Device and method for judging whether concrete pouring height of cast-in-situ bored pile is reached or not

A technology of drilling and pouring pile height, which is applied in the field of devices for judging whether the actual pouring height has reached the set height, and whether the pouring height is in place, and can solve the problems of inability to judge the pouring height, difficulty in estimating, low accuracy, etc. problem, to achieve the effect of convenient and fast detection process, ensuring accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

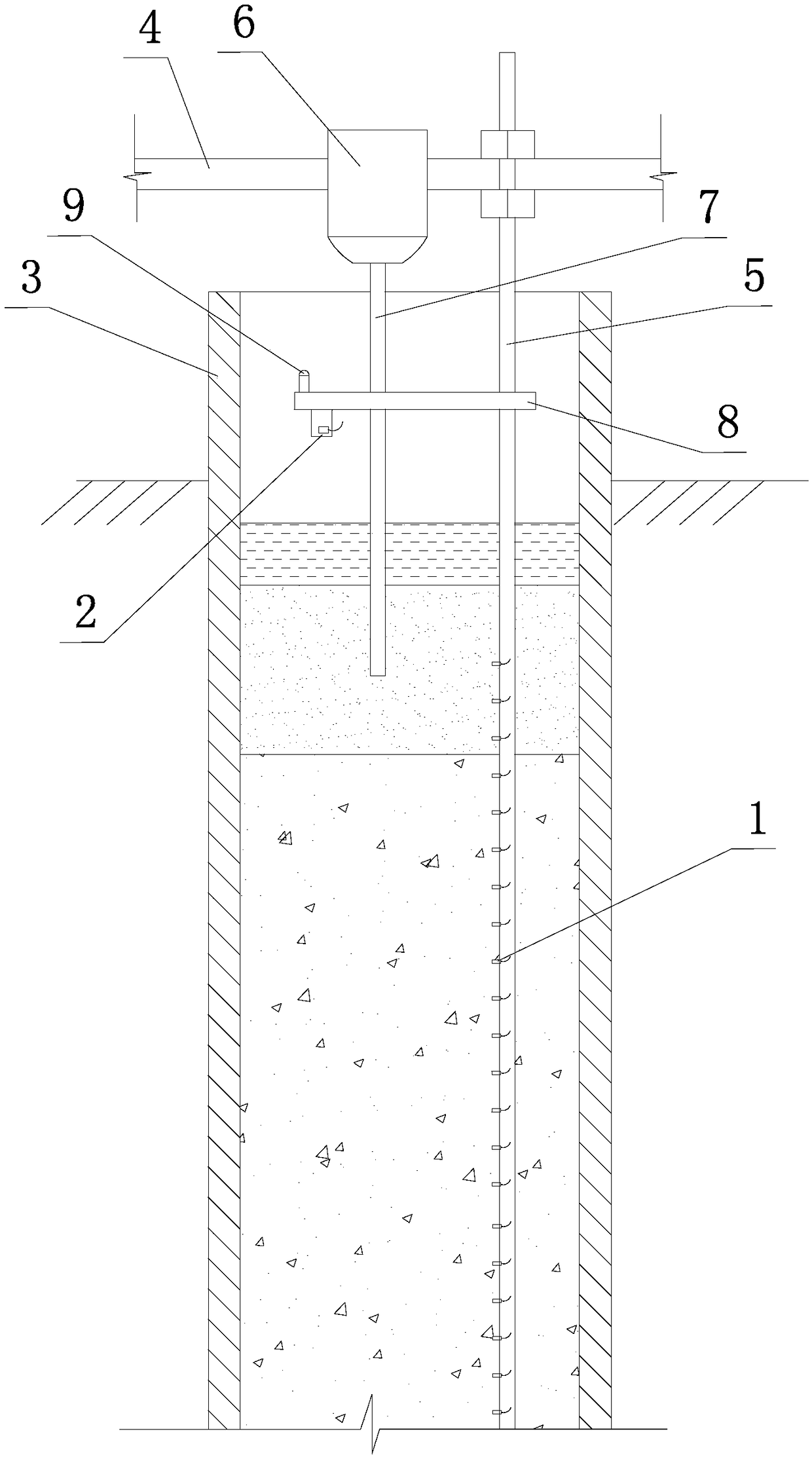

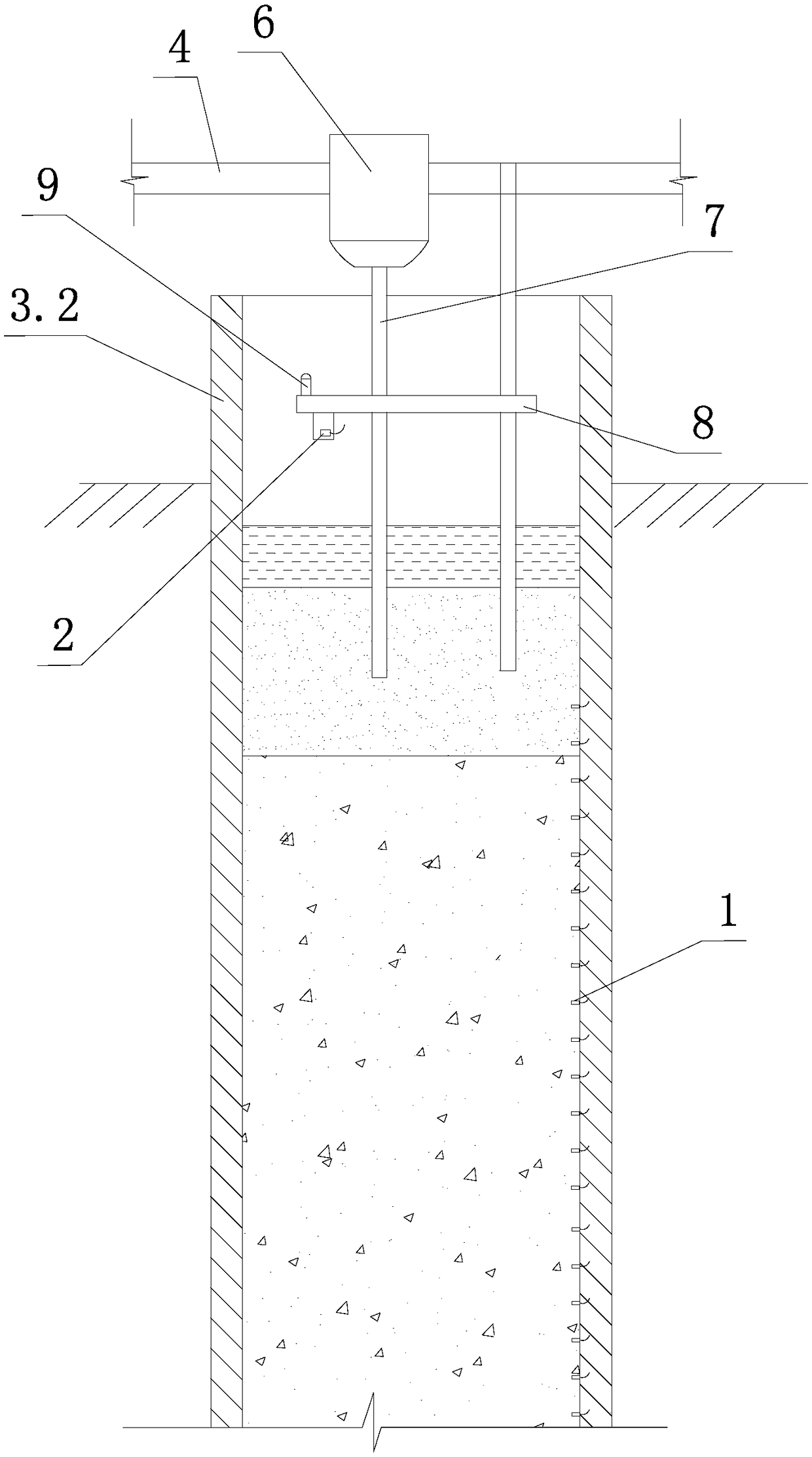

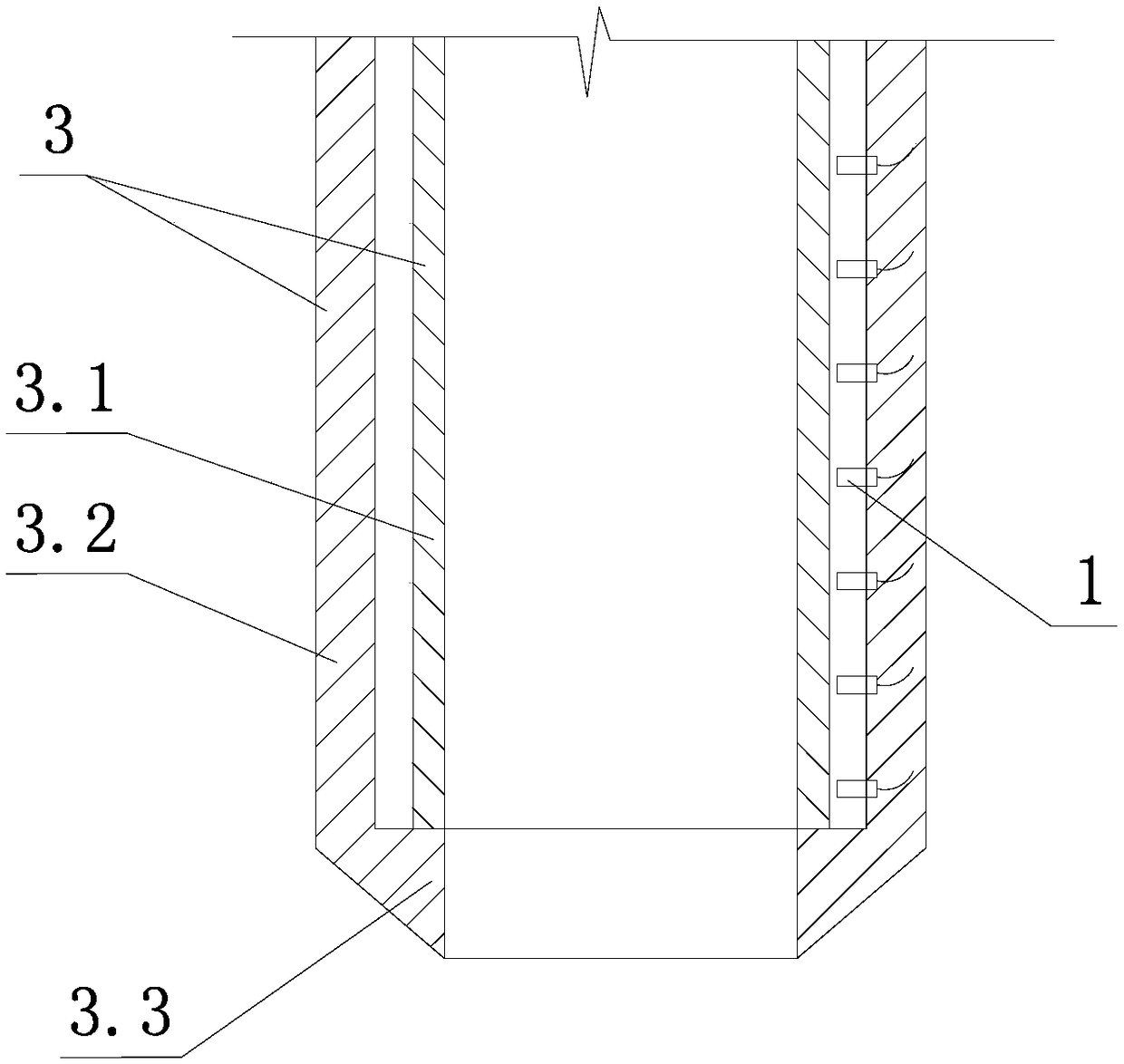

[0020] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a device for judging whether the pouring height of the bored pile is in place. It includes a main controller and a plurality of temperature sensors 1 of different heights arranged at equal intervals in the holes, and all temperature sensors 1 are connected to Main controller signal connection. Certainly, this device also comprises the full sleeve pipe 3 that a retaining wall is used.

[0021] The specific structure of the installation of the temperature sensor 1 is that the device also includes a mounting beam 4 fixed on the mouth of the full sleeve pipe 3 through a column, and a hard measuring rod 5 is fixed on the mounting beam 4. Evenly arranged on the lower section of the measuring pole 5, the temperature sensor 1 is connected to the main controller via a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com