Feeding device capable of preventing forming machine from plate excess

A forming machine and sheet material technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity, low degree of automation, and low production efficiency of the operator, so as to reduce labor intensity and improve automation level, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described by describing the embodiments below in conjunction with the accompanying drawings.

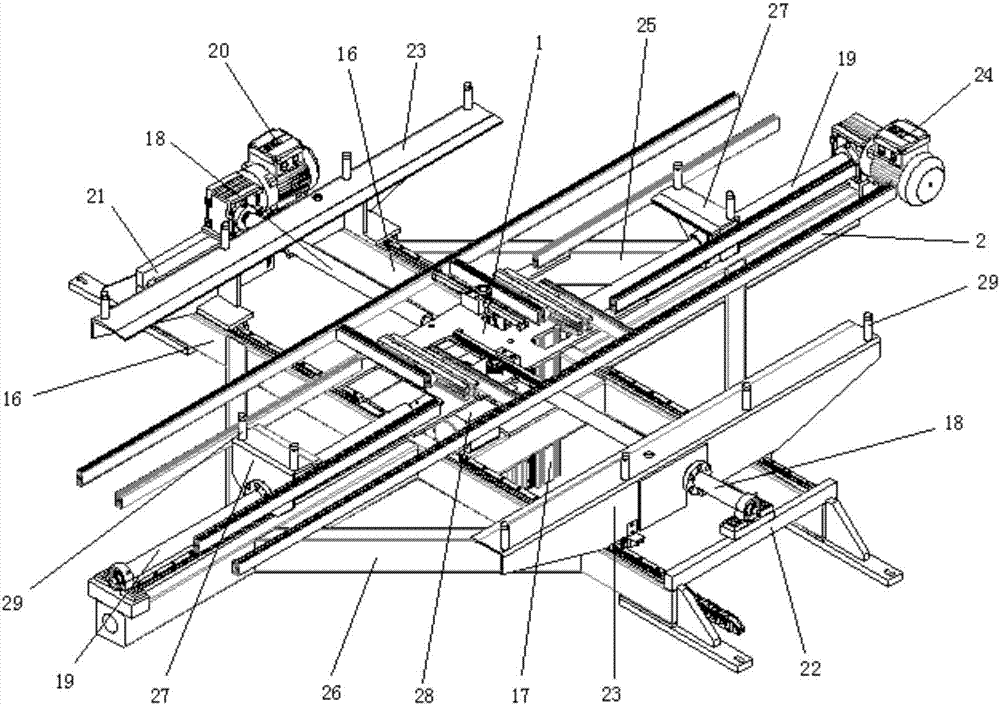

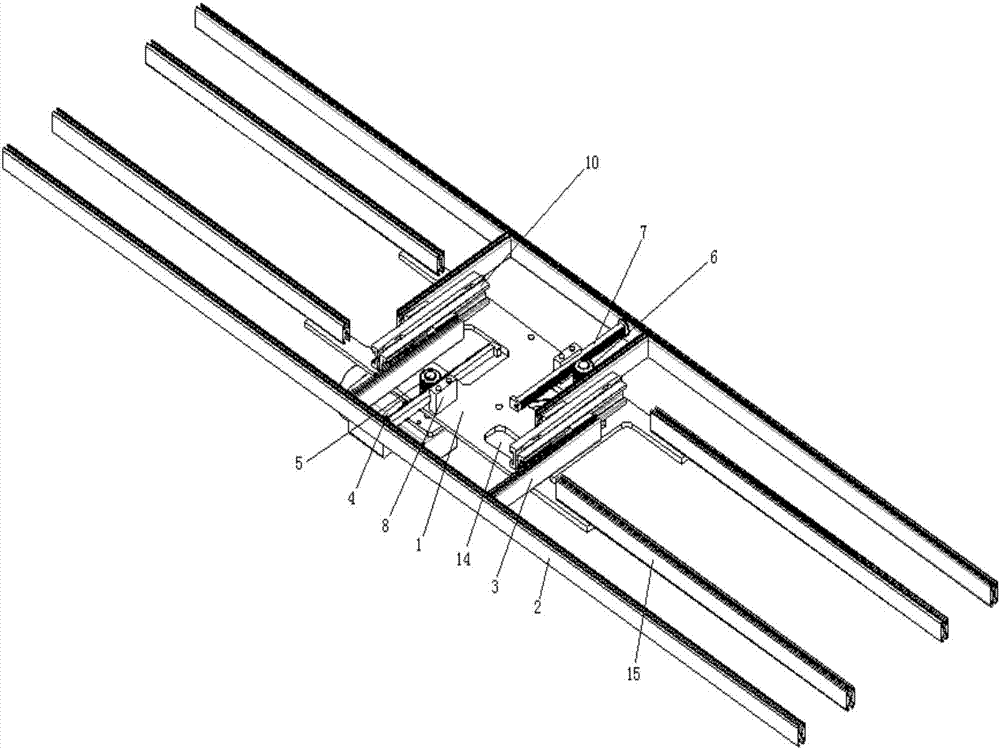

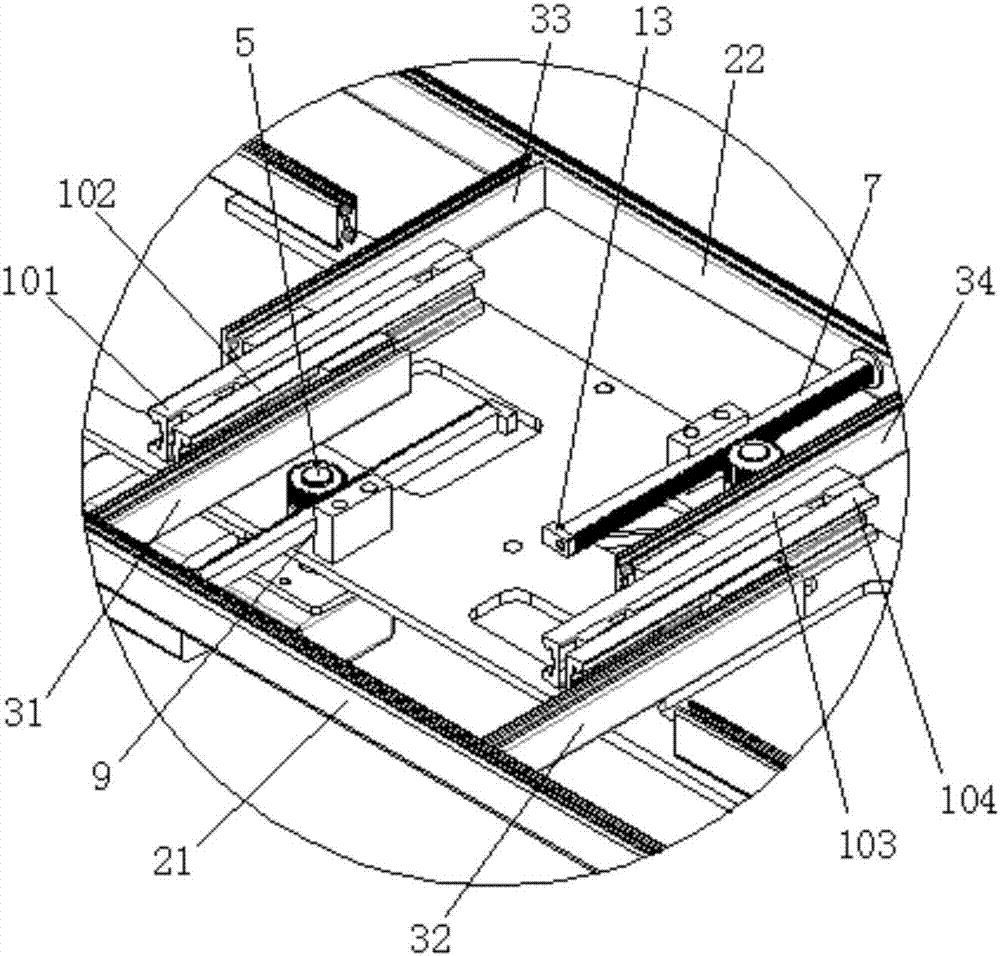

[0028] Such as Figure 1~4 As stated above, the present invention discloses a feeding device for preventing excessive sheet material of a molding machine, including a width adjustment mechanism and a centering mechanism. The width adjustment mechanism includes a supporting plate 1, the bottom of the supporting plate 1 is connected to the output end of a lift cylinder 17, and the two ends of the supporting plate 1 are symmetrically equipped with fixed plates 15, wherein each end is equipped with two The two fixed plates 15 located at the same end are symmetrically distributed, so that the supporting plate 1 can be kept in balance. Brackets 2 are installed on both sides of the pallet 1 respectively. The two brackets 2 are bracket I21 and bracket II22 respectively. Bracket I21 and bracket II22 are respectively installed on both sides of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com