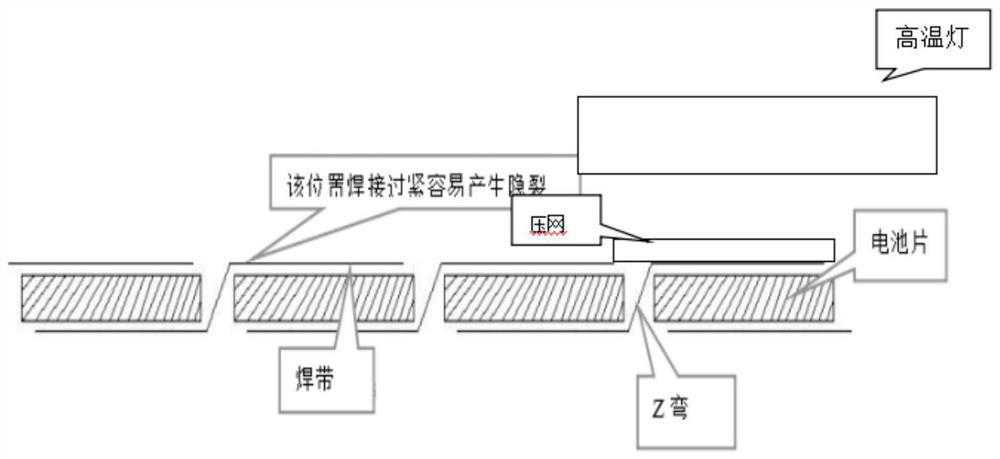

A Retrofitting Method to Solve the Too Tight Welding of Z-bend Welding Machine

A welding machine and over-tightening technology, applied in the field of welding, can solve the problems of material fatigue and poor toughness, and achieve the effects of small radiation surface, stable cooling effect and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

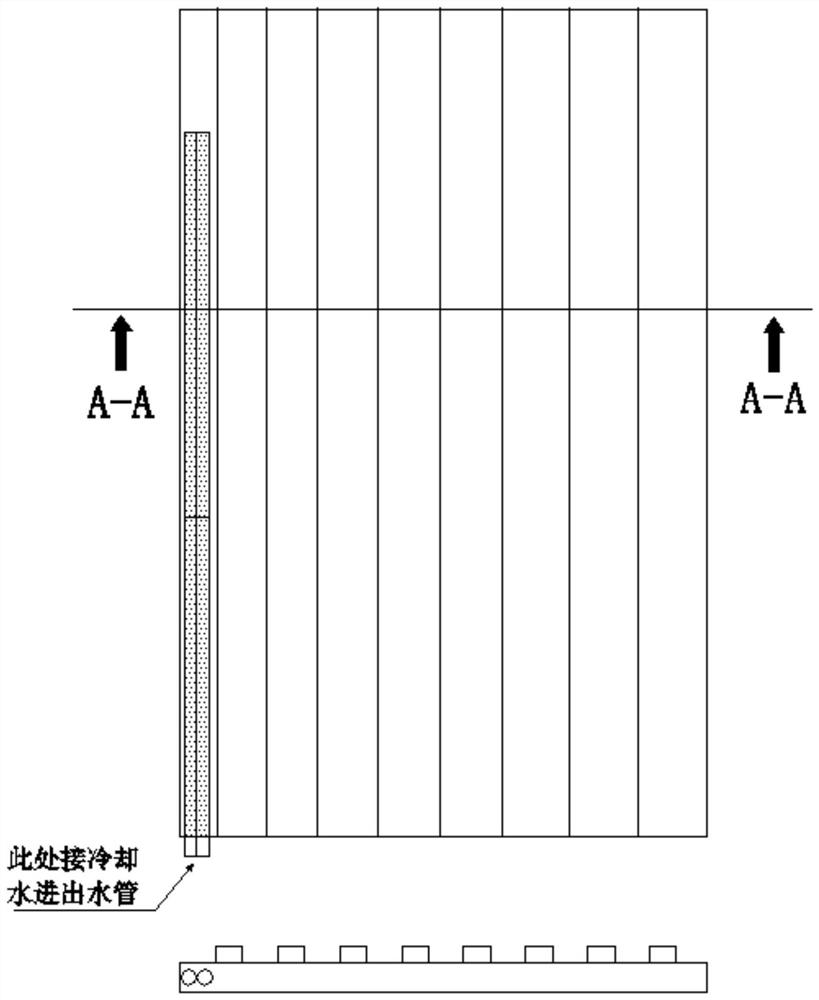

[0020] according to figure 2 As shown, this embodiment proposes a transformation method to solve the excessively tight Z-bend welding of the welding machine, including the following steps:

[0021] Step 1: Design a thin-walled copper tube of Φ4mm*560mm. The thin-walled copper tube is cast from red copper. Finally, the thin-walled copper tube is folded in half by intermediate heating to form a U-shaped thin-walled copper tube. U-shaped thin-walled copper tube The inner wall of the tube is a straight wall structure, and the wall thickness of the U-shaped thin-walled copper tube is 0.4mm;

[0022] Step 2: Transform the press net, install U-shaped thin-walled copper tubes on the upper left side of the press net, ensure that the U-shaped thin-walled copper tubes are located between the press net and the high-temperature lamp, and control the impact of the U-shaped thin-walled copper tubes on the battery An 8mm wide area is blocked where the edge of the sheet is connected to the r...

Embodiment 2

[0026] according to figure 2 As shown, this embodiment proposes a transformation method to solve the excessively tight Z-bend welding of the welding machine, including the following steps:

[0027] Step 1: Design a thin-walled copper tube of Φ4mm*560mm. The thin-walled copper tube is cast from red copper. Finally, the thin-walled copper tube is folded in half by intermediate heating to form a U-shaped thin-walled copper tube. U-shaped thin-walled copper tube The inner wall of the tube is a straight wall structure, and the wall thickness of the U-shaped thin-walled copper tube is 0.4mm;

[0028] Step 2: Transform the press net, install U-shaped thin-walled copper tubes on the upper left side of the press net, ensure that the U-shaped thin-walled copper tubes are located between the press net and the high-temperature lamp, and control the impact of the U-shaped thin-walled copper tubes on the battery An 8mm wide area is blocked where the edge of the sheet is connected to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com