Automatic turning system for battery cells

A technology of automatic flipping and battery cells, which is applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as high cost and complex structure of cleaning equipment, so as to ensure the quality of batteries, good automatic Cleaning effect, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

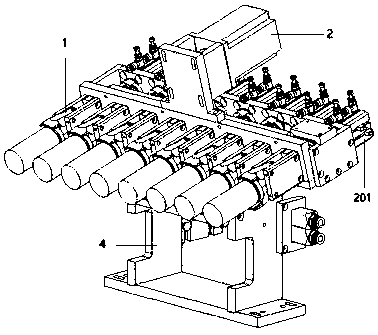

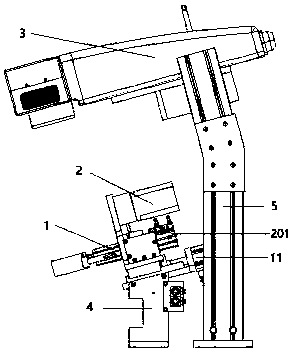

[0038] Such as figure 1 , 2 , 4, and 5, the present embodiment discloses an automatic cell overturning system, which includes an overturn mechanism for realizing the overturn of the cell and a clamping mechanism for clamping the cell during the overturn; the clamping mechanism includes Eight clamping assemblies 1, and a drive assembly for controlling the expansion and contraction of the clamping assembly; the clamping assembly includes a connecting rod 101 and a clamping claw, and one end of the connecting rod 101 is connected to the clamping claw, and the other end is connected to the drive components.

[0039]By setting the overturning mechanism and the clamping mechanism, when it is applied to the tab cleaning equipment, the overturning mechanism will automatically turn over the battery cell by 180 degrees, and the clamping mechanism will hold the battery core during the overturning, so as to realize the complete alignment of the tabs. Azimuth cleaning.

[0040] The clam...

Embodiment 2

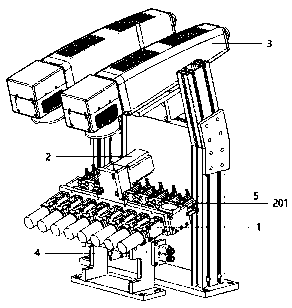

[0057] Such as figure 1 , 3 , 4, and 5, the present embodiment discloses an automatic cell overturning system, which includes an overturning mechanism for realizing the overturning of the cell and a clamping mechanism for clamping the cell during the overturn; the clamping mechanism includes 4 clamping assemblies, and a driving assembly for controlling the expansion and contraction of the clamping assembly; the clamping assembly includes a connecting rod 101 and a clamping claw, one end of the connecting rod is connected to the clamping claw, and the other end is connected to the driving assembly.

[0058] By setting the overturning mechanism and the clamping mechanism, when it is applied to the tab cleaning equipment, the overturning mechanism will automatically turn over the battery cell by 180 degrees, and the clamping mechanism will hold the battery core during the overturning, so as to realize the complete alignment of the tabs. Azimuth cleaning.

[0059] The clamping c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com