Detection system for refrigeration incapability fault of refrigerator

A technology for detecting systems and refrigerators, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc. It can solve problems such as no cooling, users cannot find out immediately, and food deterioration, so as to achieve high accuracy and avoid food deterioration. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

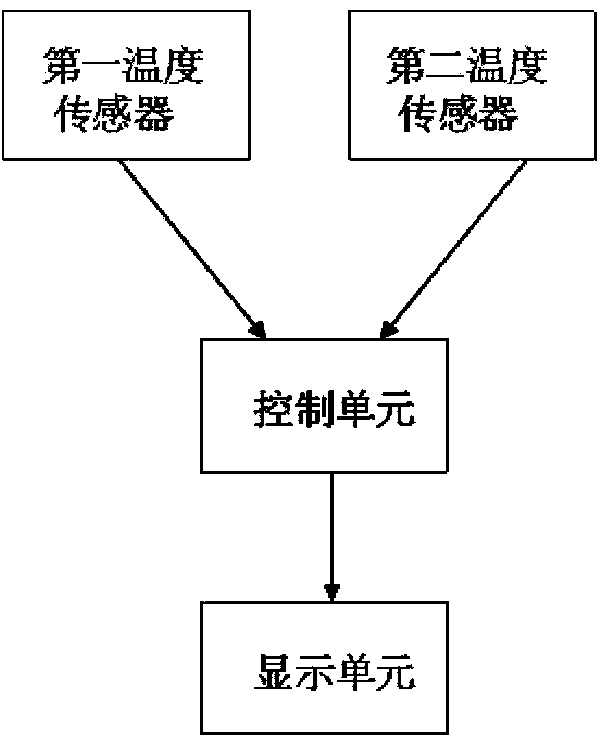

[0028] Such as figure 1 As shown, the detection system for non-refrigerating failure of a single evaporator direct cooling refrigerator in this embodiment includes a first temperature sensor, a control unit and a display unit;

[0029] The first temperature sensor is arranged in the room to be tested, and is used to detect the temperature in the room to be tested;

[0030] The control unit is used to collect the temperature in the compartment to be measured measured by the first temperature sensor, and transmit a fault signal to the display unit;

[0031] The display unit is arranged on the outer surface of the refrigerator and is used for displaying fault signals.

[0032] The detection system also includes a second temperature sensor arranged at the entrance of the evaporator, the second temperature sensor detects the temperature of the evaporator, and the control unit collects the temperature of the evaporator detected by the second temperature sensor;

[0033] The contro...

Embodiment 2

[0044] Such as figure 1 As shown, the detection system for the non-refrigerating failure of the double-cycle or multi-cycle direct cooling refrigerator in this embodiment includes a first temperature sensor, a control unit and a display unit;

[0045] The first temperature sensor is arranged in the room to be tested, and is used to detect the temperature in the room to be tested;

[0046] The control unit is used to collect the temperature in the room to be measured measured by the first temperature sensor, and transmit a fault signal to the display unit;

[0047] The display unit is arranged on the outer surface of the refrigerator and is used for displaying fault signals.

[0048] The detection system also includes a second temperature sensor arranged at the evaporator inlet of any chamber except the chamber to be tested; the second temperature sensor detects the temperature of the evaporator, and the control unit collects the temperature of the evaporator detected by the s...

Embodiment 3

[0055] Such as figure 1 As shown, the detection system for the non-refrigeration failure of the multi-chamber air-cooled refrigerator with a single evaporator in this embodiment includes a first temperature sensor, a control unit and a display unit;

[0056] The first temperature sensor is arranged in the room to be tested, and is used to detect the temperature in the room to be tested;

[0057] The control unit is used to collect the temperature in the room to be measured measured by the first temperature sensor, and transmit a fault signal to the display unit;

[0058] The display unit is arranged on the outer surface of the refrigerator and is used for displaying fault signals.

[0059] The detection system also includes a second temperature sensor arranged at the entrance of the evaporator; the second temperature sensor detects the temperature of the evaporator, and the control unit collects the temperature of the evaporator detected by the second temperature sensor;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com