Patents

Literature

154results about How to "No manual inspection required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

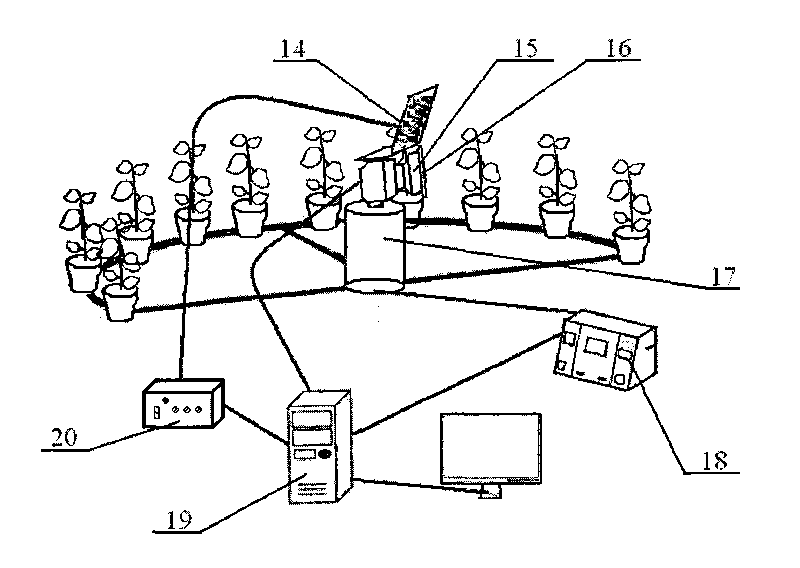

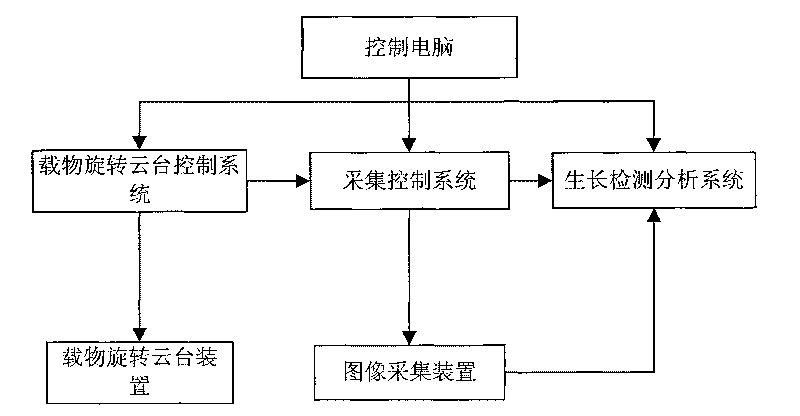

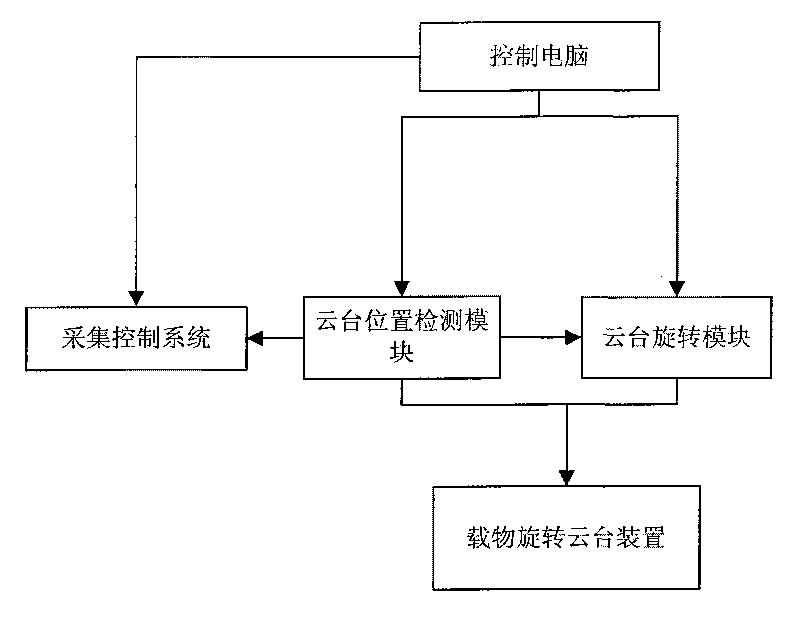

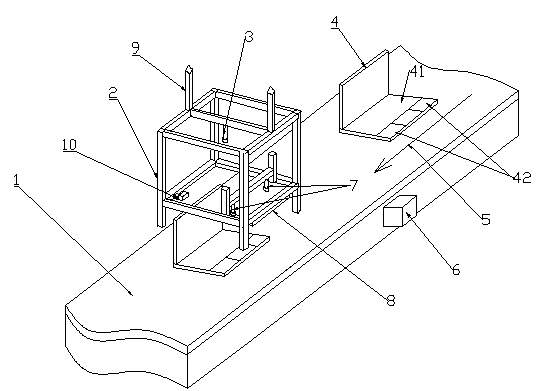

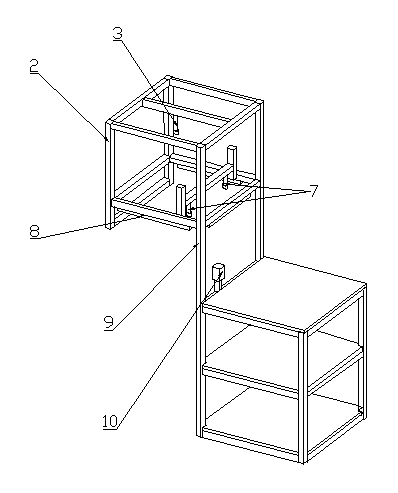

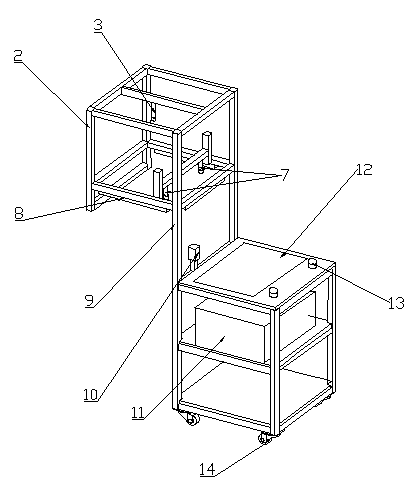

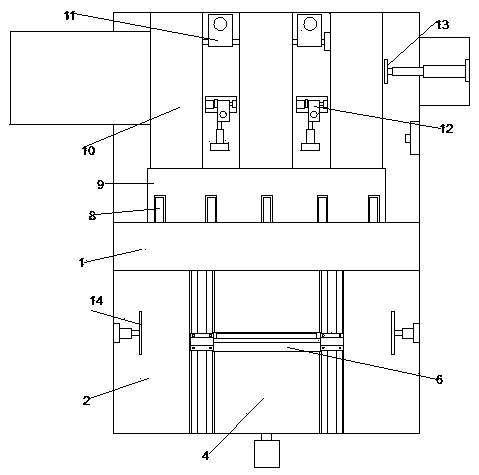

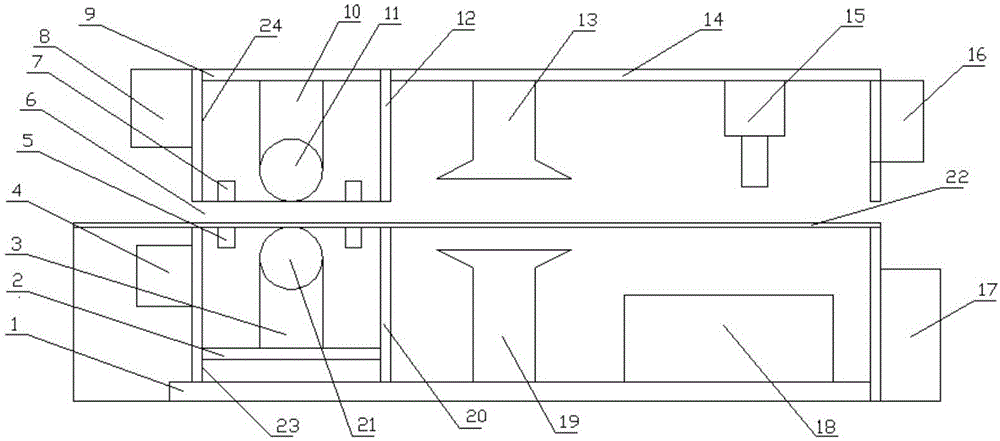

Non-contact type nondestructive detecting device for plant growth and detecting method thereof

InactiveCN101718522AHigh precisionHigh measurement accuracyUsing optical meansGrowth plantControl system

The invention provides a non-contact type nondestructive detecting device for plant growth, comprising a control computer, a material carrying and rotating holder device and an image acquisition system, wherein the control computer is internally provided with a material carrying and rotating holder control system, an acquisition control system and a growth detection and analysis system which are sequentially connected; the material carrying and rotating holder device is connected with the material carrying and rotating holder control system; and the acquisition control system and the growth detection and analysis system are respectively connected with the image acquisition device. The invention also provides a detecting method of the non-contact type nondestructive detecting device for plant growth. The invention can continuously detect a plurality of plants within a long time with a certain interval, automatically acquire images and analyze growth feature parameters of the plants at the same time of acquiring the images. The invention has the advantages of high image acquisition precision, accurate detection, and the like.

Owner:SOUTH CHINA AGRI UNIV

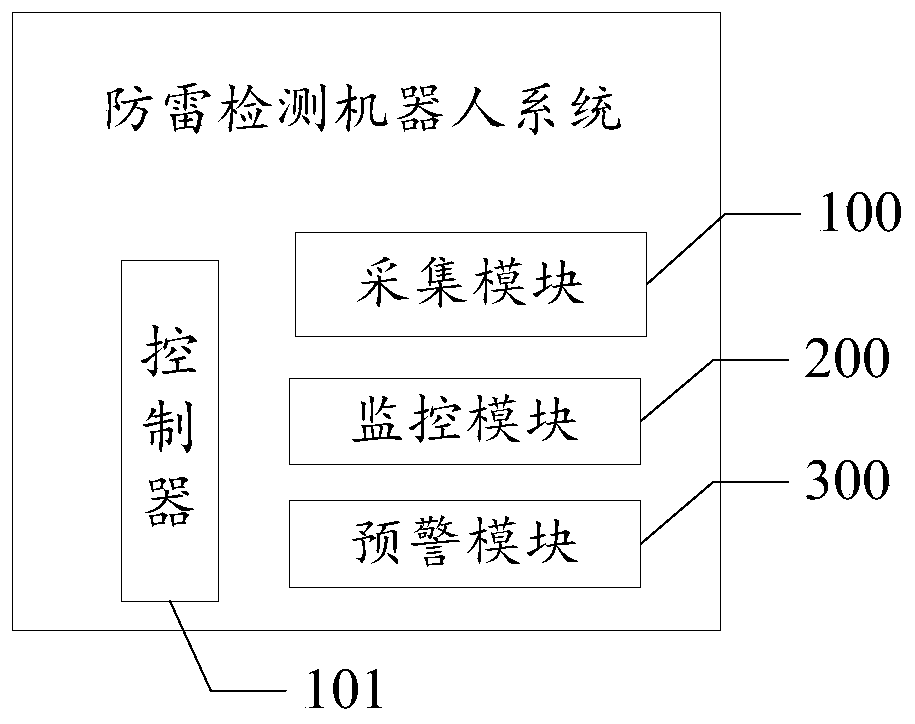

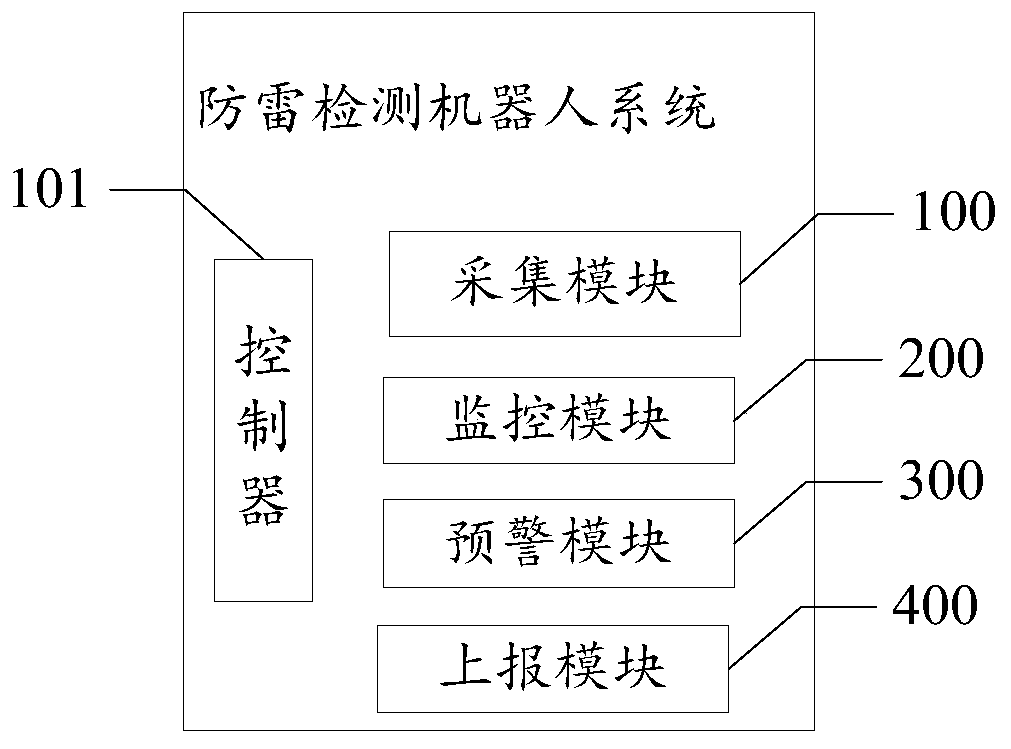

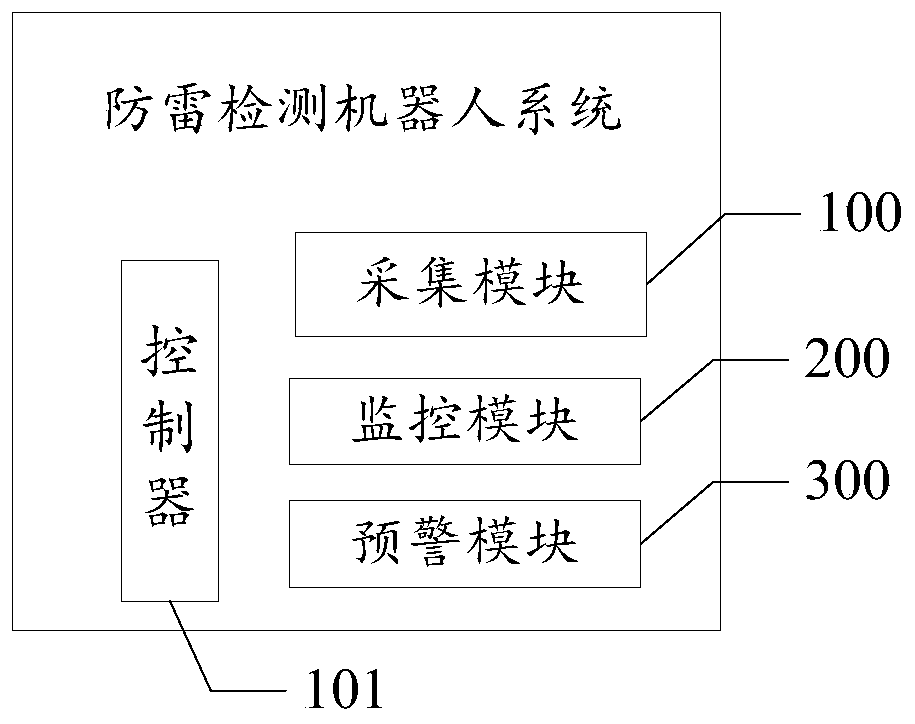

Lightning protection detection robot system

ActiveCN109839559APerformance monitoringTimely maintenanceElectrical testingWork statusComputer science

The invention discloses a lightning protection detection robot system. The lightning protection detection robot system comprises a controller, an acquisition module, a monitoring module and an early warning module. Function modules are connected in a communication connection mode. The controller receives and analyzes a detection instruction triggered by a user based on a client, and acquires a lightning protection device to be detected. The acquisition module collects performance parameters of the lightning protection device during operation, and records and stores the collected performance parameters. The monitoring module analyzes the performance parameters collected by the acquisition module in real time, and determines the working state of the lightning protection device according to the analysis result of the collected performance parameters. And then, according to the current working state of the lightning protection device, whether the lightning protection device is abnormal isidentified. The early warning module emits early warning information when the lightning protection device is abnormal to prompt work personnel to timely maintain the lightning protection device. Manual detection is not needed and detection cost is reduced.

Owner:北京雷布斯雷电安全科技有限公司

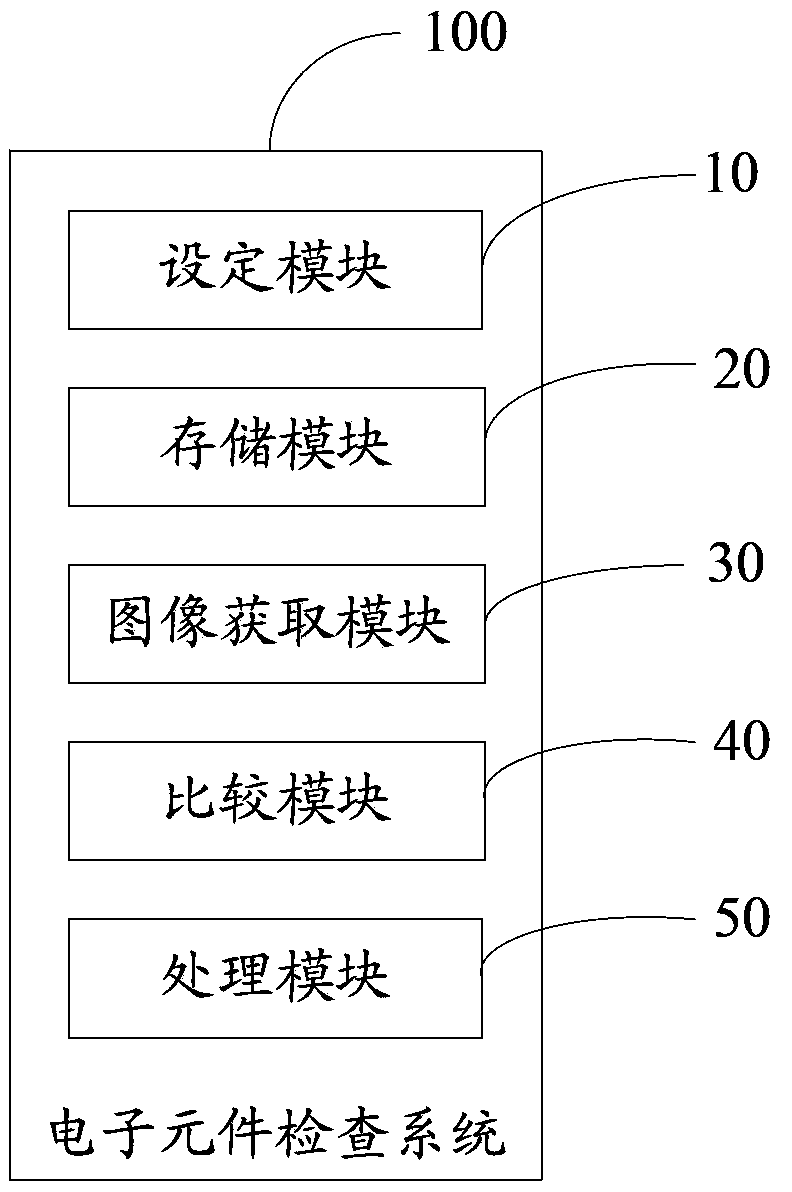

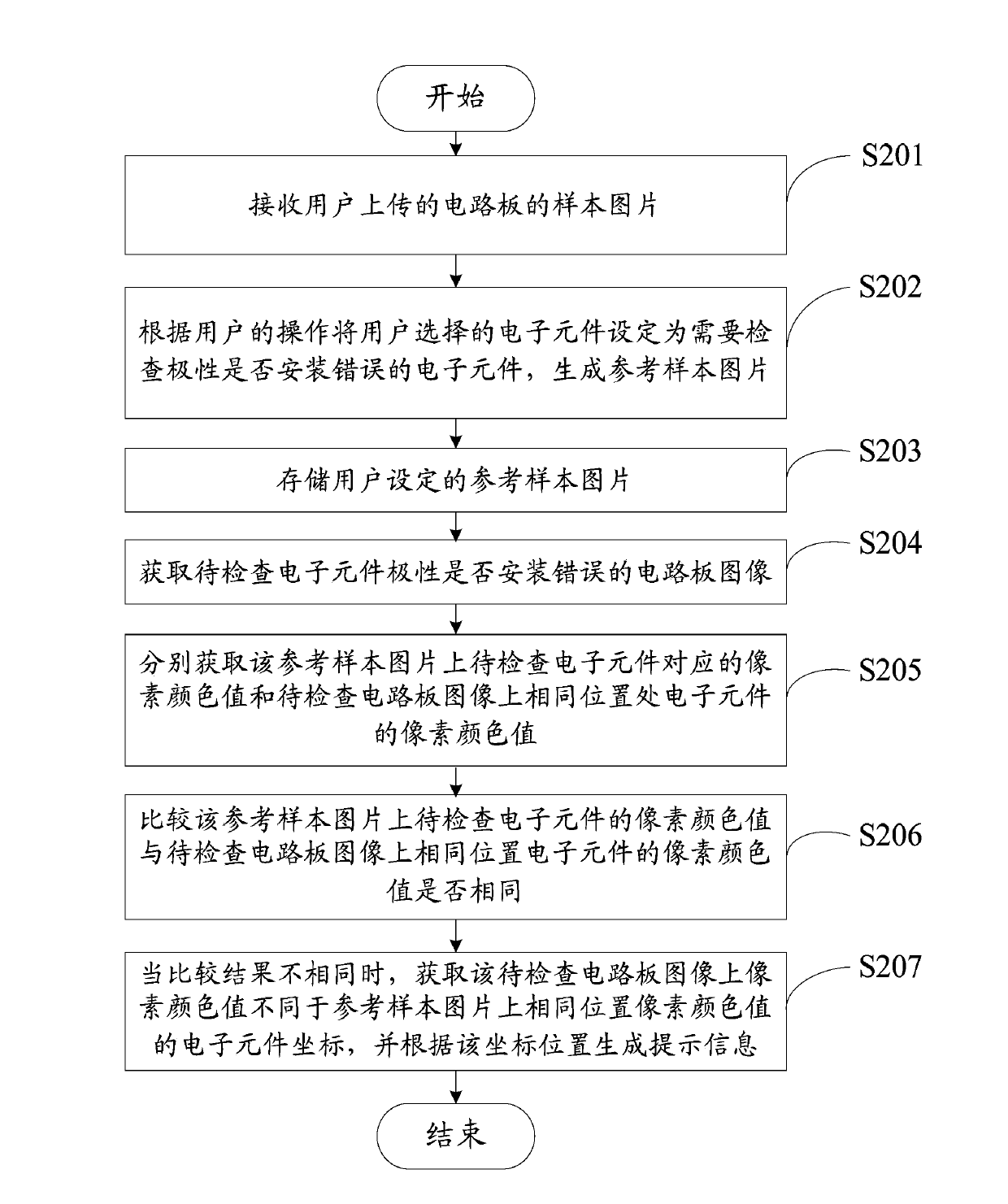

Electronic component inspection system and electronic component inspection method

InactiveCN103869215ANo manual inspection requiredShorten the timeElectrical testingReference sampleElectrical polarity

The invention provides an electronic component inspection system which comprises a setting module used for a user to set an electronic component of which the polarity needs to be inspected in a reference sample picture, an image acquisition module used for acquiring an image of a to-be-inspected circuit board of an electronic component of which the polarity is to be inspected, a comparison module used for carrying out comparison to see whether the pixel color value of the electronic component in the reference sample picture is the same with the pixel color value of an electronic component in the same position in the image of the to-be-inspected circuit board, and a processing module used for generating prompting information for prompting wrong installation of the electronic component in terms of polarity when the comparison module determines that the two pixel color values are different. The invention further provides an electronic component inspection method. According to the electronic component inspection system and the electronic component inspection method of the invention, whether an electronic component is correctly installed in terms of polarity is automatically judged through an image comparison method, no manual inspection is needed, and a lot of time and manpower are saved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

AOI visual detection device

InactiveCN104142162ADoes not affect normal workWon't breakMeasurement devicesAssembly lineVisual perception

An AOI visual detection device comprises a rack, a detector, a sensing device and a central processing unit. The detector is arranged above an assembly line and comprises imaging devices and a light source, the imaging devices are used for imaging keyboards of notebook computers in a detection region of the assembly line and outputting imaging data, and the light source is used for brightness supplement. The sensing device is arranged on the assembly line and the rack and used for sensing the detected computers and outputting sensing signals. The central processing unit is in signal connection with the imaging devices and the sensing device and is used for receiving the sensing signals and conducting corresponding data processing and control output. According to the AOI visual detection device, keyboard identifiers and volume labels of the notebook computers can be immediately and automatically detected online, the detection efficiency is improved, the labor cost is saved, and mistaken detection and missing detection caused by human factors are avoided.

Owner:江苏展志金属科技有限公司

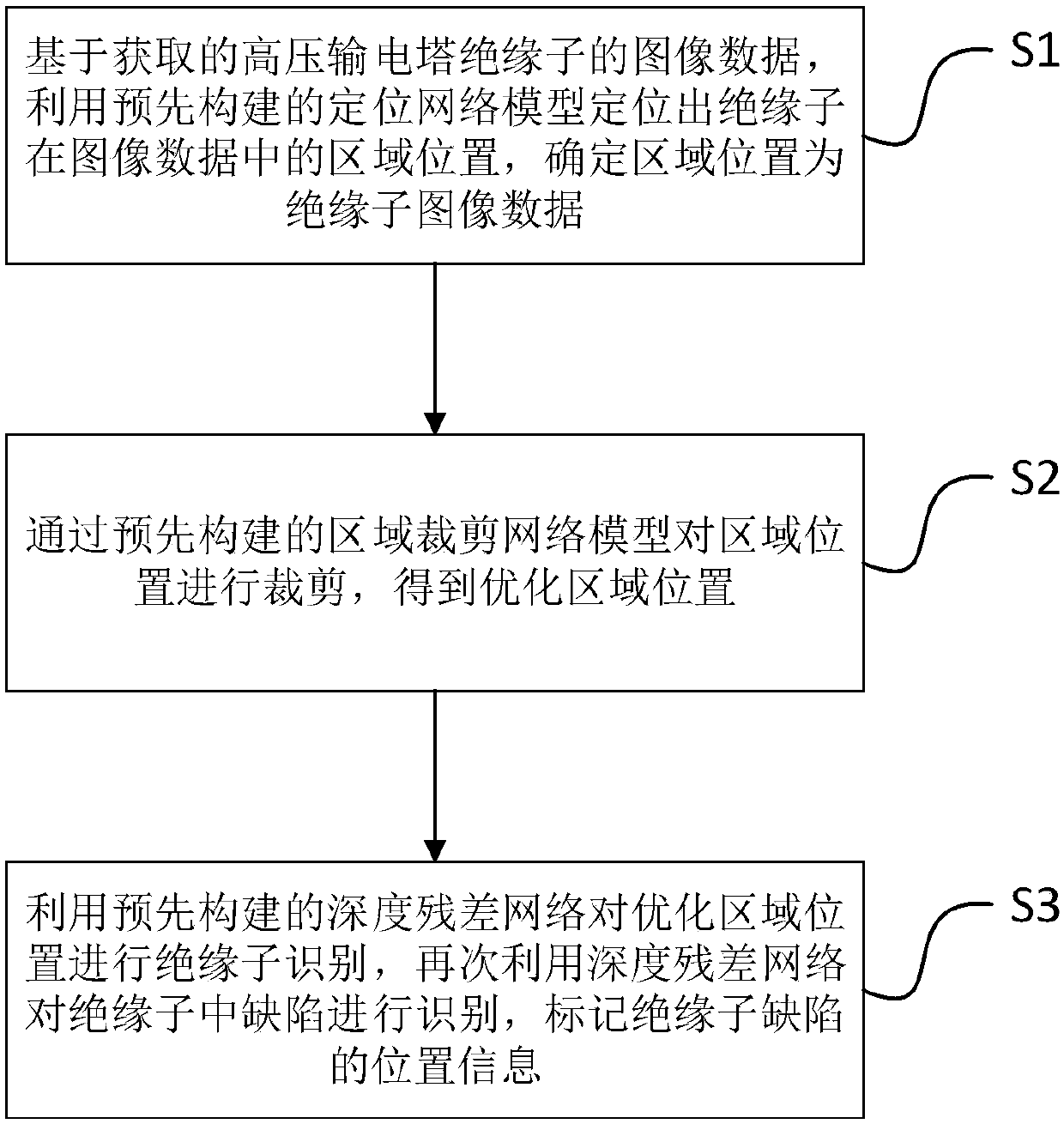

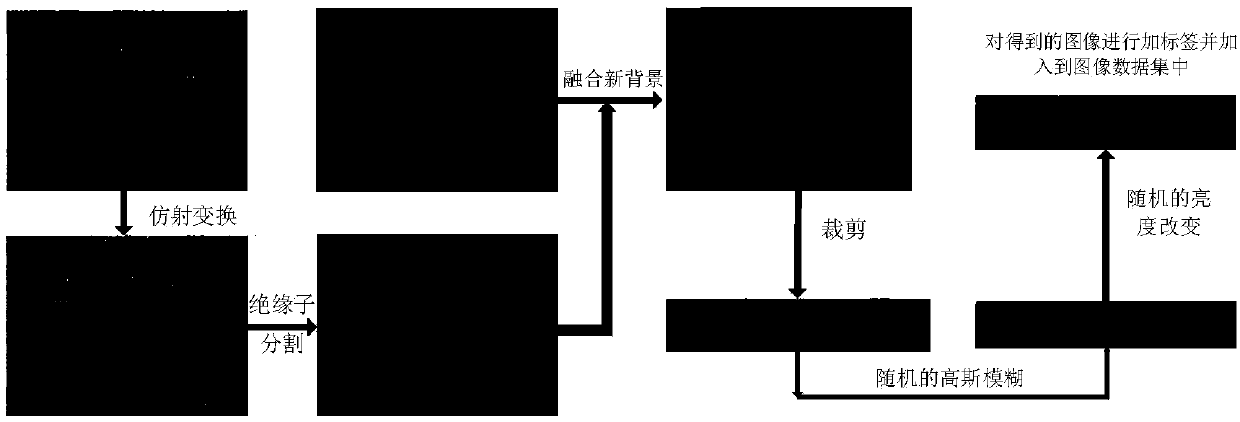

Method and device for automatically identifying defects of insulator of high voltage transmission tower

ActiveCN108648169ARegional location optimizationNo manual inspection requiredImage enhancementImage analysisTransmission towerNetwork model

The invention belongs to the technical field of high voltage transmission, and particularly relates to a method and a device for automatically identifying defects of an insulator of a high voltage transmission tower, aiming at solving the problem that the prior art cannot automatically identify defects of an insulator. The invention provides a method for automatically identifying defects of an insulator of a high voltage transmission tower, comprising: based on the acquired image data of the insulator of the high voltage transmission tower, locating the region position of the insulator in theimage data by using a pre-built positioning network model; cutting the region position by the pre-built region cutting network model to obtain the optimized region position; using the pre-built depthresidual network to identify the insulators in the optimized region position, using the deep residual network again to identify the defects in the insulator, and marking the position information of the defects of the insulator. The invention is capable of automatically identifying the position of the insulator from the image, and identifying the defects of the insulator on the basis, thereby improving the precision and accuracy of the recognition.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

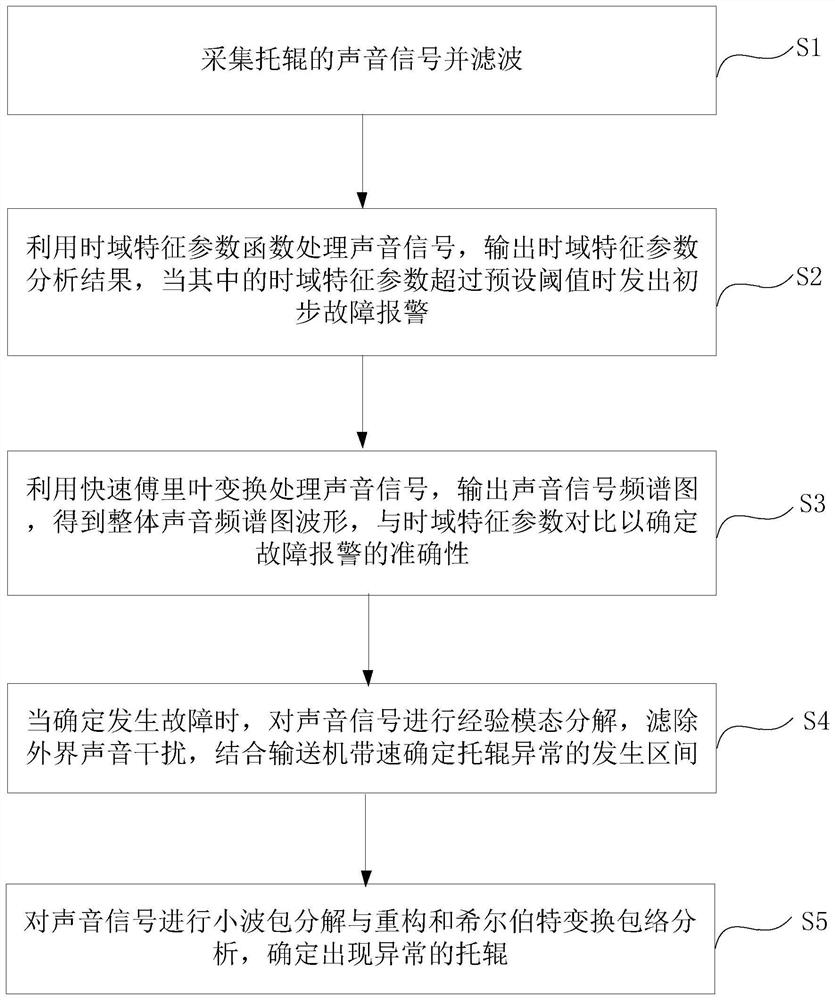

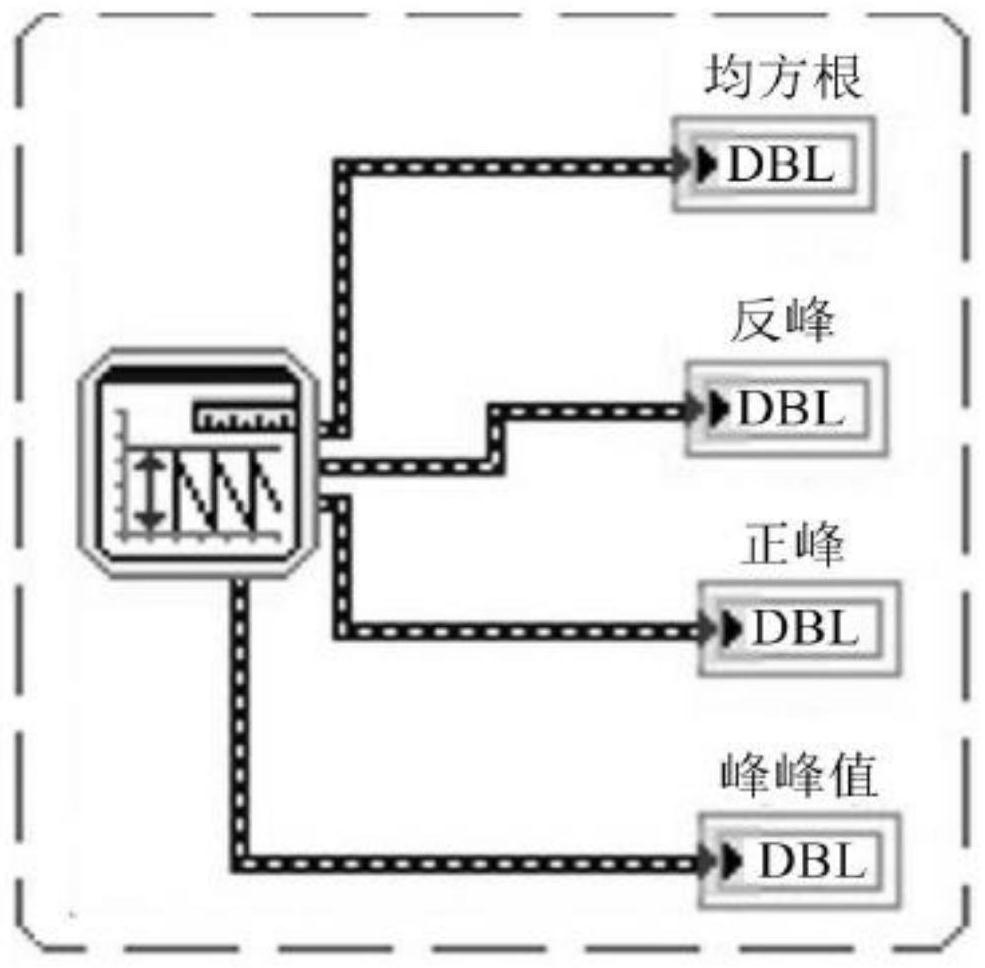

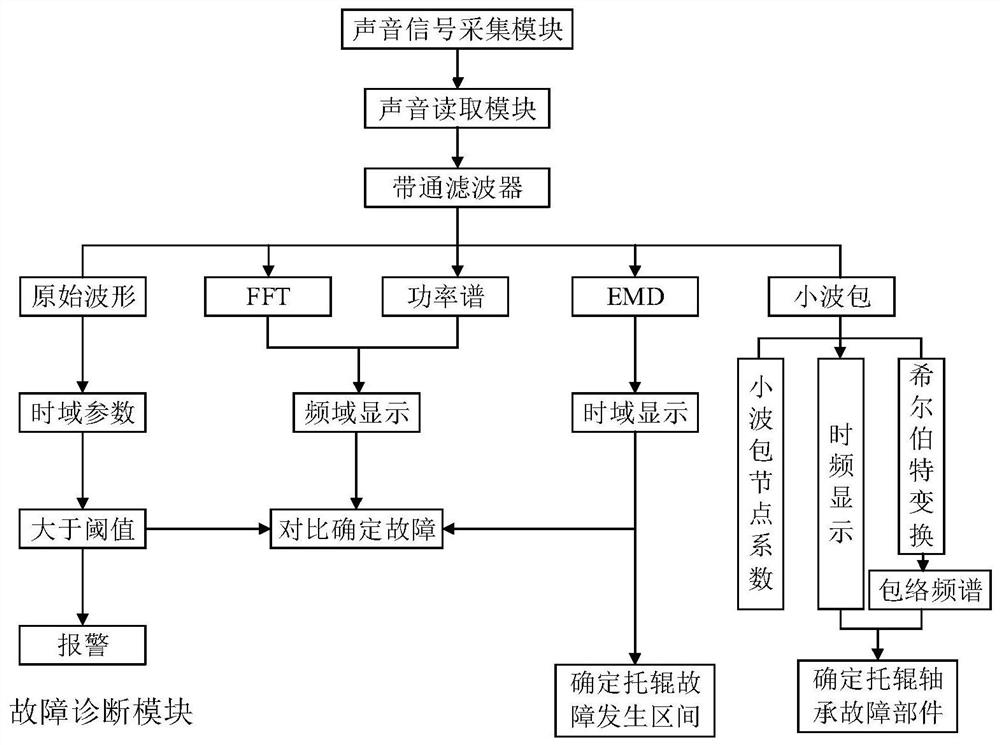

Carrier roller anomaly detection method and system

PendingCN113213101AReduce safety incidentsEnsure safetyImage enhancementImage analysisFast Fourier transformTime domain

The invention discloses a carrier roller anomaly detection method. The method comprises the steps of collecting sound signals of carrier rollers and performing filtering; processing the sound signals by using a time-domain characteristic parameter function, outputting a time-domain characteristic parameter analysis result, and when time-domain characteristic parameters exceed a preset threshold value, preliminarily alarming; processing the sound signals by using fast Fourier transform to obtain an overall sound spectrogram waveform, and comparing the overall sound spectrogram waveform with the time domain characteristic parameters to determine the alarm accuracy; when it is determined that a fault occurs, performing empirical mode decomposition on the sound signals, filtering out external sound interference, and determining the abnormal occurrence interval of the carrier rollers by combining the belt speed of a conveyor; and performing wavelet packet decomposition and reconstruction and Hilbert transform envelope analysis on the sound signals, and determining an abnormal carrier roller. The method can comprehensively detect whether the carrier rollers are abnormal or not, so that the full-automatic detection effect is achieved, safety accidents caused by damage to the carrier rollers of the belt conveyor are effectively reduced, and material conveying safety is guaranteed. The invention further discloses a carrier roller anomaly detection system.

Owner:华润电力技术研究院有限公司

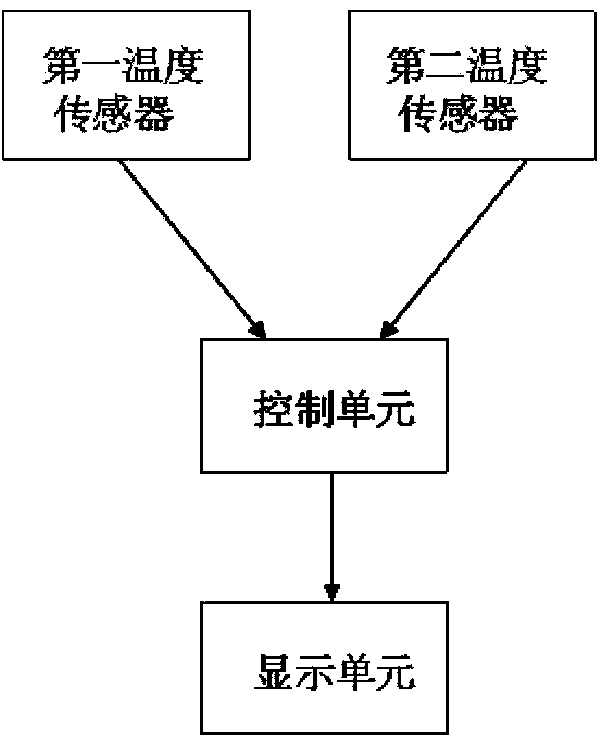

Detection system for refrigeration incapability fault of refrigerator

ActiveCN103471343ASimple methodImprove efficiencyDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses a detection system for refrigeration incapability fault of a refrigerator. The detection system is characterized by comprising a first temperature sensor, a control unit and a display unit, wherein the first temperature sensor is arranged in a chamber to be detected and is used for detecting the temperature in the chamber to be detected, the control unit is used for collecting the temperature, measured by the first temperature sensor, of the chamber to be detected, and transmitting fault signals to the display unit, and the display unit is arranged at the outer surface of the refrigerator and is used for displaying the fault signals. The system provided by the invention can be used for judging the refrigeration incapability fault of each chamber of the refrigerator, users can be reminded in time, the method is simple, the efficiency is high, the food deterioration problem caused when the refrigeration incapability fault is not found in time is effectively avoided, and meanwhile, maintenance personnel can fast judge the fault reason according to the prompted fault information.

Owner:CHANGHONG MEILING CO LTD

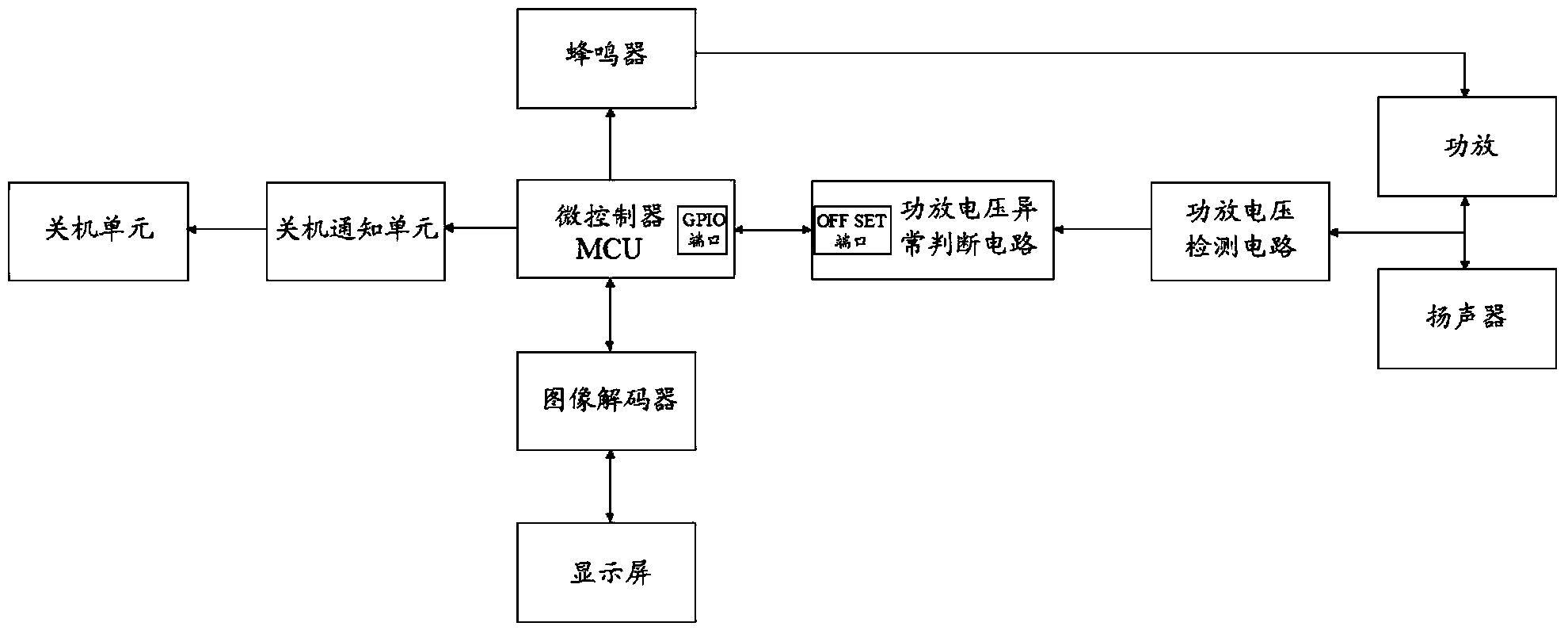

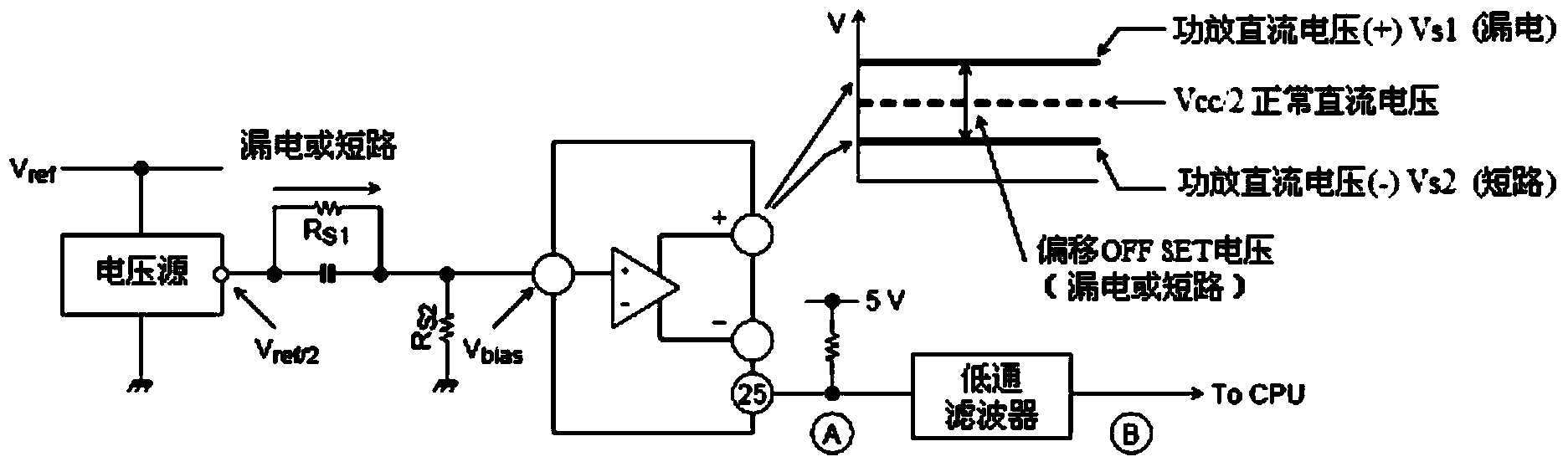

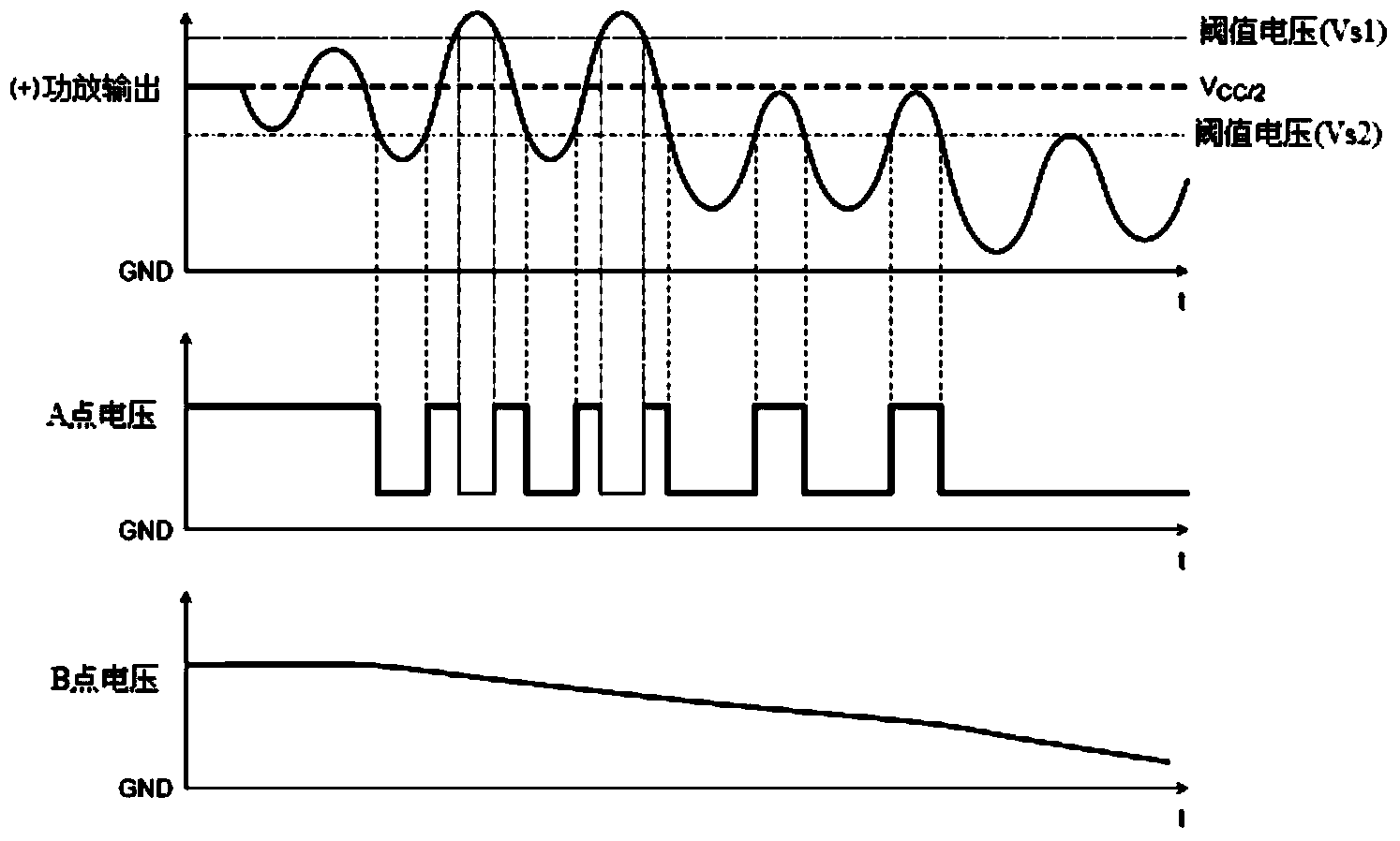

Device and method for automatically detecting abnormality of power amplifier

InactiveCN103648075AImplement automatic detectionNo manual inspection requiredElectrical apparatusMicrocontrollerAudio power amplifier

The invention provides a device and a method for automatically detecting abnormality of a power amplifier. The device comprises a power amplifier voltage detecting circuit used for detecting a voltage value output from the power amplifier to a loudspeaker, a power amplifier voltage abnormality judging circuit used for outputting a normal voltage level signal or an abnormal voltage level signal through an offset port, a microcontroller used for counting normal voltage electric pulses or abnormal voltage level pulses output by the offset port within a set period, determining the state of the power amplifier, and sending a power amplifier abnormality signal if the power amplifier is determined to be in an abnormal state, and a buzzer connected to the microcontroller and used for receiving the power amplifier abnormality signal and sending an abnormality prompt acoustical signal, wherein the abnormal prompt acoustical signal after being amplifier by the power amplifier is played through the loudspeaker. According to the invention, automatic detection of the voltage abnormality condition of the power amplifier is realized and manual detection is unnecessary; acoustical alarm or image display alarm is carried out if the power amplifier is abnormal, and the power amplifier is shut down after a set time period to protect the loudspeaker connected to the power amplifier.

Owner:FORYOU GENERAL ELECTRONICS

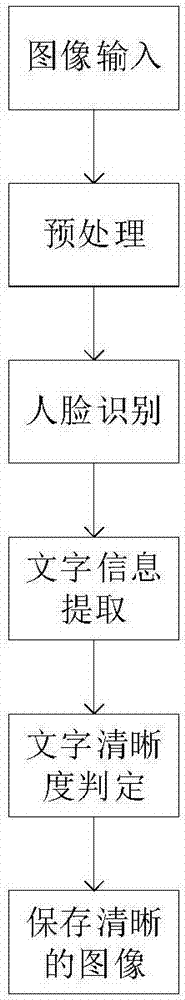

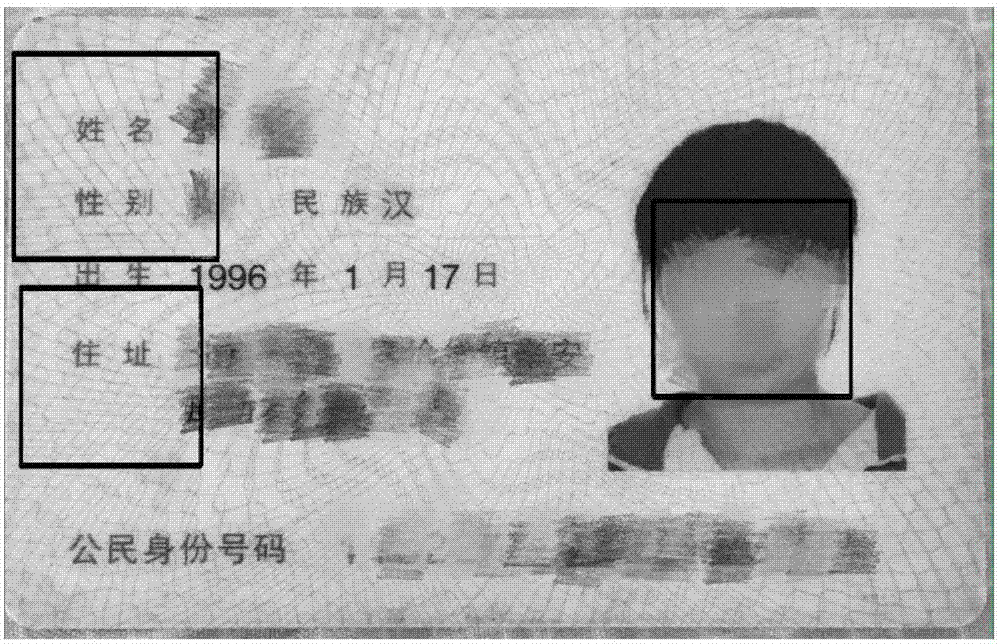

Face recognition-based identity card definition discrimination method and system

InactiveCN107977648AImprove efficiencyReduce complexityCharacter recognitionPattern recognitionApplication software

The invention relates to a face recognition-based identity card definition discrimination method and system. The method comprises the following steps of: 1, image preprocessing: converting a color mapinto a greyscale map and denoising the greyscale map; 2, recognizing and marking a face in an image; 3, selecting a character part in an identity card picture and discriminating character definitionof image character information of the part; and 4, storing clear image according to the definition discrimination result so as to be used by subsequent processing. According to the method and system,an identity card picture definition detection application program which is high in automation, high in precision and high in reliability is provided, so that the time is shortened, and the malpracticethat the manual detection is bad in stability and unreliable in detection result is overcome.

Owner:WUHAN UNIV

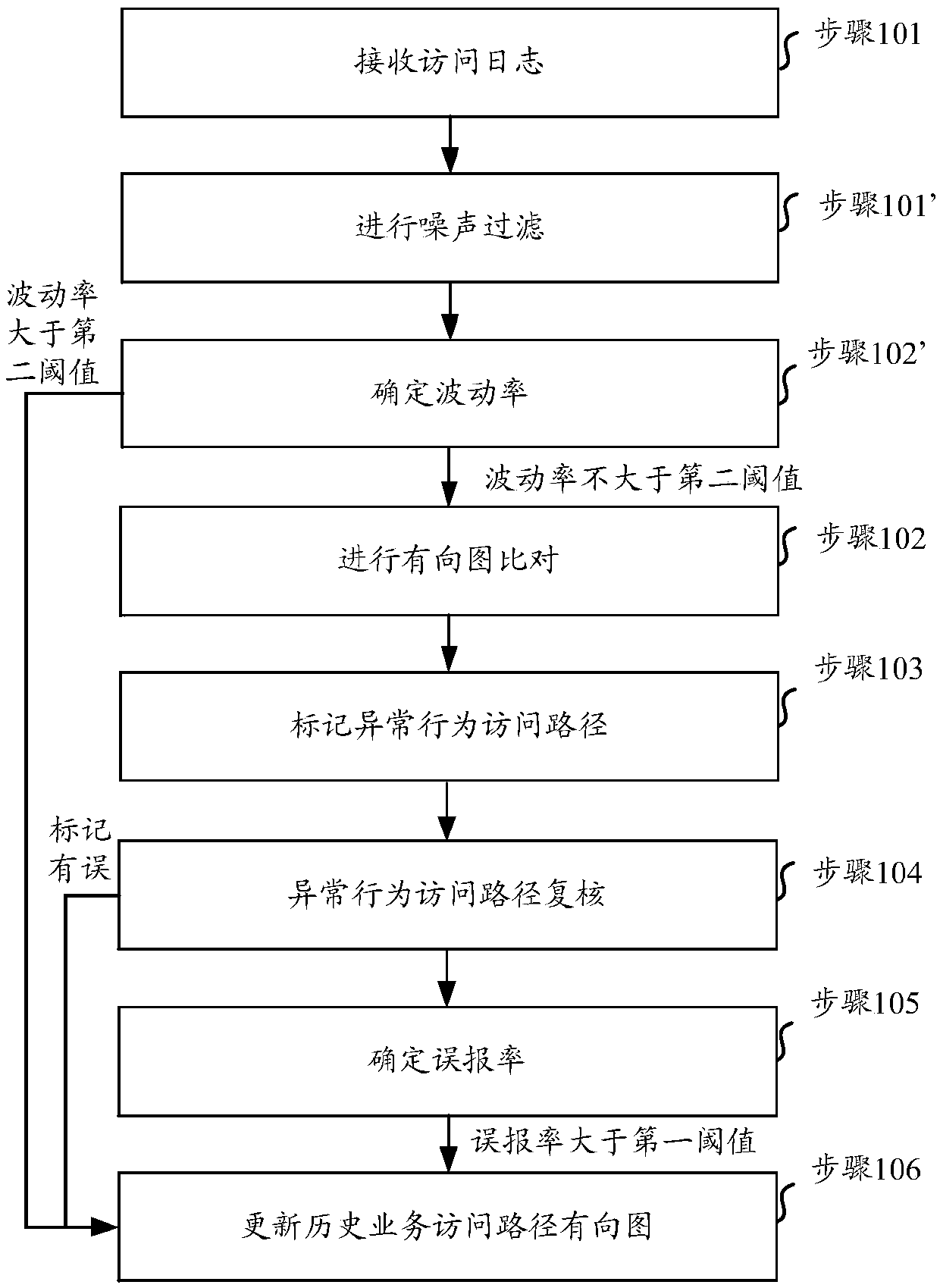

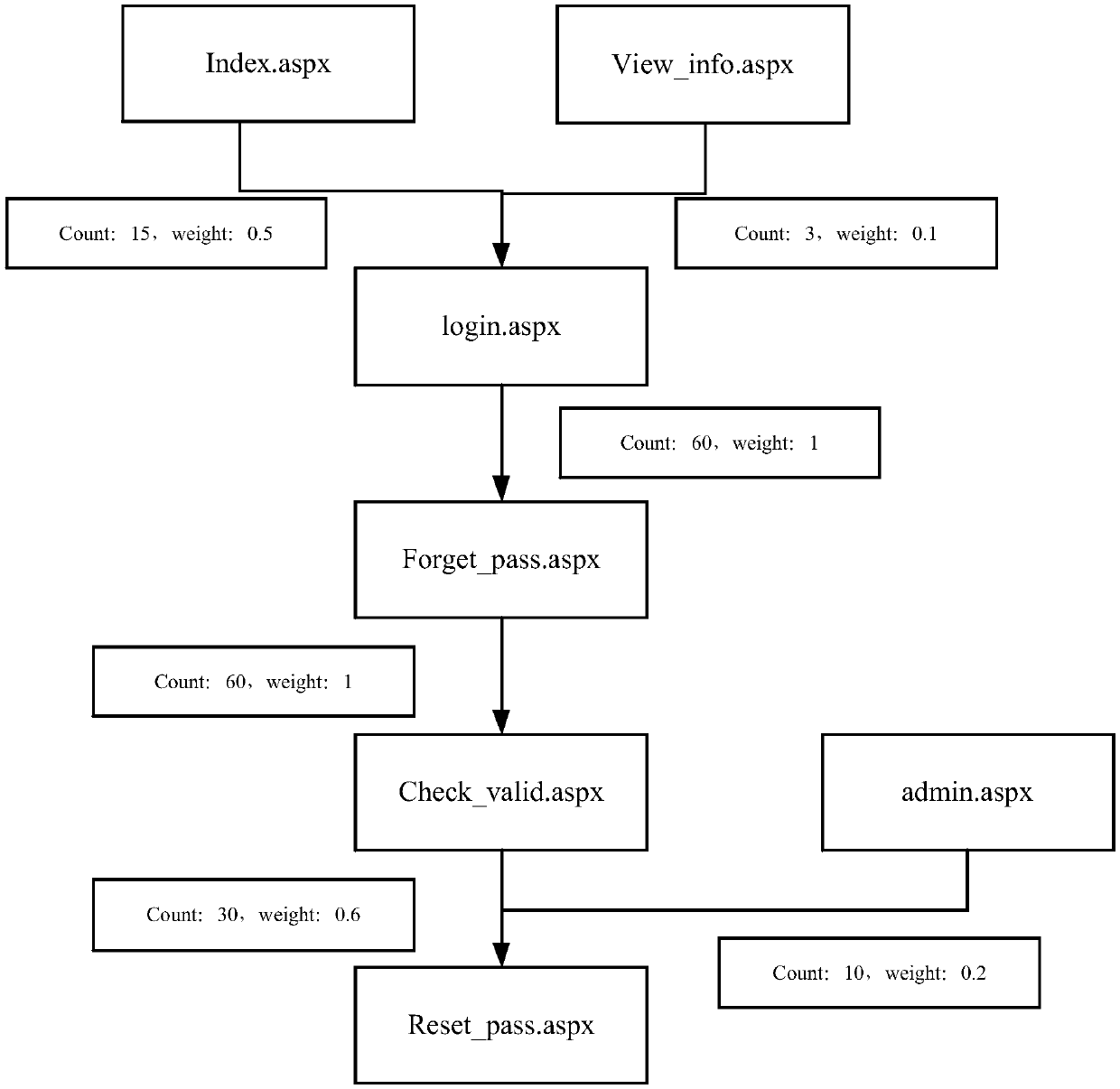

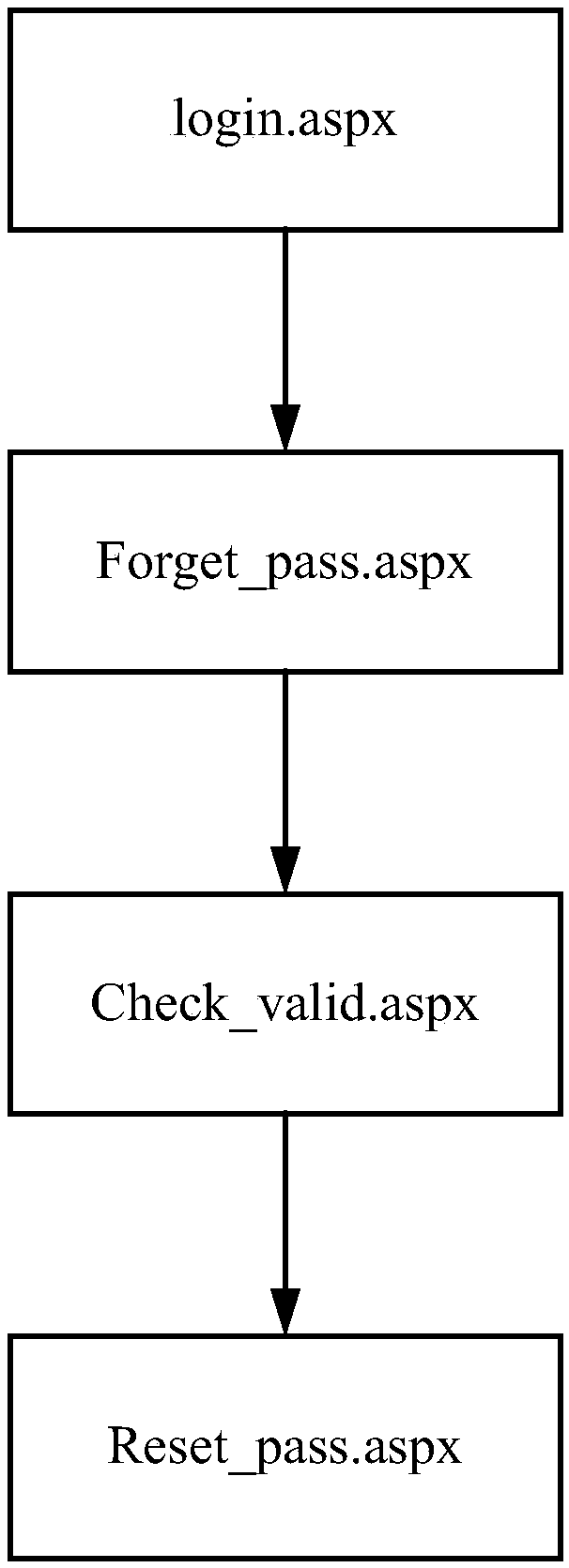

Method, device, medium and device for detecting abnormal behavior access of world wide web

ActiveCN109040073AImprove the speed of access detectionNo manual inspection requiredTransmissionDirected graphWeb page

The invention relates to the field of network security, in particular to a method, a device, a medium and a device for detecting abnormal behavior access of a World Wide Web (World Wide Web). The temporary service directed graph is determined according to the access log received in real time, and the temporary service directed graph is compared with the historical service backbone directed graph determined according to the historical access log to determine whether there is an abnormal behavior access path in the access path. Because of the access paths in the historical business backbone directed graph is the backbone path after the redundant paths which have no service meaning to obtain are removed, so that when the access paths are changed, the abnormal behaviors such as webshell accessing, horizontal unauthorization, vertical unauthorization and path crossing can be can be detected effectively, and the speed of abnormal behaviors accessing detection of the web can be improved compared with that of manual detection.

Owner:NSFOCUS INFORMATION TECHNOLOGY CO LTD +1

Concrete ground flatness detection device for building construction

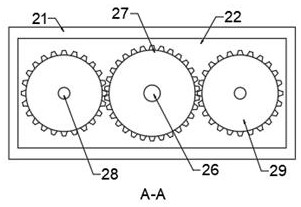

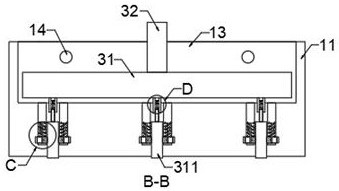

InactiveCN112683225ANo manual inspection requiredImprove detection efficiencyLiquid surface applicatorsMeasurement devicesGear wheelArchitectural engineering

The invention relates to the field of ground flatness detection, in particular to a concrete ground flatness detection device for building construction which comprises a guide rail assembly, a driving assembly, a detection assembly and a cleaning assembly, wherein the driving assembly is arranged at one end of the guide rail assembly, and the detection assembly is arranged in the guide rail assembly. And the cleaning assembly is arranged below the detection assembly. Through the arranged guide rail assembly and the driving assembly, a servo motor in the driving assembly can drive a first gear to rotate when being started, the first gear can drive a second gear to rotate when rotating, and the second gear can drive a first lead screw to rotate through a second rotating shaft when rotating; when the first lead screw rotates, the sliding plate can slide between the two side plates, and the sliding plate can drive the detection assembly at the bottom to perform detection when sliding, so that the device is driven by a motor during detection, manual detection is not needed, and the detection efficiency is greatly improved.

Owner:吴峰

Gas drilling depth detection equipment

InactiveCN103306667AHigh measurement accuracyRealize automatic real-time detectionSurveyData transmissionAccuracy and precision

The invention relates to gas drilling depth detection equipment which comprises a gas drilling machine, a drill rod and a tag reading and writing module, wherein the drill rod is fixedly arranged on the gas drilling machine by a drill rod holder; the drill rod is provided with an electronic tag with an independent ID (Identity); the tag reading and writing module is used for reading information of the electronic tag; the tag reading and writing module is connected with a computer through a data transmission line. Compared with the prior art, the gas drilling depth detection equipment implements automatic real-time detection on the drilling depth, does not require human assistance in detection, has high measurement accuracy and is safe and reliable.

Owner:JINAN SUOZHONG MINING EQUIP CO LTD

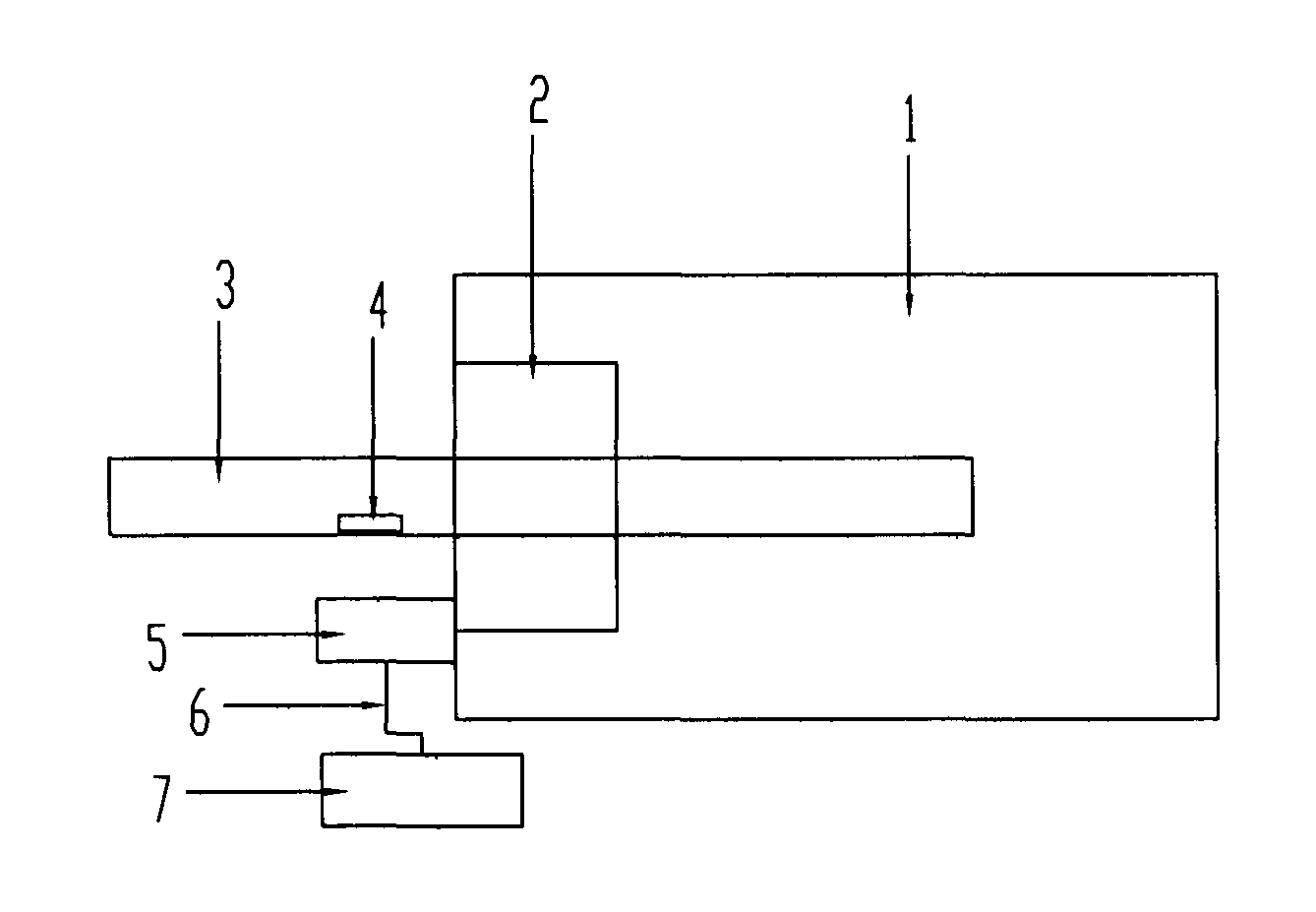

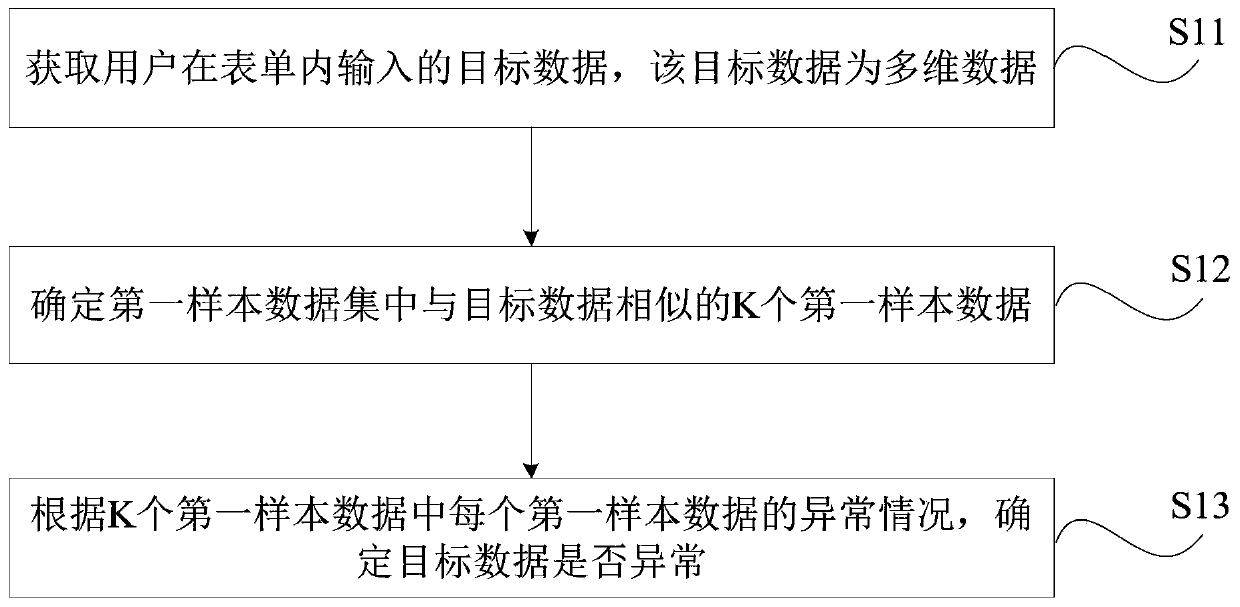

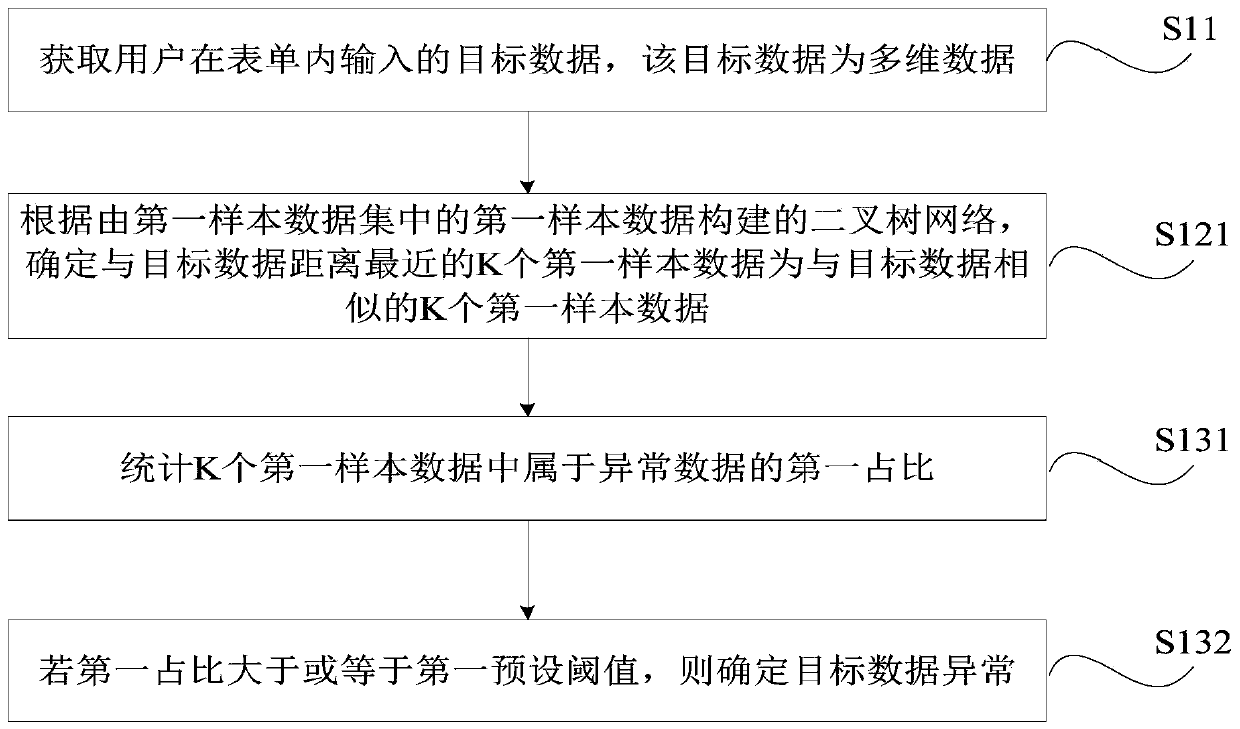

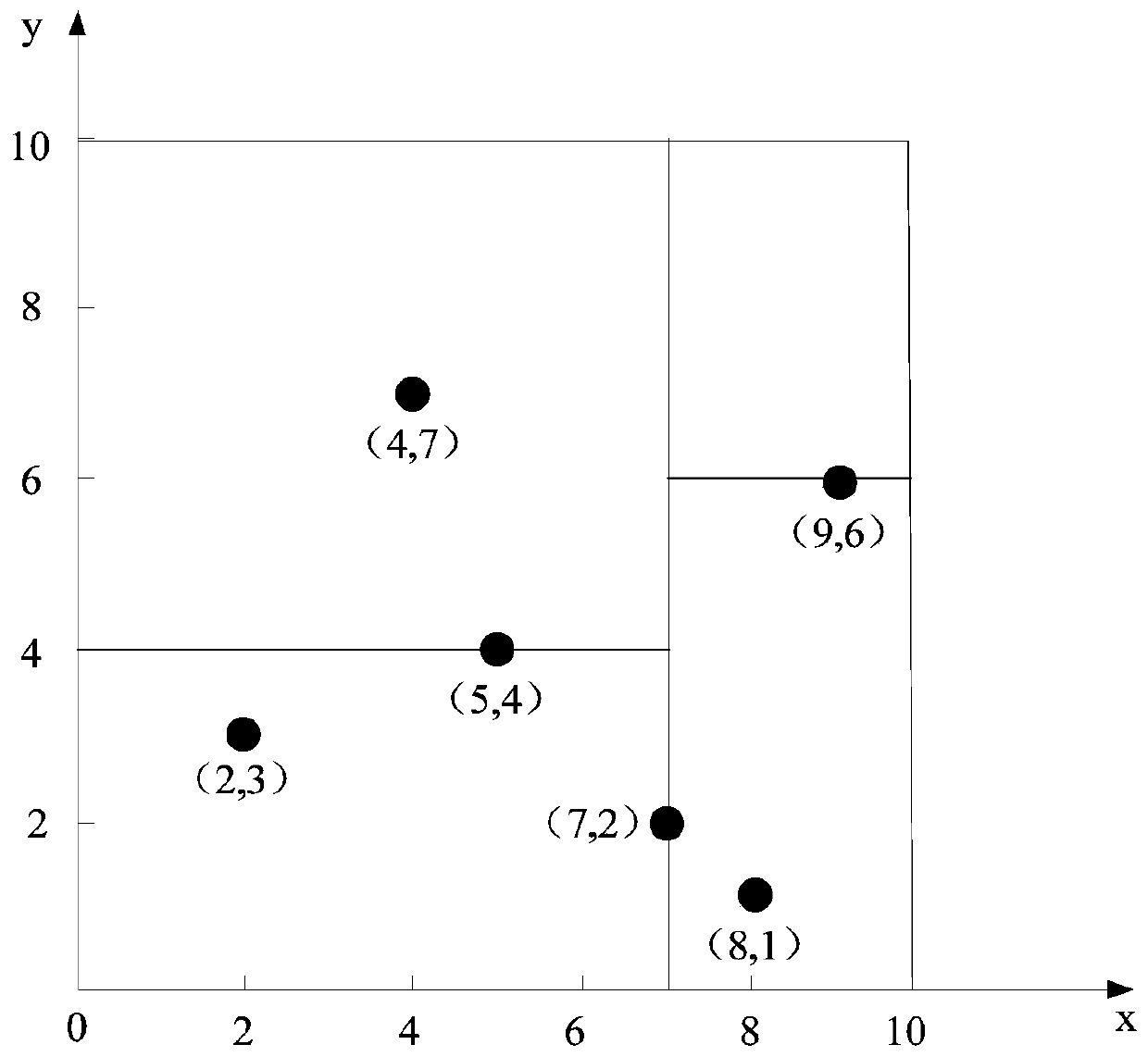

Multi-dimensional data exception detection method and device, readable storage medium and electronic device

PendingCN109753372AImprove intelligenceNo manual inspection requiredFault responseTransmissionHard codingData set

The invention relates to a multi-dimensional data exception detection method and device, a readable storage medium and an electronic device. The method comprises: acquiring target data input by a userin a form, and the target data are multi-dimensional data; determining K first sample data similar to the target data in a first sample data set, wherein the target data and the first sample data inthe first sample data set have the same dimension space; and determining whether the target data is abnormal or not according to the abnormal condition of each first sample data in the K first sampledata. Thus, the form designer can automatically detect whether the target data is abnormal or not, manual detection is not needed, the manual participation degree is reduced, and intelligence of multi-dimensional data abnormal condition detection is improved. Besides, different first sample data can be utilized to adapt to different service scenes, and the defects that in the prior art, when different service scene requirements are met through a hard coding mode, the applicability is poor, and the system processing performance is reduced are avoided.

Owner:NEUSOFT CORP

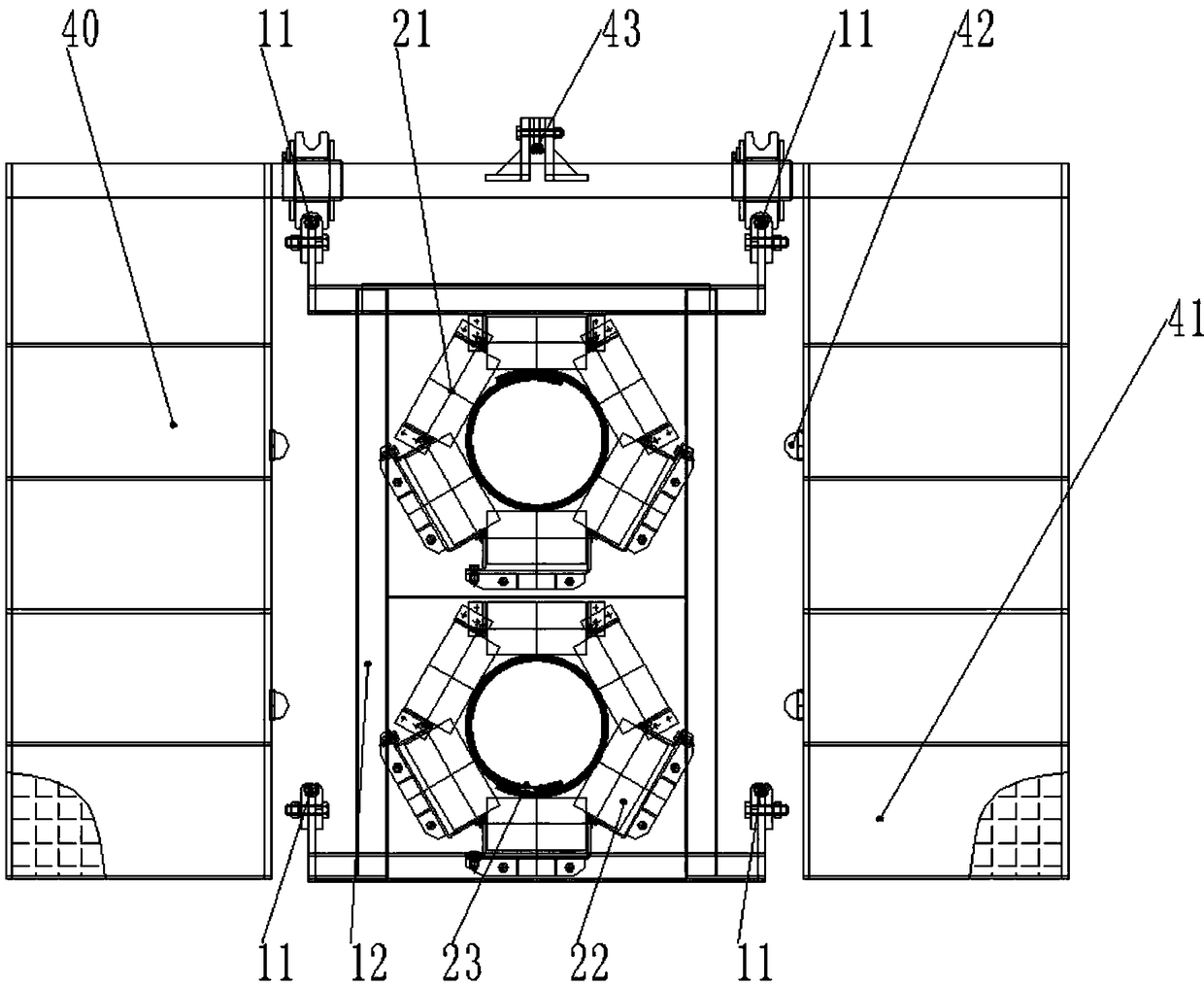

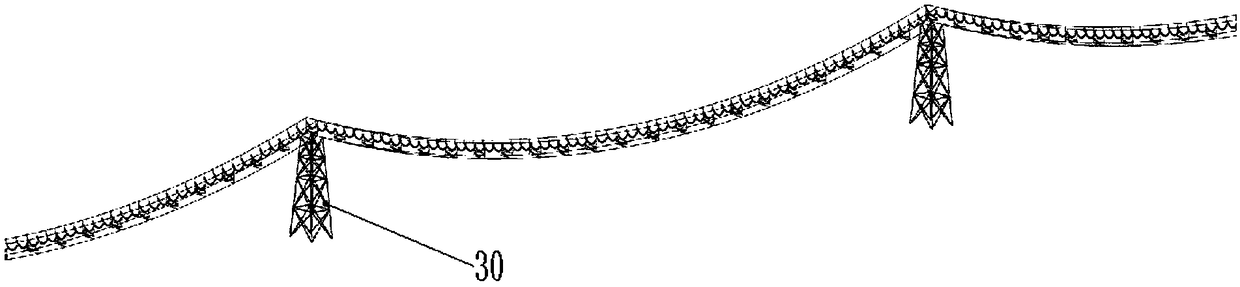

Cable pipe belt conveying structure and conveyor

PendingCN109018829ALarge spanReduce intermediate transfer linksConveyorsControl devices for conveyorsEngineeringUltimate tensile strength

The invention relates to the technical field of material conveying, and particularly provides a cable pipe belt conveying structure and a conveyor. The conveying structure comprises a cable mechanismwhich is arranged on a supporting object and is used for providing a conveying path for material conveying and a pipe belt conveying mechanism which is installed on the cable mechanism and is used forconveying materials. According to the cable pipe belt conveying structure and the conveyor, the cable structure is combined with a pipe belt machine, so that the problem of limited large-scale long-distance conveying of bulk materials in mountain areas is effectively solved; and meanwhile, a detection mechanism is adopted to replace a maintenance walkway, so that the efficiency is improved, the labor intensity is reduced, the investment cost is saved, the construction difficulty is reduced, the construction period is reduced, the comprehensive investment of projects is reduced, the social resources are saved, and practicability is achieved.

Owner:HUADIAN HEAVY IND CO LTD

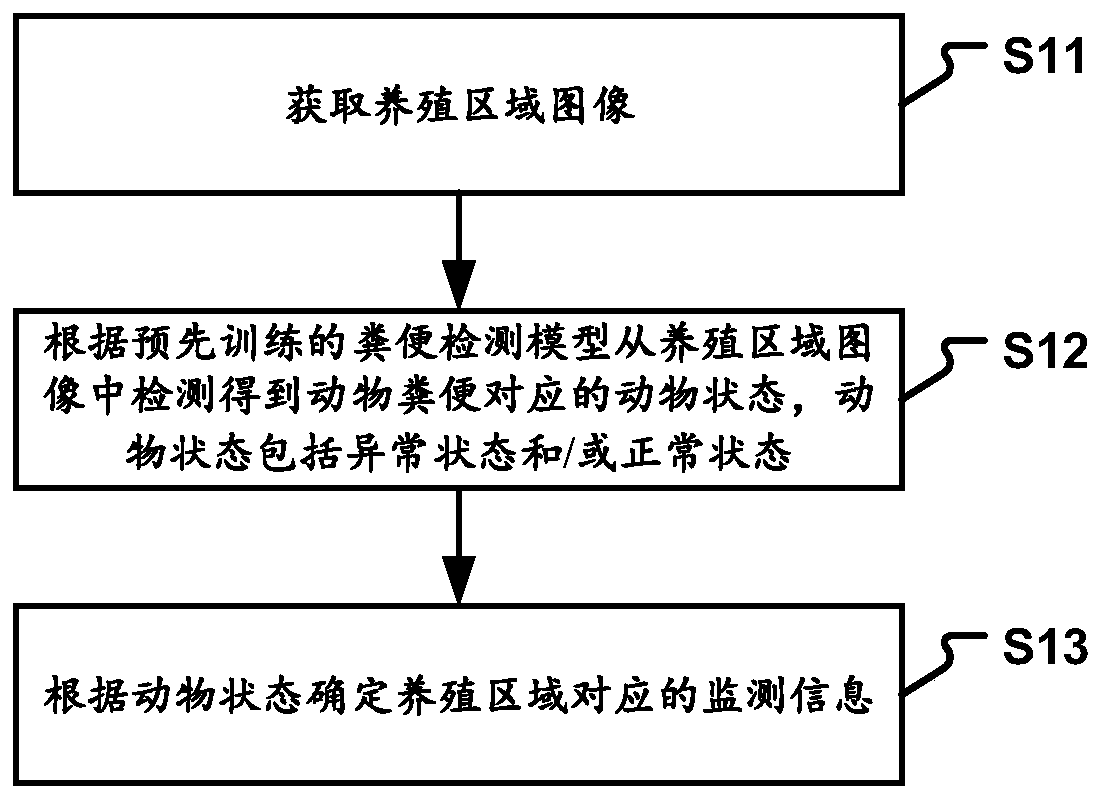

Animal abnormality monitoring method, image processing method and device

ActiveCN111183917AAutomatic detectionAccurate detectionOther apparatusAnimal scienceImaging processing

The invention relates to an animal abnormality monitoring method, an image processing method and a device. The animal abnormality monitoring method includes the steps that images of a breeding area are acquired; an animal state corresponding to animal feces is obtained by detecting from the breeding area images according to a pre-trained feces detection model, wherein the animal state includes anabnormal state and / or a normal state; and monitoring information corresponding to the breeding area is determined according to the animal state. The technical scheme is based on a computer vision method, animal feces are detected from the images through the pre-trained model, so that whether animals have epidemic states such as diarrhea or not is monitored automatically, accurately and timely, thespread of epidemic is prevented, manual detection is not needed, and the labor cost and time cost are reduced.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

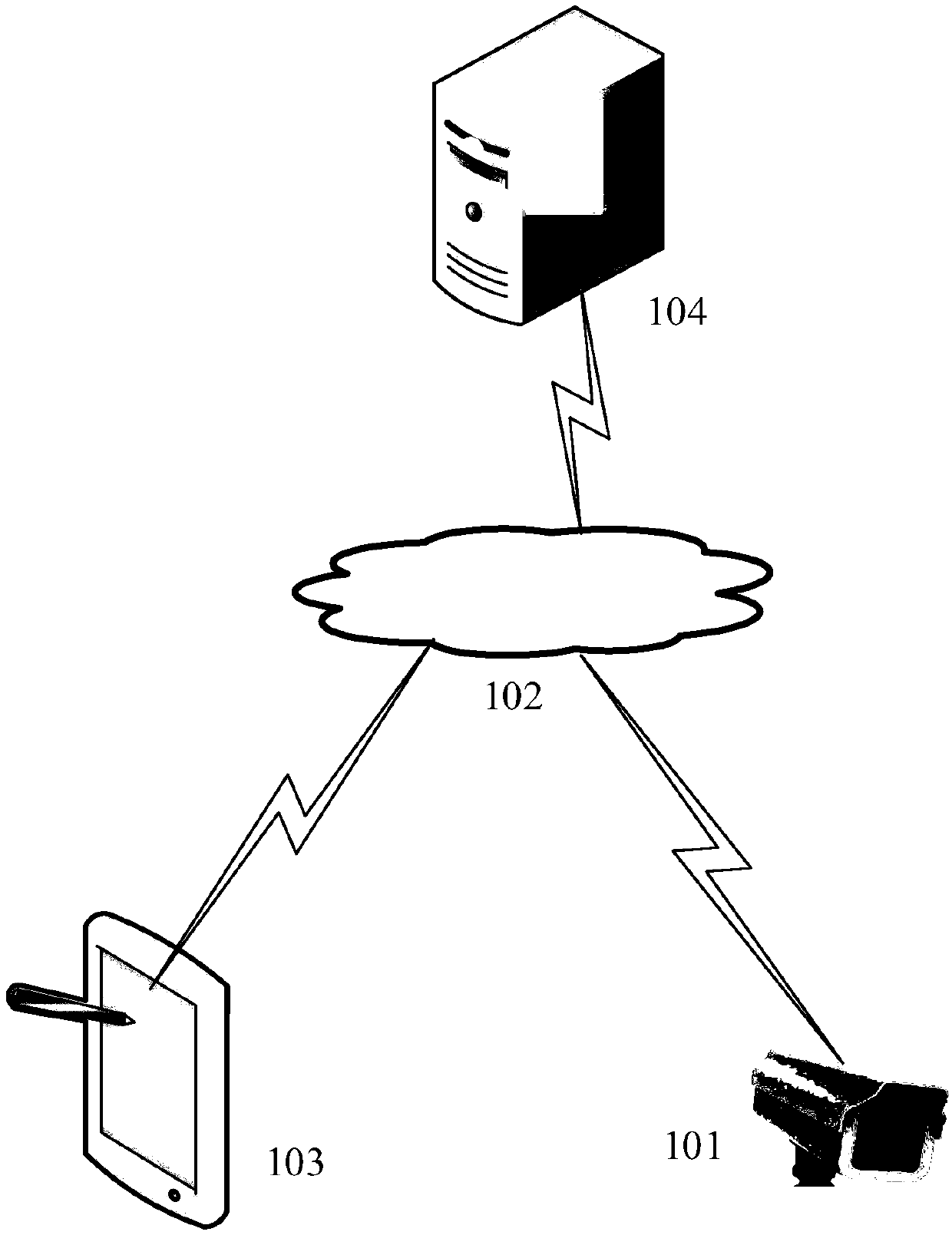

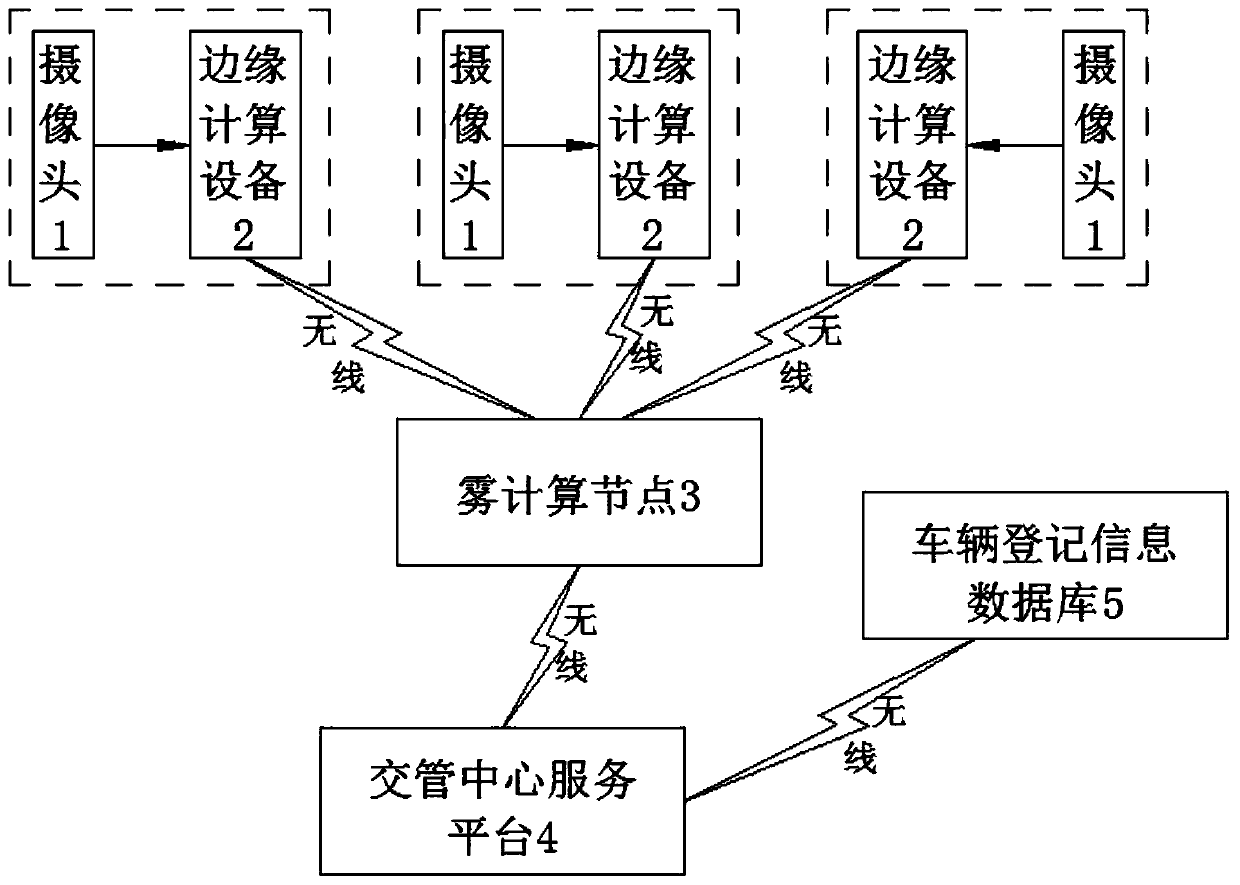

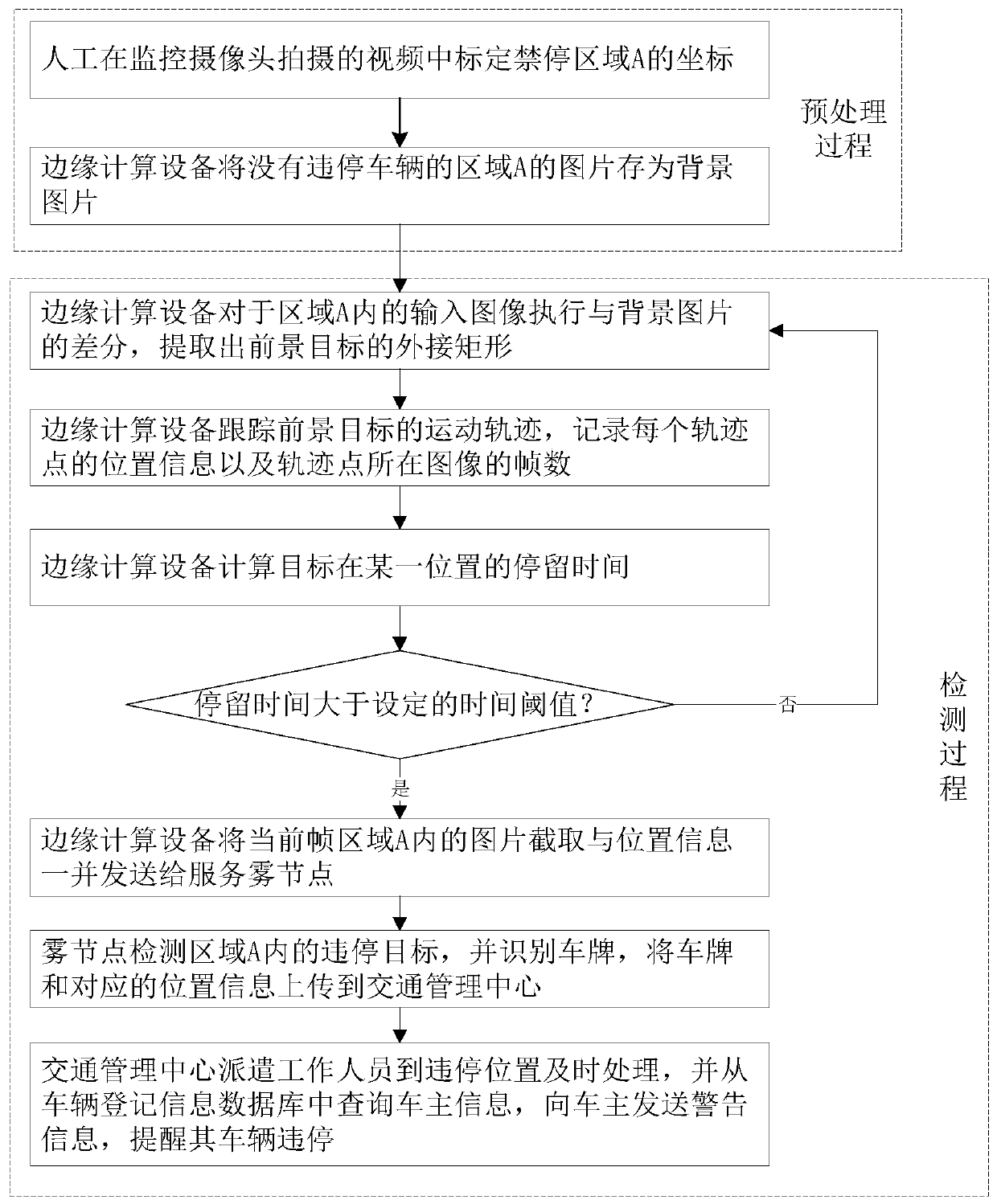

Fog calculation-based illegal parking vehicle detection system and method

ActiveCN110070729AWork efficiently and quicklyNo manual inspection requiredTraffic control supervisionClosed circuit television systemsReal-time computingControl system

The invention discloses a fog calculation-based illegal parking vehicle detection system, and relates to the technical field of traffic control systems. The system comprises a camera, an edge calculation device connected with the camera, a fog calculation node for collecting information output by the edge calculation device in a network coverage area, and a traffic control center service platformcommunicable connected with a vehicle registration information database. The camera is used for shooting the vehicle parking condition of a covered area in real time, and the shot video frame image ismarked with a no-parking area; the edge calculation device is used for detecting whether a time-out vehicle is parked in the non-parking area of the video frame image, and sending the information ofthe time-out vehicle to the fog calculation node; the fog calculation node is used for recognizing the information of the vehicle and transmitting the information of the vehicle and the position of the vehicle to the service platform; and the workers can process the illegal parking information of the vehicle through the service platform, query the owner information of the illegal parking vehicle through the vehicle registration information database, and then send warning information to the owner. The invention also discloses an illegal parking vehicle detection method.

Owner:SHANDONG INSPUR SCI RES INST CO LTD

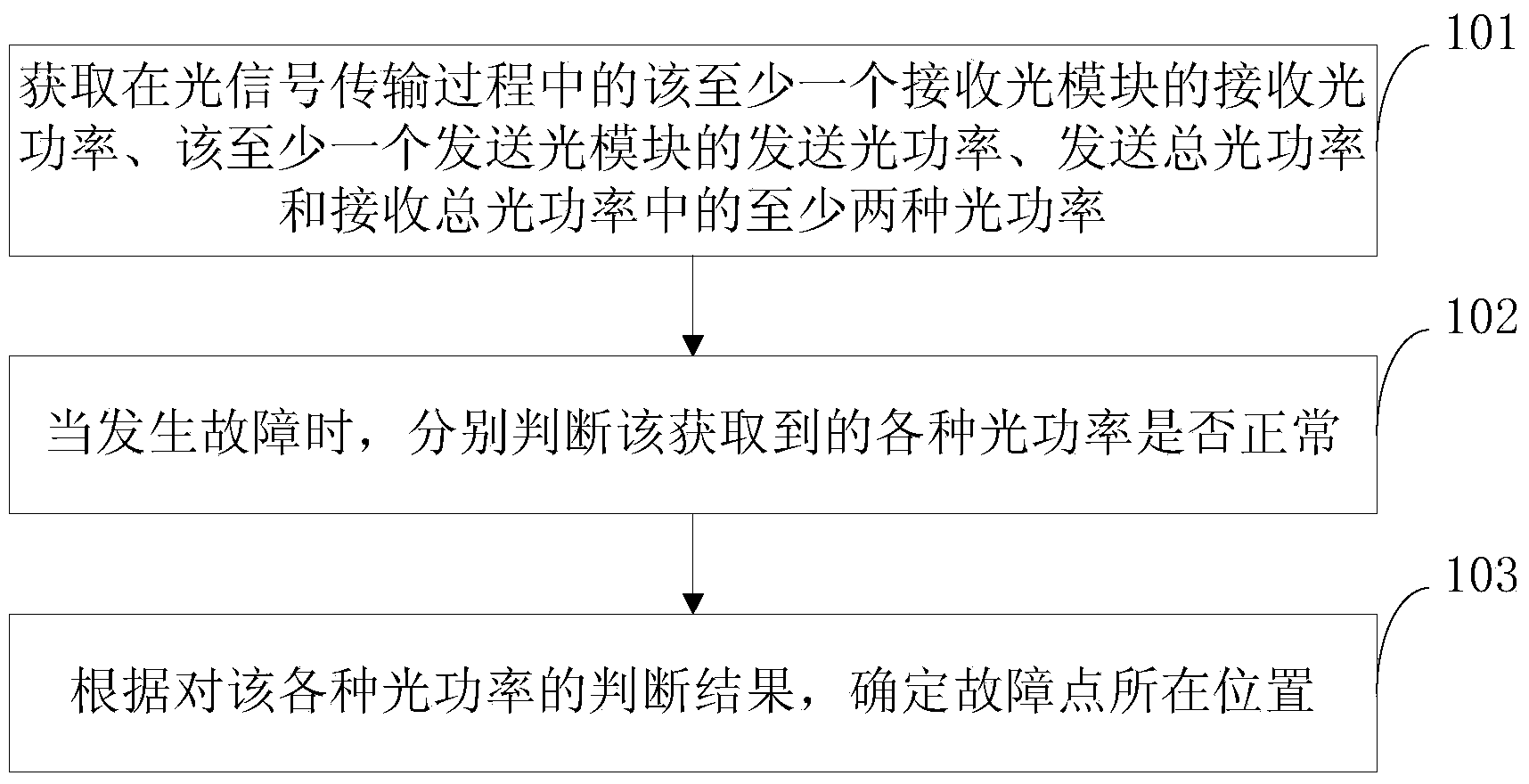

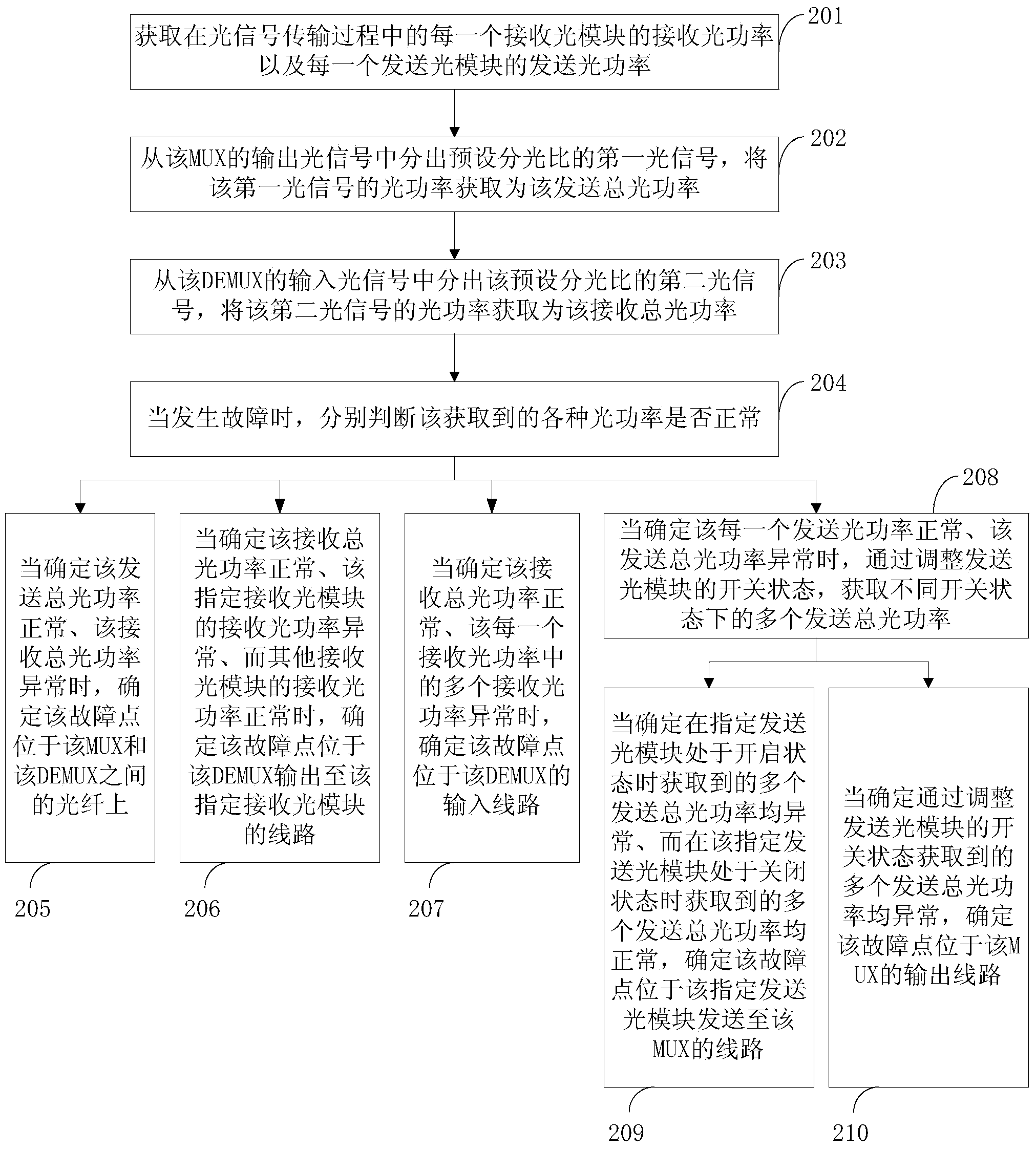

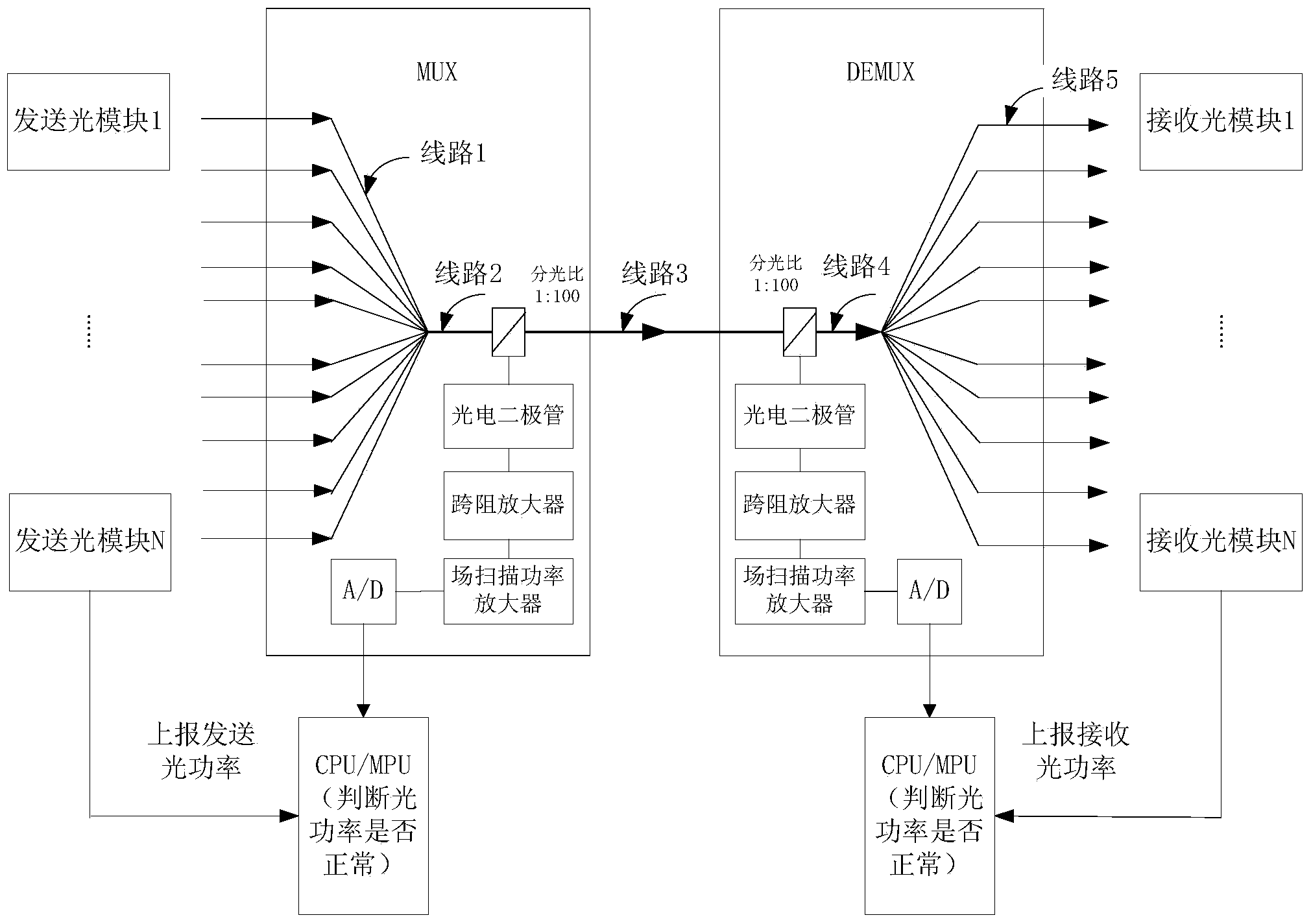

Fault detection method and device

InactiveCN103560827ASolve the problem that fault location cannot be performedFully automatedElectromagnetic transmissionOptical ModuleWorkload

The invention discloses a fault detection method and device, and belongs to the technical field of communication. The fault detection method is applied to combined wave and partial wave systems and includes the steps of obtaining receiving light power of at least one receiving light module and at least two kinds of light power in sending light power, sending total light power and receiving total light power of at least one sending light module in the light signal transmitting process, respectively judging whether the obtained various kinds of light power are normal when a fault happens, and determining the position where a fault point is located according to the judging results of the various kinds of light power. When the fault happens, the fault detection method can be used for determining the position where the fault point is located by judging whether the obtained various kinds of light power are normal, solves the problem that passive components can not carry out fault positioning, achieves automation of fault positioning, greatly reduces workload due to the fact that manual detection is not needed, reduces maintenance cost, improves fault removal speed and improves system performance.

Owner:HUAWEI TECH CO LTD

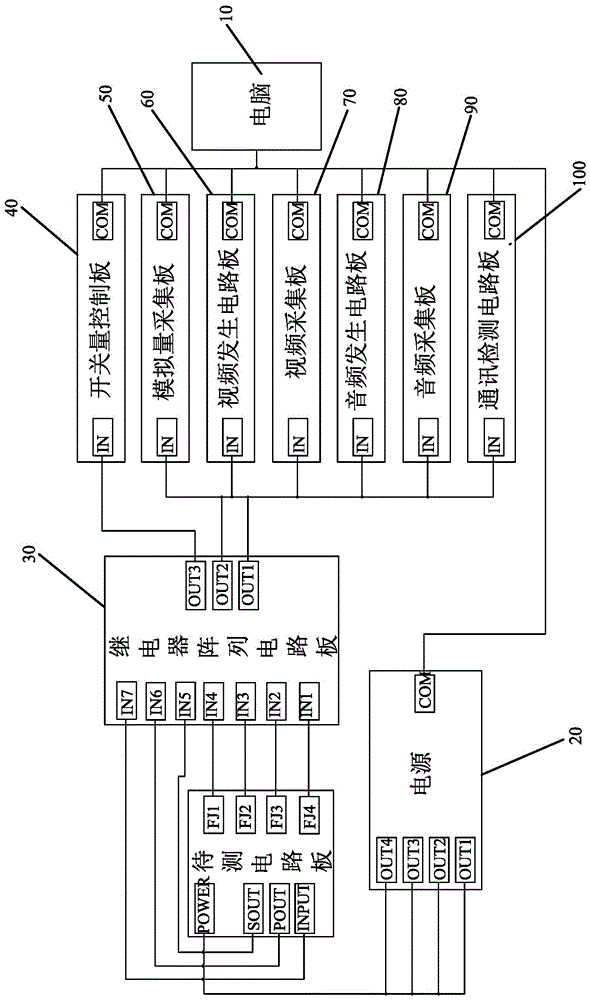

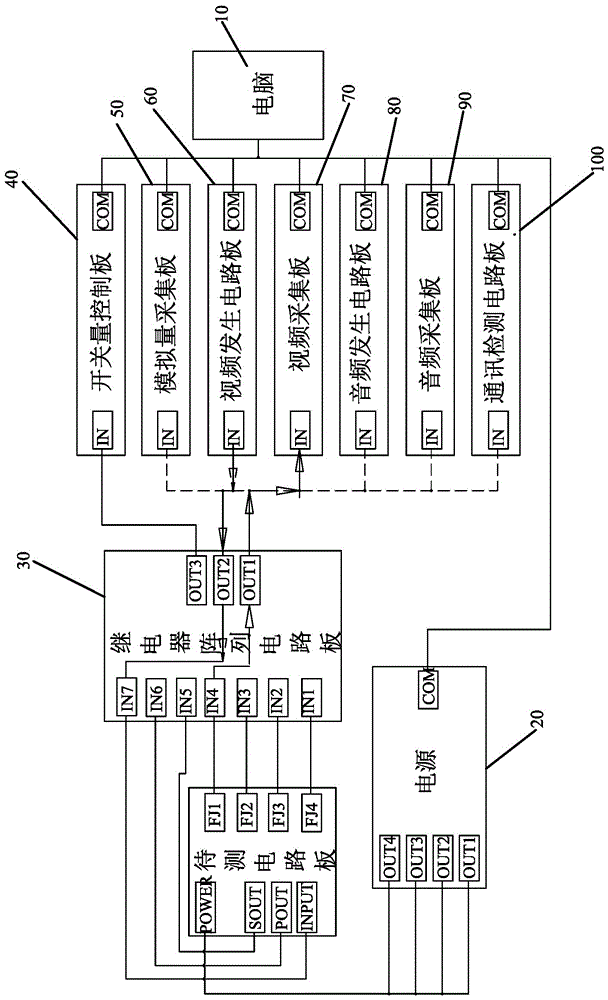

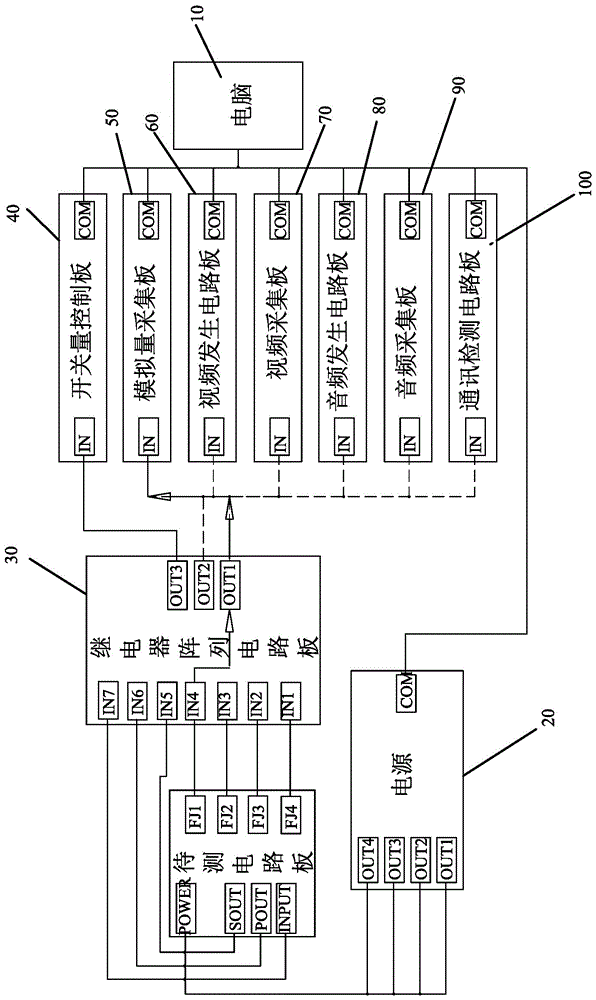

Circuit board detection system and detection method

PendingCN107526029AImprove work efficiency and reliabilitySave manpower and timeAutomated test systemsMulti itemEngineering

The invention discloses a circuit board detection system and detection method. The circuit board detection system comprises a computer, a power supply relay array circuit board, a switching quantity control panel, an analog quantity acquisition board, a video generation circuit board, a video acquisition board, an audio generation circuit board, an audio acquisition board and a communication detection circuit board. The relay array circuit board and the computer are connected with the switching quantity control panel, the analog quantity acquisition board, the video generation circuit board, the video acquisition board, the audio generation circuit board, the audio acquisition board and the communication detection circuit board. The relay array circuit board is provided with an input port and an output port. The relay array circuit board is connected with the switching quantity control panel, the analog quantity acquisition board, the video generation circuit board, the video acquisition board, the audio generation circuit board, the audio acquisition board and the communication detection circuit board through the output port. Therefore, multipath signals can be controlled and multi-item detection of the circuit board can be orderly performed so that the work efficiency and the reliability can be greatly enhanced and the detection time can be saved.

Owner:JIMEI UNIV

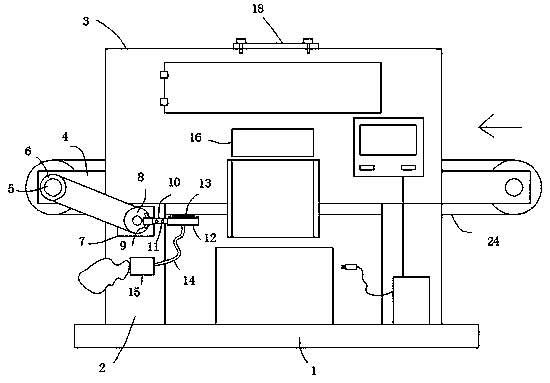

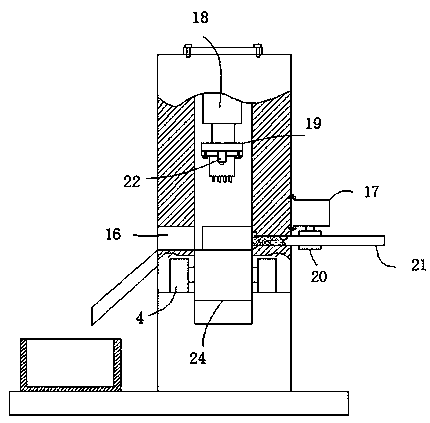

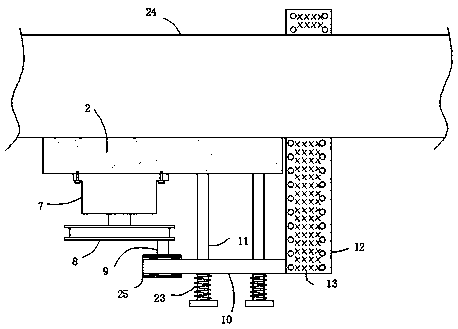

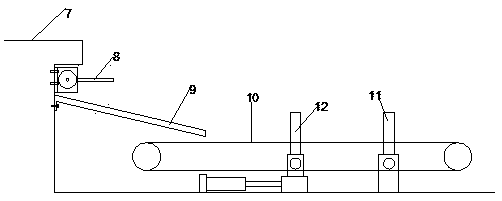

Electronic product testing production line and testing method thereof

The invention discloses an electronic product testing production line and a testing method thereof. Aiming at the problems that the manual testing efficiency for existing electronic products is slow,a use effect is not good enough, and the products are easy to pollute by dust on a conveyor belt, the invention provides the following scheme that the electronic product testing production line comprises a base, wherein two opposite installation frames are fixed onto the base; a main case is fixed between the upper ends of the two installation frames; an inlet and an outlet are formed in the leftside and the right side of the main case; a waste parts outlet is formed in the front surface of the main case; a group of fixed blocks is fixed to the each of the left side and the right side of themain case; rotary shafts are rotatably connected onto the two groups of fixed blocks; driven pulleys are fixed to one ends of the rotary shafts; and belt rollers are fixed to the other ends of the rotary shafts. According to the electronic product testing production line and the testing method thereof provided by the invention, a product automatic testing production line can be formed, so that theproduct testing efficiency is improved, the worker burden is reduced, and meanwhile, the cost is reduced; and in addition, ash removal work can be automatically carried out on the conveyor belt, so that dust on the conveyor belt is effectively prevented from polluting products.

Owner:PUTIAN UNIV

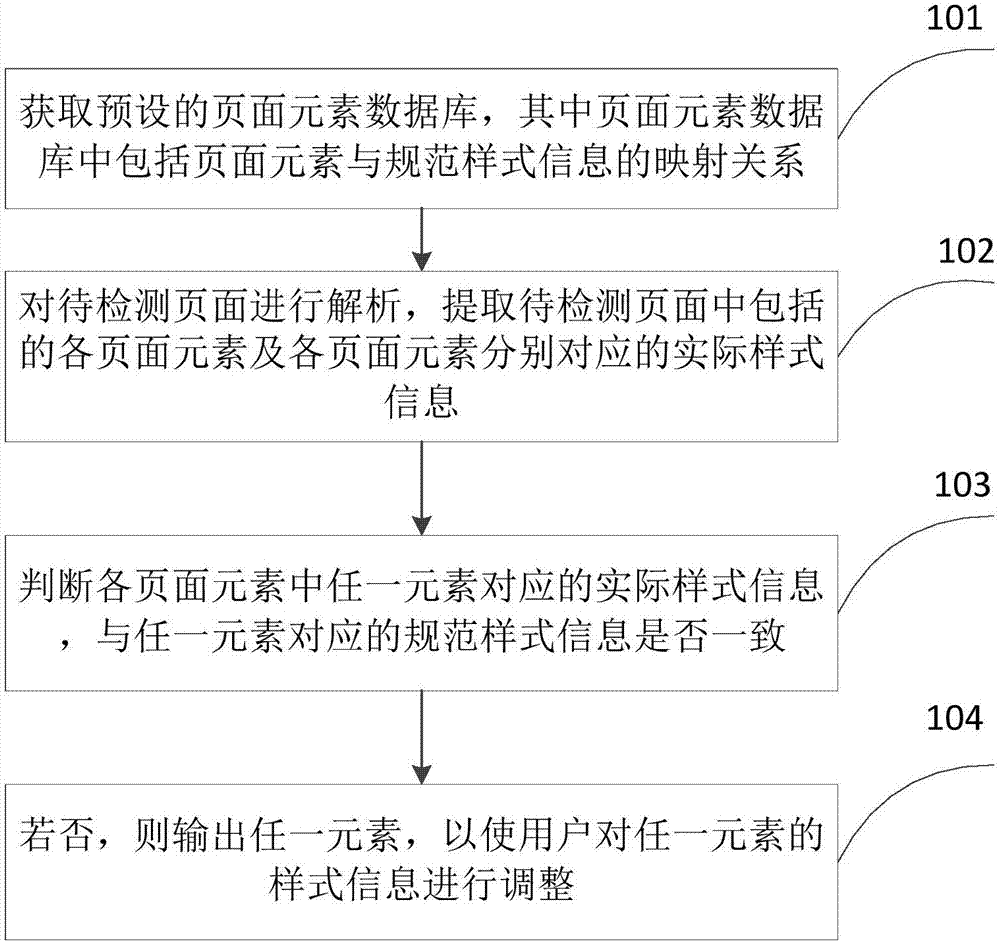

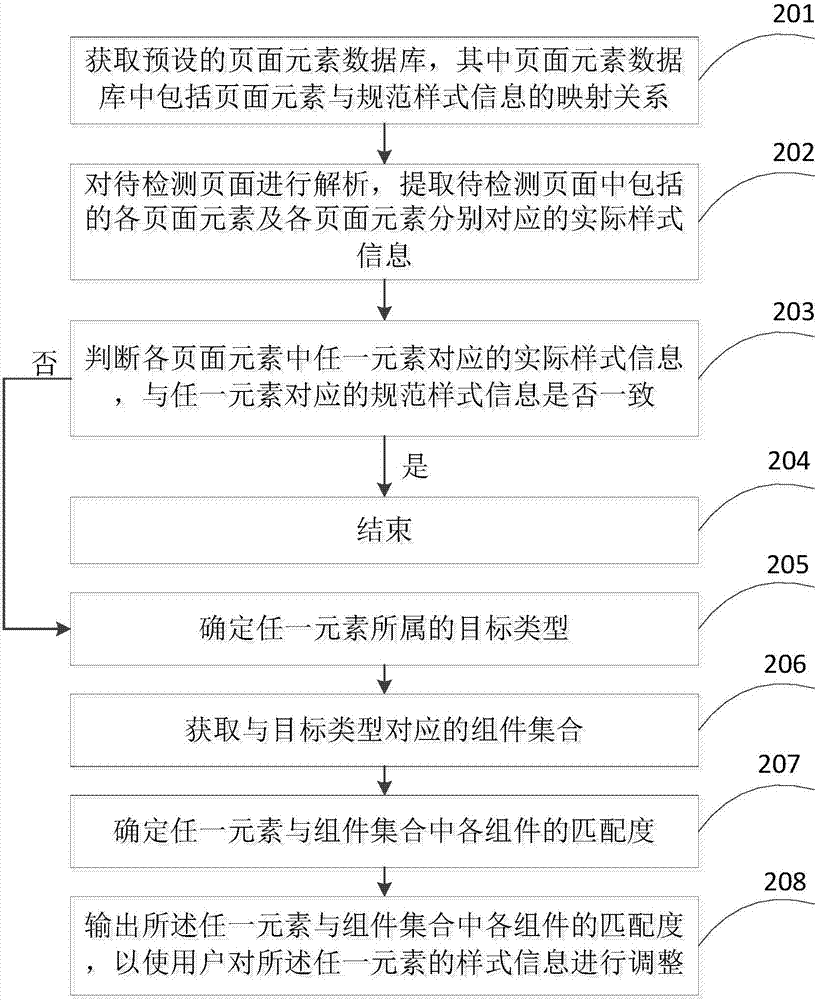

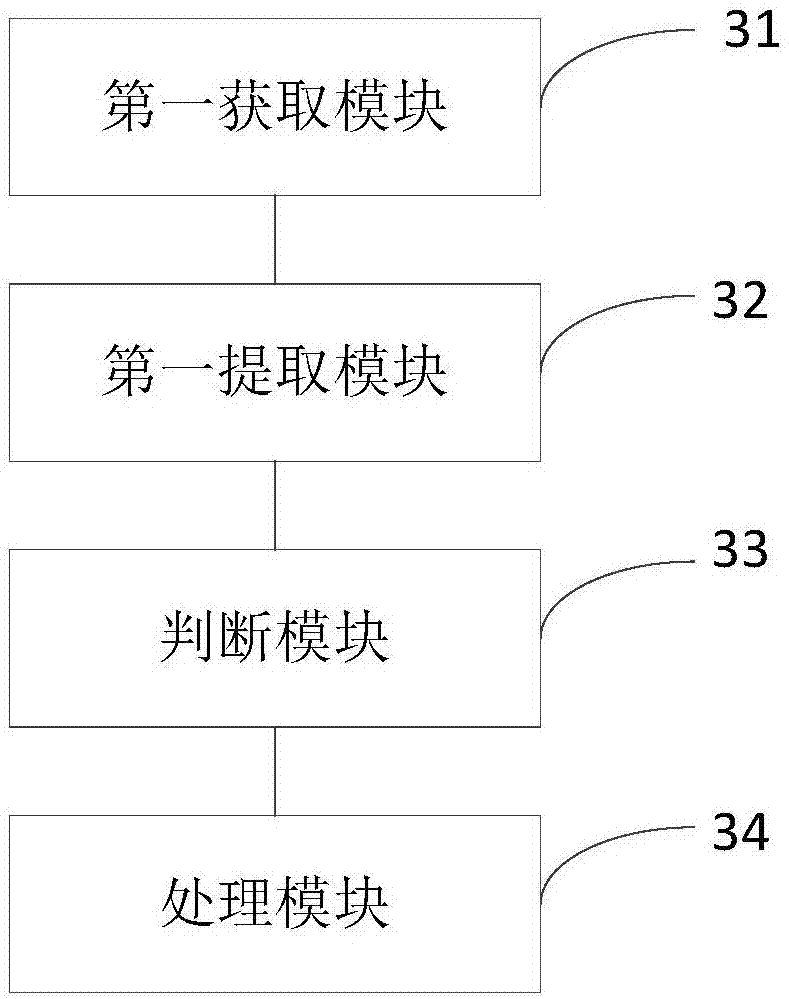

Page standard detection method and device and computer equipment

ActiveCN107544903ARealize detectionImprove experienceSoftware testing/debuggingDatabaseComputer equipment

The invention provides a page standard detection method and device and computer equipment. The method includes: acquiring a preset page element database; parsing a to-be-detected page to extract all page elements, which are included in the to-be-detected page, and actual style information respectively corresponding to all the page elements; judging whether the actual style information corresponding to any element in all the page elements is consistent with standard style information corresponding to the any element; and if not, outputting the any element to enable a user to adjust the style information of the any element. Therefore, detection on page standard is realized, thus the user can be enabled to adjust the style information of the any element when the actual style information of the any element in the to-be-detected page is not consistent with the preset standard style information, conditions are provided for standardizing styles of all the element in the page, unifying the page styles and improving the user experience, and later page maintenance costs are reduced due to no need for artificial detection.

Owner:NEUSOFT CORP

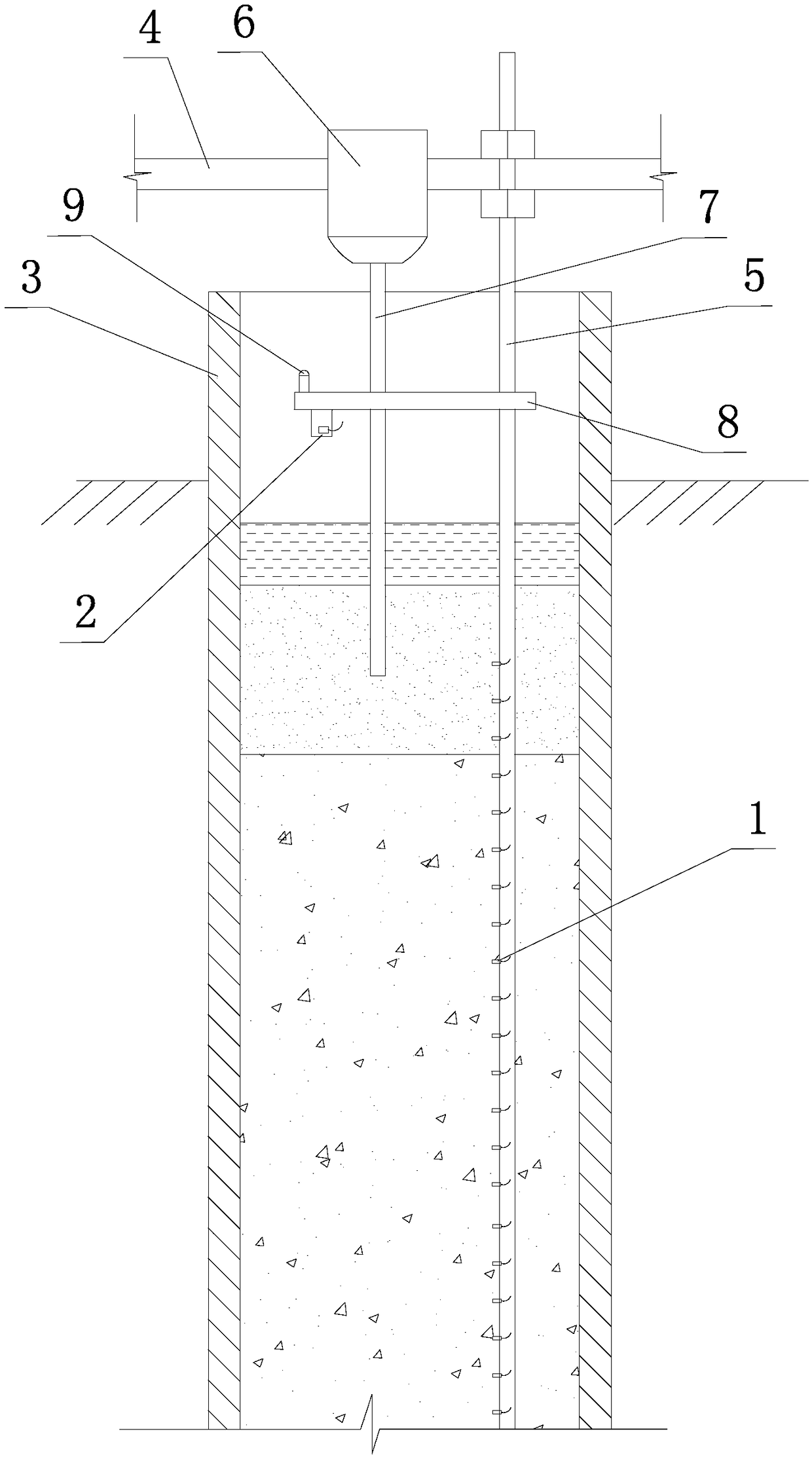

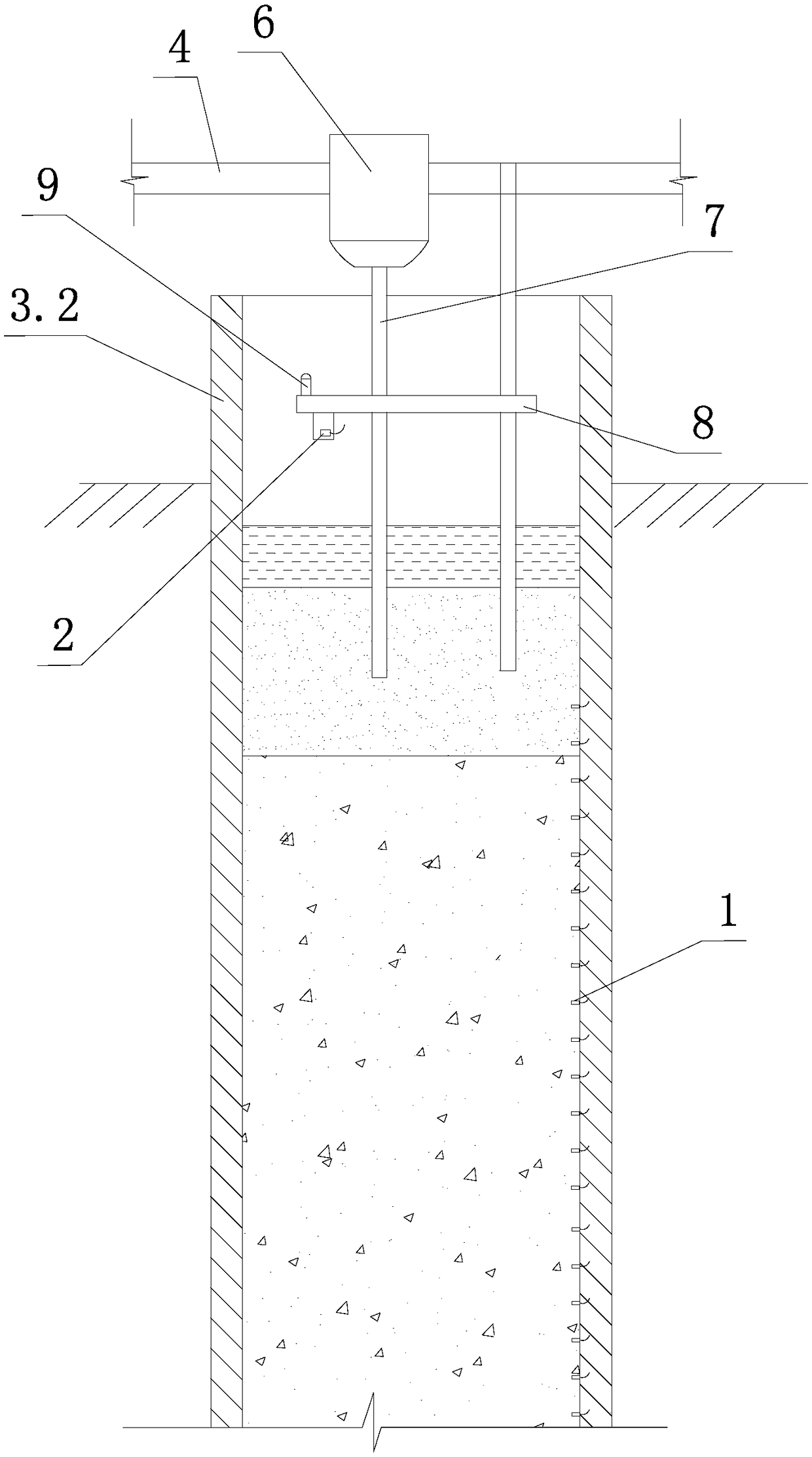

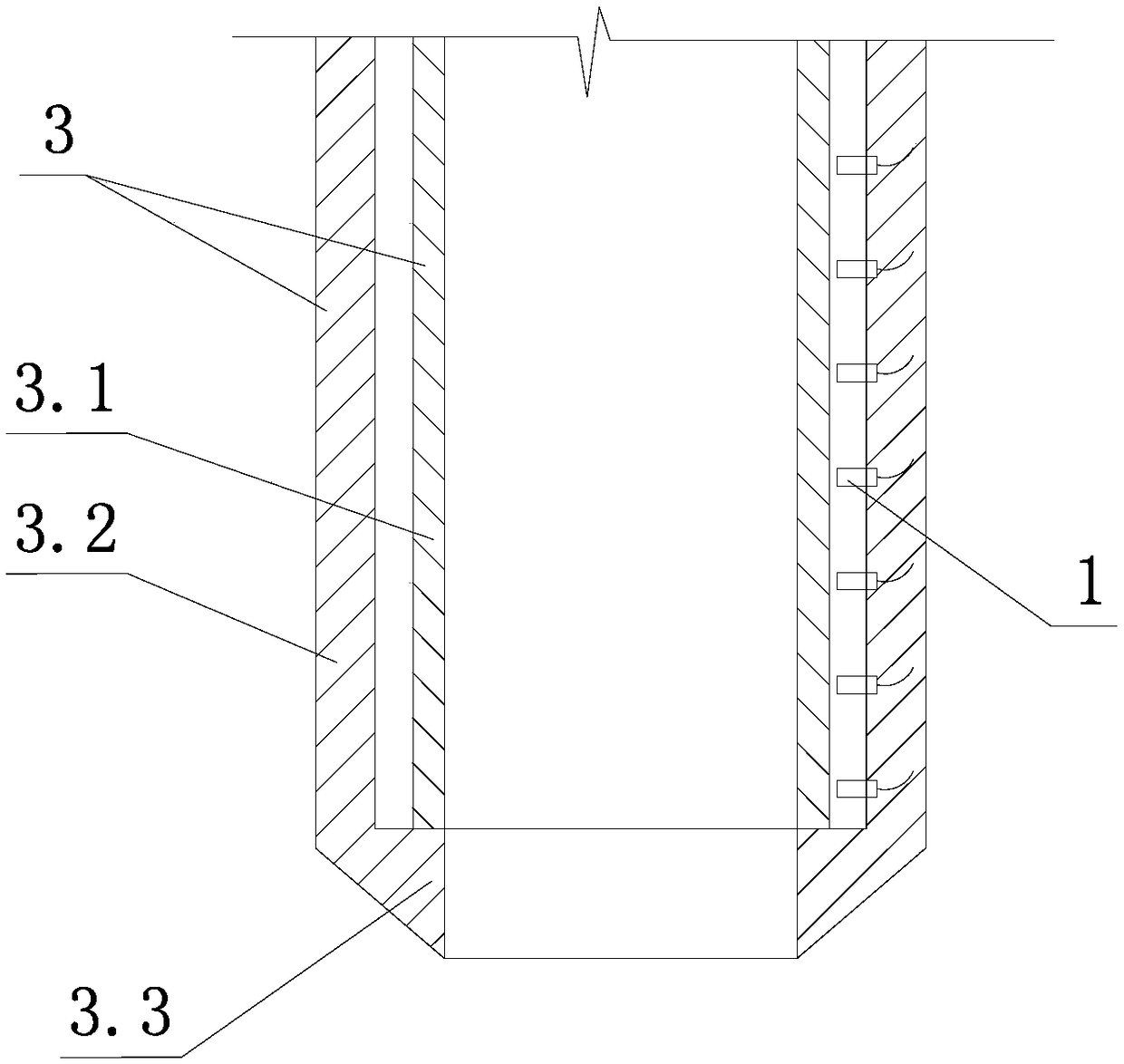

Device and method for judging whether concrete pouring height of cast-in-situ bored pile is reached or not

PendingCN109339037AHigh precisionReduce mistakesMeasurement devicesBulkheads/pilesEngineeringHeight difference

The invention discloses a device and a method for judging whether concrete pouring height of a cast-in-situ bored pile is reached or not. The device comprises a main controller and a plurality of temperature sensors at different heights, which are arranged in formed holes at equal distance, and further comprises a moving mechanism which is arranged along the height of the formed holes, wherein allof the temperature sensors are in signal connection with the main controller; the lower end of the movable mechanism is equipped with a pressure sensor; and the pressure sensor is also in signal connection with the main controller. The key point of the method is characterized in that the main controller calculates height difference Hn between n groups of temperature sensors, temperatures of whichare increased to T0, and the other temperature sensor above which heat up is started, and a mean value is fitted as a thickness of a laitance and mud layer of a concrete layer surface. The device andthe method are precise in judged results, and are quick and convenient in process.

Owner:中地君豪高科股份有限公司

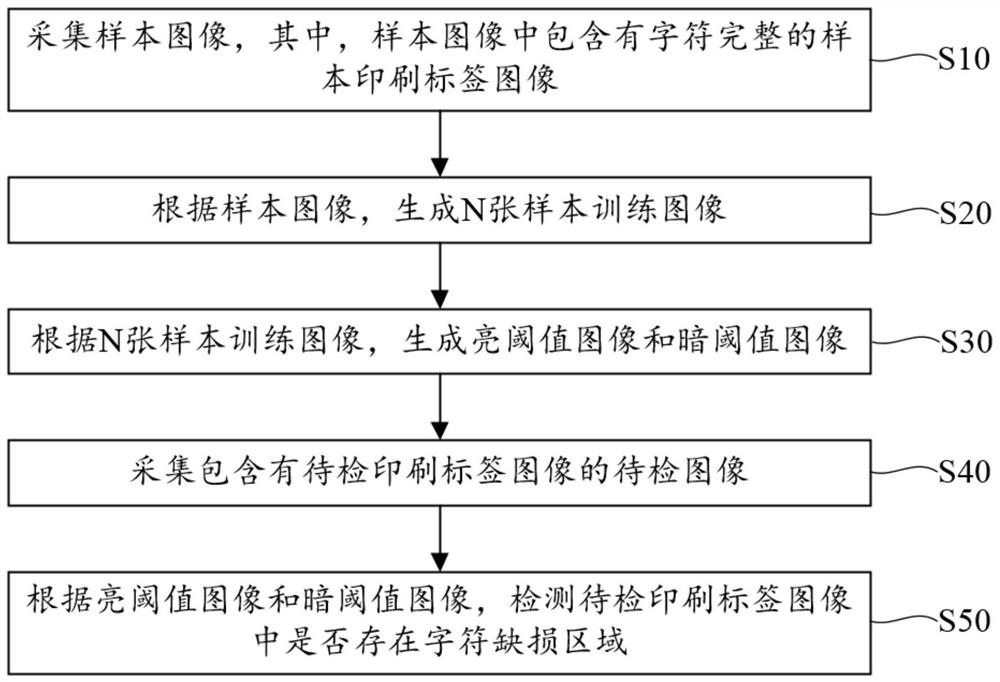

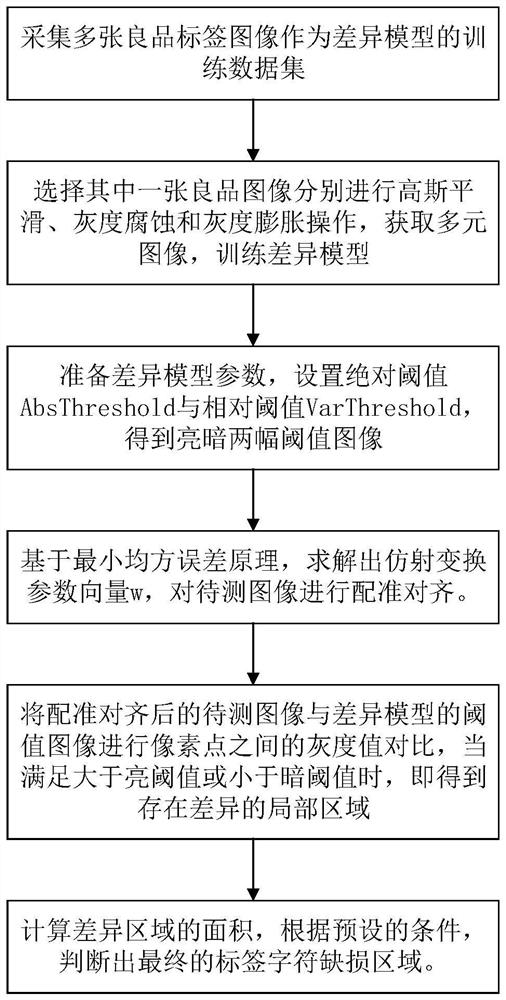

Character integrity detection method and device for printed label

PendingCN114266764AReduce workloadAffect accuracyImage enhancementImage analysisRadiologySample image

The invention provides a character integrity detection method and device for a printed label, and the method comprises the steps: collecting a sample image which comprises a sample printed label image with complete characters; generating N sample training images according to the sample images; generating a bright threshold image and a dark threshold image according to the N sample training images; collecting a to-be-detected image containing the to-be-detected printing label image; and according to the bright threshold image and the dark threshold image, detecting whether a character defect area exists in the to-be-detected printing label image. Automatic detection is achieved, manual detection is not needed, the labor cost is reduced, and the detection accuracy is improved. The method does not need to collect a large number of sample images, reduces the workload of collecting the sample images, and reduces the influence on the precision of the finally trained sample model due to the difference between a plurality of sample images. The detection accuracy can be improved.

Owner:深圳市前海研祥亚太电子装备技术有限公司

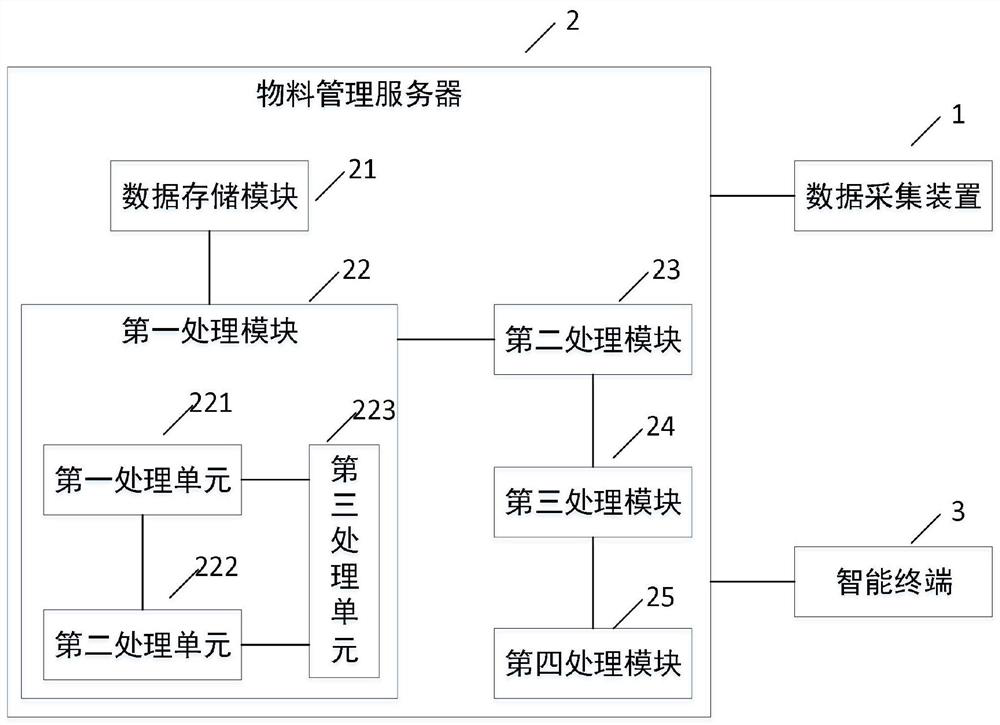

Production material intelligent management system

PendingCN111611325AGuaranteed FIFORealize paperless managementVisual data miningStructured data browsingRelational tableIndustrial engineering

The invention provides a production material intelligent management system, and relates to the technical field of enterprise raw material management, and the system comprises a plurality of data collection devices which are used for collecting storage environment data in a storage warehouse in real time; and a material management server used for storing a corresponding relation table between the current storage position of each medicine raw material and each data acquisition device; performing matching in the corresponding relation table according to the current storage position to obtain associated storage environment data; comparing the storage environment data with preset standard environment requirements; generating a first material information list according to the data comparison result, an externally input material code, a material validity period and a current storage position; according to the current time and the validity periods of all the materials, the remaining valid timeof all the medicine raw materials is obtained through processing, and according to the sequence of the remaining valid time from small to large, all rows of data in the first material information list are arranged to obtain a second material information list. The system has the advantages that material information is visually presented, and paperless management is achieved.

Owner:SHANGHAI KAIBAO PHARMA +1

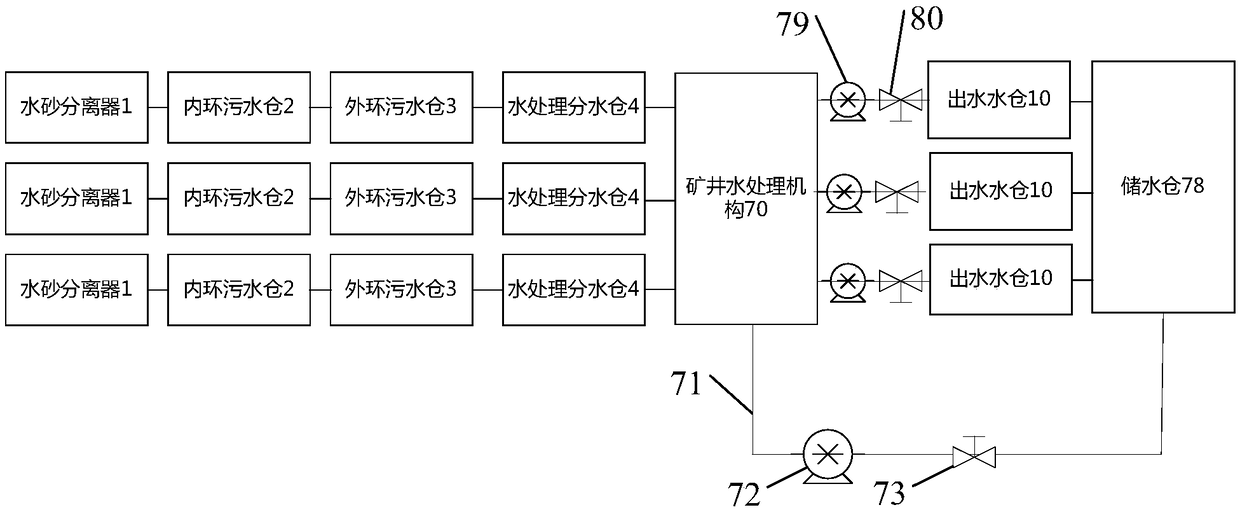

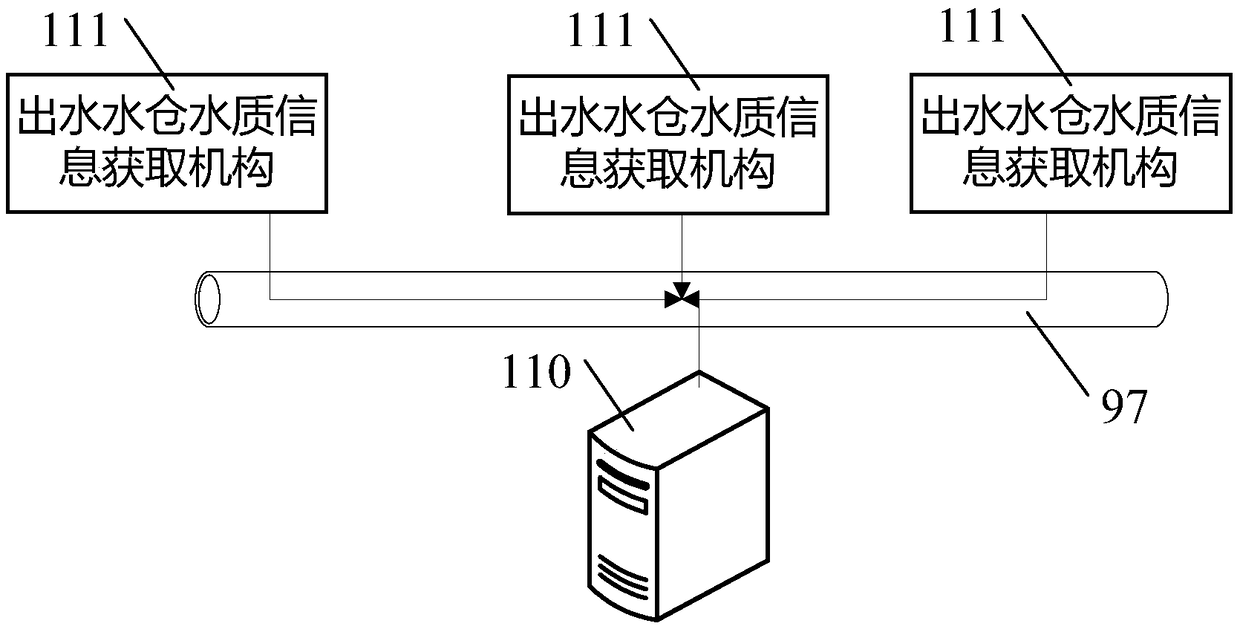

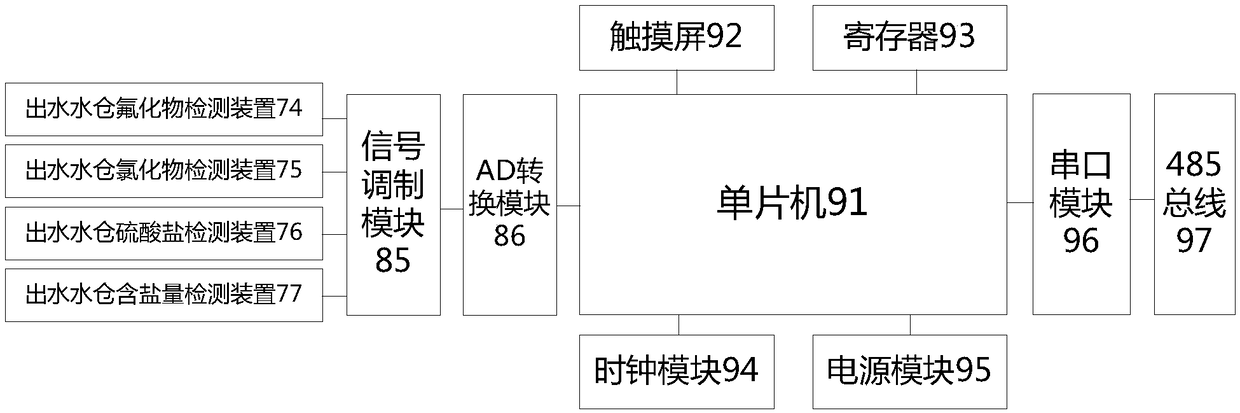

Multiple treating-based mine water quality treating and monitoring system

ActiveCN109384290AProtect normal service lifeAvoid spread outWater/sewage treatment by magnetic/electric fieldsRepeated treatmentWater quality

The invention provides a multiple treating-based mine water quality treating and monitoring system. According to the system, a water quality control host can correspondingly compare a fluoride content, a chloride content, a sulfate content and a salt content in mine water in a certain water-out sump with preset threshold values after a liquid level meter of the water-out sump senses a liquid levelsignal, and control starting of a reflux valve and operating of a reflux pump when a certain content exceeds the corresponding preset threshold value, so as to enable the mine water in the water-outsump to return to a mine water treating mechanism for secondary treatment. When water quality is unqualified, secondary treatment is performed. The system is provided with a plurality of water-out sumps, so that the treated mine water can be separately stored; if the water treatment is unqualified, the treatment process can be suspended to adjust the medicament and ratio, and then the treatment can be carried out to ensure that the water treatment can meet the requirements. The system can avoid the phenomenon that when detection is carried out after treatment of a large quantity of mine water,repeated treatment is required if a large quantity of water is unqualified in quality.

Owner:SHANDONG DONGSHAN WANGLOU COAL MINE

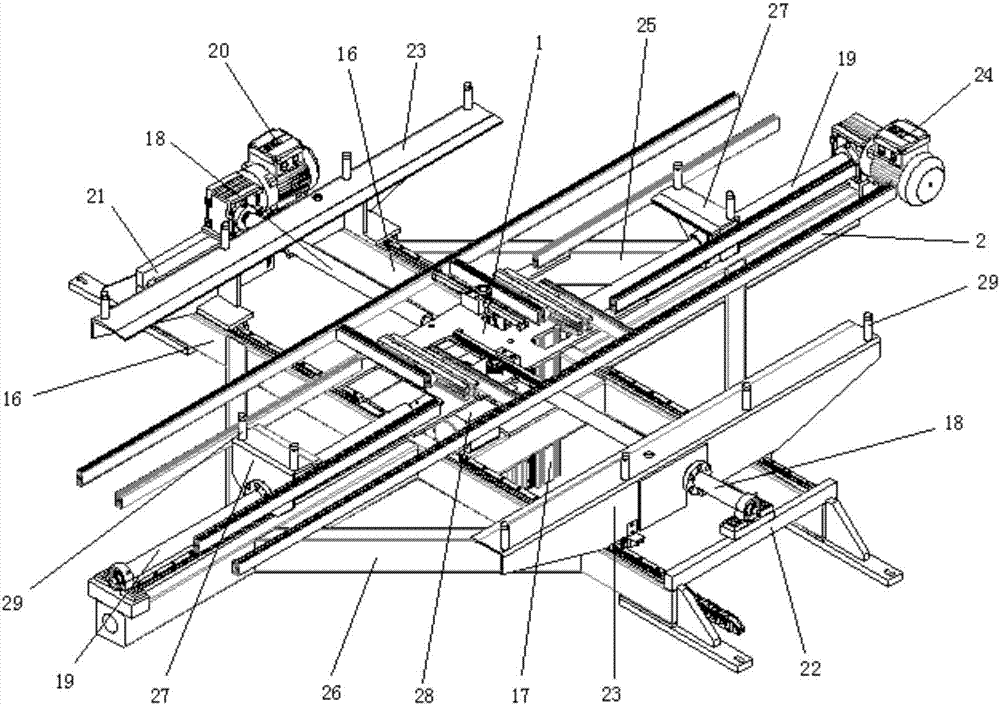

Automatic feeding and discharging small plate shearing machine

PendingCN109663866AAutomatic removalNo manual inspection requiredMetal-working feeding devicesShearing machinesSteel barMechanical engineering

The invention discloses an automatic feeding and discharging small plate shearing machine. The machine comprises a rack. A conveying table and a discharging table are arranged on the front and rear sides of the rack correspondingly. A pushing mechanism is arranged on the conveying table and comprises a lead screw. The lead screw is arranged at the lower end of a supporting plate. Supporting blocksare arranged in the positions, located on the two sides of the lead screw, of the conveying table correspondingly. Supporting slide grooves are formed in the middles of the supporting blocks correspondingly. A push seat is arranged on slide blocks of the lead screw. The slide blocks are arranged at the two ends of the push seat correspondingly. Mounting seats are arranged at the two ends of a supporting seat. The two ends of the push seat are fixed to the two mounting seats correspondingly. A shearing groove is formed in a workbench. An overturning guide plate and an oblique guide plate are arranged on the side wall of the shearing groove. A plurality of small conveying belts are arranged at the lower end of the oblique guide plate. Two fixed overturning inspection plates and a movable overturning inspection plate are arranged on the discharging table. A push plate is arranged on the lateral side of the discharging table. The automatic feeding and discharging small plate shearing machine is simple in structure and reasonable in design, the widths of sheared steel bars can be detected automatically, and in addition, steel bars with the widths not meeting standards can be rejected.

Owner:南通航力重工股份有限公司

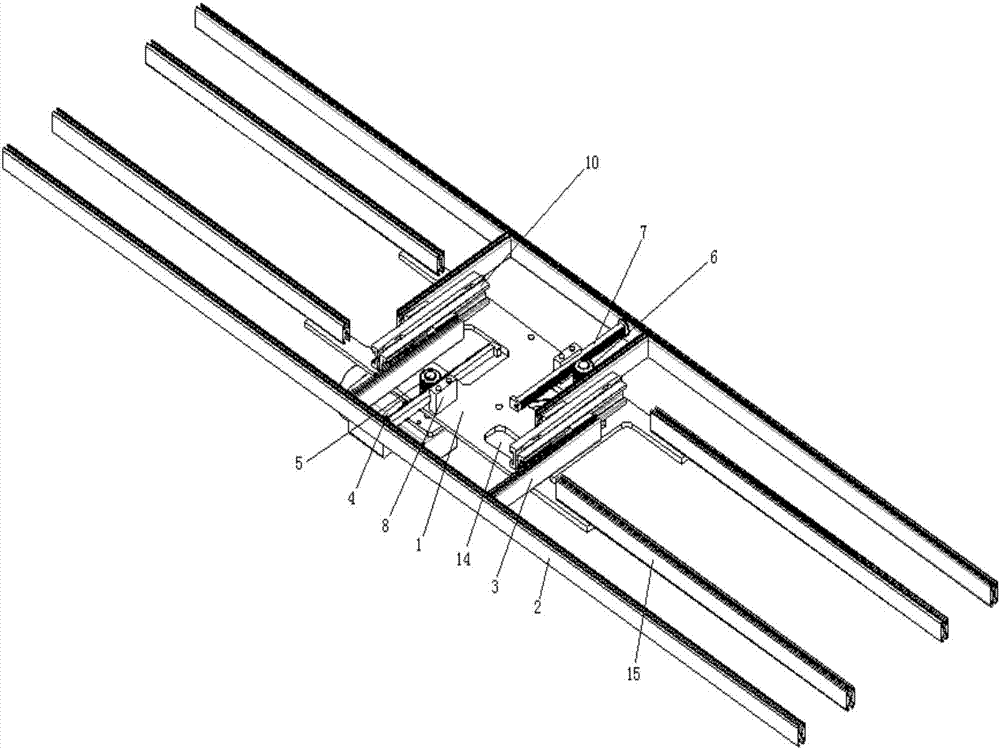

Feeding device capable of preventing forming machine from plate excess

ActiveCN107442678AReduce labor intensityPromote repairMetal-working feeding devicesMetal working apparatusAutomatic controlControl system

The invention discloses a feeding device capable of preventing a forming machine from plate excess. The feeding device comprises a width adjustment mechanism and a centering mechanism, wherein the width adjustment mechanism comprises a supporting plate fixedly mounted in a rack of the former; a bracket is mounted on each of two sides of the supporting plate; connecting pieces and a rack are mounted on each bracket; two servo motors I are mounted at the bottom of the supporting plate and controlled by a control system of the former; the output ends of the servo motors I drive the brackets to move through controlling meshing between driving gears and the racks; the centering mechanism comprises two parallelly distributed transverse guide rails, and lead screw systems mounted on the transverse guide rails; a lifting cylinder is fixedly mounted between the two transverse guide rails; and a feeding detection device is further mounted at the bottom of the supporting plate. According to the feeding device, the widths of the brackets are automatically controlled and adjusted through the servo motors I, and the number of plates is automatically detected through the feeding detection device, so that waste is avoided, the labor intensity of an operator is reduced, and the adjustment efficiency is improved.

Owner:ANHUI XINMENG EQUIP CO LTD

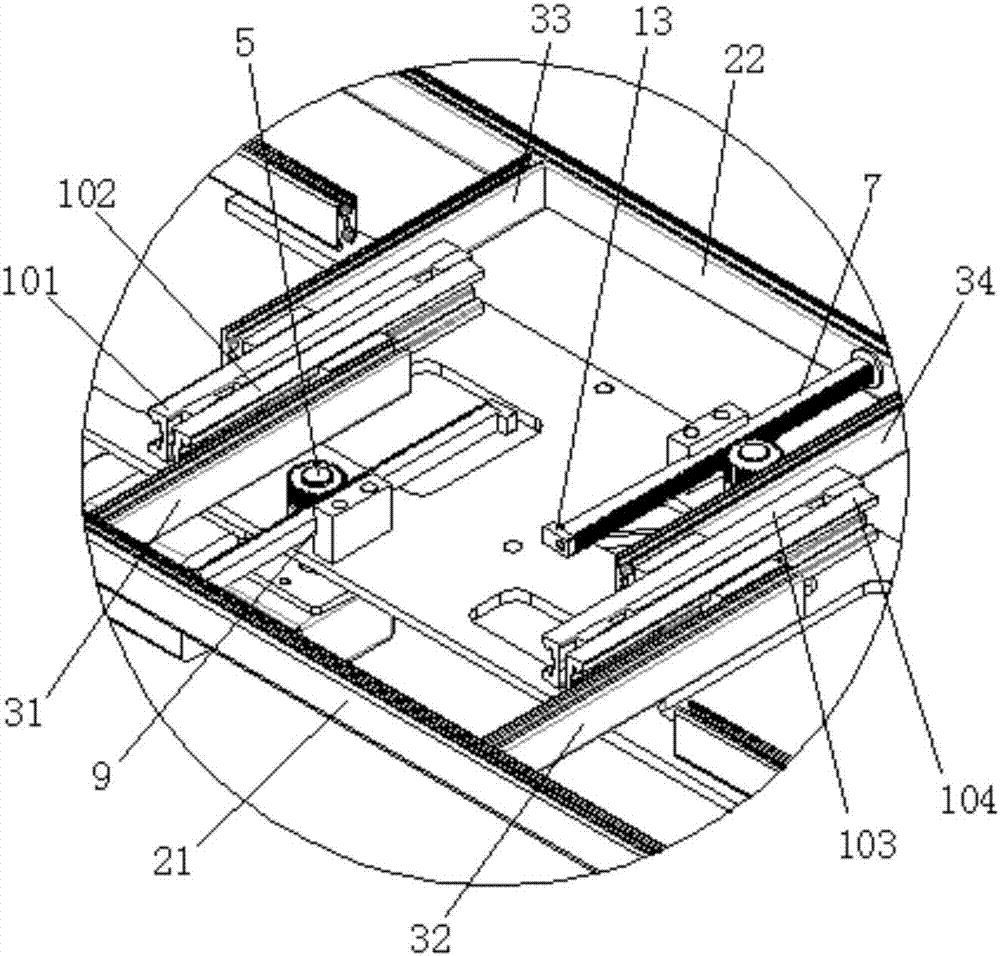

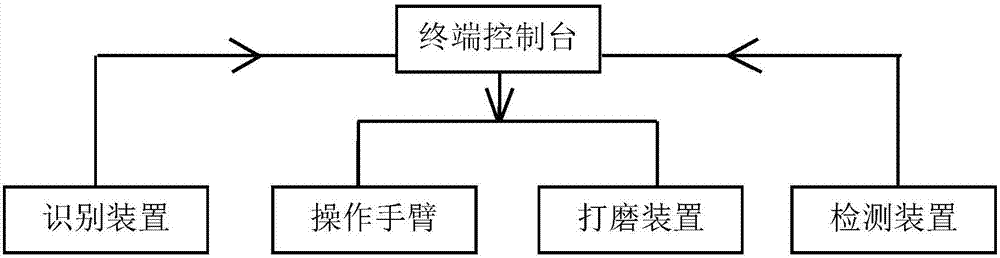

Workpiece polishing automatic identification and detection system

InactiveCN107877366ANo manual inspection requiredGrinding feed controlGrinding machinesLaser rangingEngineering

The invention discloses a workpiece polishing automatic identification and detection system. The workpiece polishing automatic identification and detection system comprises a terminal control console,an operating arm, a polishing device, an identification device, a detection device and a conveying table. The identification device, the polishing device and the detection device are sequentially arranged, the identification device is electrically connected with the input end of the terminal control console so as to transmit a signal to the terminal control console, the operating arm and the polishing device are electrically connected with the output end of the terminal control console, the terminal control console transmits the signal to the operating arm and the polishing device, and the identification device is used for identifying different workpieces on the conveying table; and the signal is sent to the polishing device through the terminal control console, an unused polishing procedure is transferred by the polishing device according to the signal, meanwhile the terminal control console sends a signal to the operating arm, the operating arm moves a workpiece to a workpiece clamping device, an inductor is arranged on the workpiece clamping device, the workpiece clamping device conducts releasing and clamping actions on the workpiece under the command of the inductor, and thedetection device comprises a laser range finder.

Owner:TIANJIN SANMUSEN ELECTRIC FURNACE

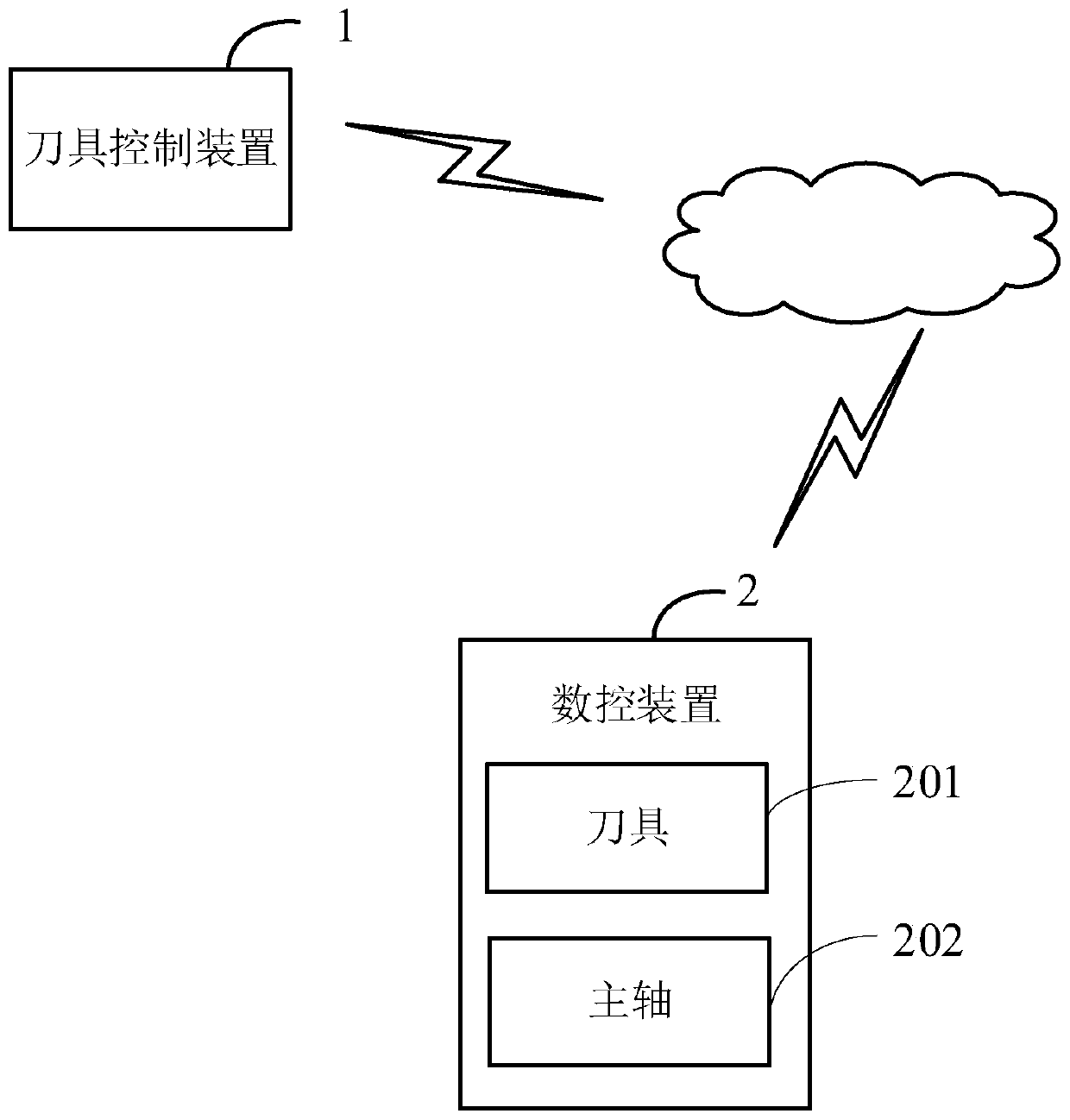

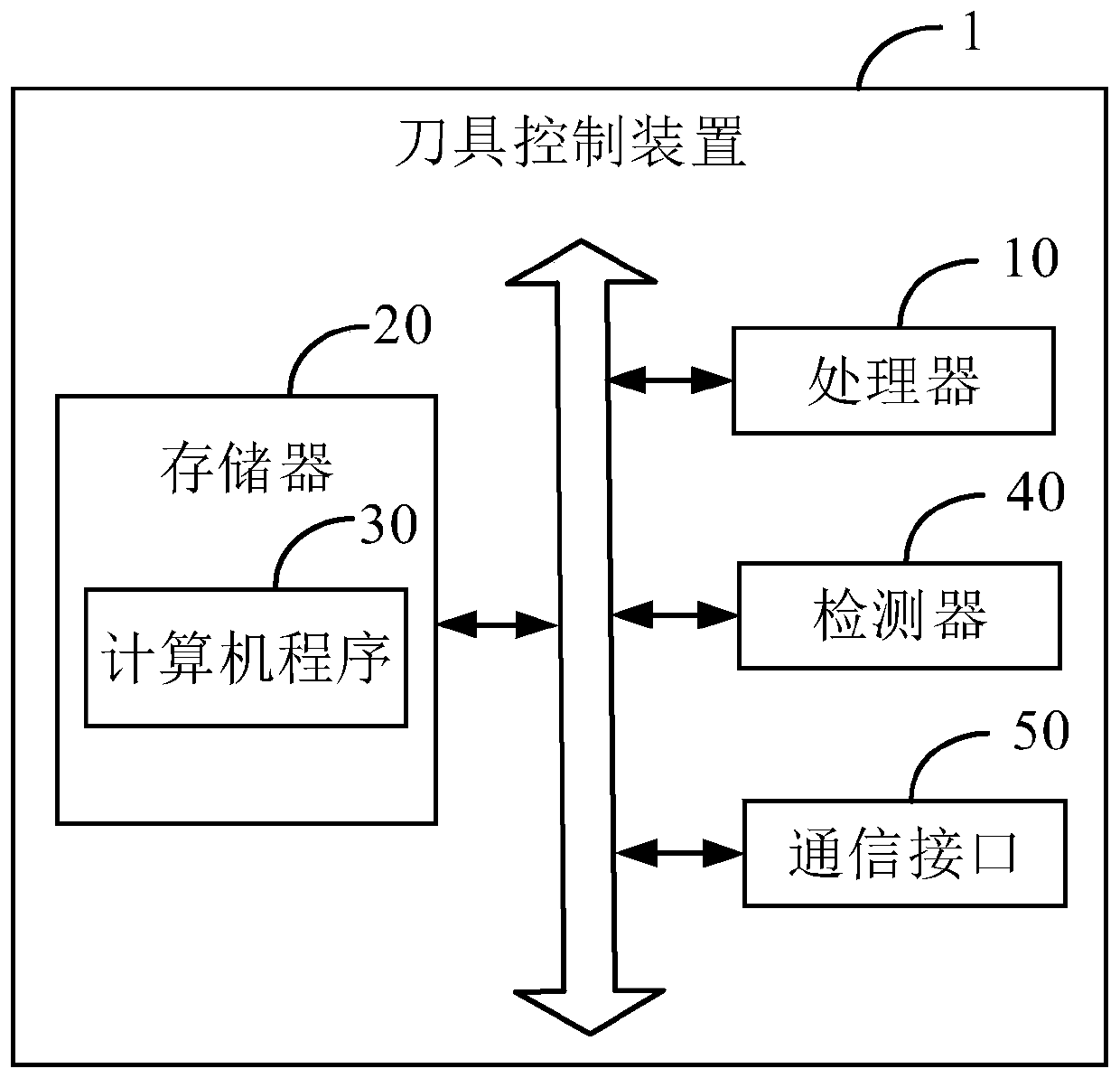

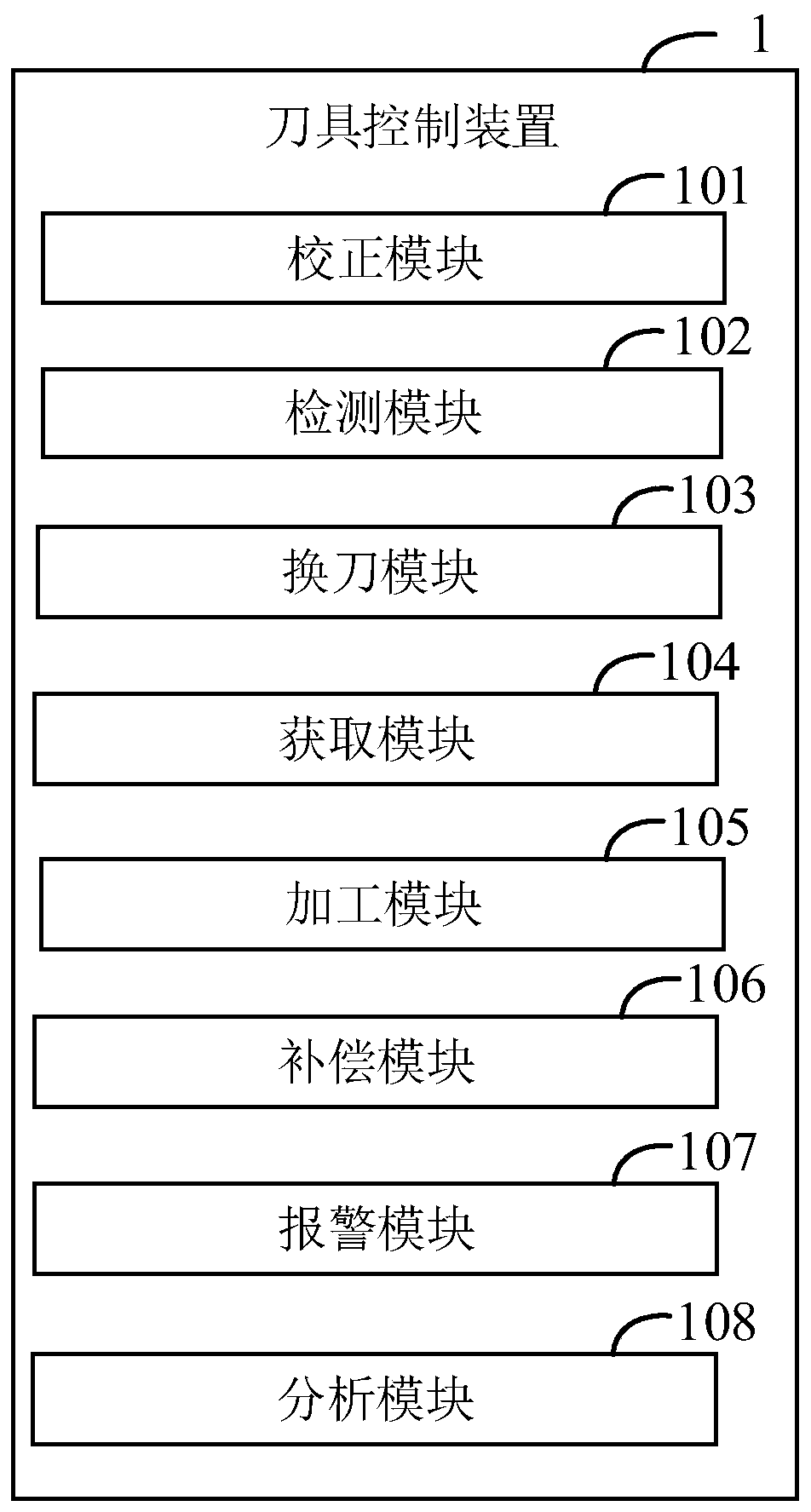

Cutter control device and control method

InactiveCN111538286AHigh precisionNo manual inspection requiredMeasurement/indication equipmentsNumerical controlMechanical engineeringIndustrial engineering

The application provides a cutter control method which comprises the steps: acquiring first parameters that are formed by detecting a first cutter and comprise at least one of the service life, the cutter breaking condition and the tipping condition of the first cutter; according to the first parameters, sending out a control instruction to control the first cutter to machine a workpiece; acquiring second parameters that are formed by detection when the first cutter processes the workpiece and comprise at least one of a length lengthening condition, a length abrasion condition, a radial abrasion condition and a blade thickness abrasion condition; and according to the blade thickness abrasion condition, sending out a compensation instruction so as to carry out position compensation on the first cutter. The invention further provides a cutter control device. According to the application, the accuracy of cutter quality detection is effectively improved, and the production efficiency is improved.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

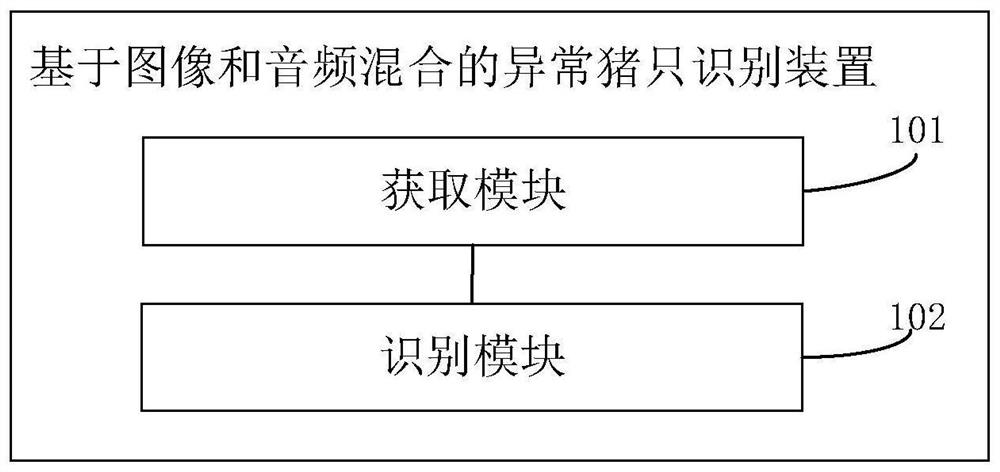

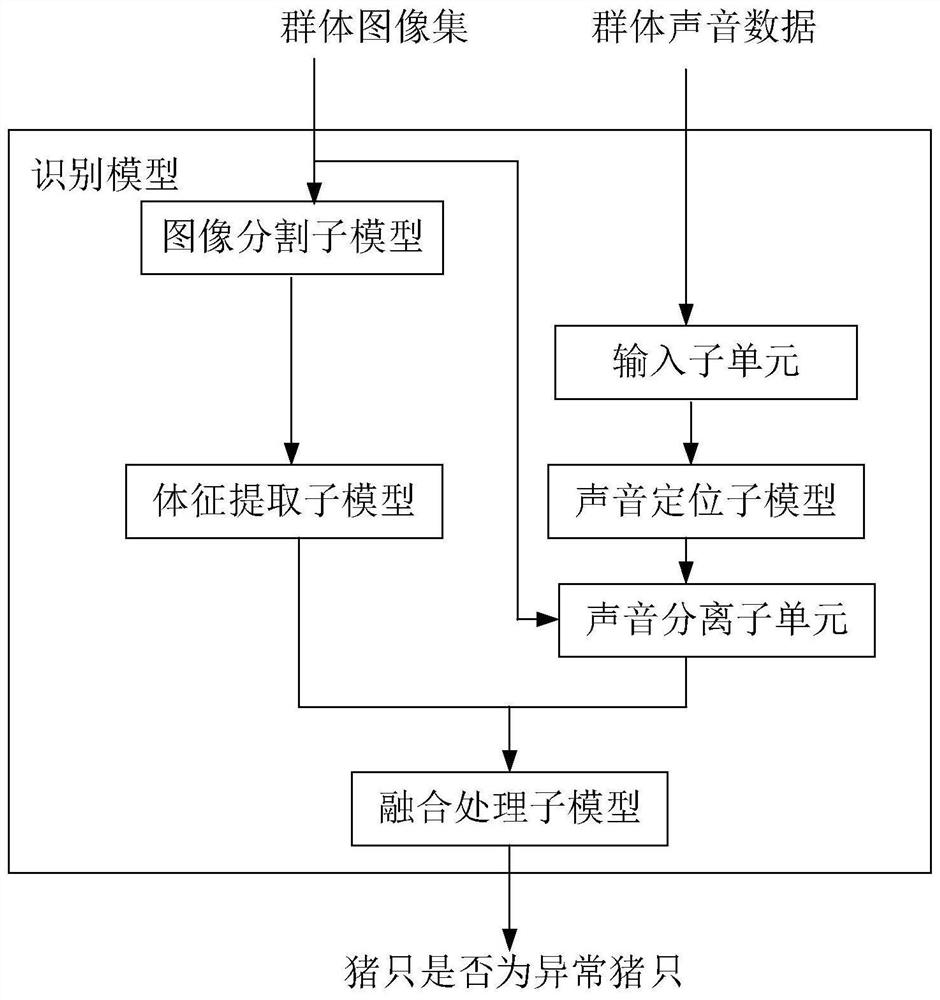

Abnormal pig recognition device, system and method based on image and audio mixing

PendingCN111860203AImprove accuracyImprove detection efficiencyEpidemiological alert systemsSpeech analysisPattern recognitionRadiology

The embodiment of the invention provides an abnormal pig recognition device, system and method based on image and audio mixing, and the method comprises the steps of obtaining a group image set and group sound data of pigs in a group raising fence, and recognizing whether each pig is an abnormal pig or not through a recognition model in a recognition module according to the group image set and thegroup sound data, wherein the recognition model comprises a fusion processing sub-model, and the fusion processing sub-model outputs a recognition result of whether any pig is an abnormal pig or notaccording to the sign change information and the individual sound data of any pig determined through the group image set and the group sound data. Through combination of the image and the sound, the accuracy of abnormal pig identification is improved, and the reliability of a detection result is high. Meanwhile, manual detection is not needed, the detection efficiency of abnormal pigs is improved,effective epidemic prevention and control are facilitated, and losses are reduced.

Owner:BEIJING FOCUSED LOONG TECH CO LTD

Grinding machine with detection function

InactiveCN106625162AWith detection functionRealize the detection functionGrinding feed controlGrinding machinesTransmission channelEngineering

The invention discloses a grinding machine with a detection function. The grinding machine comprises a grinding machine bracket, a grinding machine power center, a grinding machine pedestal and a transmission channel, wherein two lower grinding head supporting columns, a lower optical detection camera and the grinding machine power center are arranged above the grinding machine pedestal in sequence; a lower transverse rod is arranged in the lower grinding head supporting columns; a lower connection rod is arranged above the lower transverse rod; a lower grinding head is arranged on the lower connection rod; the transmission channel is arranged above the lower grinding head; two upper grinding head supporting columns, an upper optical detection camera and a suction head are arranged above the transmission channel in sequence; an upper transverse rod is arranged in the upper grinding head supporting columns; an upper connection rod is arranged below the upper transverse rod; an upper grinding head is arranged below the upper connection rod; and a transmission belt is arranged on the transmission channel. The grinding machine capable of detecting the grinding effect, which is provided by the invention, realizes a grinding machine detection function, does not need manual detection, and can improve the efficiency and the product quality and reduce the cost.

Owner:CHANGSHU SHUANGYUE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com