertical column 21, and the vertical column 21 is fixed with two sets of horizontal struts 22, and the horizontal strut 22 at the upper end is fixed with a vertical mounting plate 41. The upper end of mounting plate 41 is fixed with vertical cylinder 42, and the piston rod of vertical cylinder 42 is fixed on the support plate 43, and the lower end surface of support plate 43 is fixed with some vertical pillars 44, and the lower end of vertical pillar 44 is fixed on Square installation piece 45, on the square installation piece 45, is interspersed with some T-shaped locating rods 46, is inserted with stage clip 47 on the location rod 46, and the upper end of stage clip 47 is pressed against the lower end face of square installation block 45, described The upper end of the positioning rod 46 passes through the square mounting block 45 and fixes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com