Welding equipment for continuous splicing of plates and welding method thereof

A technology for welding equipment and plates, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of insufficient welding strength and affect the welding quality of plates, and achieve the effect of improving stability and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

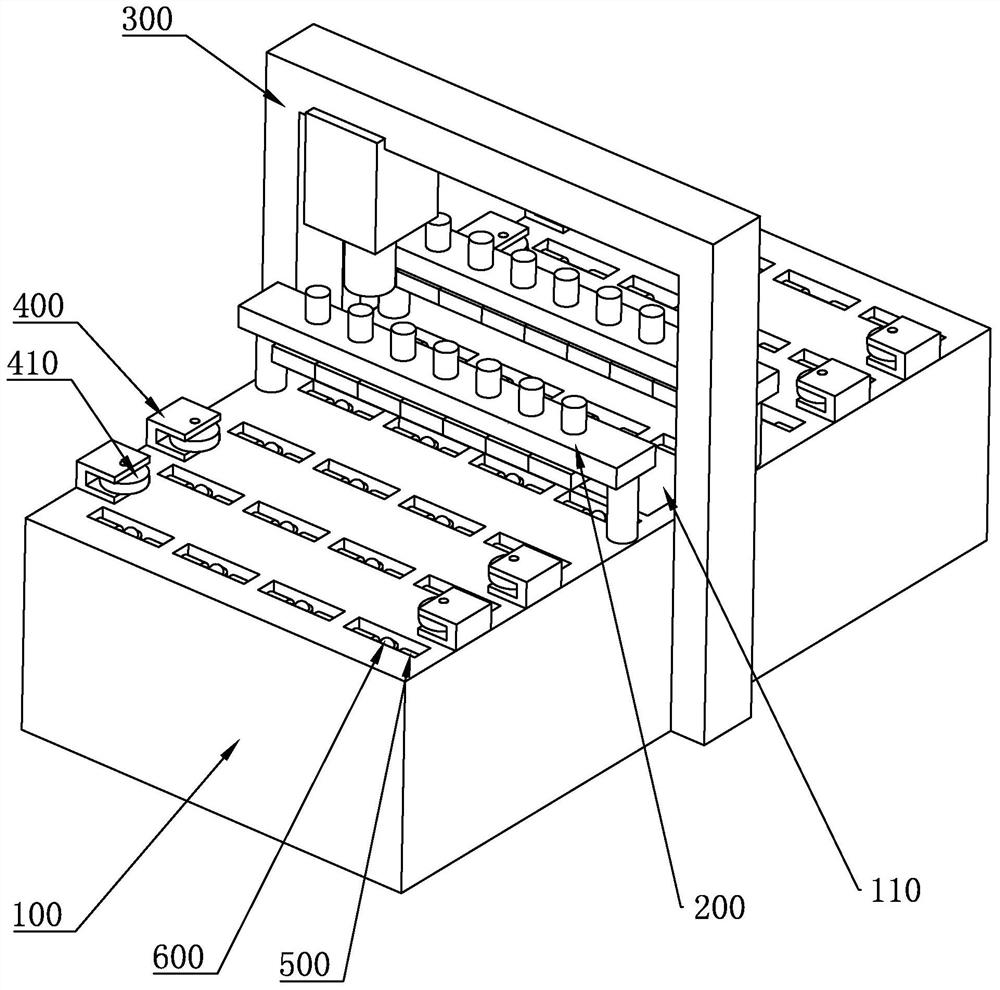

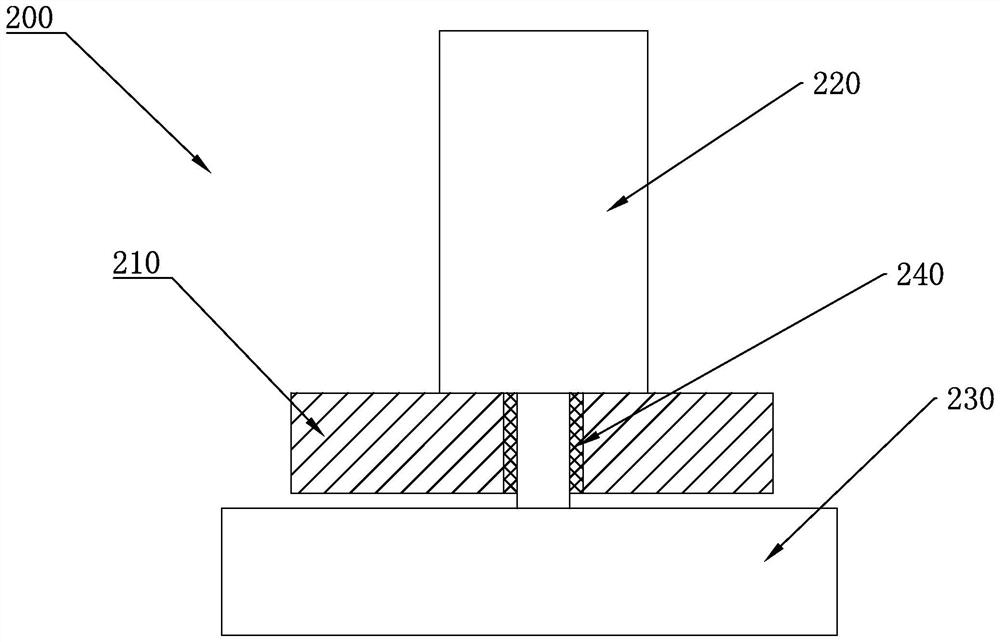

[0048] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the embodiment of the present application provides a welding equipment for continuous splicing of plates, including: a welding table 100, a welding slot 110 is provided in the middle of the welding table 100, the plate is placed on the upper surface of the welding table 100, and the plate Placed on both sides of the welding slot 110 respectively, the gap between the plates is placed above the welding slot 110; the pressing device 200, the pressing device 200 is placed on both sides of the welding slot 110 and corresponds to the plate, The compression device 200 includes a compression seat 210, a compression cylinder 220, a compression member 230, and a guide sleeve 240. The compression cylinder 220 is installed on the compression seat 210, and the compression member 230 is installed on the compression cylinder 220. The guide sleeve 240 is installed on the compression seat 210 and is adapted to the expansion r...

Embodiment 2

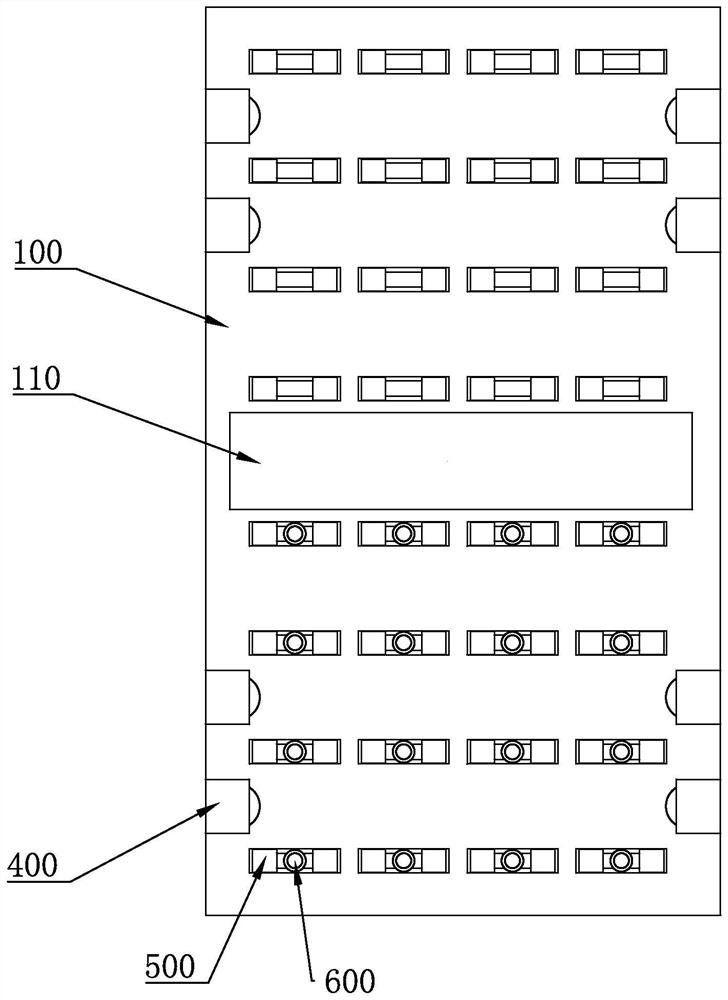

[0051] like Figure 5 As shown, the embodiment of the present application provides a welding equipment for continuous splicing of plates. In addition to the above-mentioned technical features, it further includes: a limit movable seat 400, which is placed on both sides of the welding table 100 The sides are evenly distributed; the limit roller 410, the limit movable seat 400 is connected with the limit roller 410 through a rotating shaft; the rack 420, the rack 420 is connected with the limit movable seat 400; the gear 430, the gear 430 is meshed with the corresponding two racks 420, the gear 430 rotates to drive the rack 420 to move, and when the gear 430 rotates, the corresponding limit movable seat 400 moves relatively or in the opposite direction at the same time; the drive motor 440, the drive The motor 440 is installed on the welding table 100 , and the gear 430 is installed on the output shaft of the driving motor 440 .

[0052] The limit movable seat 400 is movably inst...

Embodiment 3

[0054] like Image 6 As shown, the embodiment of the present application provides a welding equipment for continuous splicing of plates. In addition to the above-mentioned technical features, it further includes: a conveying device 500, which is evenly distributed on the welding table 100, and the The conveying device 500 includes a conveying installation seat 510, a conveying roller 520, and a hydraulic cylinder 530. The conveying roller 520 is connected to the conveying installation seat 510 through a bearing, and the hydraulic cylinder 530 is placed between the conveying installation seat 510 and the welding table 100. ; the adjustment device 600, the adjustment device 600 is placed on one side of the welding slot 110, and is movably installed on the delivery installation seat 510, the adjustment device 600 drives the plate to move, and adjusts the size of the gap between the two plates; , the delivery installation seat 510 is provided with an installation groove 511 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com