Electronic component inspection system and electronic component inspection method

A technology of electronic components and inspection systems, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as consuming a lot of time and manpower, and achieve the effect of saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

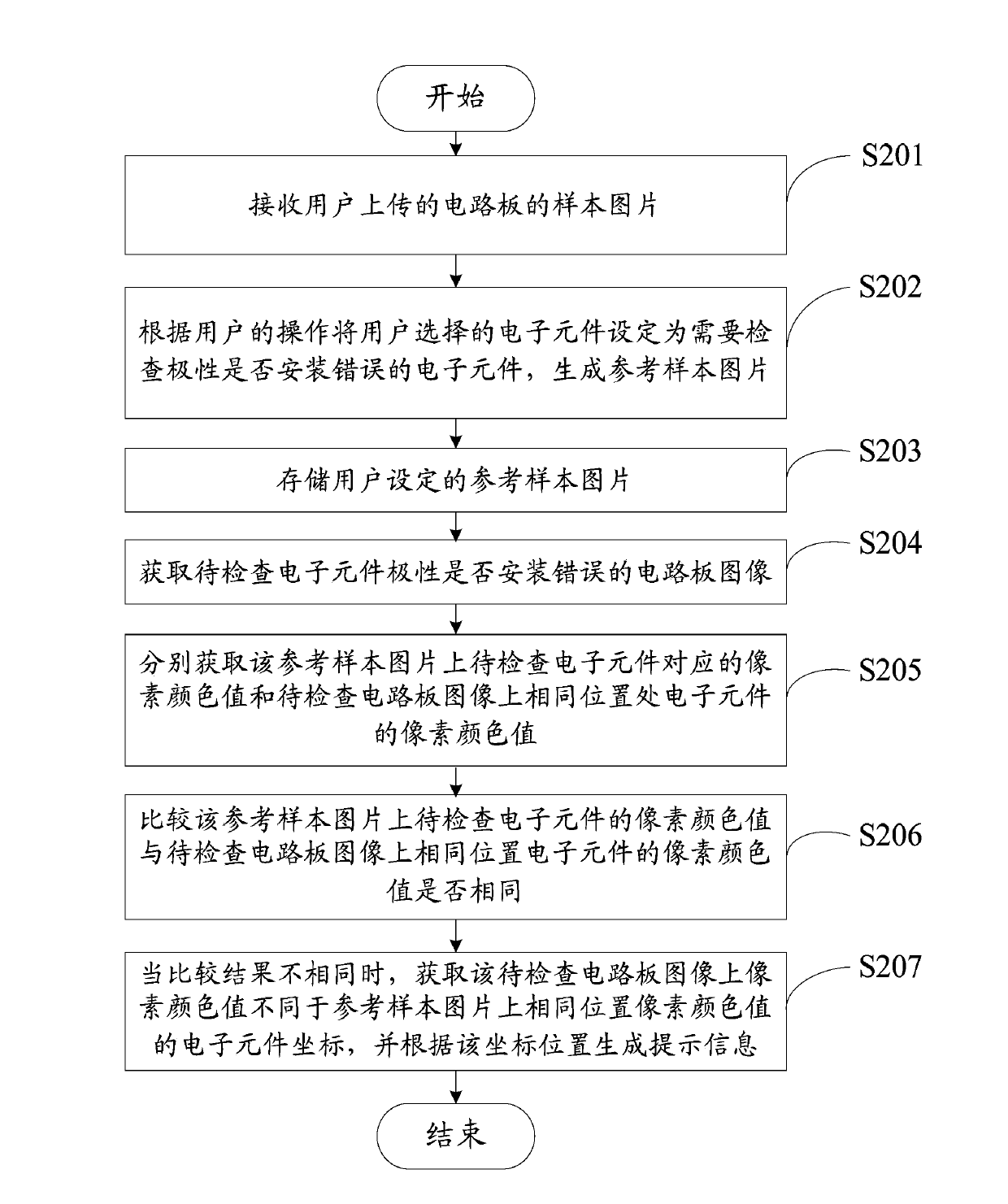

[0012] The electronic component inspection system and inspection method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

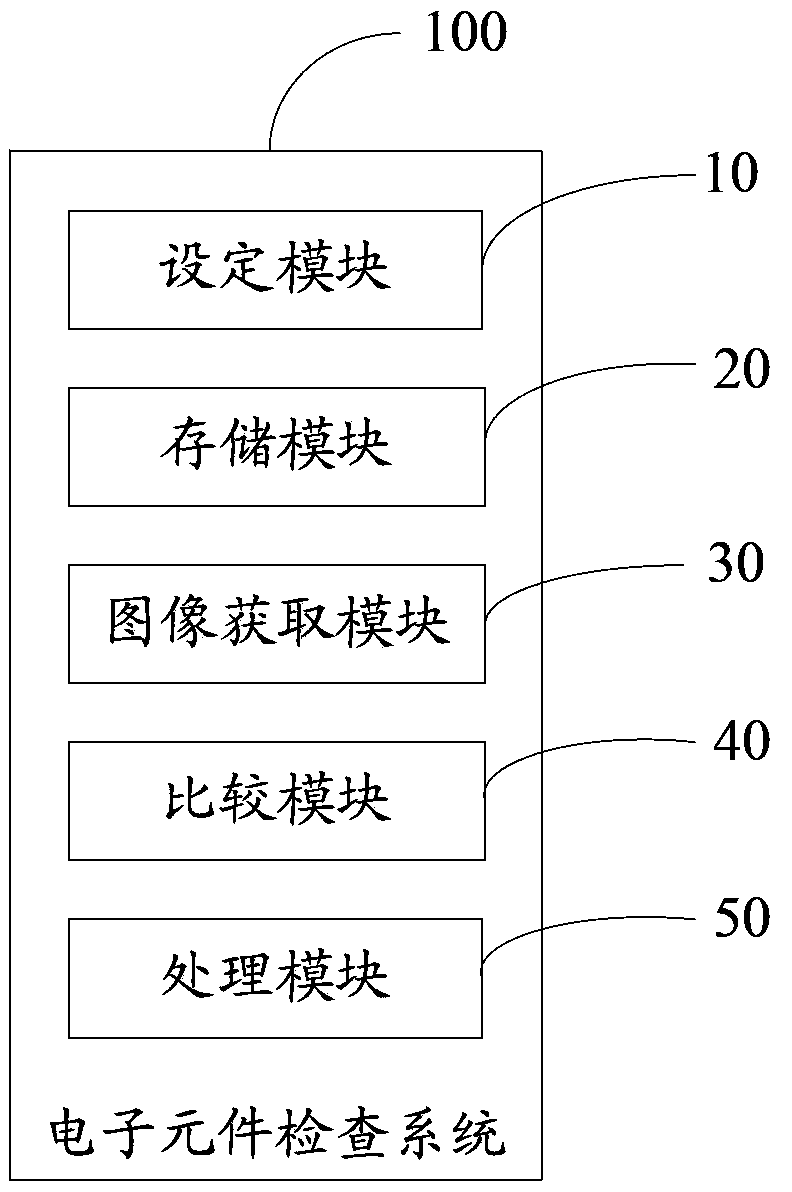

[0013] Please refer to figure 1 In a preferred embodiment of the present invention, the electronic component inspection system 100 is used to check whether the polarity of the electronic component in the circuit board is reversed. The electronic component inspection system 100 includes a setting module 10, a storage module 20, an image acquisition module 30, a comparison module 40, and a processing module 50.

[0014] The setting module 10 is used to receive a sample picture of a circuit board uploaded by a user through an input unit, where the sample picture of the circuit board includes a coordinate axis, and each electronic component on the circuit board corresponds to a coordinate value. The setting module 10 is also used to set the electronic component selected by the user as an electronic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com