Local reducing stirring head

A mixing head, local technology, applied in the field of local variable diameter mixing head, can solve the problems of affecting the quality of the weld, material overflowing the weld, intrusion of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

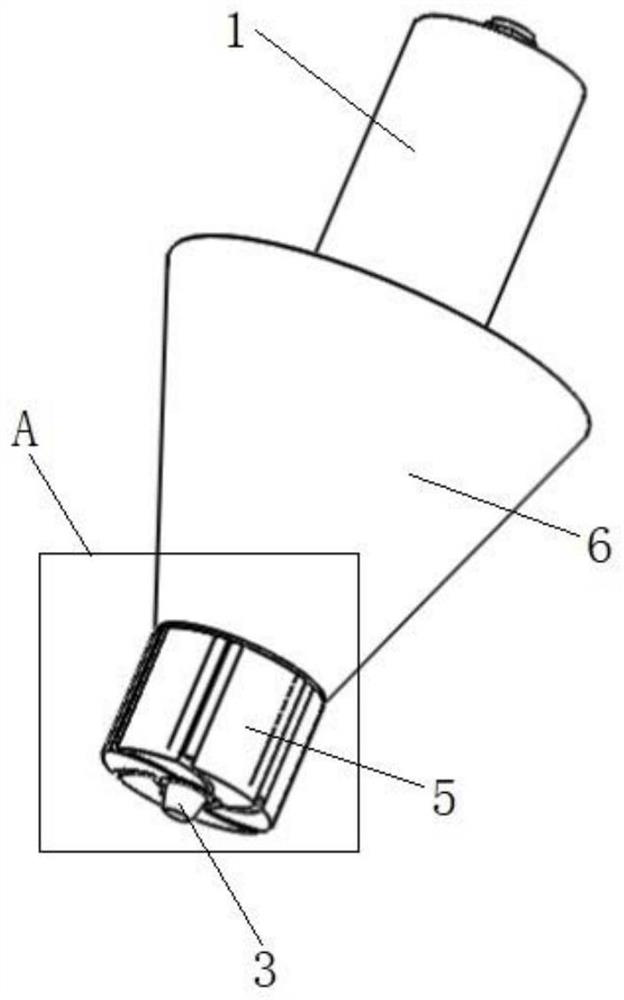

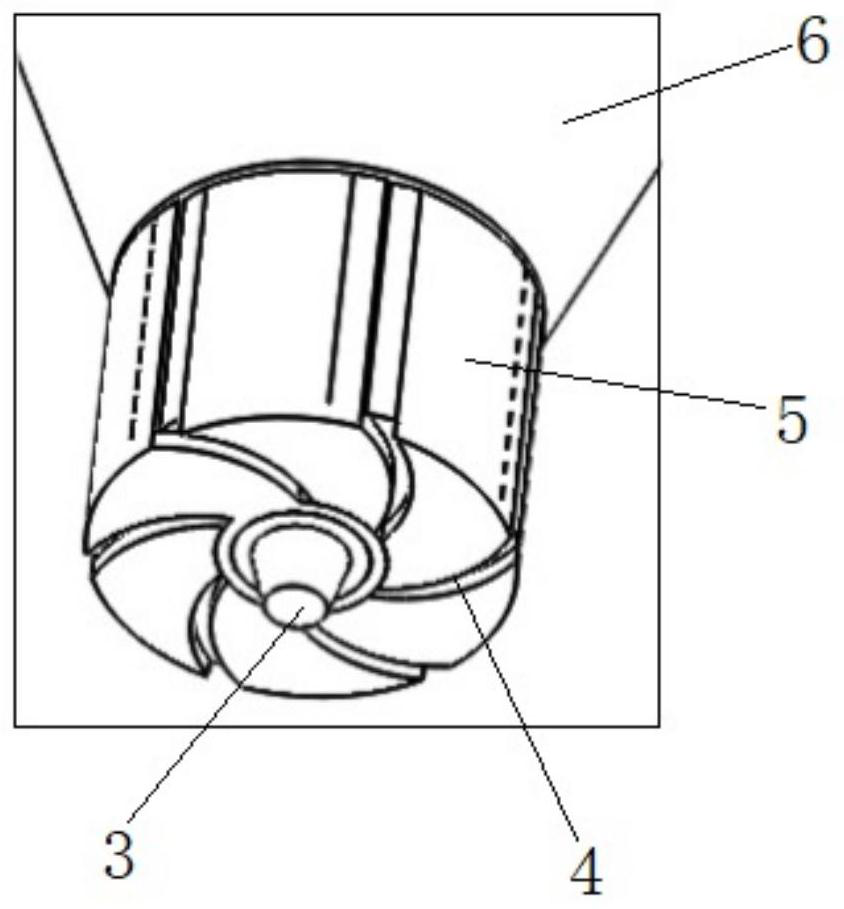

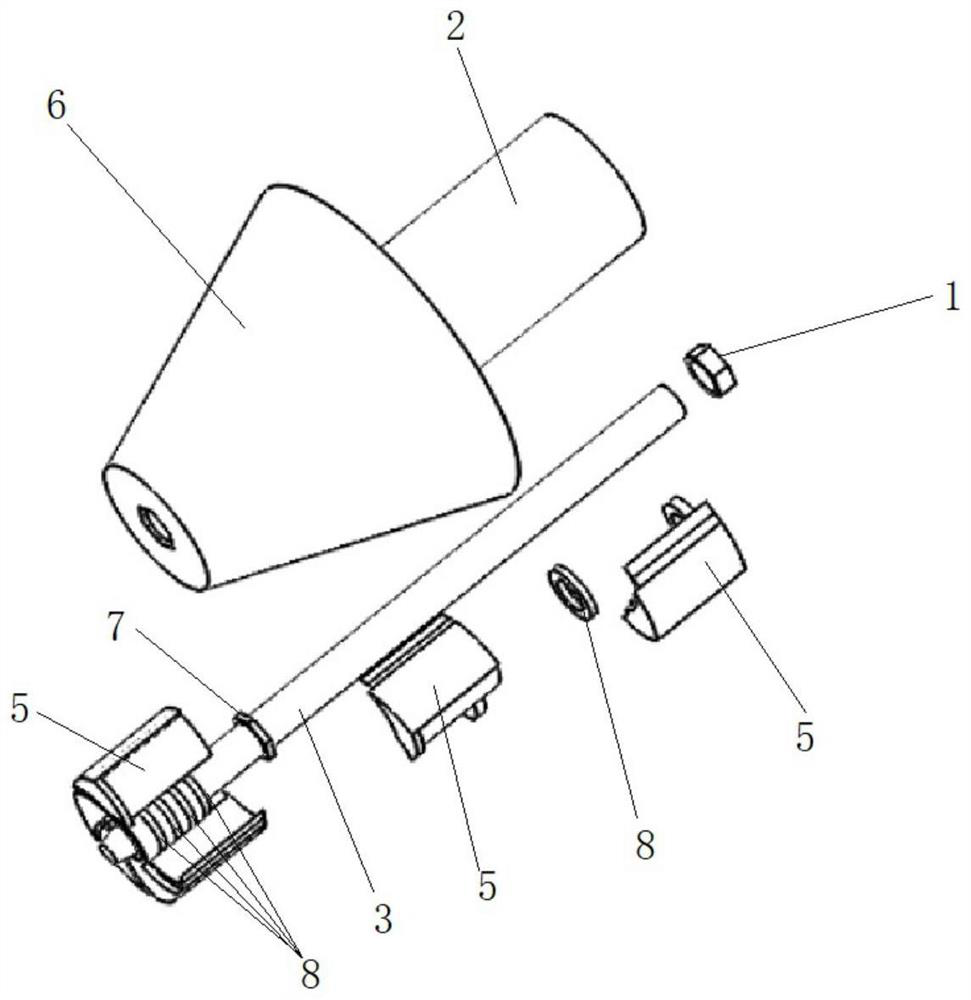

[0031] Such as Figure 1-6 As shown, this embodiment provides a partially variable-diameter stirring head, which includes a stirring needle 3, a shaft shoulder, a stirring head transition end 6 and a clamping end 2, and the shaft shoulder, the stirring head transition end 6 and the clamping end 2 Pass through the stirring pin 3 sequentially from bottom to top, and be locked and fixed by the fastening nut 1 of the stirring head as the second fastener; wherein, the shoulder includes several moving shoulder blocks 5; The moving shoulder block 5 is pivotally connected to the stirring needle with the stirring needle as a pivot, and the stirring needle plays the role of installation and positioning; the inner side of each moving shoulder block 5 has an arc-shaped surface 15, The arc-shaped surface 15 is used as a cladding surface, and it overlaps the outer side of the adjacent moving shoulder block 5. Preferably, the adjacent moving shoulder block 5 has an arc-shaped surface 15 on t...

Embodiment 2

[0039] This embodiment provides a friction stir welding equipment, including a driving motor, a main shaft and a stirring head, wherein the stirring head is the locally variable-diameter stirring head described in Embodiment 1. The friction stir welding equipment provided in this embodiment is suitable for reducing the shoulder intrusion during friction stir welding of curved surfaces, and effectively improving welding quality. When welding materials, under the action of the main shaft rotation, the stirring head rotates to generate centrifugal force, and the moving shoulder block is thrown out to reach the maximum diameter state. When the end point of the convex surface or the lowest point of the concave surface of the stirring needle as the base point, the front end of the shoulder of the stirring head touches the welding material, and the moving shoulder block is subjected to the resistance of the material to it, and the resistance counteracts the centrifugal force and shrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com