Energy-storage arc pulling type spindle welding machine

A stud welding machine and drawn arc technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increasing product weight and volume, increasing use restrictions, high manufacturing costs, etc., and achieve weight reduction and volume, reduce welding cost, and fast rising speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

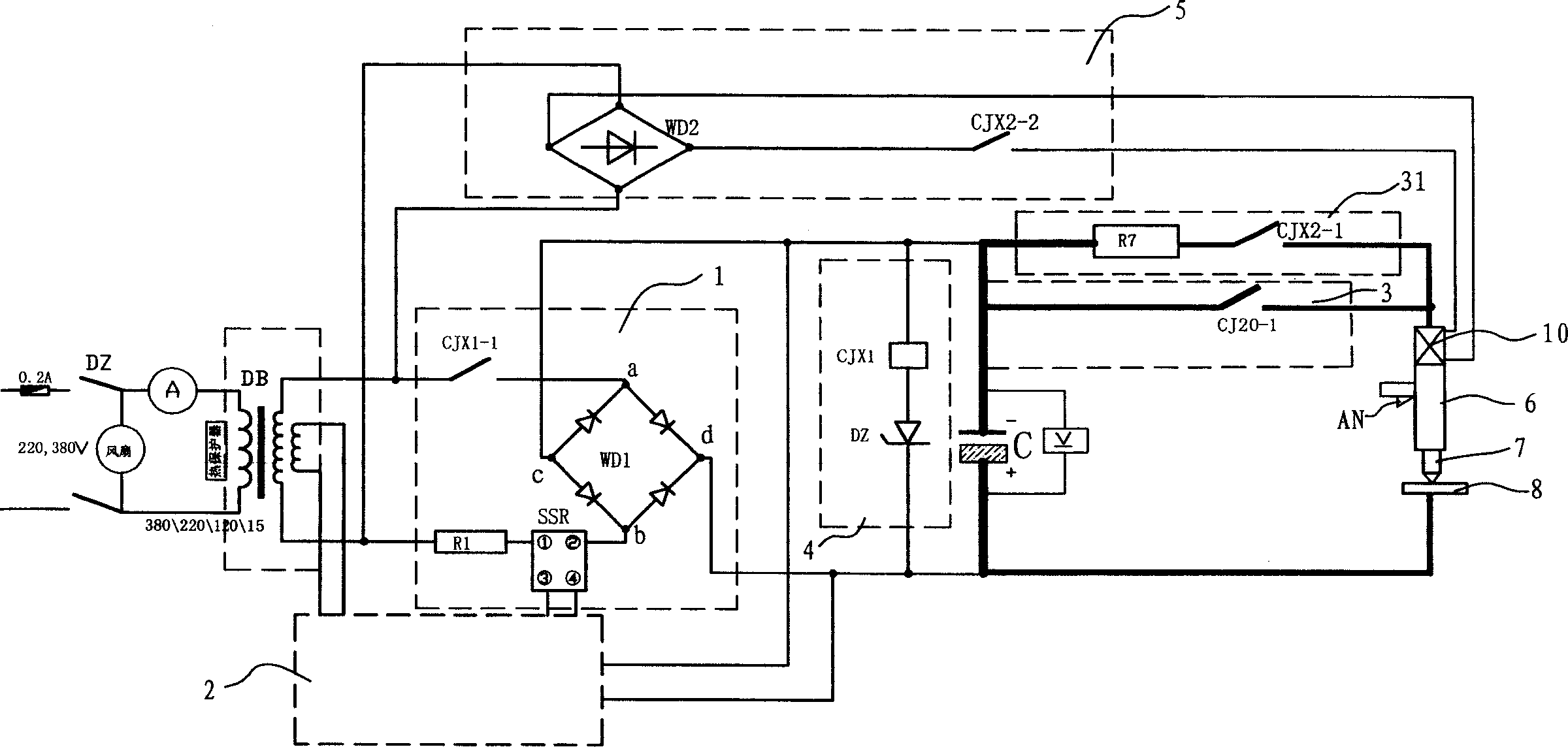

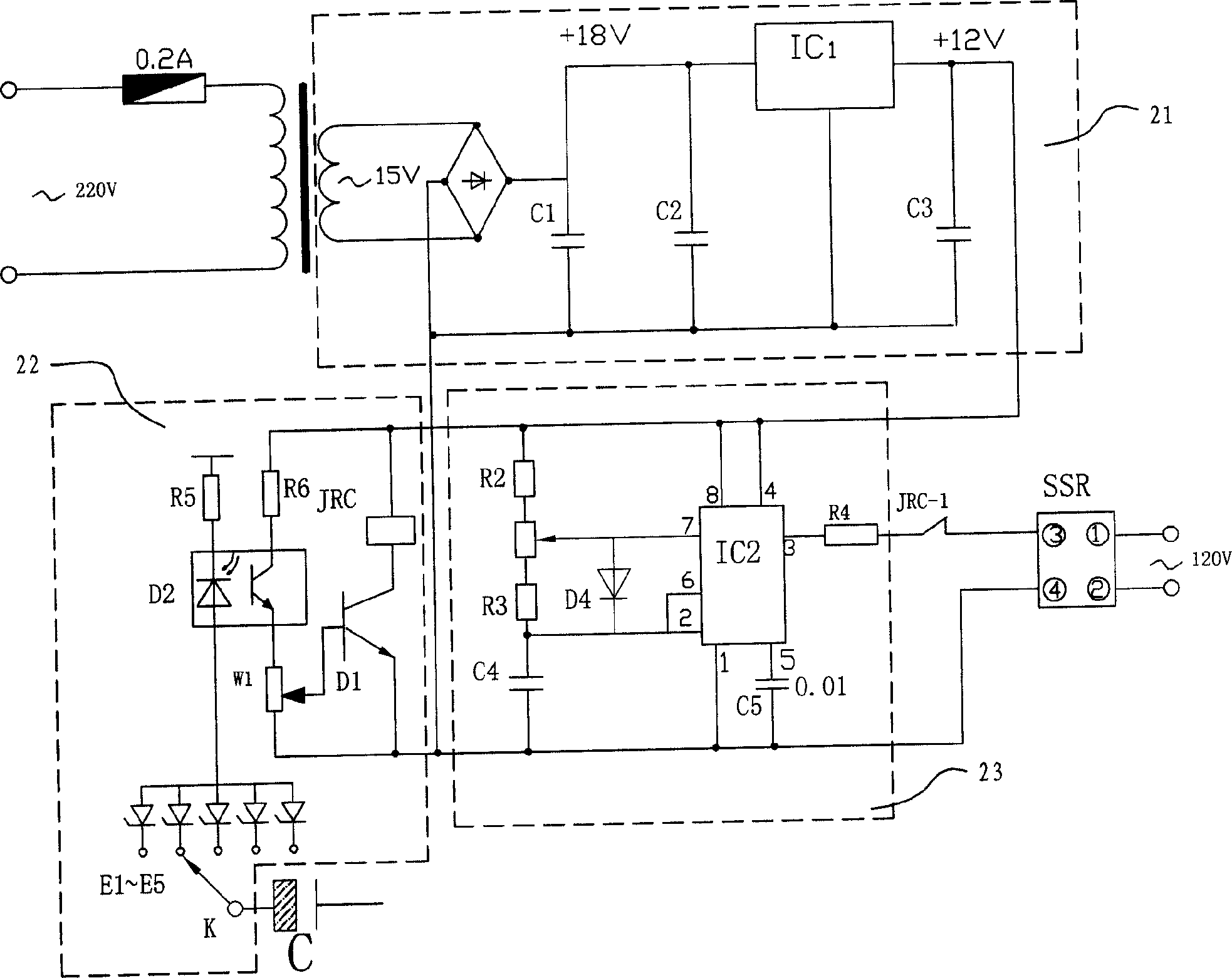

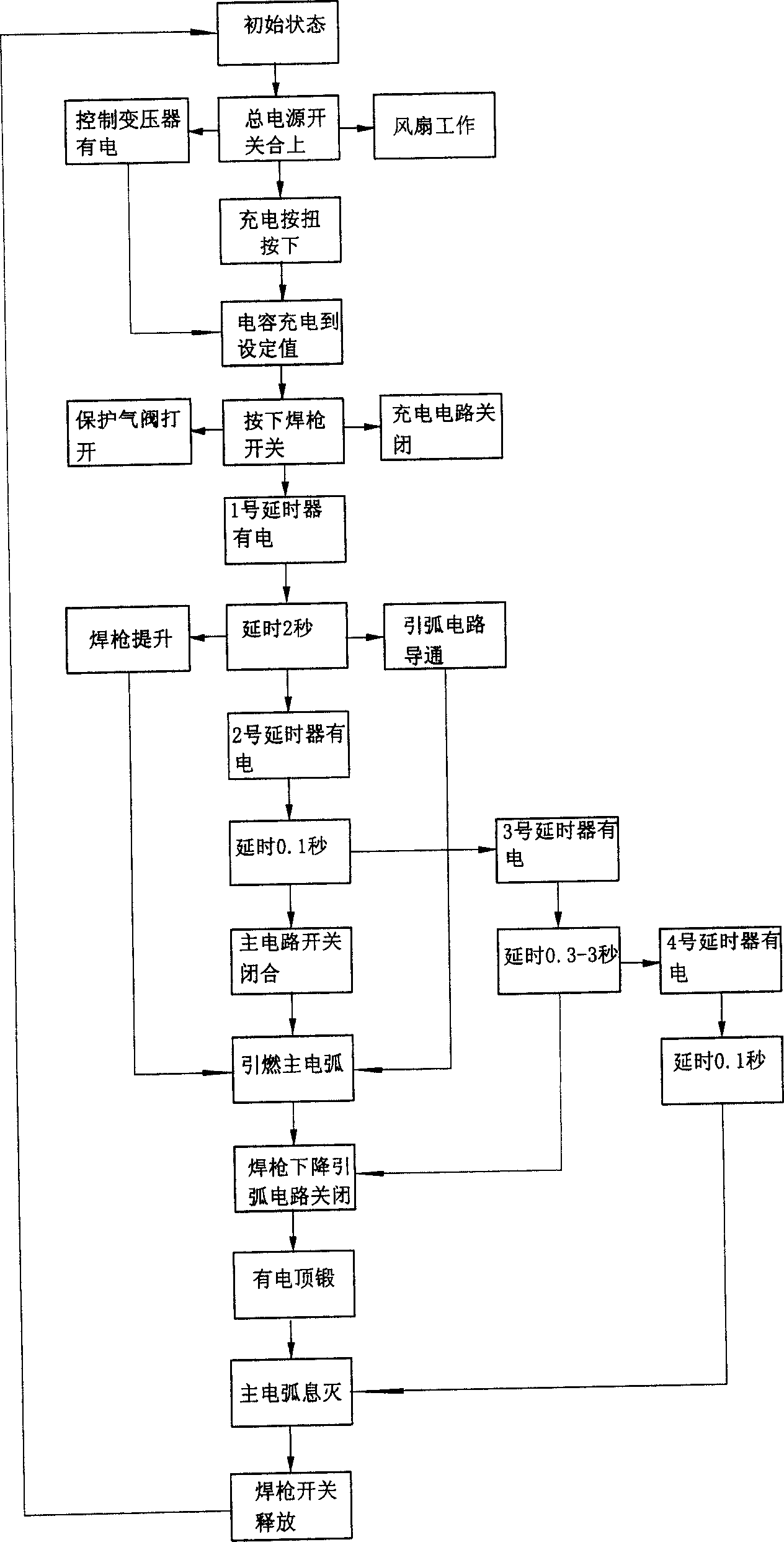

[0025] Example: Reference figure 1 , The energy storage drawn arc stud welding machine in the present embodiment includes a casing 200, a welding torch 6, a transformer DB, a control panel 201 and an internal circuit composed of electrical components. The internal circuit includes a welding torch circuit 5, a rectifying and charging circuit 1, Discharge circuit 3 , protection circuit 4 , pilot discharge circuit 31 , control module 2 and supercapacitor C.

[0026] The welding torch circuit 5 includes a rectifier bridge WD2 and a first normally closed contact CJX2-1 of the third relay CJX2, and the discharge circuit 3 includes a first normally closed contact CJ20-1 of the first relay CJ20.

[0027] The rectification and charging circuit (1) includes a normally closed contact CJX1-1 controlled by the second relay CJX1, a solid state relay SSR, a rectifier bridge WD1 and a first current limiting resistor R1, and the first input terminal a of the rectifier bridge WD1 is connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com