Patents

Literature

63results about How to "Does not affect welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

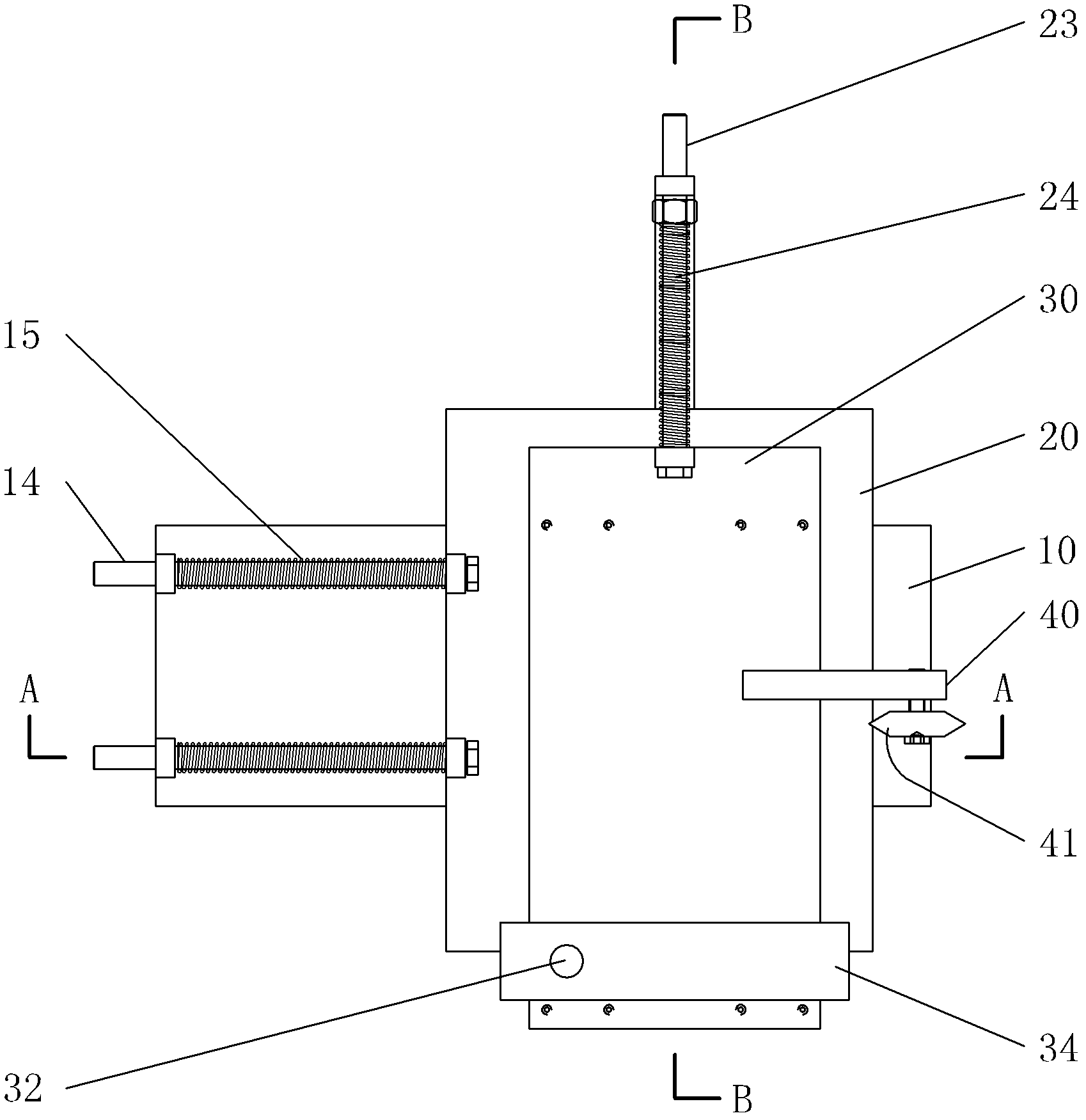

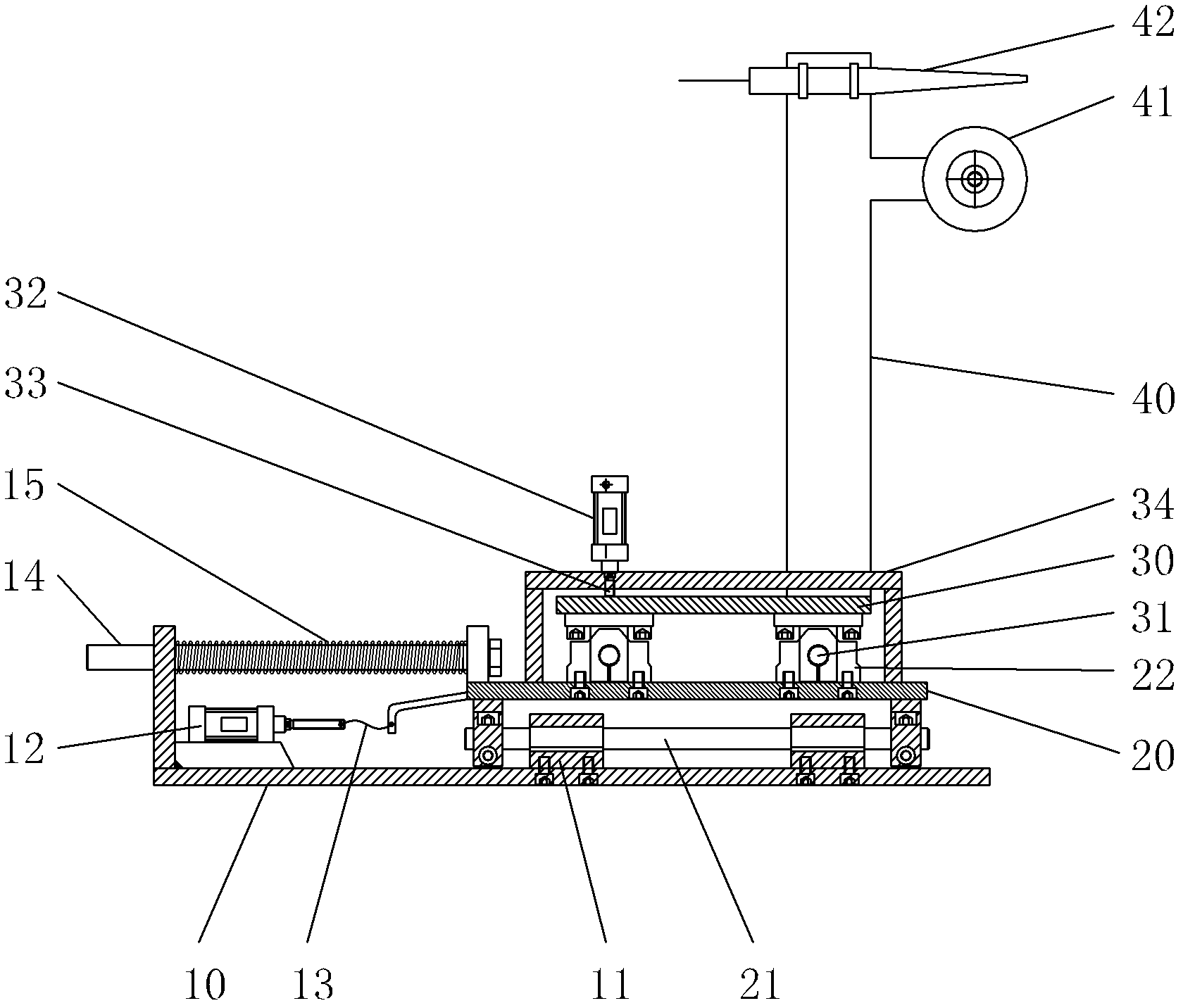

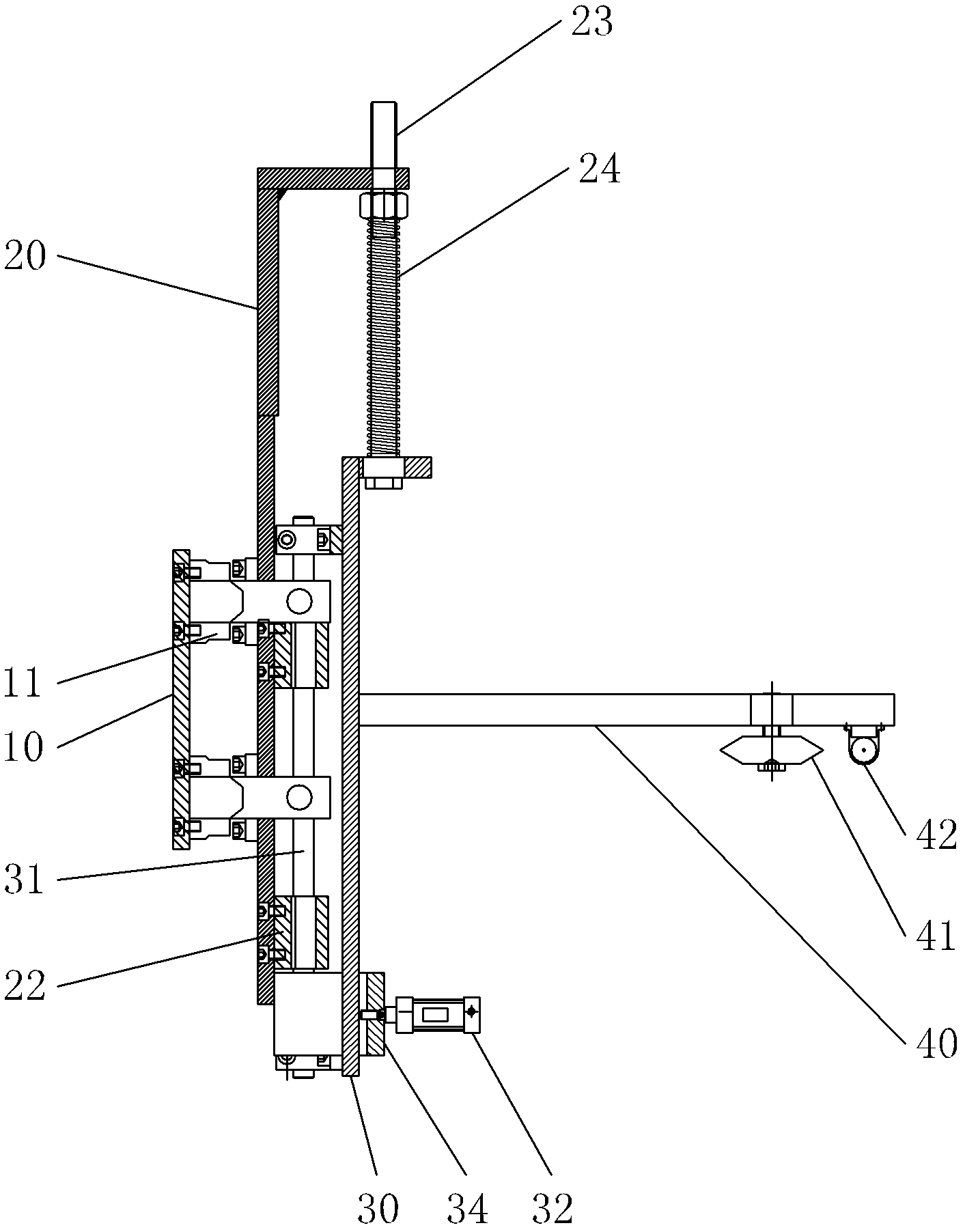

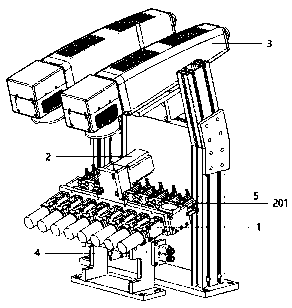

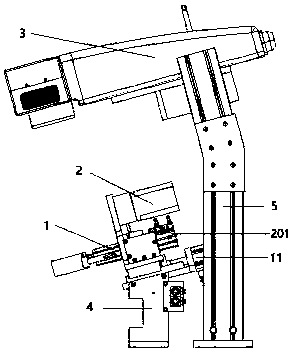

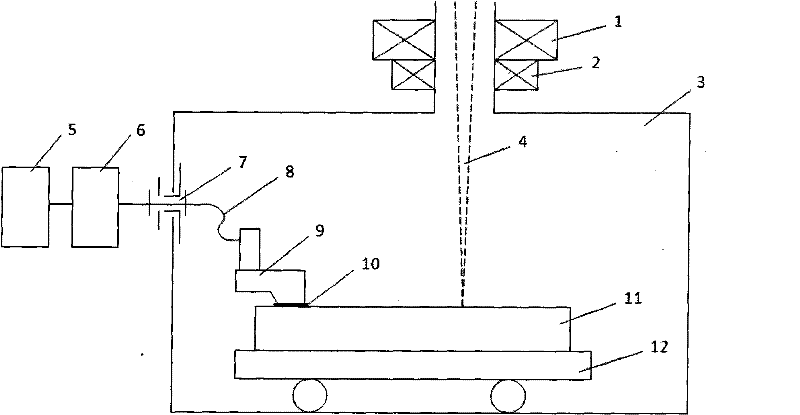

Automatic tracking seam welding/cutting manipulator

InactiveCN102513755AEasy to installEasy maintenanceWelding/cutting auxillary devicesArc welding apparatusWeld seamSlide plate

The invention belongs to the technical field of a welding machine, and particularly relates to a creeping-type automatic tracking seam welding machine, which is characterized in that: a slide plate which can move transversely along a base is arranged on the base, a compression spring is arranged between the slide plate and the base, the slide plate is provided with a slide platform which moves longitudinally along the slide plate, a compression spring is arranged between the slide plate and the slide platform, the slide platform is provided with a cantilever, one side on the outer end part of the cantilever is provided with a roller which rolls along an annular seam of a work-piece to be welded, a welding torch is arranged on the cantilever at one side of the roller, a joint line of centers of the welding torch and of the roller is parallel to a central line in the length direction of the cantilever, and one side of the line of centers of the welding torch and the roller is provided with a press block or a press wheel for pressing one side welding element or an outer layer welding element. The automatic tracking seam welding / cutting manipulator has beneficial effects that: the automatic tracking seam welding / cutting manipulator has a simple structure and low production cost, is convenient to install, repair and use, can automatically track a seam trace to realize the movable welding, has high welding quality, and is suitable for seam welding annular weld seams.

Owner:柯友义

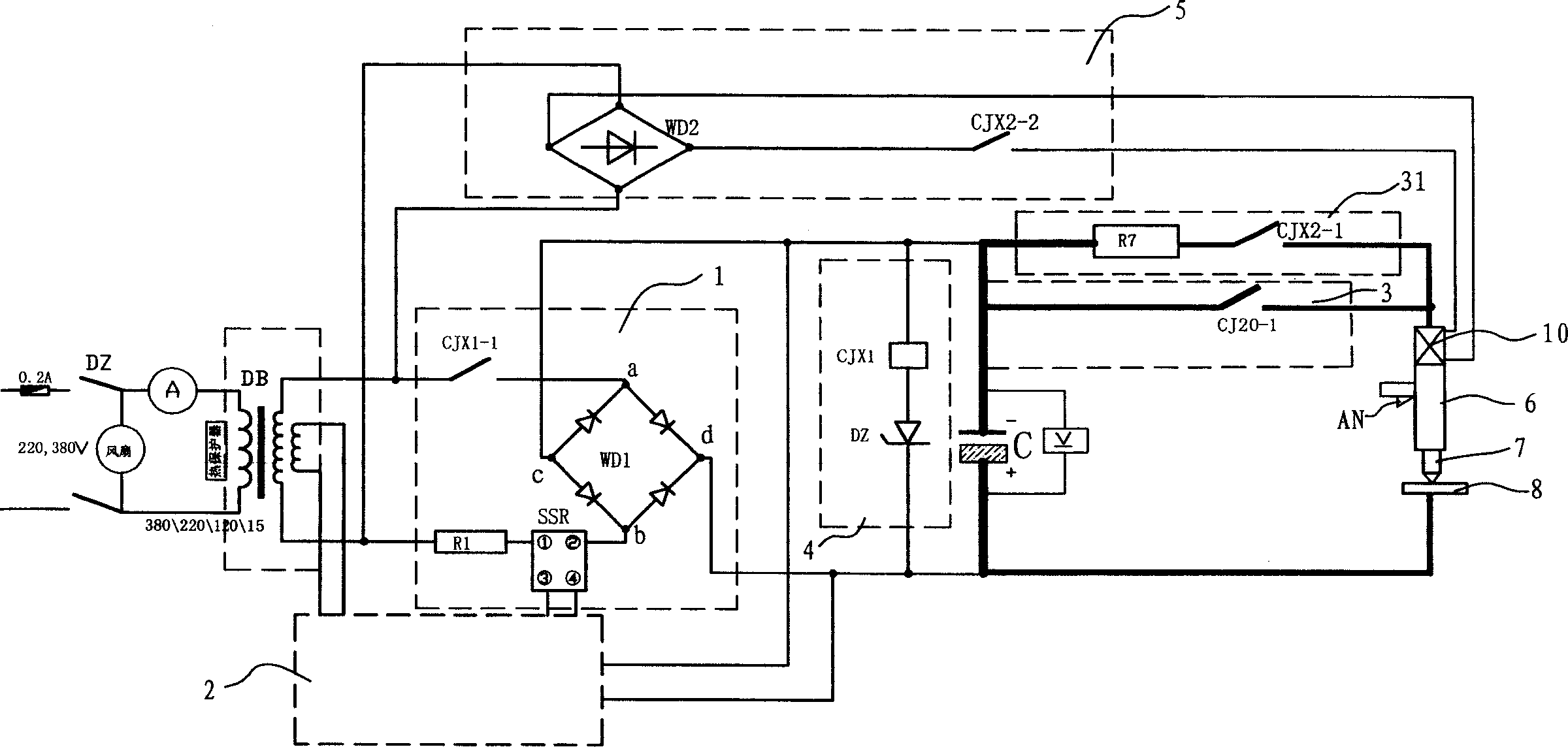

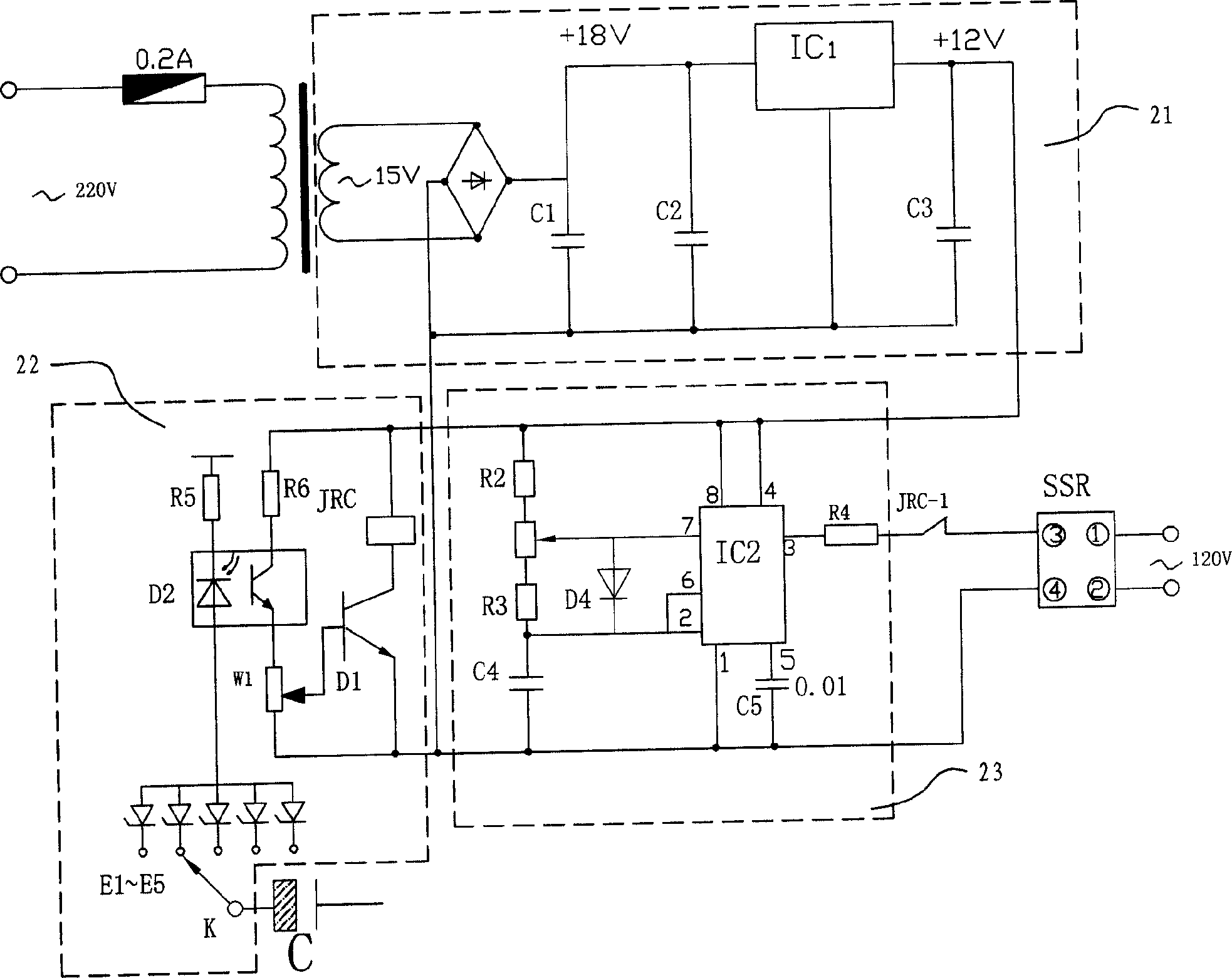

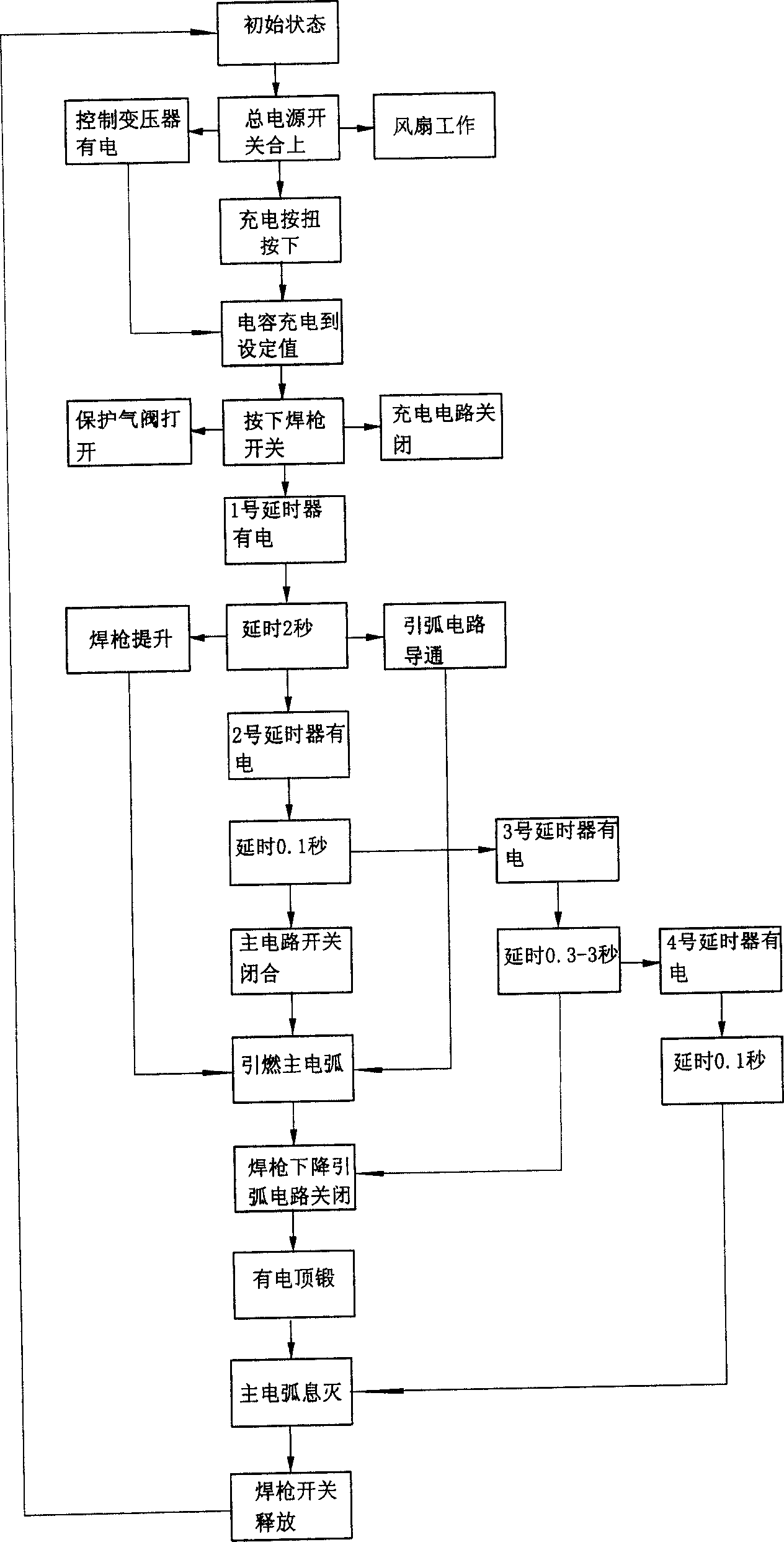

Energy-storage arc pulling type spindle welding machine

InactiveCN1911585ATo achieve the purpose of weldingDepth of melting layerArc welding apparatusTransformerSupercapacitor

The energy-storing arc type stud welding machine includes a casing, a transformer, a control panel, a welding gun and an inner circuit comprising electric elements. The inner circuit includes a welding gun circuit, a rectifying and charging circuit, a discharging circuit, a control module and an energy storing device. The discharging circuit includes the normally closed contact of the first relay; the energy storing device has super capacitor, which constitutes the charging circuit and the discharging circuit together which other parts; and the control module constitutes the control loop together with the rectifying and charging circuit and the super capacitor. Compared with available technology, the present invention has the advantages of small size, light weight, high welding quality, capacity of connecting external capacitor and low cost.

Owner:俞岳皋

Welding process of boss of hydrogenation reactor

ActiveCN103170815AAvoid the hassle of surfacingAvoid levelingArc welding apparatusEngineeringWelding process

The invention relates to a welding process of a boss of a hydrogenation reactor. A port in one end of a cylindrical shell section is processed flatly after coiling, circle checking and flaw detection of the cylindrical shell section are qualified; and then a surfacing position of the boss is marked, and thus the trouble that a cylinder body is firstly leveled and then overturned for surfacing the boss when the boss is surfaced is avoided, the leveling procedure during processing of the boss is avoided, therefore the production time is saved, the levelness of the boss is ensured, and the purpose of ensuring the welding quality of the boss is achieved.

Owner:青岛兰石重型机械设备有限公司

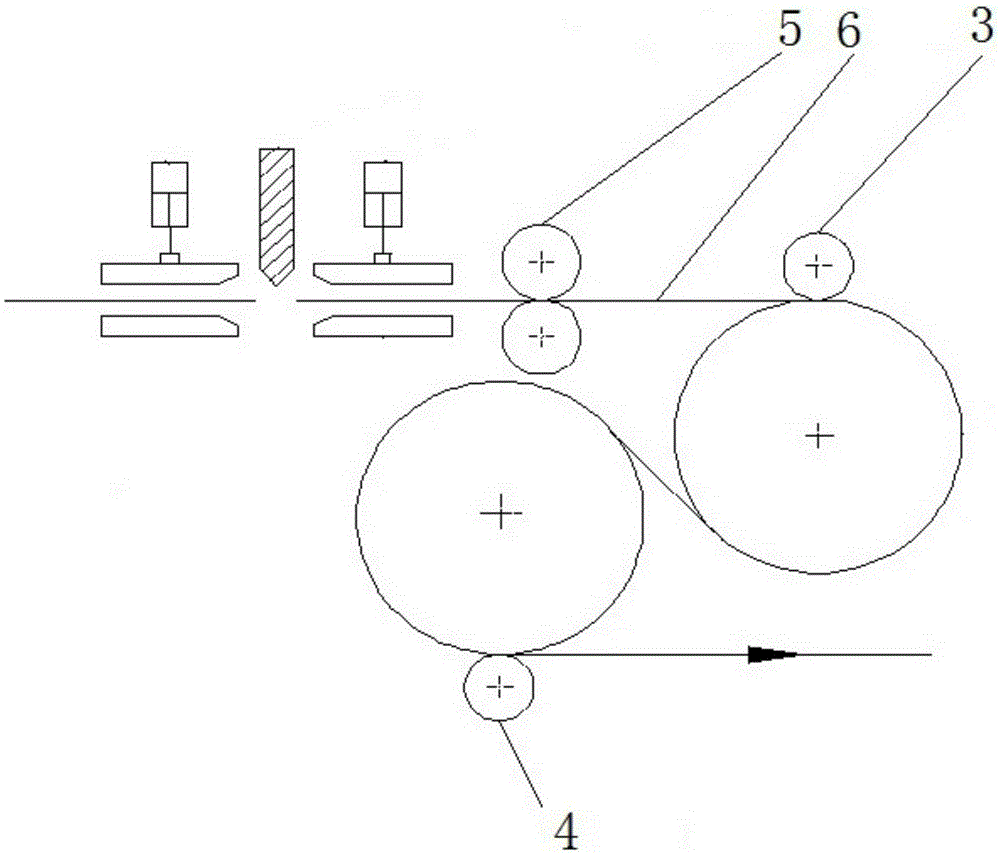

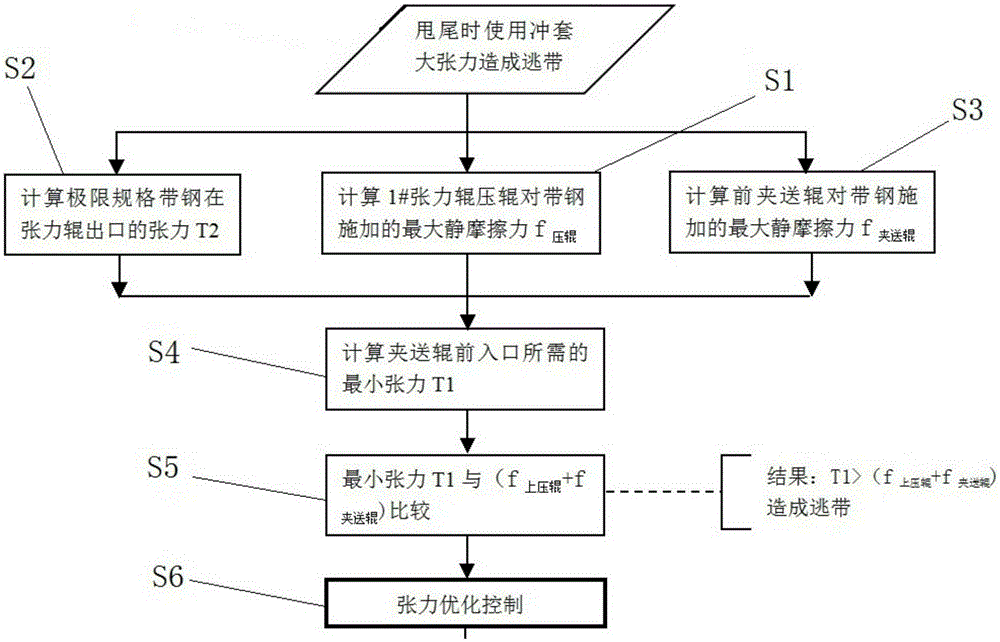

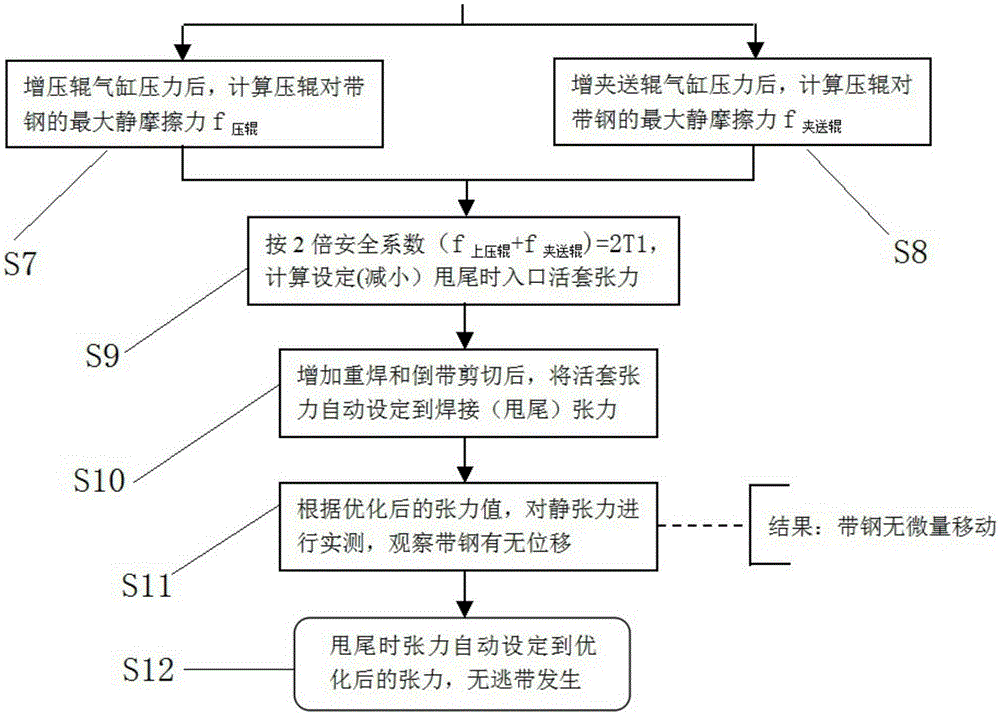

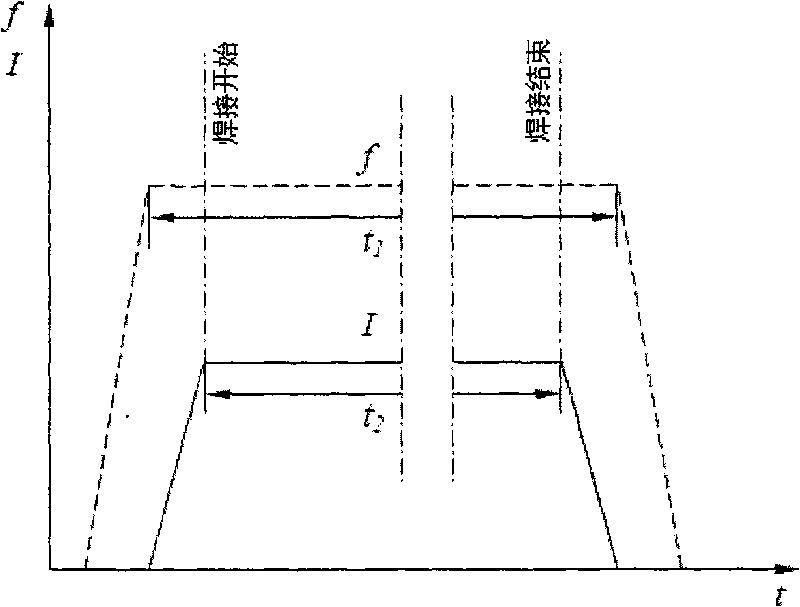

Tension control optimization method during welding tail swinging of cold-rolling strip steel

InactiveCN106807760ANo escape zoneNo deviationTension/compression control deviceStrip steelEngineering

The invention discloses a tension control optimization method during welding tail swinging of cold-rolling strip steel. The method includes the following steps that the required minimum tension of an inlet in front of pinch rolls is calculated; the minimum tension is compared with the total pressure of an upper pressuring roll and the pinch rolls; and optimization controlling is performed on tension. By means of the tension control optimization method during welding tail swinging of the cold-rolling strip steel, no abnormal deviation of the strip steel in a loop can be guaranteed, and the effects that no abnormal escape of a strip tail occurs and the welding quality is not affected are guaranteed.

Owner:BAOSHAN IRON & STEEL CO LTD

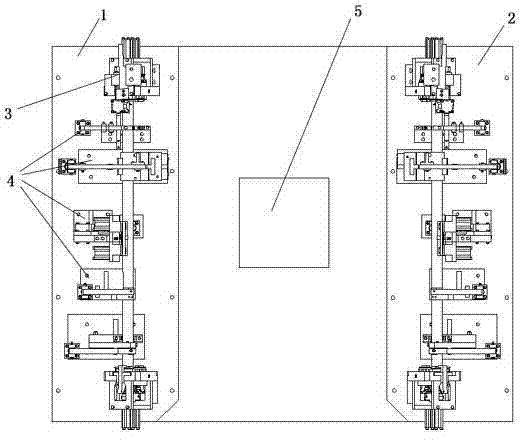

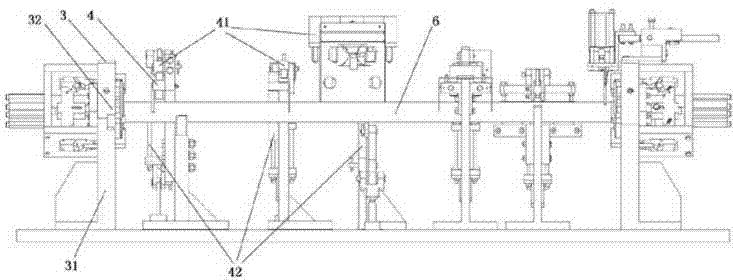

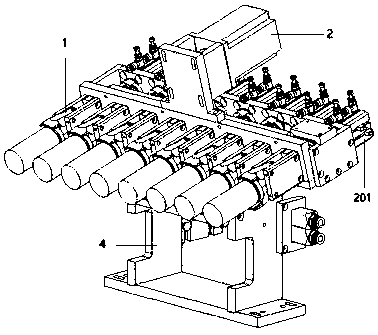

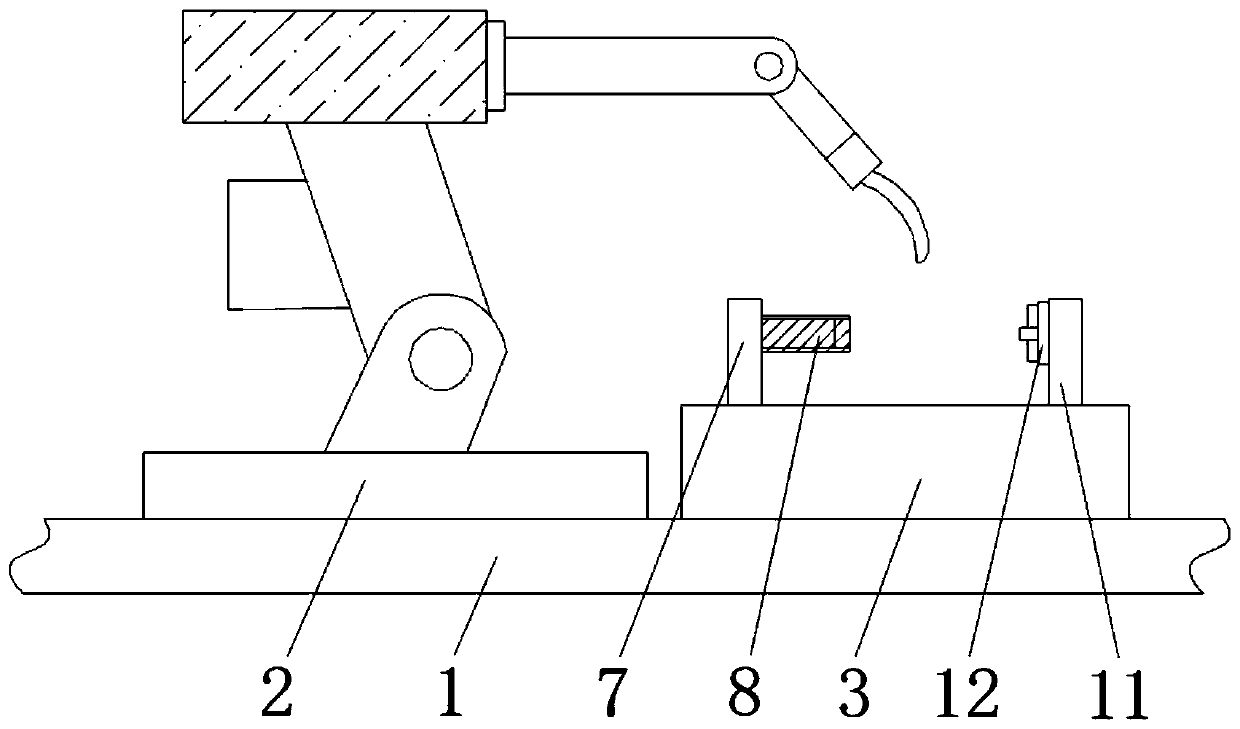

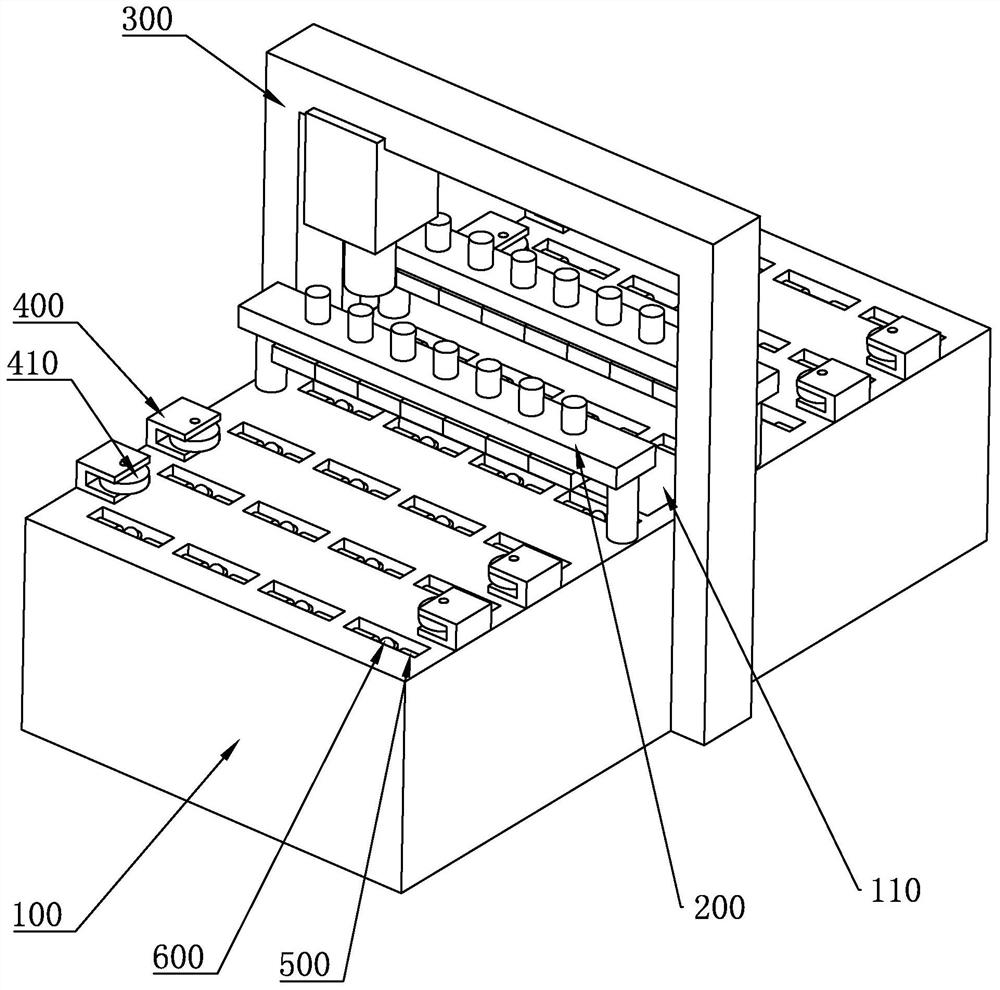

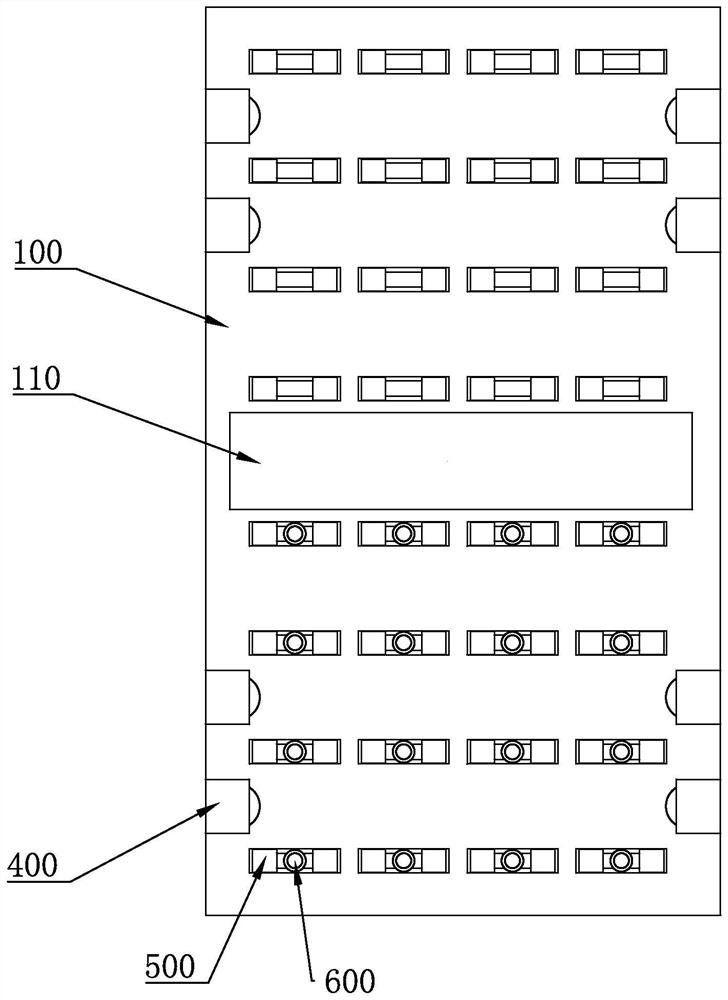

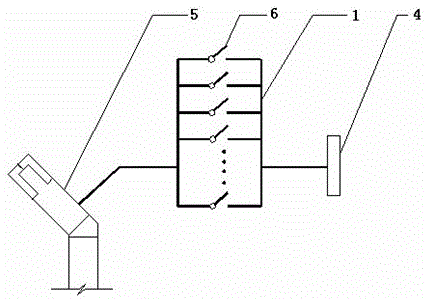

Automatic welding device and method for vehicle console installing support

InactiveCN103934604AGuaranteed welding efficiencyReduce labor costsWelding/cutting auxillary devicesElectrode holder supportersEngineeringWelding

The invention aims to provide an automatic welding device for a vehicle console installing support. The automatic welding device comprises a workbench I, a workbench II, pipe clamping devices, fixtures and a welding robot. The workbench I and the workbench II are arranged oppositely in parallel. The workbench I and the workbench II are respectively provided with the pipe clamping devices and the fixtures. The pipe clamping devices and the fixtures on the workbench I and the pipe clamping devices and the fixtures on the workbench II are in mirror distribution correspondingly. The welding robot is arranged between the workbench I and the workbench II and can rotate 360 degrees. A welding gun arranged on the welding robot can cover welding points of parts corresponding to all the fixtures on the workbench I and the workbench II. The invention further provides an automatic welding method for the vehicle console installing support. The automatic welding device and method have the advantages that welding efficiency is high, welding quality is stable, and production cost is low.

Owner:韦建军 +4

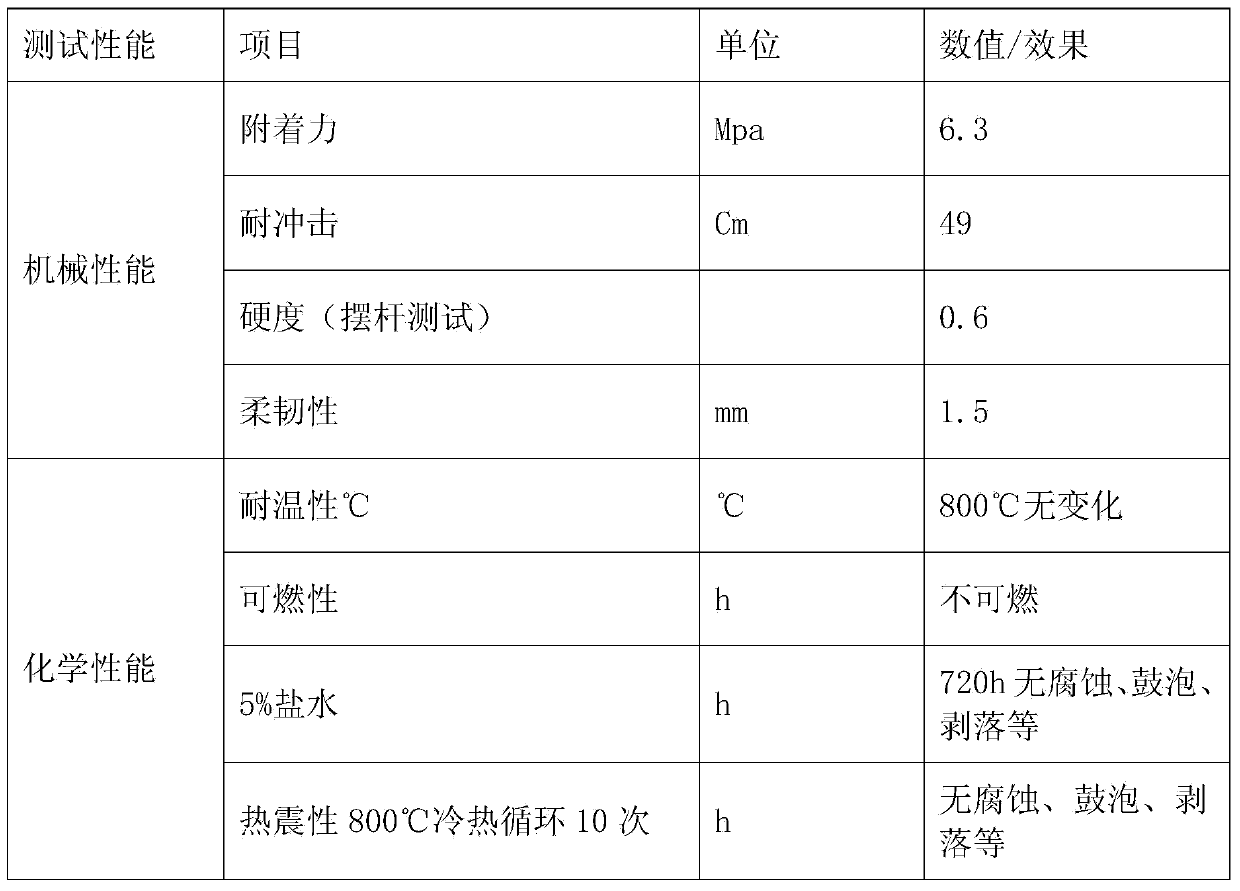

Heat insulation and corrosion prevention coating and preparation method thereof

InactiveCN104212342AExcellent weather resistanceStable conductivityFireproof paintsAnti-corrosive paintsSilicone resinWeather resistance

The invention discloses a heat insulation and corrosion prevention coating. The heat insulation and corrosion prevention coating comprises the following components in percentage by mass: 35-45% of epoxy-modified organic silicon resin, 6-8% of hollow microspheres, 12-18% of composite flame retardant, 14-18% of hydrotalcite, 10-12% of titanium dioxide, 2-5% of toughener, 1-3% of defoamer and 3-5% of drier. The invention further discloses a preparation method of the heat insulation and corrosion prevention coating. The product disclosed by the invention has excellent weather resistance, aging resistance, radiation resistance, wear resistance, impact resistance, resistance to high temperature and low temperature, stable electric conductivity and strong adhesion; the resistivity can meet the anti-static requirements and further ensure the long service life of the coating; simultaneously, the product is efficient, convenient and simple to construct, and can really realize self-curing of the inorganic coating at normal temperature and realize excellent resistance to salt fog and aging resistance; the coating has self-repair property, local scratches caused by external force can be still protected, the coating can not be damaged by cutting or welding, and the welding quality is not affected by welding with the coating.

Owner:JIANGSU MARINE VICTORY COATING

Method for welding non-coating stainless steel plate in laser mode

ActiveCN103658985AGuaranteed weld strengthGuaranteed bright appearanceVehicle componentsWelding/soldering/cutting articlesSteel platesWall plate

The invention relates to a method for welding a non-coating stainless steel plate in a laser mode. An upper layer panel and a lower layer panel are stacked up, a layer of protecting film is arranged on the exposed surface of the lower layer panel, and the upper layer panel and the lower layer panel are connected by enabling a laser welding light beam to penetrate through the protecting film to reach a certain depth of the lower layer panel. On the premise that the assembling precision meets the laser welding requirements, the welding technology methods are selected in the aspects of controlling the appearance quality and guaranteeing the connector connecting strength according to the product requirements for a railway vehicle non-coating stainless steel vehicle body and the technology characteristics, and a certain welding width and a certain welding depth are controlled by controlling the welding technology parameters such as welding power and welding speed. The welding joint cannot be oxidized and the welding heat can be more centralized by adopting the special technologies of welding the exposed wall plate provided with the protecting film and placing an aluminum alloy base plate on the lower surface of a workpiece, the strength of the welding joint is guaranteed, the back face of the exposed welding joint cannot deform obviously, and the color of the back face of the exposed welding joint cannot change obviously.

Owner:CRRC QINGDAO SIFANG CO LTD

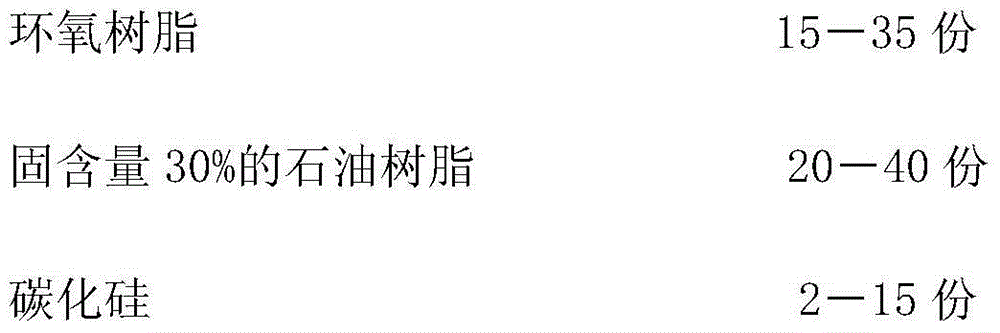

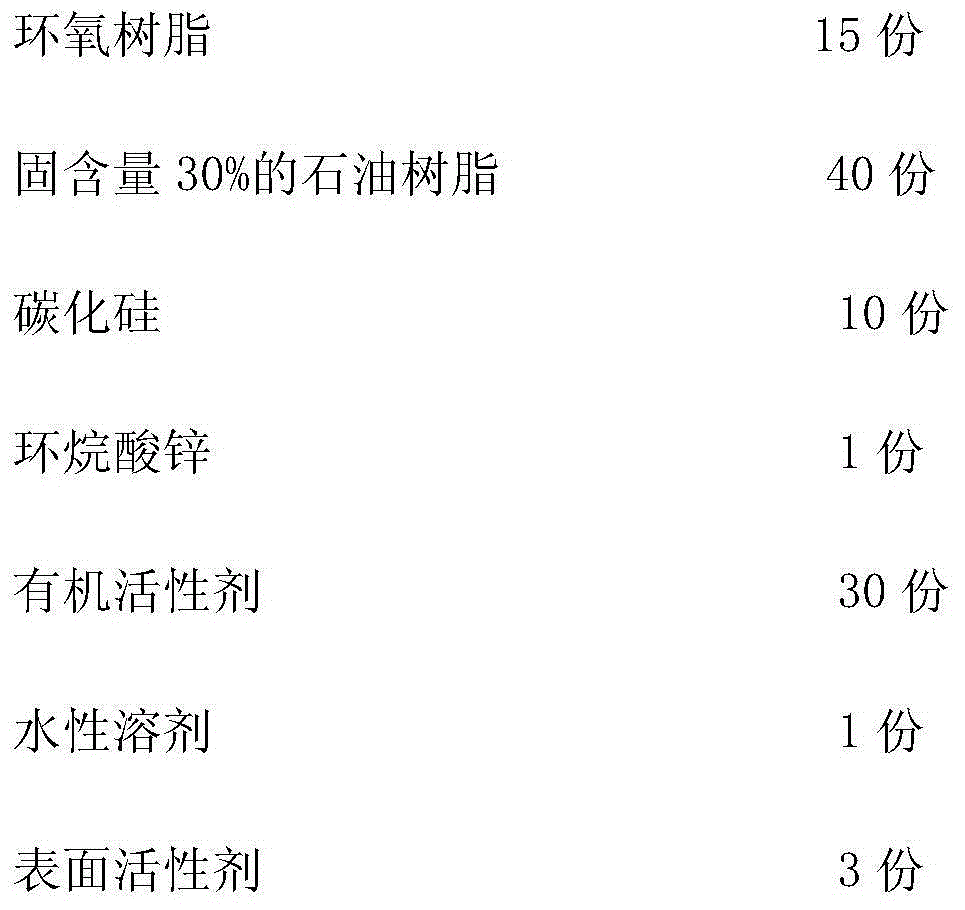

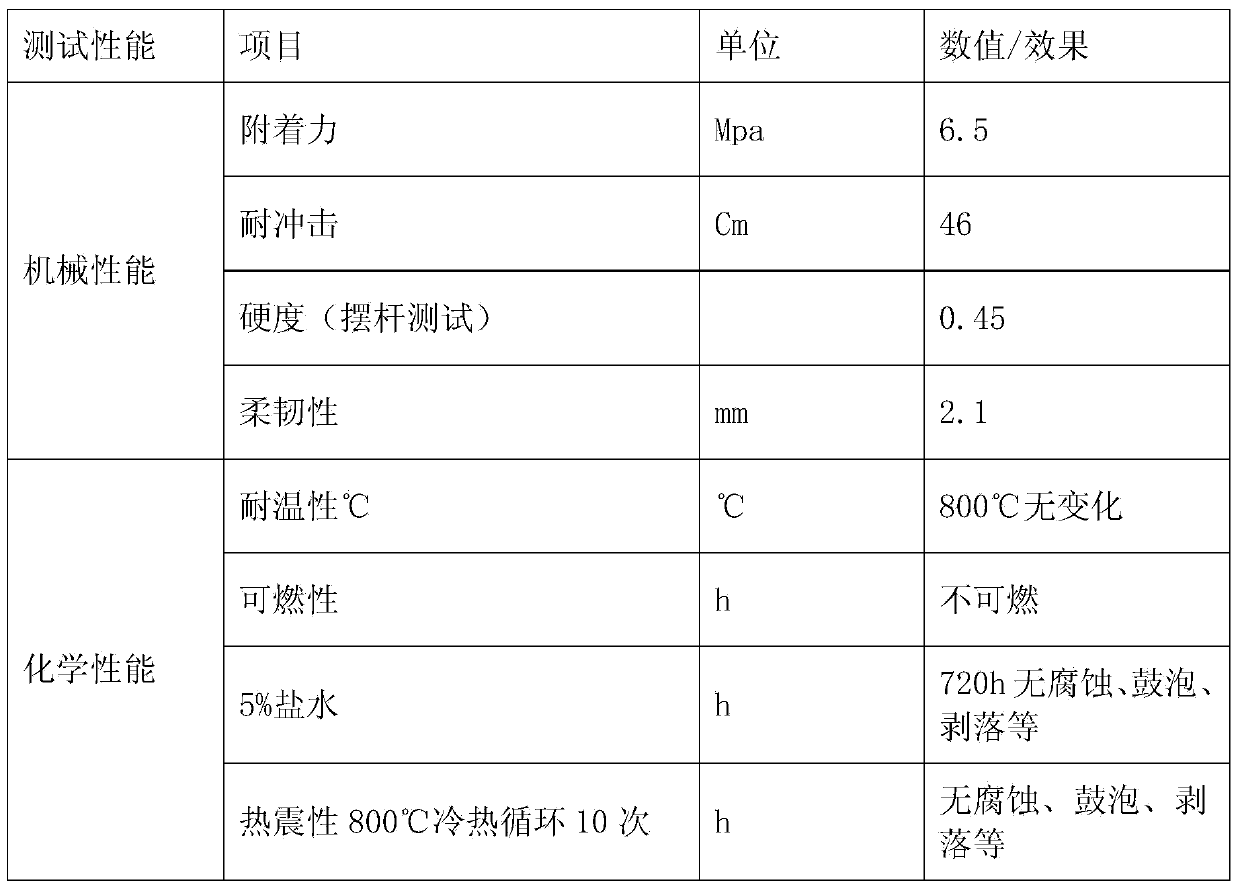

Active and anticorrosive water-based paint and preparation method thereof

ActiveCN105017937AExcellent weather resistanceGood thermal stabilityAnti-corrosive paintsEpoxy resin coatingsChemical industrySolvent

The invention belongs to the field of the chemical industry and relates to anticorrosive paint and in particular relates to active and anticorrosive water-based paint and a preparation method thereof. The paint comprises the following components in parts by mass: 15-35 parts of epoxy resin, 20-40 parts of petroleum resin with solid content of 30%, 2-15 parts of silicon carbide, 0.5-8 parts of zinc naphthenate, 30-45 parts of organic active agent, 2-4 parts of water-based solvent and 1-3 parts of surfactant. The product has the beneficial effects that the product can be used under severe conditions, has long-acting anticorrosive property, has dry film thickness over 300mu m and has excellent weather resistance, aging resistance, radiation resistance, wear resistance and impact resistance and good thermal stability; the paint has strong adhesion and can undergo spray moulding on random curved surfaces, slopes and vertical surfaces, without sagging; the paint is efficient and convenient, a formula system can be randomly adjusted, and normal-temperature self-solidification of inorganic paint can be authentically realized; besides, a coating has self-repair property, can be still protected from local scratches caused by external forces and is free from cutting and welding damages; the quality of tape coating welding is not affected.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

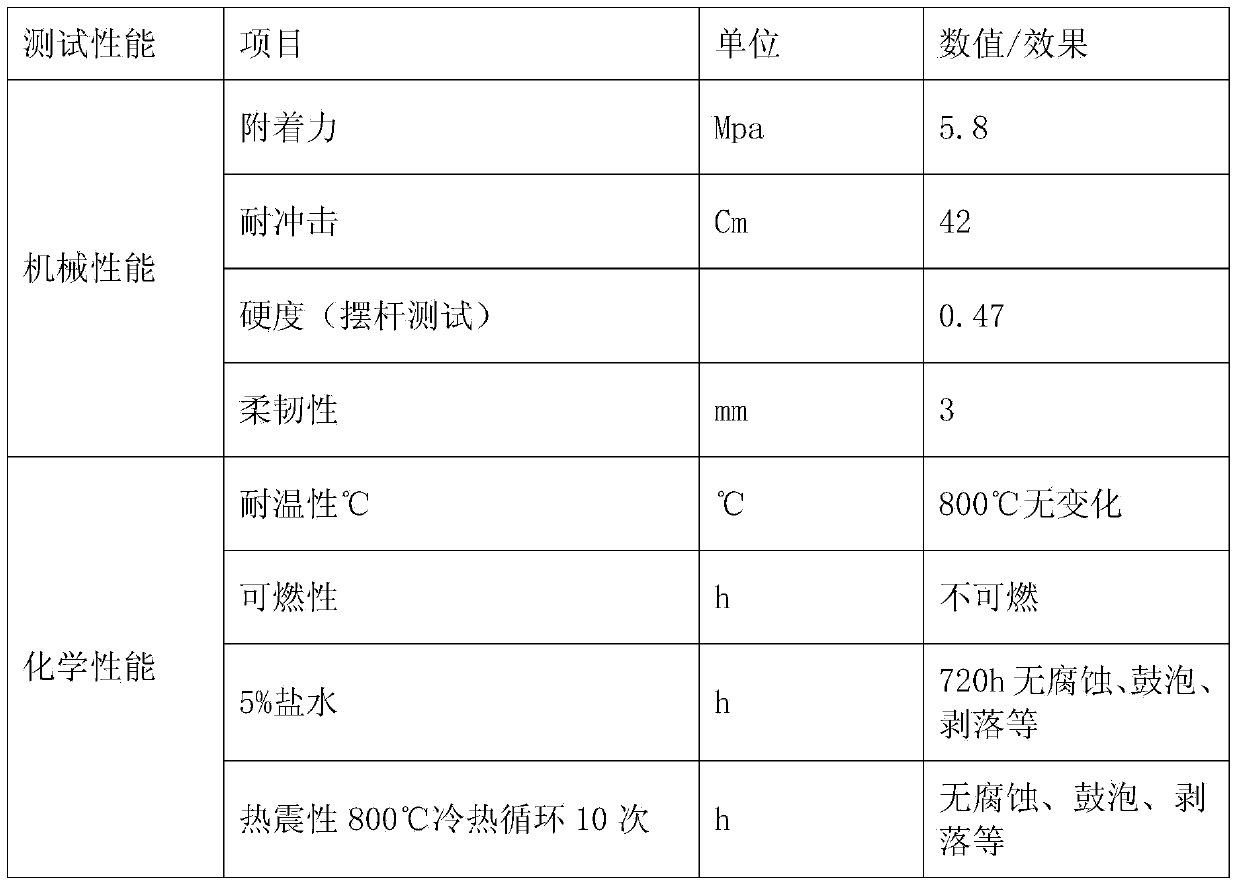

Elastic anticorrosive paint and preparation method thereof

InactiveCN104212343AAnti-agingRadiation resistantAnti-corrosive paintsEpoxy resin coatingsAging resistanceDiluent

The invention discloses elastic anticorrosive paint which is prepared from the following components in percentage by weight: 6-12% of a flexibilizer, 30-45% of polysiloxane, 25-55% of packing, 5-8% of a crosslinking agent, 10-18% of a diluent, 5-10% of an auxiliary, 1-5% of sodium pyrophosphate, 1-3% of sodium tripolyphosphate and 2-4% of polyacrylate resin. The invention further discloses a preparation method of the elastic anticorrosive paint. A product disclosed by the invention is strong in adhesive force and the binding force of a coating and a matrix is strong; and the paint is efficient and convenient and simple to construct, and the inorganic paint is self-cured at normal temperature, so that the high-efficiency construction can be ensured and the paint has excellent salt mist resistance and aging resistance. The coating is self-repaired and local scratch caused by external forces still can be protected. The coating is free from cutting and welding damages and the welding quality is not affected with the coating.

Owner:JIANGSU MARINE VICTORY COATING

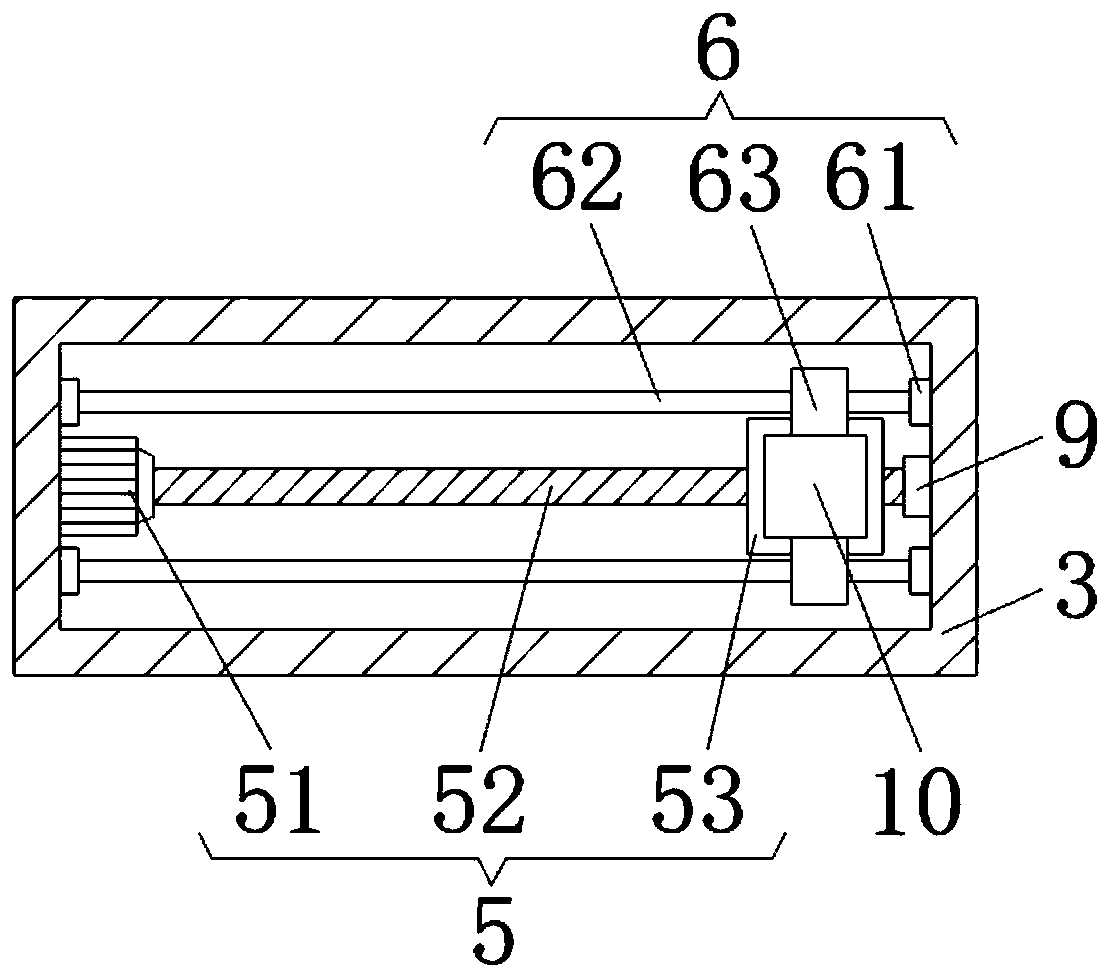

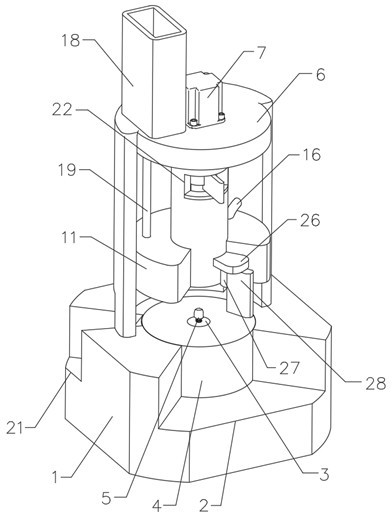

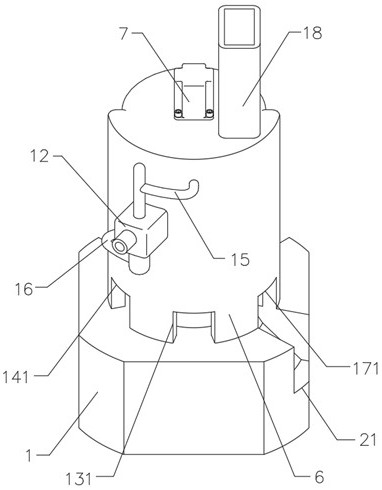

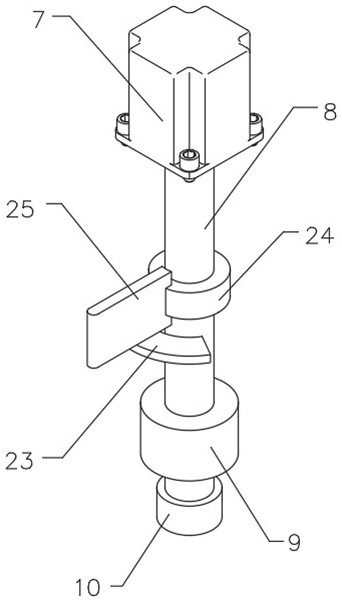

Automatic turning system for battery cells

ActiveCN107597778AFlip flexibleFlip AccurateFinal product manufactureSecondary cells manufactureEngineeringAutomatic testing

The invention discloses an automatic turning system for battery cells. The automatic turning system for the battery cells comprises a turning mechanism used for turning the battery cells and a clamping mechanism used for clamping the battery cells when the battery cells are turned. The clamping mechanism comprises one or more clamping assemblies and a driving assembly used for controlling the clamping assemblies to stretch and retract. Each clamping assembly comprises a connecting rod and a clamping jaw, wherein one end of the connecting rod is connected with the clamping jaw, and the other end of the connecting rod is connected with the driving assembly. As the turning mechanism and the clamping mechanism are arranged, when the automatic turning system for the battery cells is applied toelectrode cleaning equipment, the turning mechanism can automatically turn the battery cells by 180 degrees, the clamping mechanism can clamp the battery cells in the turning process, and thus omnibearing cleaning of electrodes is achieved.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

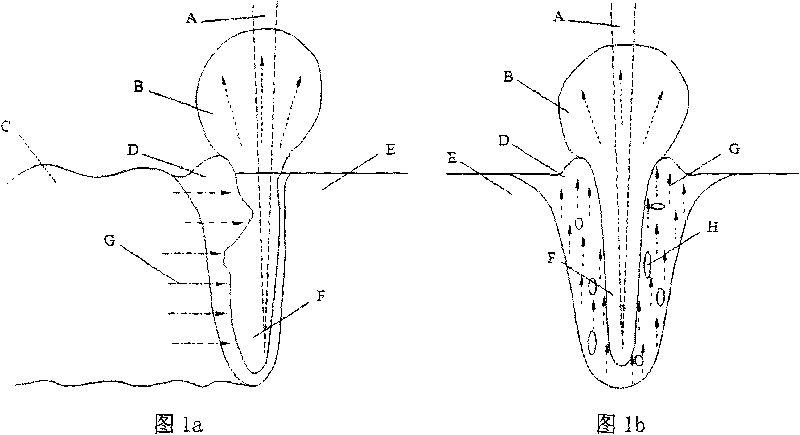

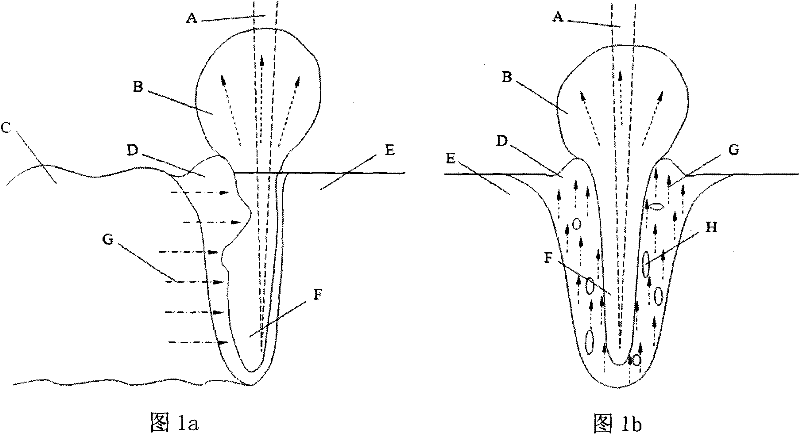

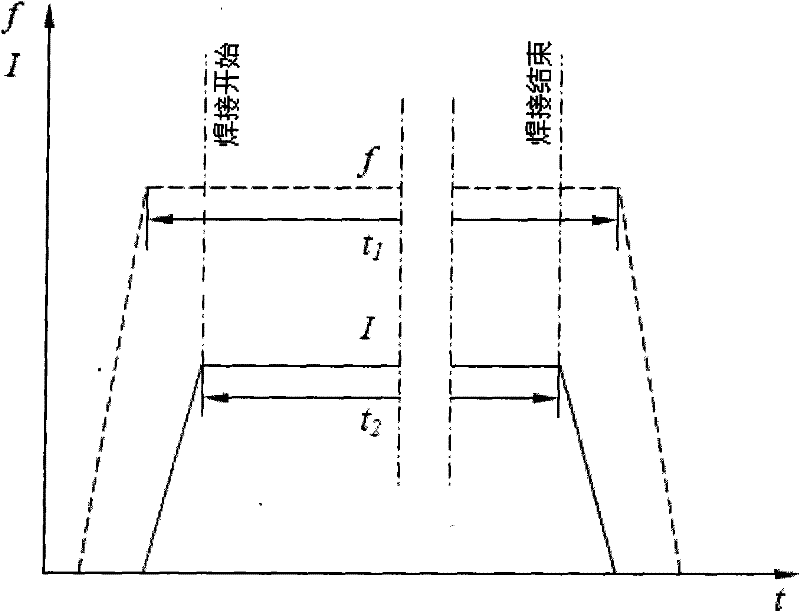

Ultrasound-assisted vacuum electron beam welding method of magnesium and magnesium alloy

InactiveCN101693323ATo promote floatingEasy to fillMechanical vibrations separationElectron beam welding apparatusUltrasonic assistedUltrasound assisted

The invention discloses an ultrasound-assisted vacuum electron beam welding method which is applied to magnesium and magnesium alloy and can solve the technical difficulty that magnesium, magnesium alloy and especially cast magnesium alloy generate pores, cold shut and other cavity-type defects in the vacuum electron beam welding process. During the vacuum electron beam welding process, the technology applies structure load ultrasound energy with certain frequency and amplitude of vibration, wherein the frequency of ultrasound is 20-50kHz and the amplitude of vibration is 5-40mum. By conducting continuous oscillation on a molten pool generated by vacuum electron beam welding and the nearby area to a certain extent, the method can effectively eliminate the pores, cold shut and other cavity-type defects in the welding process and obtain high-quality welding joints.

Owner:CHONGQING UNIV OF TECH

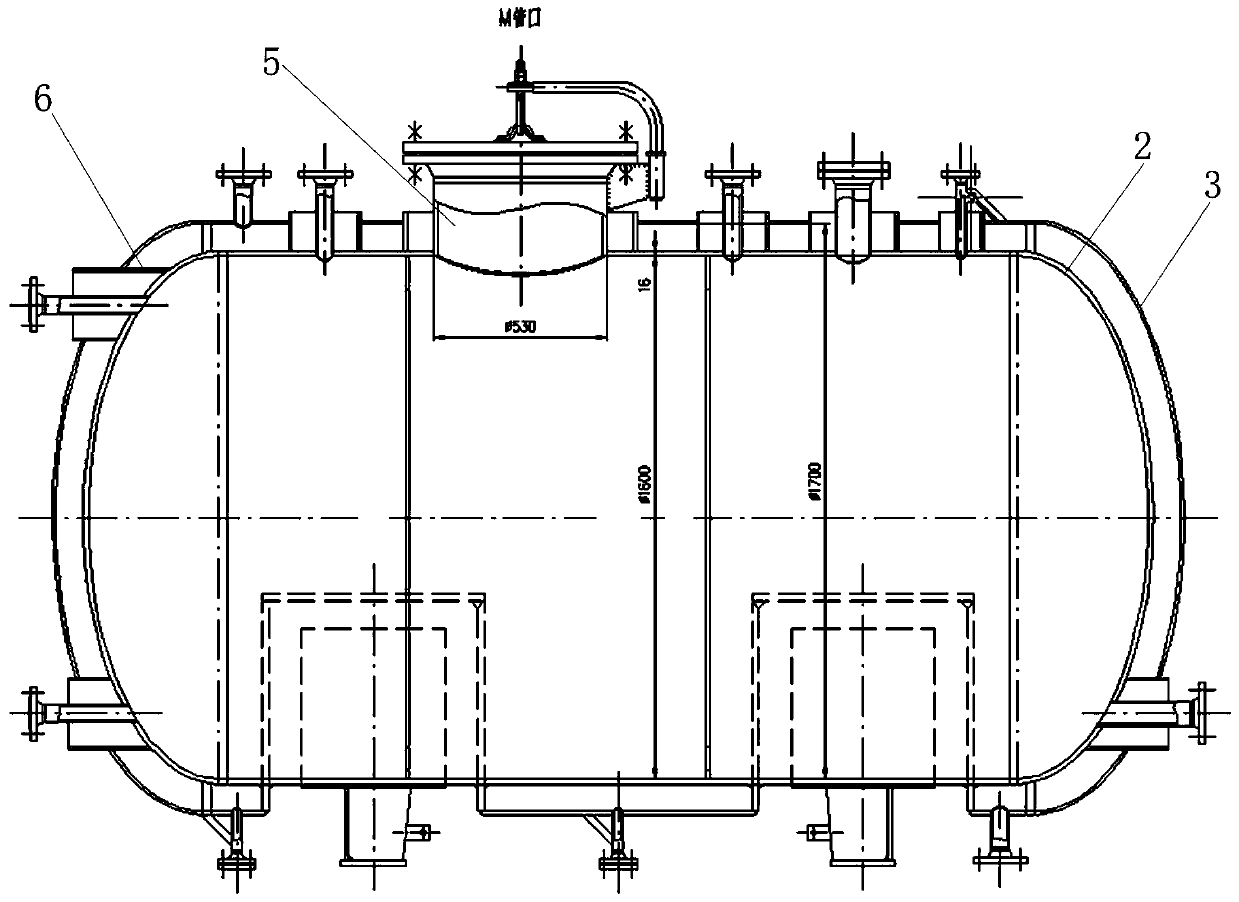

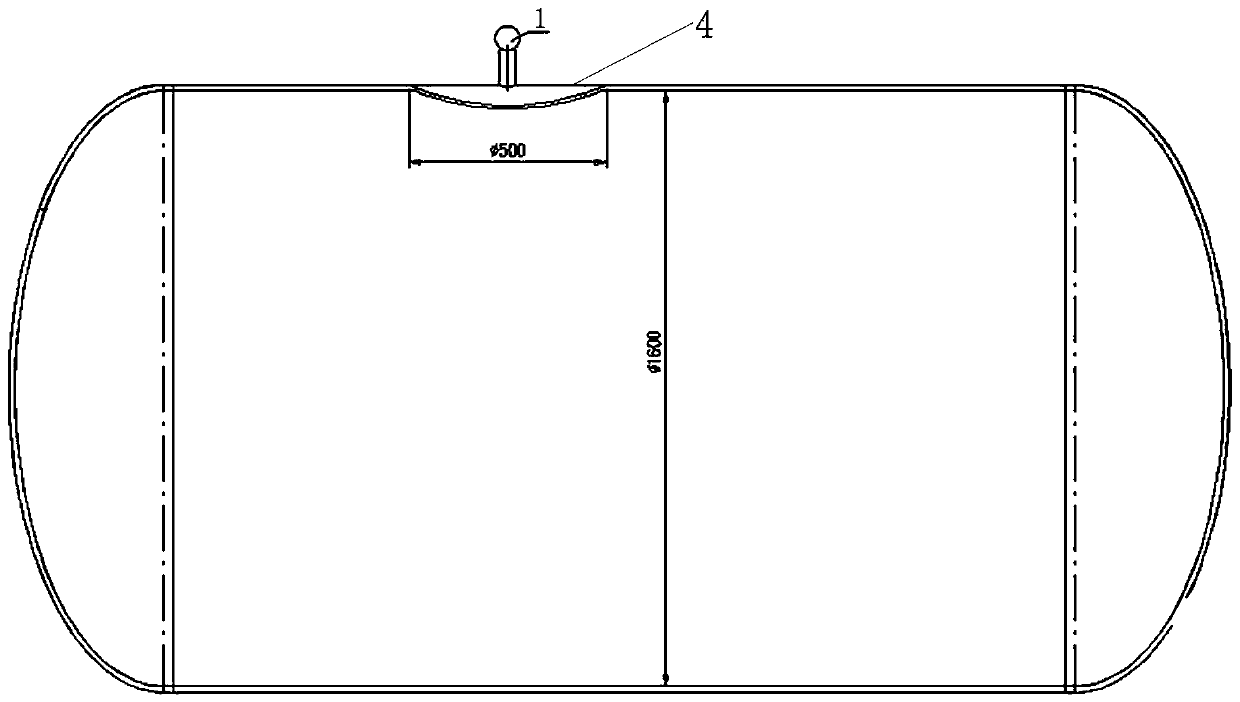

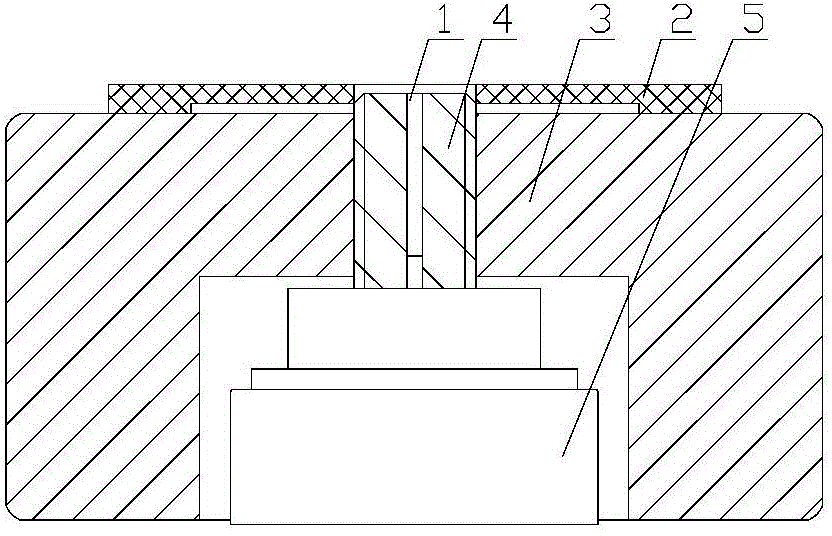

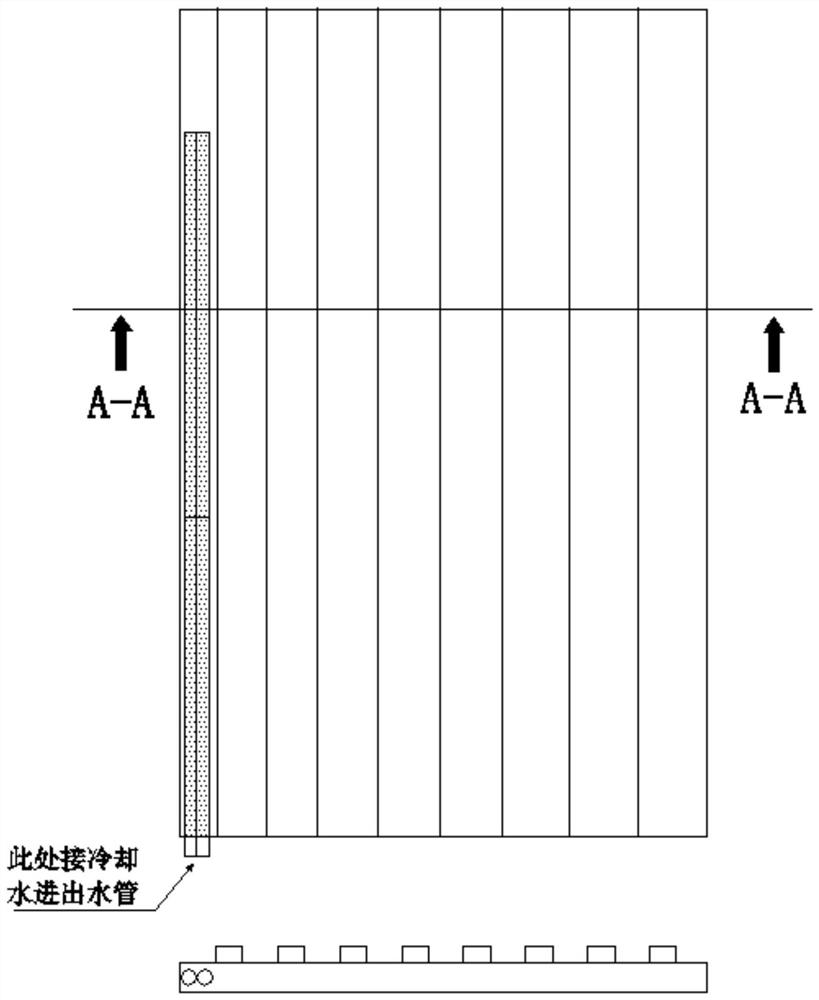

Manufacturing and pressure testing method for jacketed vessel with inner cylinder as inner groove

ActiveCN109894765AImprove welding qualityDoes not affect welding qualityMaterial strength using tensile/compressive forcesWelding apparatusEngineeringWeld seam

The invention relates to a production technology of the jacketed vessel, in particular to a manufacturing and pressure testing method for a jacketed vessel with an inner cylinder as the inner groove.The problem that the quality of the container welding is difficult to improve due to the failure of an inner cylinder to be fully processed into an inner groove in the manufacturing process of an existing jacketed vessel is solved. The method comprises the following steps that (1) a hole with the diameter less than the diameter of a herringbone hole is pre-formed in the position, prepared to be formed with the herringbone hole, of the inner cylinder, group welding is conducted on the inner cylinder, an arc plate left by pre-hole-forming is welded to the pre-formed hole from the exterior, the opening hole of the arc plate is connected with a water injection pipe and a pressure gauge, and the pressure testing is conducted on the inner cylinder; (2) a jacket and the inner cylinder are mountedin a sleeved mode, the herringbone hole with the aperture greater than the pre-formed hole and used as the inner groove is continue to be processed in the position of the pre-formed hole, and the pressure testing after the jacket group welding is conducted; and (3) the equipment whole group welding is conducted. The manufacturing and pressure testing method is suitable for the pressure testing ofthe jacketed vessel with the inner cylinder as the inner groove, the welding seam groove can be processed according to the requirements, the pressure testing is completed, and the processing qualityis improved.

Owner:SHANXI YANG MEI CHEM IND MACHINERY

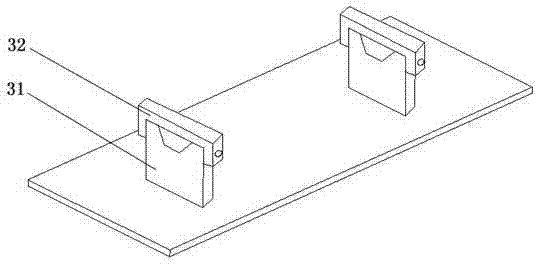

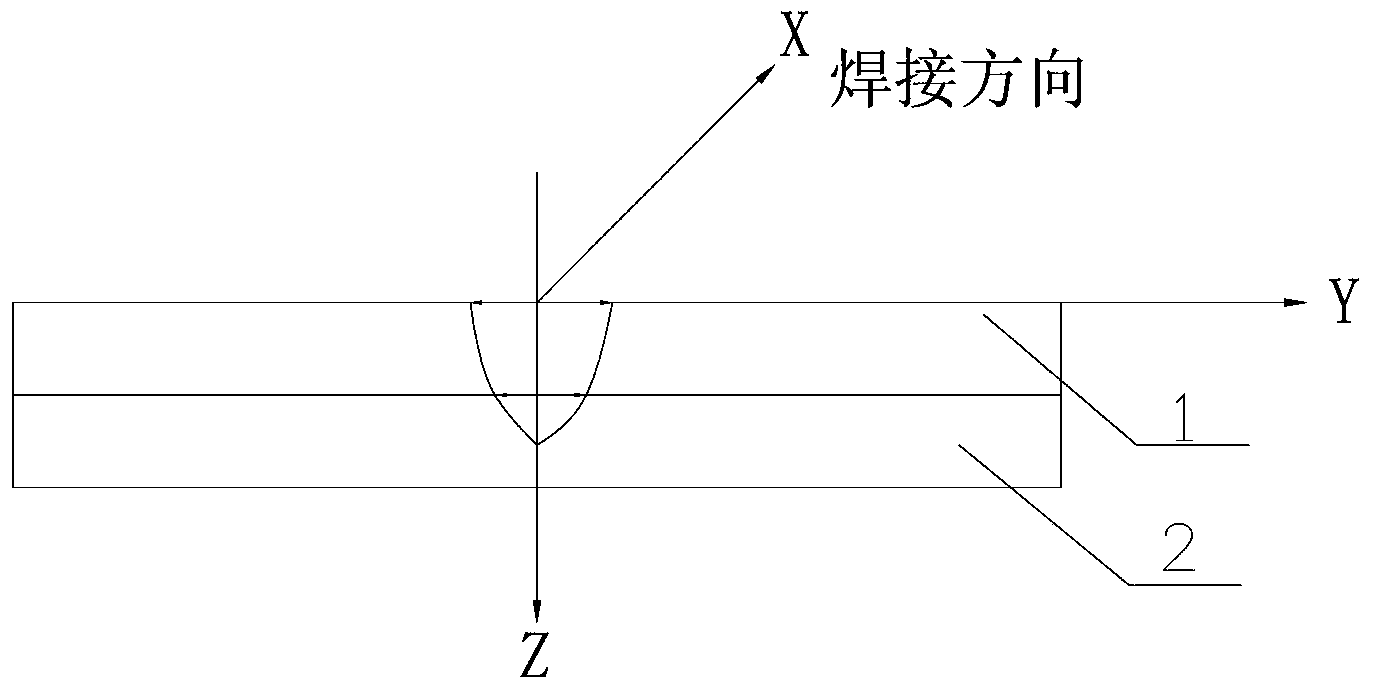

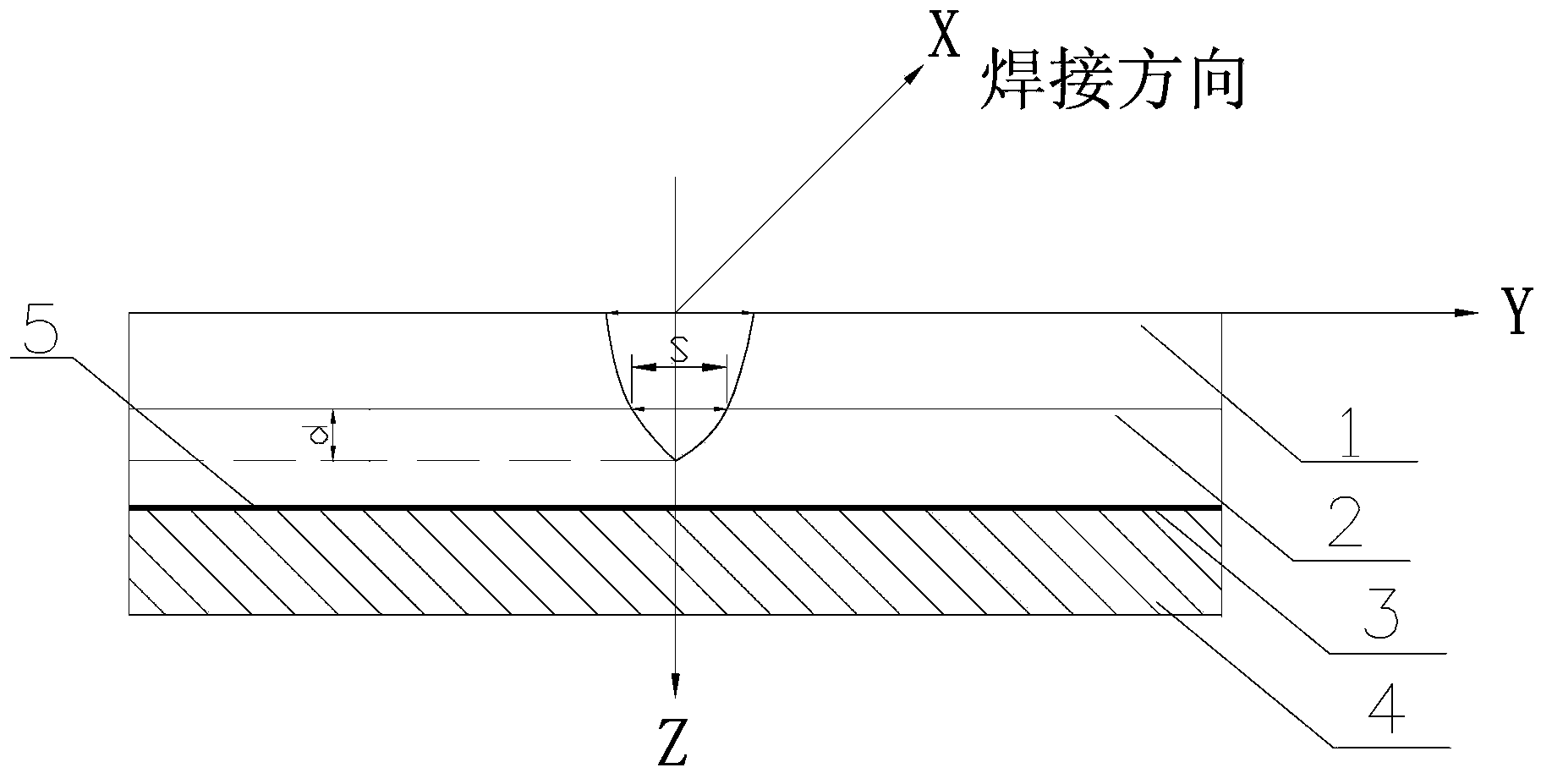

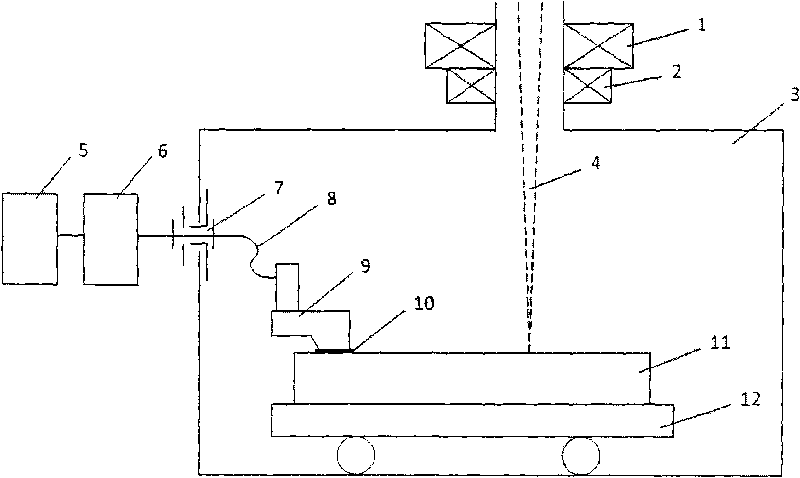

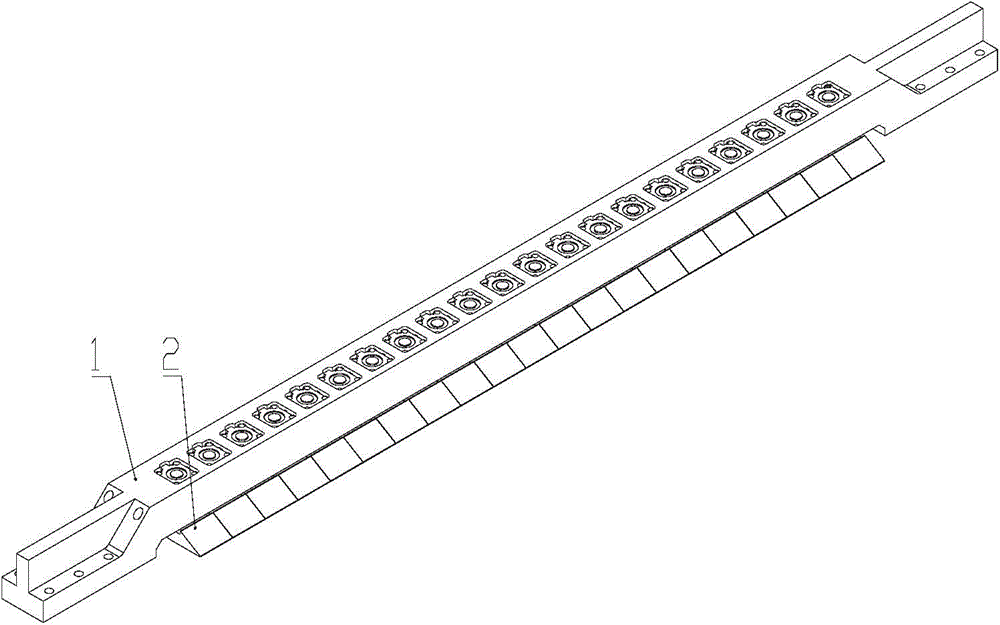

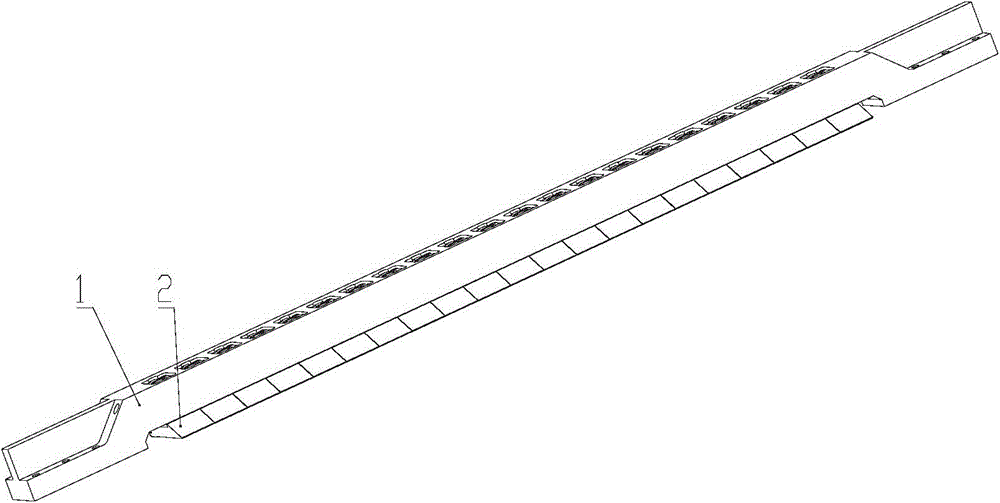

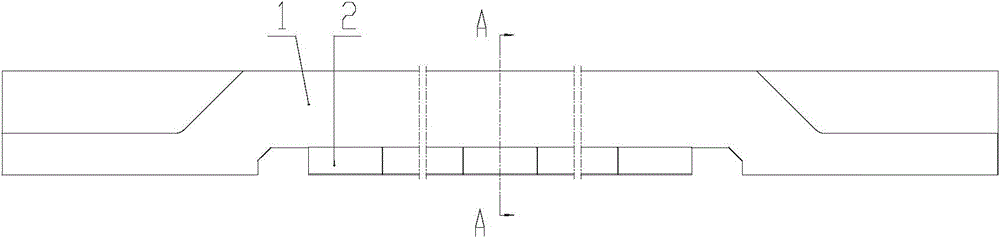

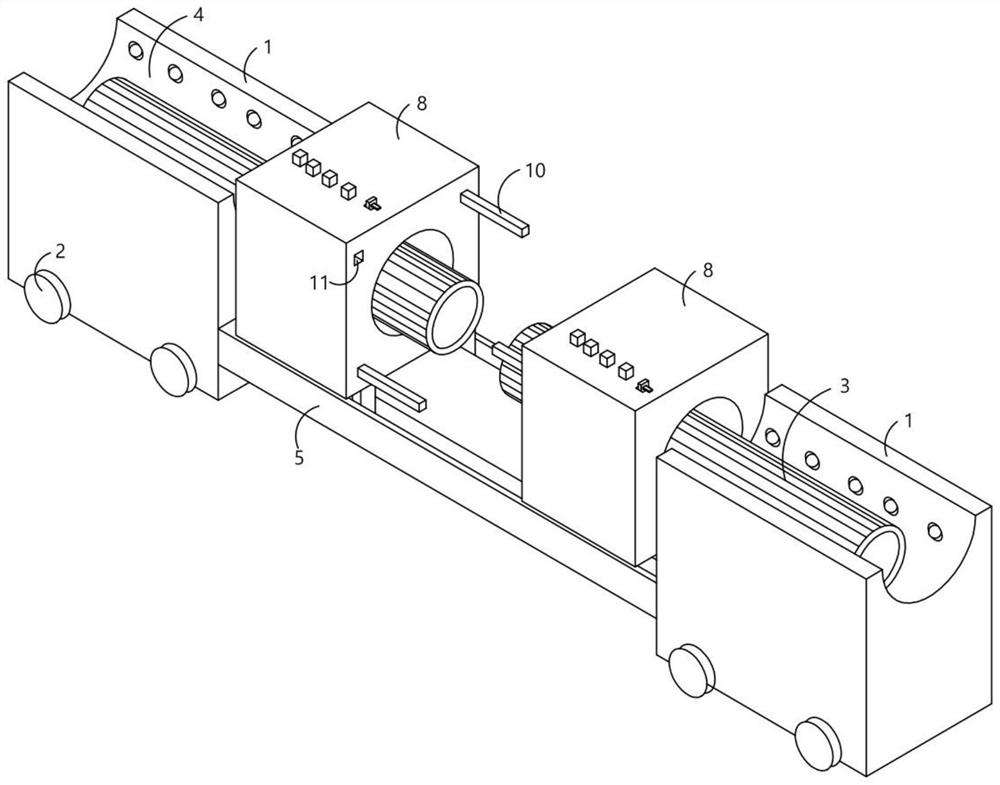

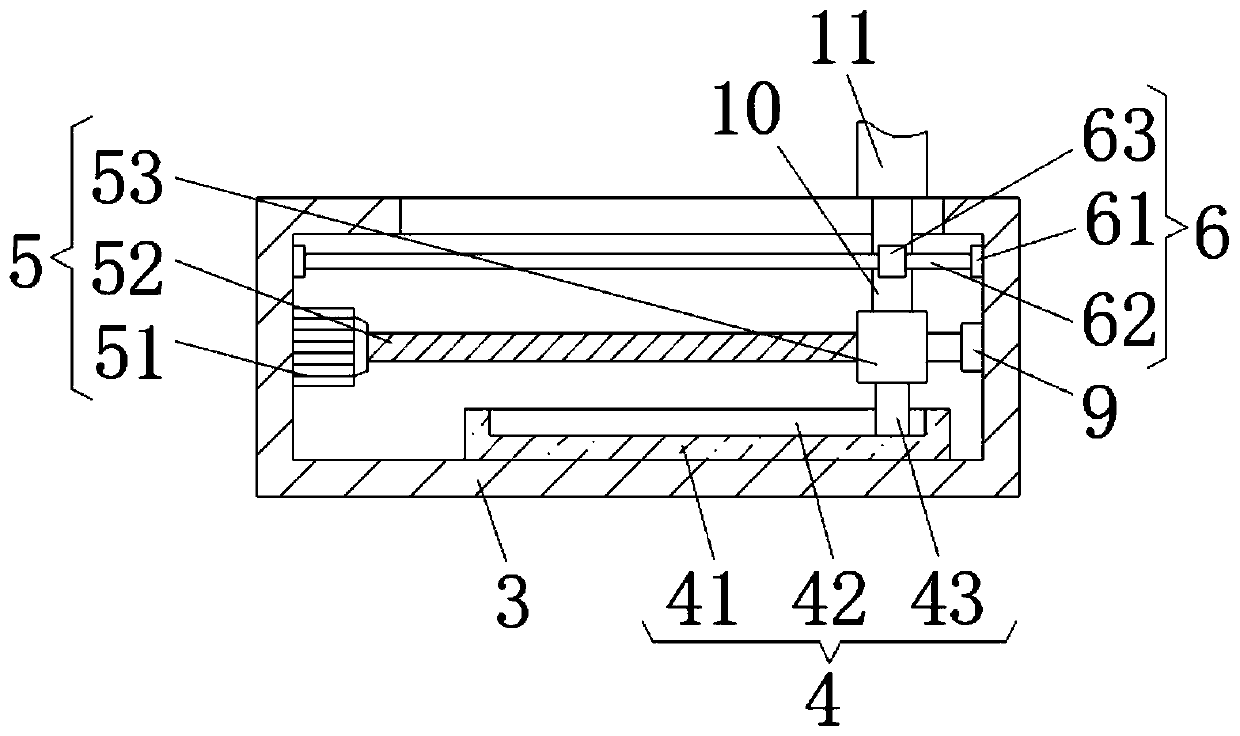

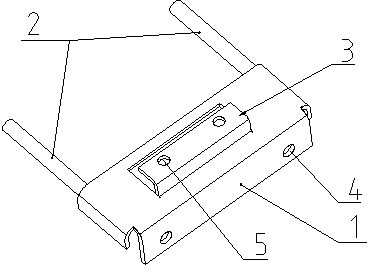

Panel pressing device applied to laser tailor-welding

InactiveCN104416291AImprove the quality of correctionGood compression effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser

The invention belongs to the technical field of laser welding, and particularly relates to a panel pressing device applied to laser tailor-welding. The panel pressing device comprises a pressing beam and pressing components, wherein the pressing beam is provided with a plurality of stepped through holes along the length direction; one set of the pressing component is arranged in each stepped through hole. According to a method, a plurality of groups of pressing components are used for vertically acting on a welded panel, and a plurality of groups of pressing load are applied, so that the welded panel can be pressed and fixed. The device disclosed by the invention has the advantages of being simple in structure, low in cost, convenient to dismount, replace and maintain and the like; the method is good in pressing effect, uniform in pressing force and high in panel correction quality; the panel can be effectively fixed; the requirements of laser tailor-welding on flatness of the pressed panel are satisfied; the welding quality are ensured not to be affected by cracking of the edge of the panel due to welding stress caused in a welding process.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

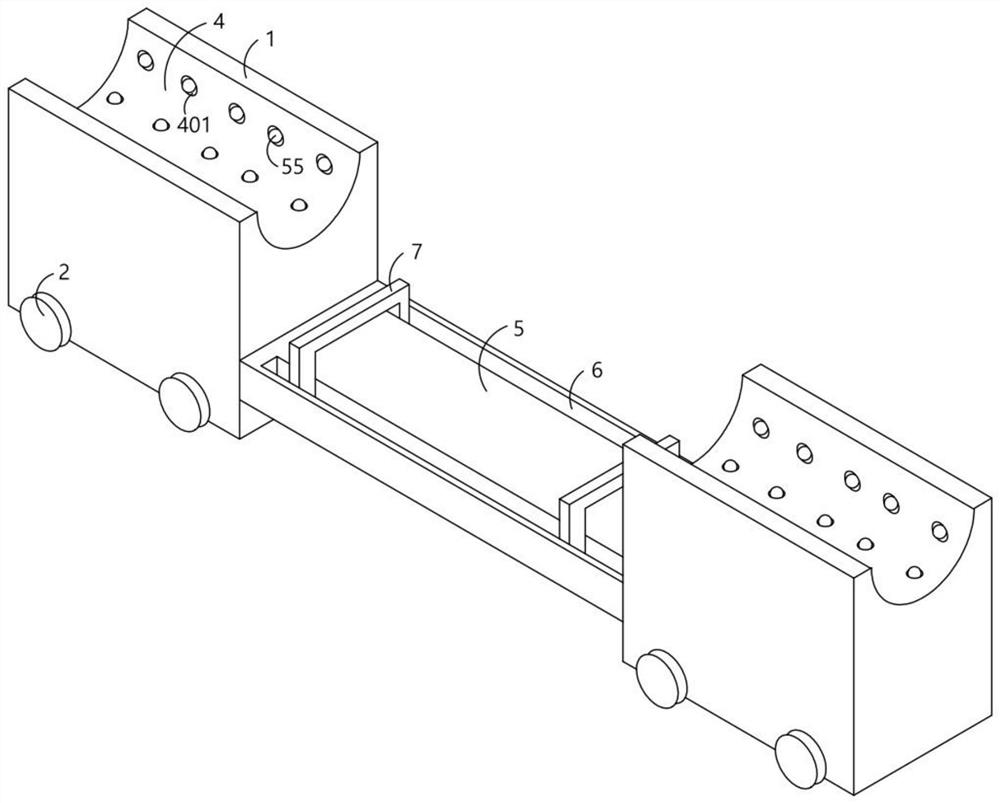

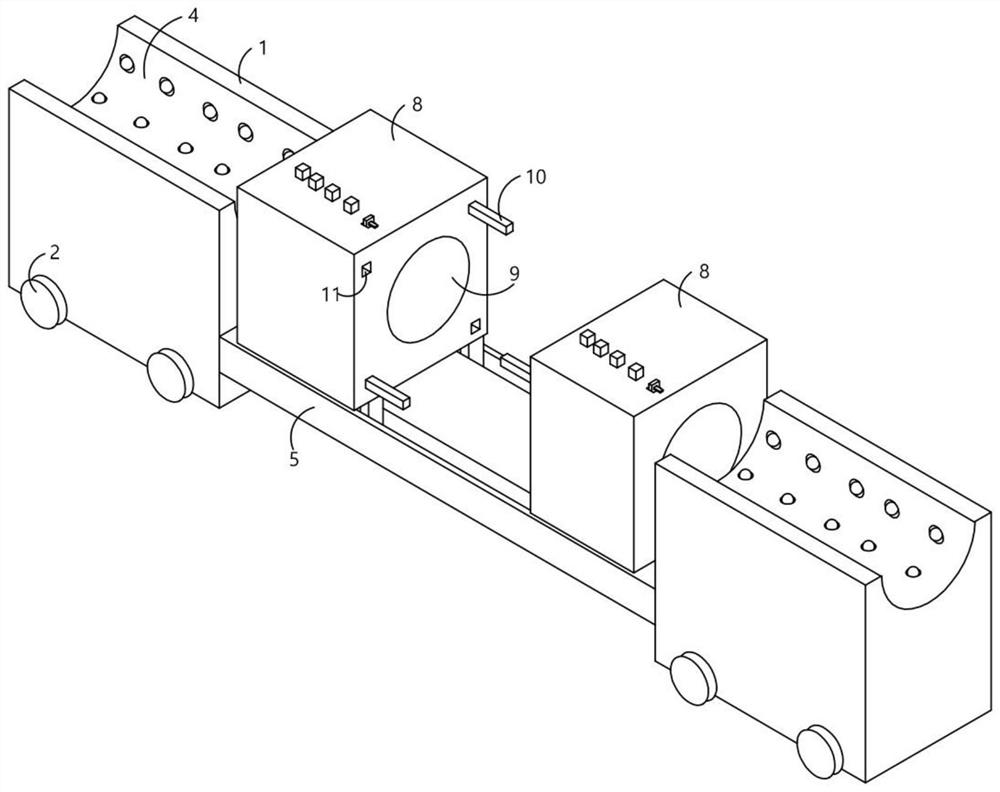

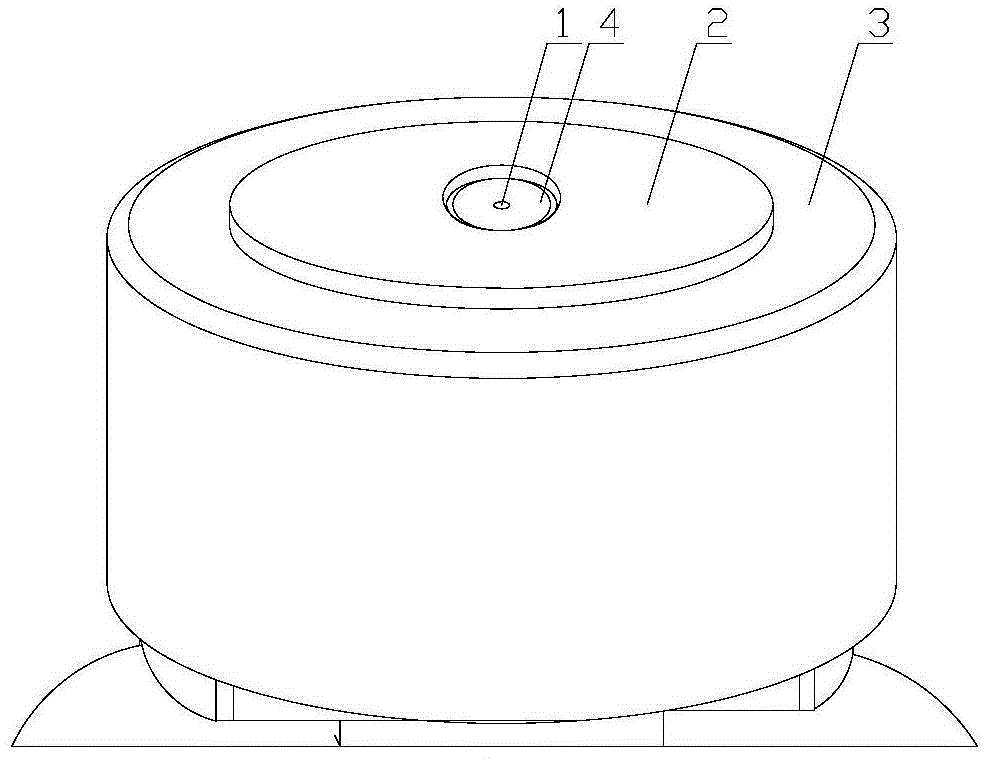

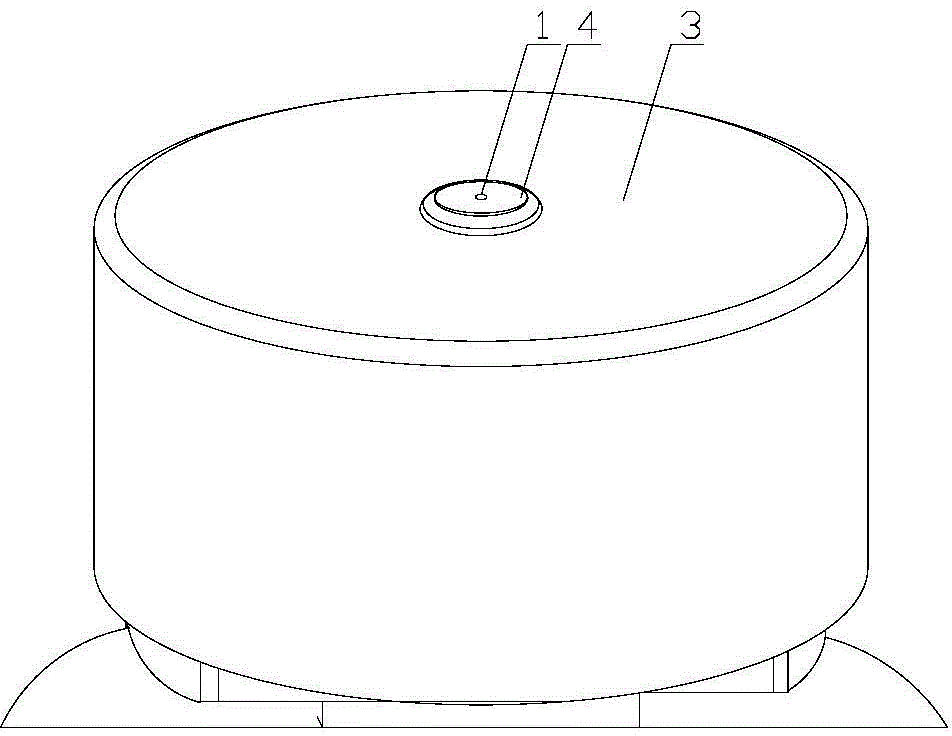

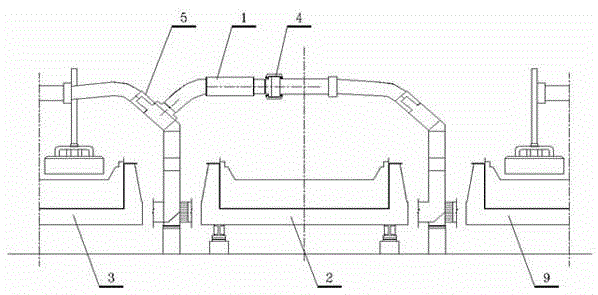

Large-diameter pipeline welding device

ActiveCN114799642ADoes not affect the levelDoes not affect welding qualityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention provides a large-diameter pipeline welding device which comprises two placing tables, each placing table is provided with a placing groove used for placing a pipeline, a track plate is fixedly arranged between the placing tables, two telescopic track rods are movably arranged on the surface of the track plate, and the telescopic track rods are fixedly connected with a fixing box. A through hole allowing a pipeline to movably penetrate through is formed in the fixing box, the fixing box is fixedly connected with a plurality of inserting rods, inserting grooves allowing the inserting rods to be movably inserted are formed in one side of the fixing box, and a fixing plate used for fixing the pipeline and an air bag are arranged in the through hole. In the using process, a pipeline is firstly placed in a containing groove, a welded part of the pipeline is washed and dried, the center of the pipeline and the center of a through hole are located on the same horizontal plane by adjusting a telescopic rail rod, then the pipeline is fixed through a fixing plate and an air bag, and the two fixing boxes are fixed through inserting rods and buckle assemblies; and the pipeline can be moved at will during welding.

Owner:中交三航(南通)海洋工程有限公司

Welding method for liquid injection hole of lithium ion battery threaded pole

ActiveCN105364327AImprove work efficiencyEliminate scrappingCell component detailsWelding apparatusMelting tankElectrical battery

The invention relates to a welding method for a liquid injection hole of a lithium ion battery threaded pole. The manufacturing process comprises the step that fusion sealing welding is carried out on the liquid injection hole of a welded battery. The welding method is characterized in that the manufacturing process further comprises the step that before sealing welding, a ceramic ring is arranged on the threaded pole in a sleeving manner, and a closed weld pool is formed at the welding part of the liquid injection hole in the threaded pole in the circumferential direction. By means of the characteristics that ceramic is low in heat conductivity, and the ceramic and metal cannot be welded, the closed weld pool is formed at the welding part of the liquid injection hole in the threaded pole; when the liquid injection hole is welded, the ceramic ring effectively prevents liquid in the closed weld pool from flowing outwards, a thread on the battery pole is protected, and the phenomenon that the battery is scrapped due to the thread damage caused by seal welding is eliminated. Meanwhile, due to the fact that the ceramic is low in heat conductivity, the welding quality cannot be affected even when the heat of the welding weld pool is absorbed. The metal in the fusion state cannot be welded to the ceramic into a whole so that the consequence that the ceramic ring cannot be taken down after welding cannot happen, and the work efficiency of the welding of the liquid injection hole is improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Rust removal and prevention agent for metal surfaces

InactiveCN106010159ALow costExtended service lifeAnti-corrosive paintsPolyester coatingsVarnishRust converter

The invention discloses a rust removal and prevention agent for metal surfaces. The rust removal and prevention agent is prepared from 20-30 parts of tartaric acid, 20-70 parts of ethyl formate, 50-150 parts of alkyd resin varnish, 60-200 parts of ethyl benzene, 20-70 parts of isoamyl alcohol and 1-7 parts of iron powder. Therefore, the rust removal and prevention agent not only has a metal rust protection function, but is also capable of welding with paint while not influencing the welding quality of a welding mouth; furthermore, the rust removal and prevention agent is lower in cost and long in service life.

Owner:黄健

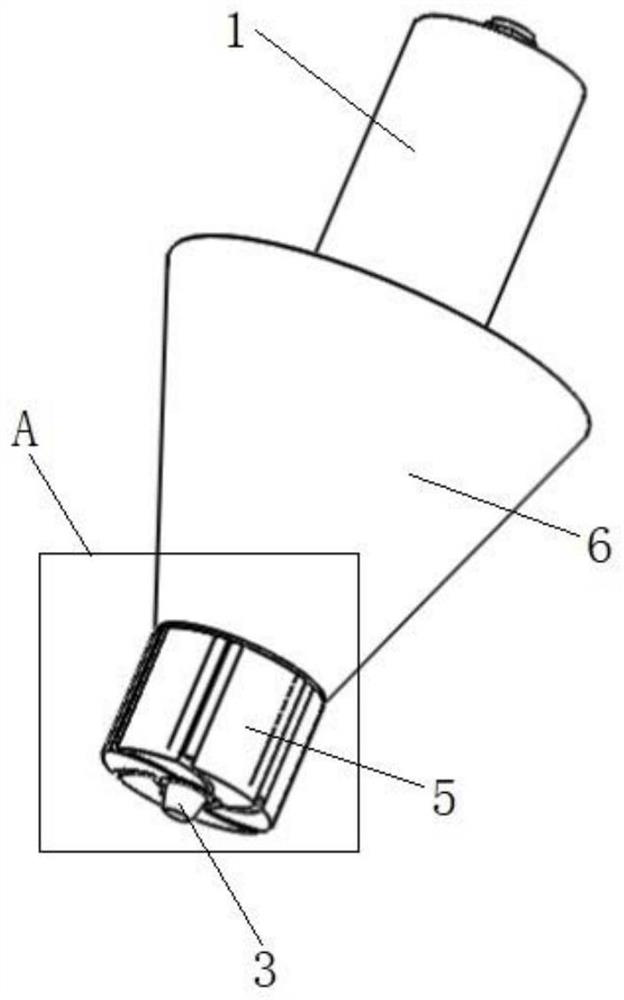

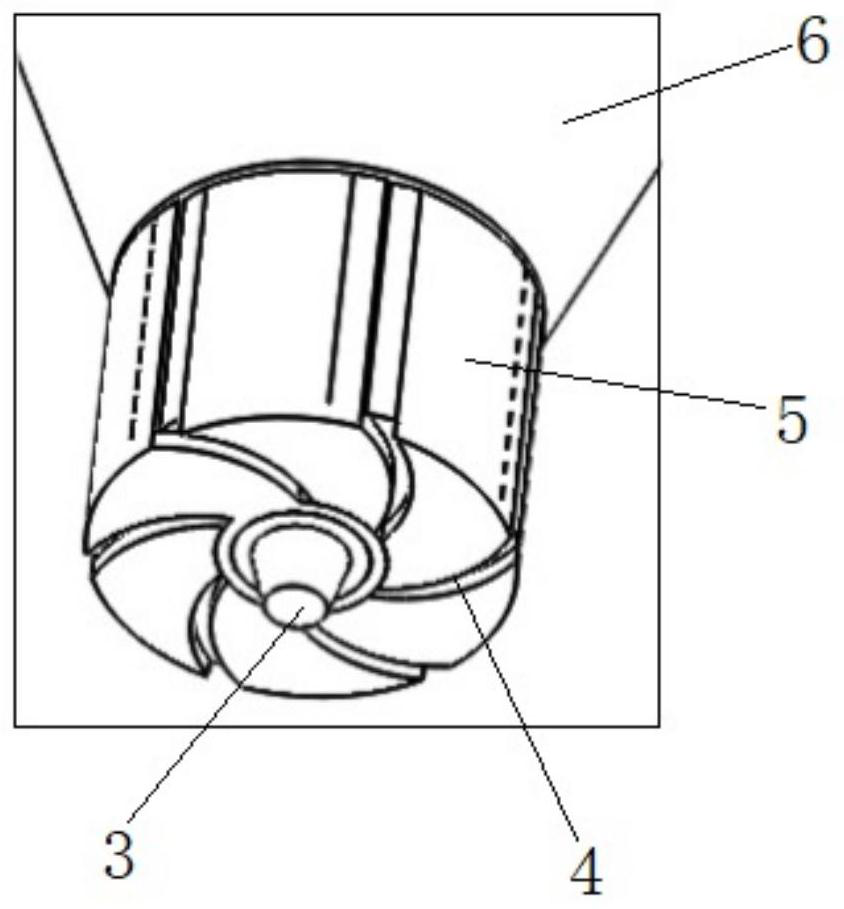

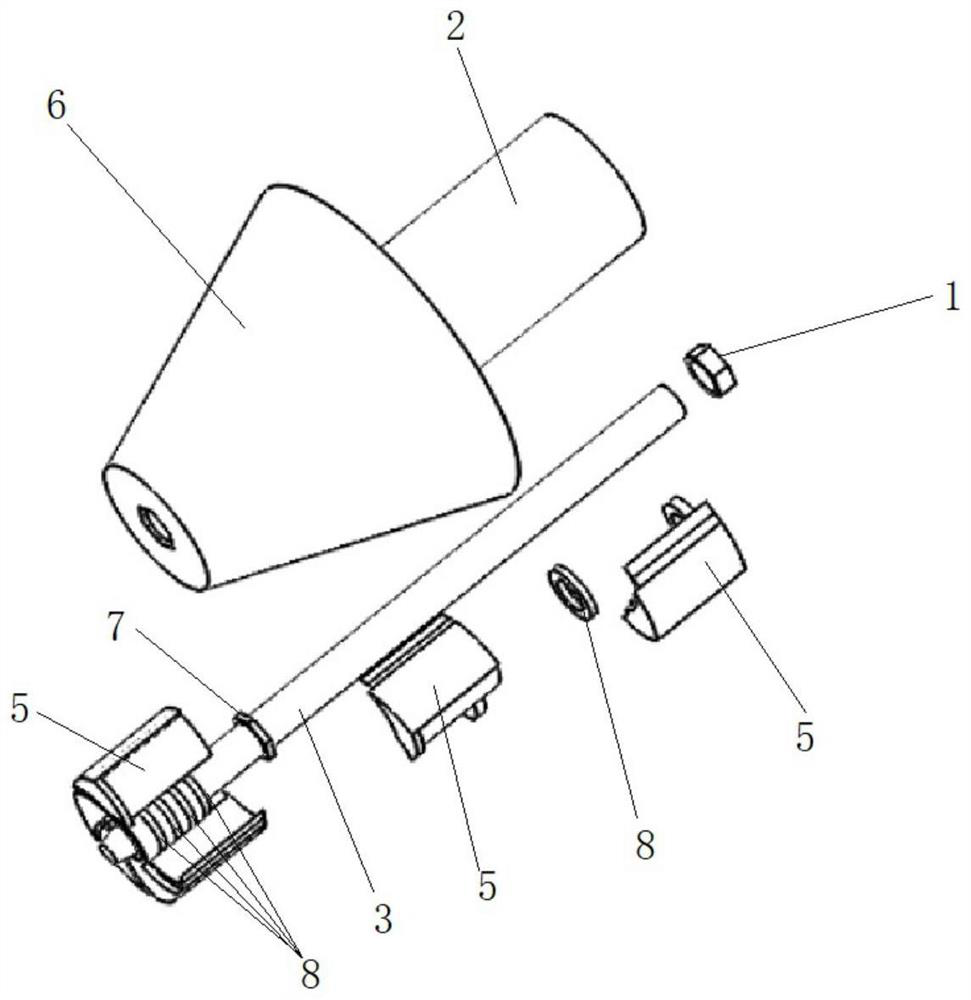

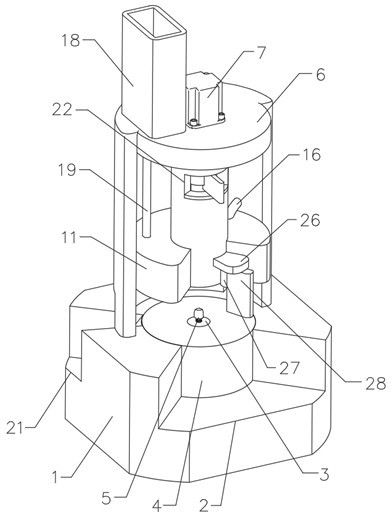

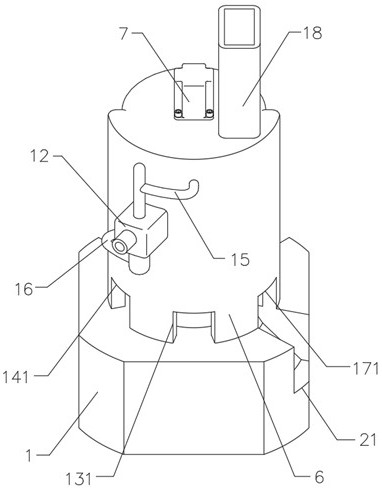

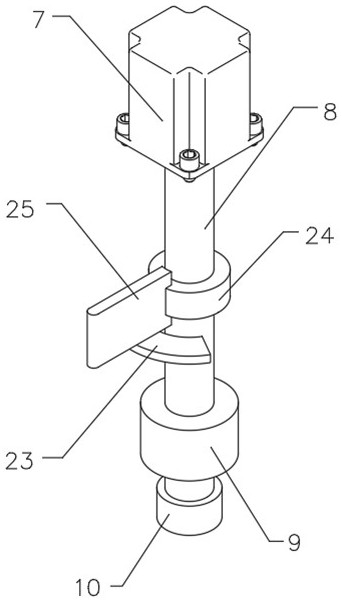

Local reducing stirring head

ActiveCN112658461AReduce widthReduce contact areaNon-electric welding apparatusClassical mechanicsLap joint

The invention relates to the technical field of friction stir welding, in particular to a local reducing stirring head. The local reducing stirring head is provided with a stirring needle and a shaft shoulder. The shaft shoulder comprises a plurality of movable shaft shoulder blocks which are connected to the stirring needle in a pivoted mode. The inner side of each movable shaft shoulder block is provided with an arc-shaped face which is connected to the outer side of an adjacent movable shaft shoulder block in a lap joint mode. An arc-shaped gap is formed between the bottom edges of every two adjacent movable shaft shoulder blocks, and the width of each arc-shaped gap can be changed along with different pivoting motion of the movable shaft shoulder blocks on the two sides, so that the multiple arc-shaped gaps with the variable widths are formed in the working end face of the shaft shoulder and can reduce the shaft shoulder invasion amount during curved surface friction stir welding, the shaft shoulder diameter can be partially changed without the need of shaft shoulders of multiple sizes to be installed, and the welding efficiency can be effectively improved.

Owner:安徽万宇机械设备科技有限公司

Ultrasonic auxiliary vacuum electron beam welding method of aluminum and aluminum alloy

InactiveCN101690991BTo promote floatingEasy to fillWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic assistedStructural load

The invention discloses an ultrasonic auxiliary vacuum electron beam welding method applied to aluminum and an aluminum alloy, which can solve the technical problem that the aluminum, the aluminum alloy and especially cast aluminum alloy generate cavity type defects such as air hole, cold laps and the like in the process of welding a vacuum electron beam so as to improve mechanical properties of welding joints. In the technology, structural load ultrasonic energy with certain frequency and certain amplitude is applied in the process of welding the vacuum electron beam, the ultrasonic frequency is between 15 and 50 kHz, and the amplitude is between 10 and 50 mu m. A molten pool and adjacent areas thereof generated by welding the vacuum electron beam are continuously oscillated to a certainextent, so that the cavity type defects such as the air hole, the cold laps and the like can be effectively eliminated in the process of welding to obtain high quality welding joints.

Owner:CHONGQING UNIV OF TECH

Electric welding technology

InactiveCN101148004ADoes not affect welding qualityWelding quality is not affectedWelding apparatusSlagEngineering

The electric welding process with simple welding slag elimination includes the steps of painting mixture fluid comprising double ground powder and water to the areas around welded parts in the workpieces, air drying, welding and eliminating welding slag. The mixture fluid comprising double ground powder with coarse whiting as the main component and water in the weight ratio of 1 to 100-1000 can form one coating on the surface of the welded workpieces, and the coating not affected by the welding slag makes the welding slag no smelting to the areas around welded parts in the workpieces and easy to eliminate. The present invention has greatly raised production efficiency.

Owner:陈竹年

Welding device for impeller machining for fan accessory machining

ActiveCN113601096ARealize rotation transpositionAchieve weldingWelding/cutting auxillary devicesAuxillary welding devicesImpellerElectric machinery

The invention discloses a welding device for impeller machining for fan accessory machining. The welding device comprises a machining table, a machining groove is formed in the upper end of the machining table, a rotating column is rotationally connected to the bottom of the interior of the machining groove, a rotating table is fixed to the side wall of the rotating column, a threaded hole is formed in the top of the rotating column, and a positioning column is in threaded connection with the top of the rotating column; and a rack is fixed to the upper end of the machining table, a motor is fixed to the top of the rack, a rotating shaft is fixed to an output shaft of the motor, a push rod is fixed to the bottom of the rotating shaft, a pressing plate is fixed to an end of the push rod, and a protective sleeve is fixed to the inner top of the rack. The welding device has the advantages that the welding angle and the angle interval of two blades are obtained by accurately controlling the blades, so that the accuracy of blade welding machining is guaranteed, the product quality is improved, meanwhile, the labor intensity and difficulty of workers are reduced, and the overall machining efficiency is higher.

Owner:南通通惠风机有限公司

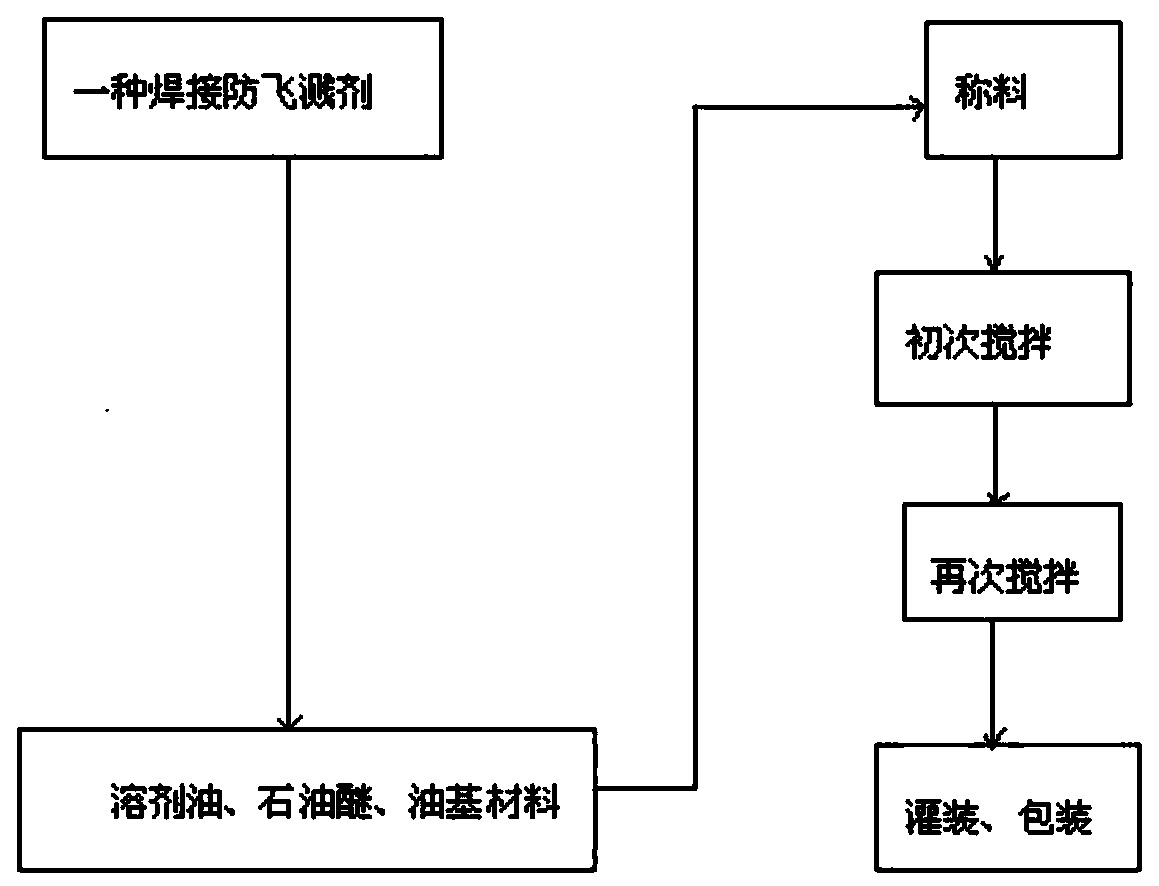

Welding spatter prevention agent and preparing method

ActiveCN111250898AReduce adhesionFree from grinding damageWelding/cutting media/materialsSoldering mediaSlag (welding)Naphtha

The invention discloses a welding spatter prevention agent. The welding spatter prevention agent comprises 25 parts of solvent naphtha, 5 parts of petroleum ether and 70 parts of oil-based materials per centum, wherein the base-based materials are lubricating oil, the above raw materials are subjected to high-temperature blending and stirring, and the agent is obtained. A preparing method of the welding spatter prevention agent comprises the five procedures of weighing, primary stirring, secondary stirring, filling and packaging. When the agent is used, a user directly sprays the agent to thesurface of a non-welding surface, due to the fact that the oil-based materials that is the lubricating oil are used as the main raw materials, the oil-based materials can effectively form an isolationfilm between welding slag and the object surface, adhesive power between the welding slag and the object surface can be reduced, and the welding slag is prevented from being bonded on the object surface. Convenience is brought to the welding work, labor intensity of a worker is reduced, work efficiency and product fineness can be improved, dust and noise pollution can be reduced, and on the basis, the agent has the good application prospect.

Owner:柯福(上海)化工科技有限公司

Welding flange device for producing automobile parts

ActiveCN110293328ASolve positioningSolve the problem of inconvenient retrievingWelding/cutting auxillary devicesAuxillary welding devicesMotor vehicle partEngineering

The invention discloses a welding flange device for producing automobile parts. The device comprise a bottom plate, wherein a welding robot is fixedly connected to the left side of the top of the bottom plate; a shell is fixedly connected to the right side of the top of the bottom plate; a sliding device is arranged at the bottom of the inner cavity of the shell; and a driving device is arranged at the left side of the inner cavity of the shell. According to the welding flange device, the bottom plate, the welding robot, the shell, the sliding device, the driving device, a stabilizing device,a baffle, a cylindrical rod, a bearing seat, a moving column, a moving plate and a pneumatic chuck are mutually matched, so that the advantages of good positioning effect, convenience in material taking and the like are achieved, and the problems of poor positioning effect and inconvenience in material taking of an existing welding flange device are solved; and when people weld a flange piece anda connecting pipe, the device can be accurately calibrated, deviation during welding does not exist, the welding quality is not affected, and the device is more convenient to use.

Owner:盐城市韩景汽车配件有限公司

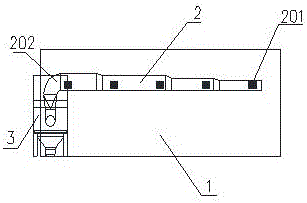

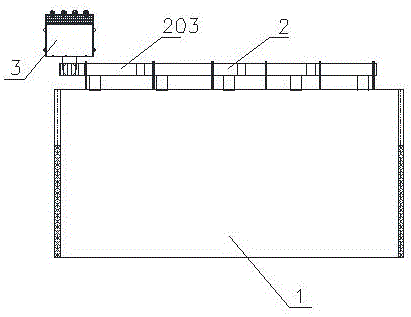

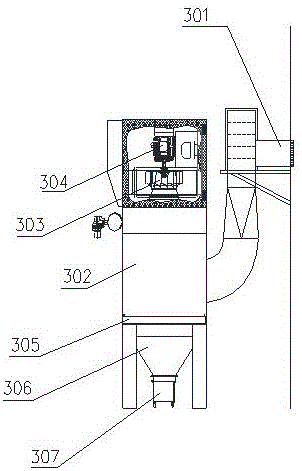

Telescopic room welding fume purification system

The invention discloses a telescopic room welding fume purification system which is characterized by comprising a telescopic gantry type framework structure, a dust absorption structure and a filter cylinder dust removing device. The framework structure covers a whole welding station, one surface of the framework structure is fixed, the dust absorption structure is arranged on the fixed surface side of the framework structure, the distance between the dust absorption structure and the ground is 2.5-3.5m, the dust absorption structure is provided with a plurality of exhaust openings, the exhaust openings are formed in the fixed surface side of the framework structure and cover the inside of a framework, and an air outlet of the dust absorption structure is connected with the filter cylinder dust removing device. The telescopic room welding fume purification system has the advantages that the system is simple to manufacture, low in cost and short in period, use space can shrink or expand according to requirements, use of a top crane cannot be affected, 90% of space of the welding station is closed, welding fume is difficult to overflow, dust collection effect is good, lighting is not affected, welding efficiency and welding quality are not affected, and the system is simple to operate.

Owner:合肥盖特工程设备制造有限公司

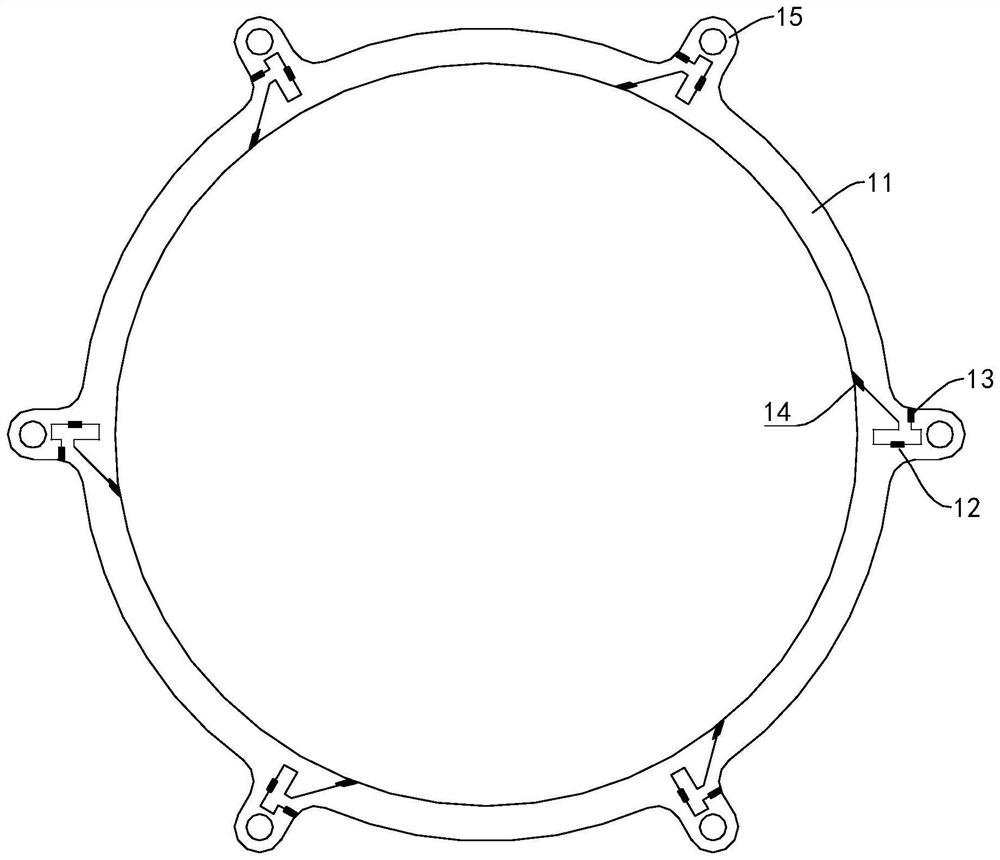

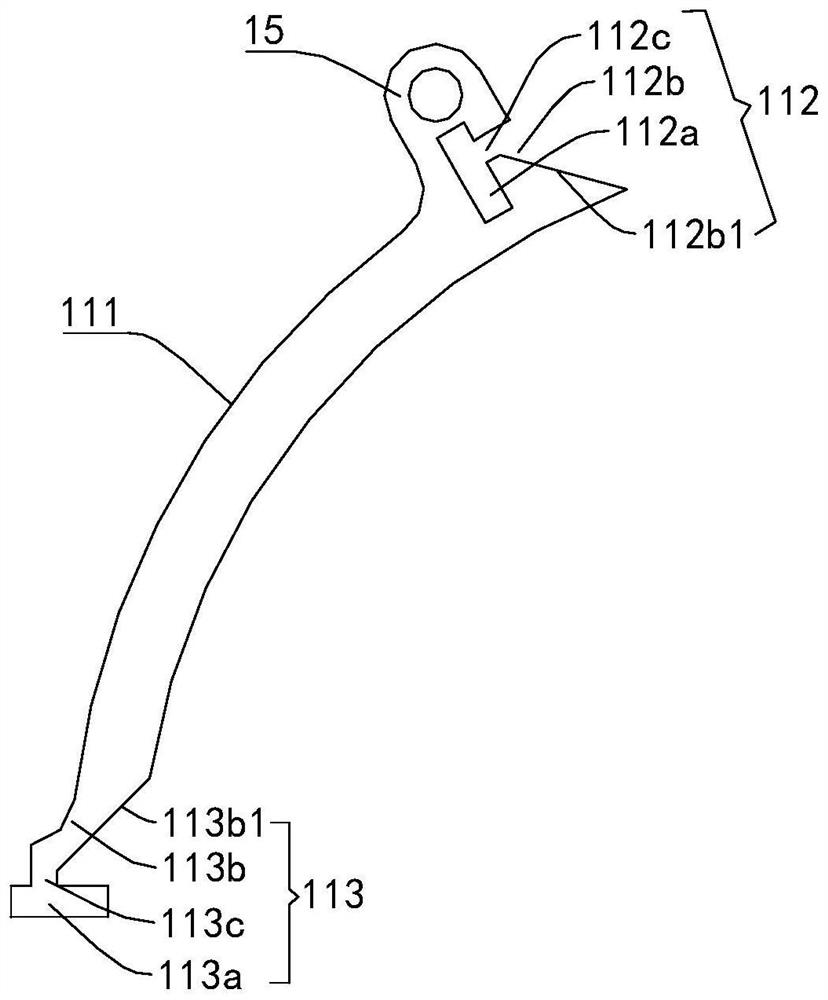

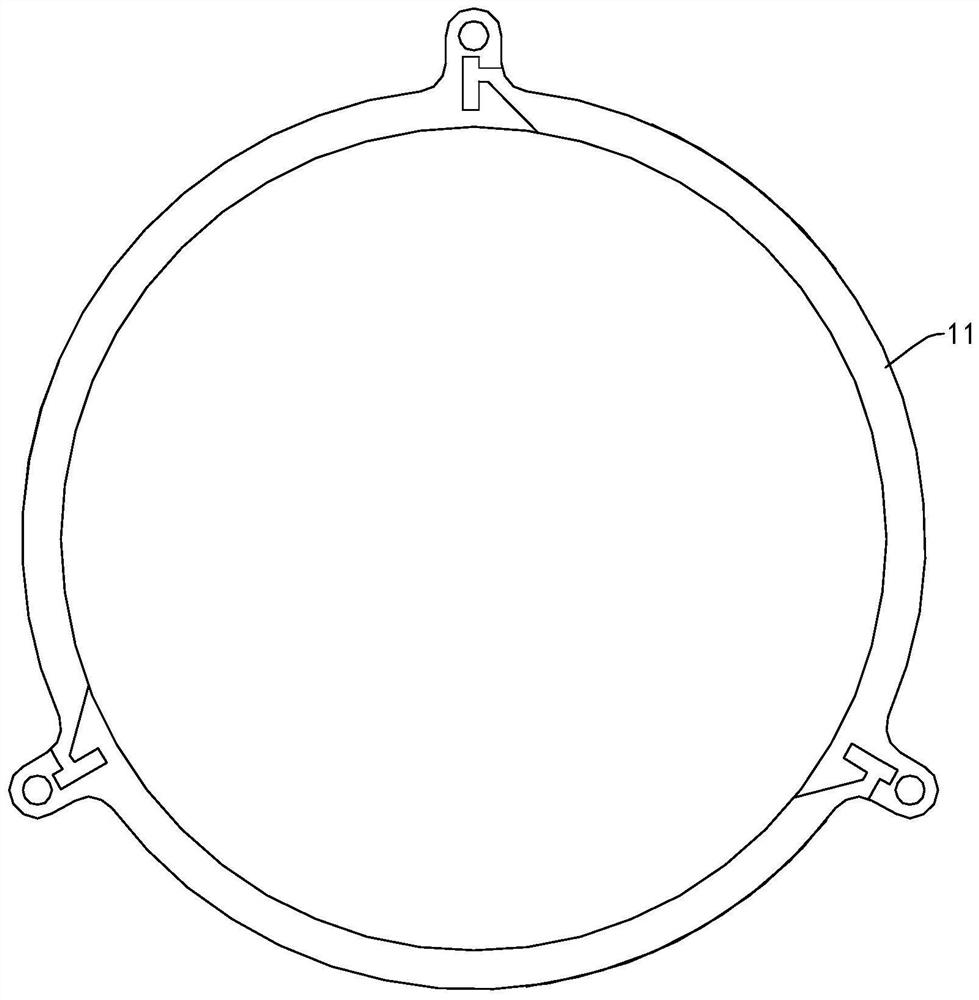

Planar embedded annular structure and manufacturing process thereof

ActiveCN113336410AImprove stabilityImprove reliabilitySludge treatmentProduct inspectionManufactured material

The invention provides a plane embedded annular structure and a manufacturing process thereof. The plane embedded type annular structure comprises a plurality of arc section units, wherein the arc section units are sequentially connected end to end to form the annular structure, each arc section unit comprises an arc section main body, one end of each arc section main body is provided with a special-shaped splicing opening part, the other end of each arc section main body is provided with a special-shaped splicing block part matched with the corresponding special-shaped splicing opening part, the special-shaped splicing opening parts and the special-shaped splicing block parts of the adjacent arc section units are spliced, and a plurality of welding points are arranged at the splicing positions of the special-shaped splicing opening parts and the special-shaped splicing block parts, so that the special-shaped splicing opening parts and the special-shaped splicing block parts can be welded at the welding points. The invention discloses a manufacturing process of a plane embedded type annular structure. The manufacturing process comprises the steps of raw material detection, plate flattening, nesting programming, cutting, product inspection, splicing assembly, laser welding and product flattening. According to the invention, the utilization rate of raw materials is increased, the precision and planeness required by the annular structure in the spiral dehydrator are guaranteed, and the stability is high.

Owner:成都环能德美环保装备制造有限公司

Welding equipment for continuous splicing of plates and welding method thereof

InactiveCN113857756AEasy to moveIncreased flatness requirementsWelding/cutting auxillary devicesAuxillary welding devicesWeld strengthPortal frame

The invention discloses welding equipment for continuous splicing of plates, and belongs to the technical field of welding equipment. According to the key point of the technical scheme, the welding equipment comprises a welding table top, pressing devices and a welding device, and a welding groove hole is formed in the middle of the welding table top; the pressing devices are arranged on the two sides of the welding groove hole and correspond to the plates, each pressing device comprises a pressing seat, a pressing air cylinder, a pressing piece and a guide sleeve, the pressing air cylinders are installed on the pressing seats, the pressing pieces are installed on telescopic rods of the pressing air cylinders, and the guide sleeves are installed on the pressing seats and matched with the telescopic rods of the pressing air cylinders; and the welding device comprises a first welding machine head, a second welding machine head and a portal frame, the first welding machine head is arranged above the plates, and the second welding machine head is arranged below the plates. According to the welding equipment, the two sides of plate gaps are welded, and the welding strength between the plates is improved.

Owner:浙江九树机械有限公司

Motorcycle installation support connecting structure

InactiveCN103171648ADoes not affect welding qualityPrecise positioningCycle standsSoftware engineeringFlanging

The invention discloses a motorcycle installation support connecting structure. The motorcycle installation support connecting structure comprises an installation support plate and support rods. Flanging mechanisms are arranged on two sides of the installation support plate; the support rods are two tubing parts which are respectively located on the inner sides of the flanging mechanisms of the two sides of the installation support plate, and the installation support plate is welded and connected with the support rods; the front end of the installation support plate is provides with a flanging, and two round through holes are formed in two edges of the flanging; a rectangle boss is arranged on the upper portion of the installation support plate, the boss is in a stamping-notching structure, and one side of the boss is integrated with the installation support plate. Due to the fact that the flanging mechanisms of two sides of the installation support plate are tightly pasted and welded with an installation support, and welding seams are located on the inner sides, welding quality is not influenced, and positioning is easy to conduct; the stamping-notching structure, namely, a notch-bending structure is adopted to manufacture integrated parts by a boss structure, materials are saved, molding process is simplified, production efficiency is improved, production cost is reduced, and safety performance is improved.

Owner:万李

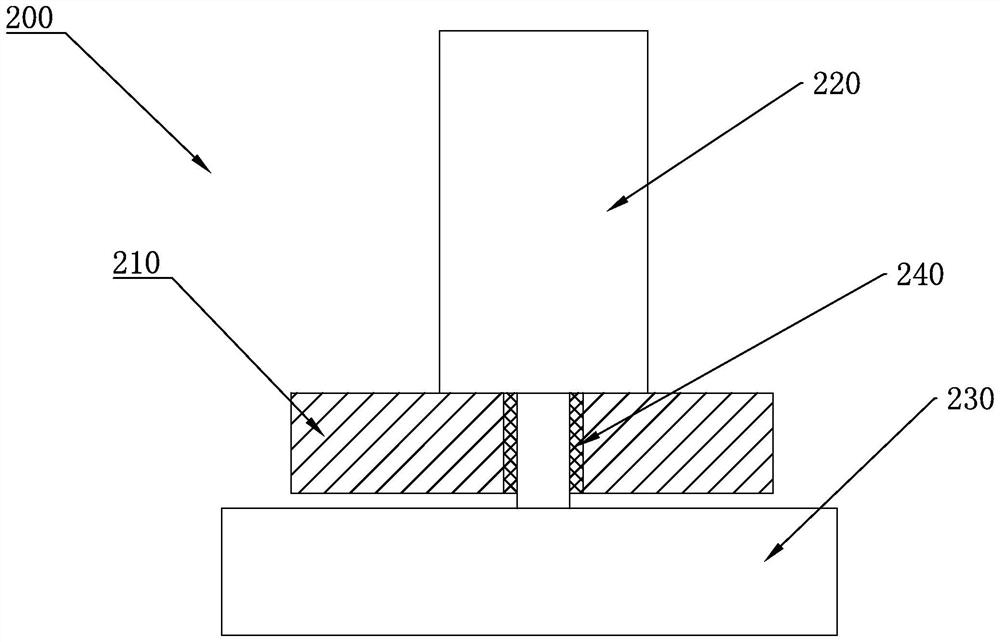

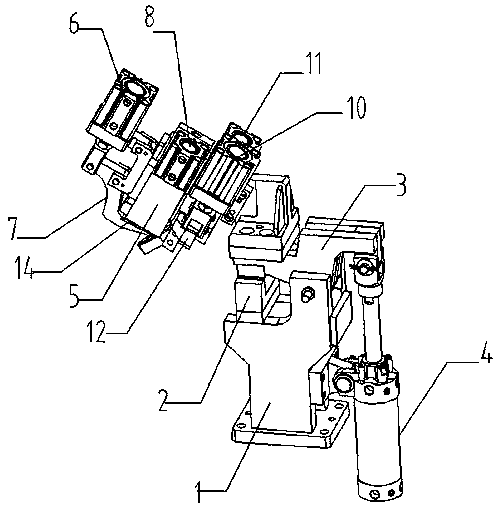

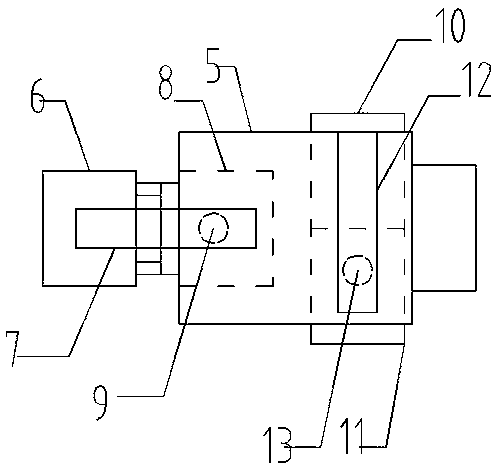

Clamping mechanism of cross beam welding fixture

InactiveCN110814614AEnough pressureEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringPhysics

The invention provides a clamping mechanism of a cross beam welding fixture. The clamping mechanism comprises a base, wherein a fixture block is arranged on the left side of the upper end of the base;the right side of the upper end of the base is connected with a rotating arm through a shaft pin; an overturning cylinder is arranged on the right side of the base; the left side of the overturning cylinder is connected with the base through a shaft pin; the upper end of the overturning cylinder is connected with the right end of the rotating arm through a shaft pin; the left end of the rotatingarm is connected with a mounting plate; a first cylinder is arranged on the left side of the mounting plate; the lower end of the first cylinder is connected with a first pressing arm through a shaftpin; a second cylinder is arranged in the middle of the mounting plate; the lower end of the second cylinder is connected with a first pressing point; a third cylinder and a fourth cylinder are arranged on the right side of the mounting plate; the third cylinder is arranged on the front side of the fourth cylinder; the lower end of the third cylinder is connected with a second pressing arm througha shaft pin; and the lower end of the fourth cylinder is connected with a second pressing point. The clamping mechanism is scientific and reasonable in structural design, simple in structure, convenient to use, accurate in positioning, reliable in clamping and convenient to use.

Owner:WUHU POWER TECH

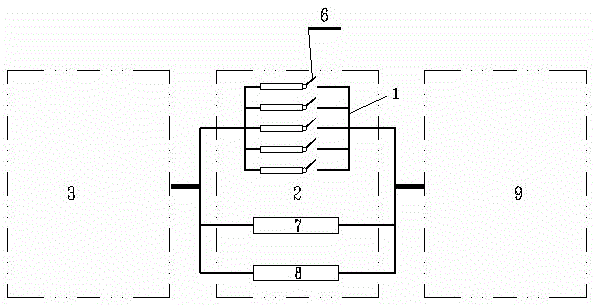

A live welding compensation device under full current for aluminum electrolytic cell series

ActiveCN103806015BReduce magnetic fieldVersatileWelding/cutting auxillary devicesAuxillary welding devicesAluminium electrolysisTotal current

The invention discloses a current drainage compensating device with a variable resistance adjustment function when welding a cathode steel rod with electricity under the full current of a series of aluminum electrolytic cells. Drainage magnetic compensation device (1) acts as a draining conductor, connecting the anode busbar (4) of the overhaul electrolyzer (2) and the column busbar (5) of the downstream electrolyzer, so that part or all of the series current does not pass through the overhaul electrolyzer (2) It itself or the bottom of the tank short-circuits the busbar (8), but directly enters the downstream electrolytic tank (3) through the magnetic compensation device (1). One or more sets of current-carrying switches are set on the current-draining magnetic compensation device (1). By closing and opening the switches, the resistance of the current-draining magnetic compensation device (1) is changed to adjust its current flow, so as to achieve the purpose of controlling the magnetic field in the target area. , the invention shortens the welding operation time, simplifies the structure and process, and avoids the influence of welding on electrolytic production.

Owner:GUIYANG AL-MG DESIGN & RES INST

A welding device for impeller processing for fan accessories processing

ActiveCN113601096BRealize rotation transpositionAchieve weldingWelding/cutting auxillary devicesAuxillary welding devicesImpellerElectric machinery

Owner:南通通惠风机有限公司

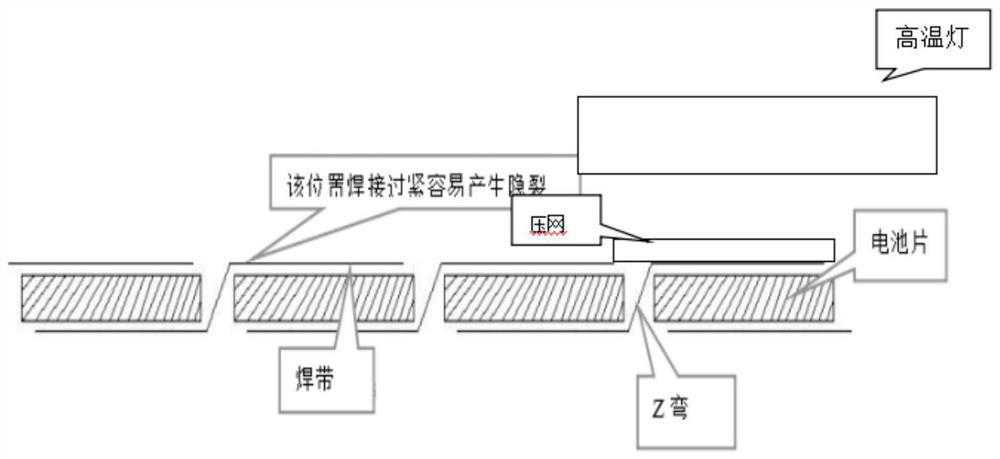

A Retrofitting Method to Solve the Too Tight Welding of Z-bend Welding Machine

Owner:HENGSHUI YINGLI NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com