Diesel engine cylinder turning chuck

A diesel engine and cylinder block technology is applied in the field of diesel engine cylinder block overturning chucks, which can solve the problems affecting the service life of the diesel engine and the wear of the cylinder block, and achieve the effects of flexible overturning, high work efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with a diesel engine cylinder body reversing frame adopting the structure of the present invention and the accompanying drawings.

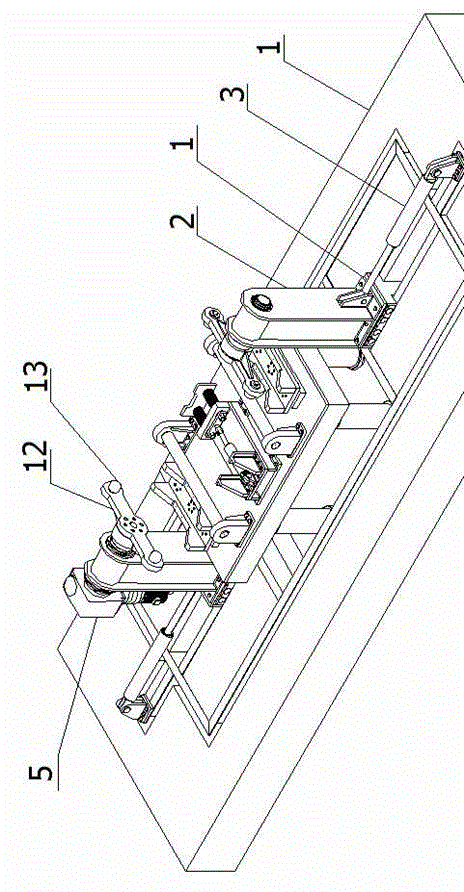

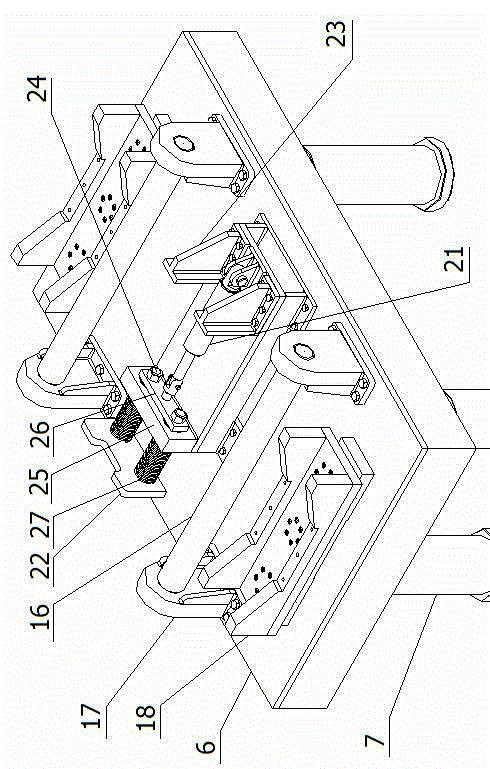

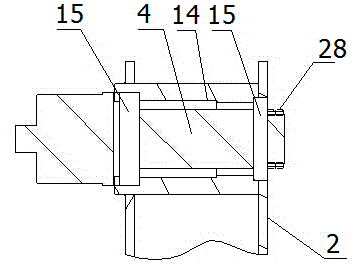

[0018] Such as Figure 1 to Figure 5 As shown, a diesel engine cylinder overturn frame in this specific embodiment includes a base 1, and the base 1 is provided with a cylinder clamping device and a cylinder lifting device, and the cylinder clamping device is included in the base 1 The clamping bracket 2 arranged oppositely at both ends and the hydraulic cylinder I3 used to drive the clamping bracket 2 to move in the relative direction, the clamping bracket 2 is provided with the clamping bracket 2 along the relative direction of the two clamping brackets 2 to rotate Coordinated rotating shaft 4, any of the clamping brackets 2 is provided with a drive motor 5 for driving the rotating shaft 4 to rotate, and the opposite ends of the two rotating shafts 4 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com