Elastic anticorrosive paint and preparation method thereof

An anti-corrosion coating and elastic technology, applied in anti-corrosion coatings, conductive coatings, polyester coatings, etc., can solve problems such as air pollution, lack of timely maintenance, fire, etc., achieve long-term anti-corrosion life, efficient and convenient construction, and ensure long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

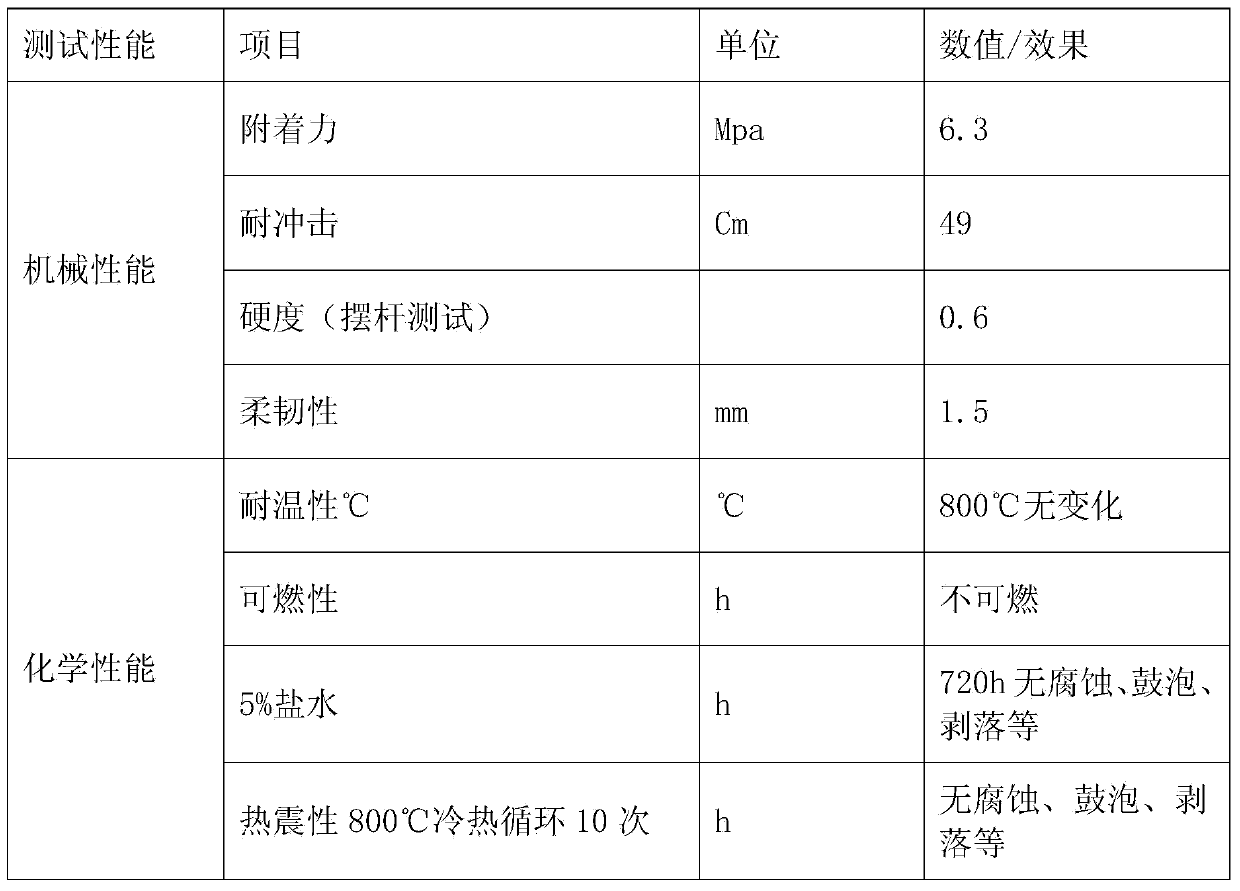

Embodiment 1

[0037] The present embodiment provides a kind of elastic anticorrosion paint, and its composition comprises the following components by mass percentage:

[0038] Toughener: 6%

[0039] Polyorganosiloxane: 39%

[0040] Filler: 25%

[0041] Cross-linking agent: 5%

[0042] Thinner: 14%

[0043] Auxiliary: 5%

[0044] Sodium pyrophosphate: 1%

[0045] Sodium tripolyphosphate: 3%

[0046] Polyacrylate resin: 2%

[0047] Among them, the toughening agent is a mixture of epoxy resin, phenolic resin and unsaturated polyester resin; the filler is a mixture of zinc oxide, aluminum oxide and iron oxide; the crosslinking agent is polyacrylate; the diluent is toluene and xylene. Mixture; auxiliary agent is urea-formaldehyde resin.

[0048] The present embodiment provides a kind of preparation method of elastic anticorrosion coating, comprises following specific steps:

[0049] Step (1): Put polyorganosiloxane, crosslinking agent, diluent, additives, sodium pyrophosphate, sodium tr...

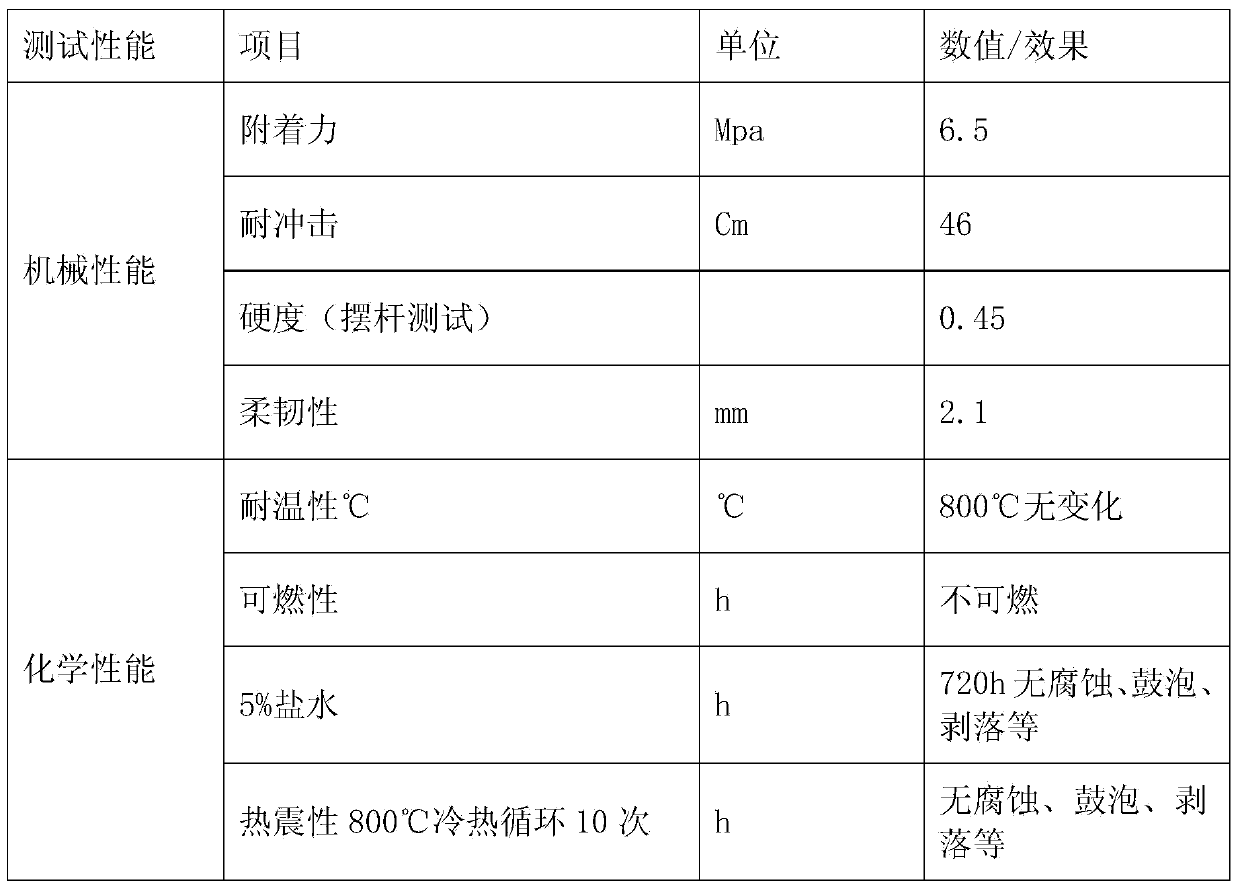

Embodiment 2

[0055] The present embodiment provides a kind of elastic anticorrosion paint, and its composition comprises the following components by mass percentage:

[0056] Toughener: 8%

[0057] Polyorganosiloxane: 30%

[0058] Filler: 25%

[0059] Crosslinker: 8%

[0060] Thinner: 13%

[0061] Auxiliary: 10%

[0062] Sodium pyrophosphate: 3%

[0063] Sodium tripolyphosphate: 1%

[0064] Polyacrylate resin: 2%

[0065]Among them, the toughening agent is unsaturated polyester resin; the filler is talcum powder; the crosslinking agent is a mixture of polystyrene diallyl phthalate resin modification and polystyrene; the diluent is n-butanol and styrene Mixture; auxiliary agent is unsaturated polyester resin.

[0066] The present embodiment also provides a method for preparing an elastic anti-corrosion coating, comprising the following specific steps:

[0067] Step (1): Put polyorganosiloxane, crosslinking agent, diluent, additives, sodium pyrophosphate, sodium tripolyphosphate and...

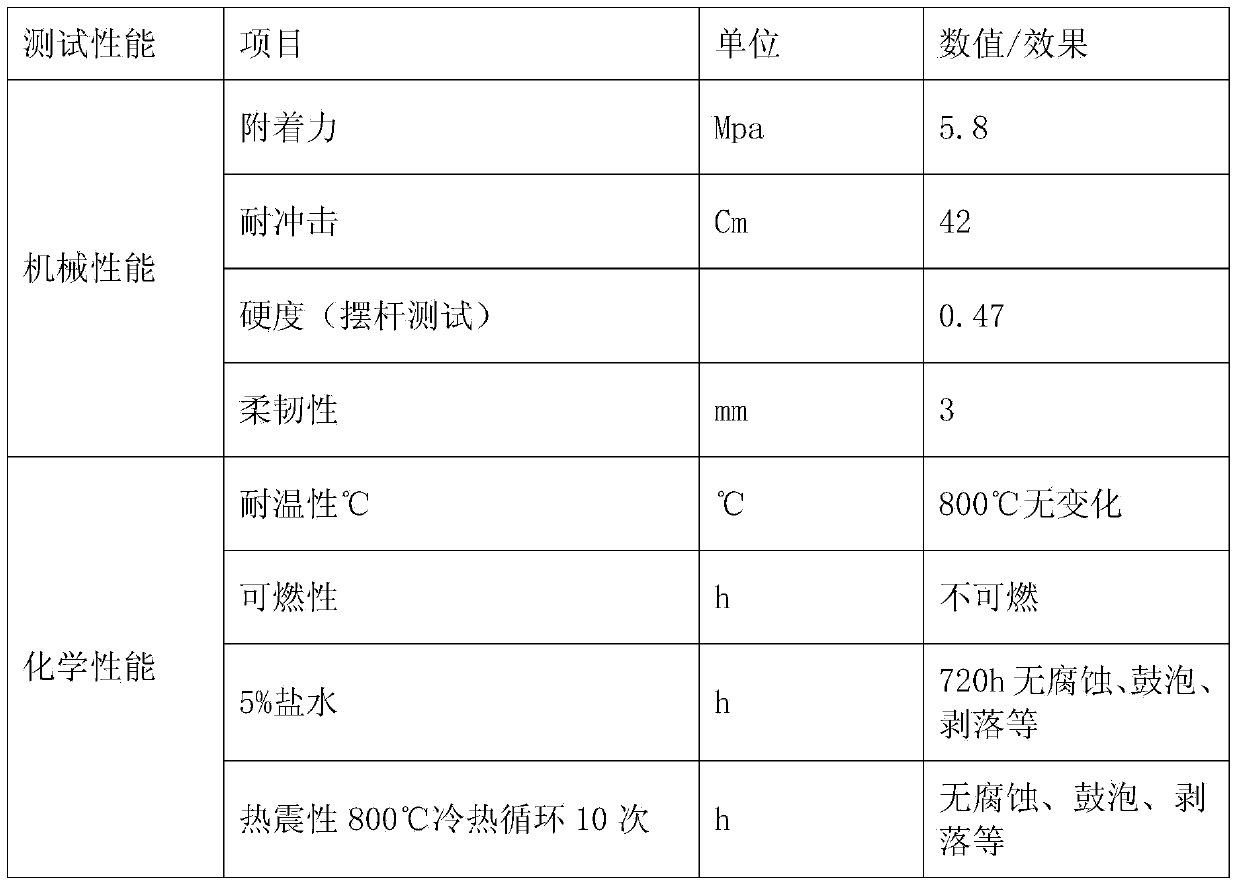

Embodiment 3

[0073] The present embodiment provides a kind of elastic anticorrosion paint, and its composition comprises the following components by mass percentage:

[0074] Toughener: 8%

[0075] Polyorganosiloxane: 32%

[0076] Filler: 35%

[0077] Cross-linking agent: 6%

[0078] Thinner: 10%

[0079] Auxiliary: 9%

[0080] Sodium pyrophosphate: 5%

[0081] Sodium tripolyphosphate: 1%

[0082] Polyacrylate resin: 4%

[0083] Among them, the toughening agent is epoxy resin; the filler is a mixture of calcium carbonate and talc; the crosslinking agent is epoxy resin; the diluent is a mixture of benzene, toluene and xylene; the auxiliary agent is phenolic resin and melamine formaldehyde resin mixture.

[0084] The present embodiment also provides a method for preparing an elastic anti-corrosion coating, comprising the following specific steps:

[0085] Step (1): Put polyorganosiloxane, crosslinking agent, diluent, additives, sodium pyrophosphate, sodium tripolyphosphate and polya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com