Large-diameter pipeline welding device

A welding device and large-diameter technology, which is applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of damage to the level of splicing, damage of solder joints or pre-welding, and short welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

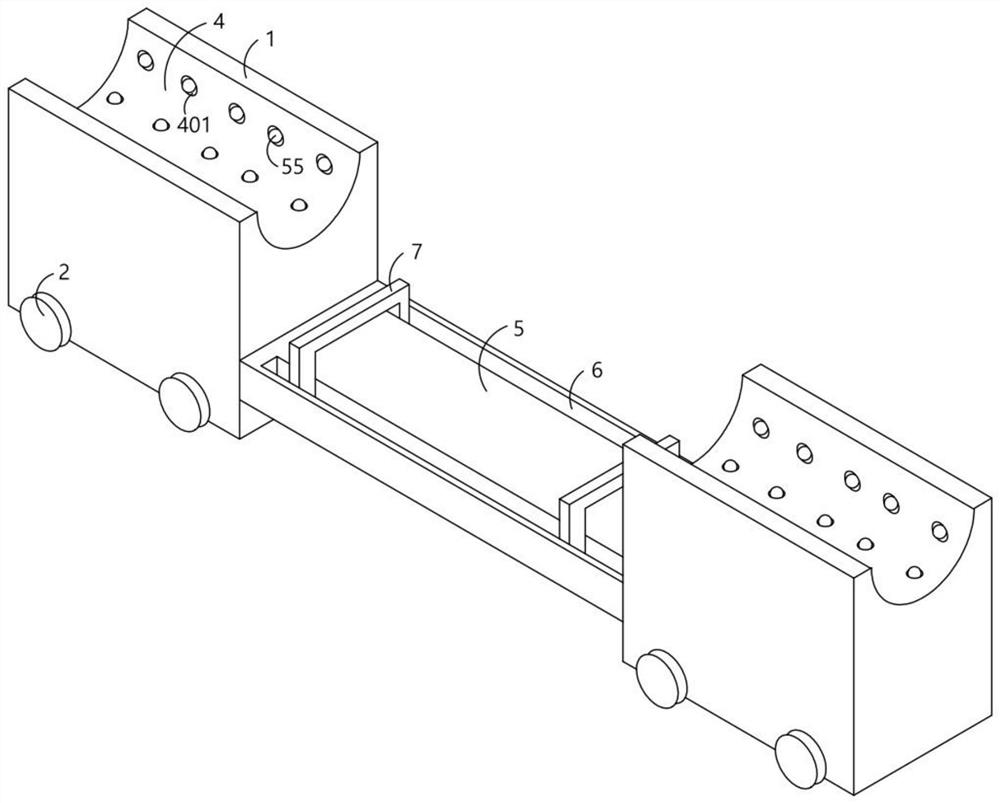

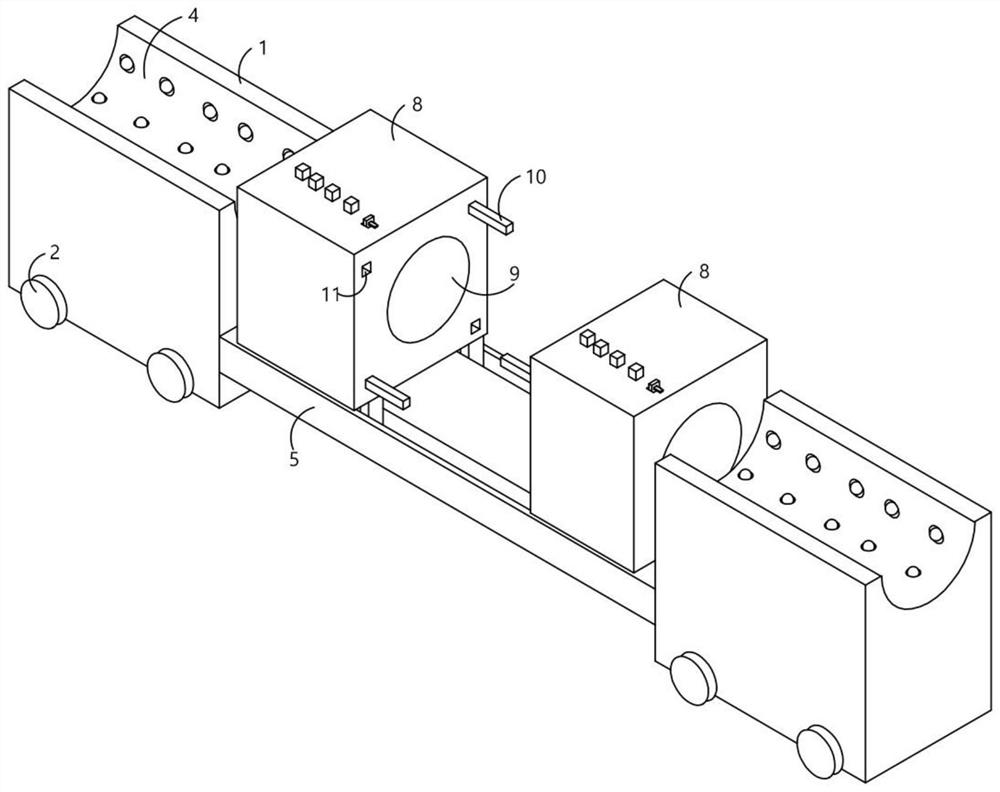

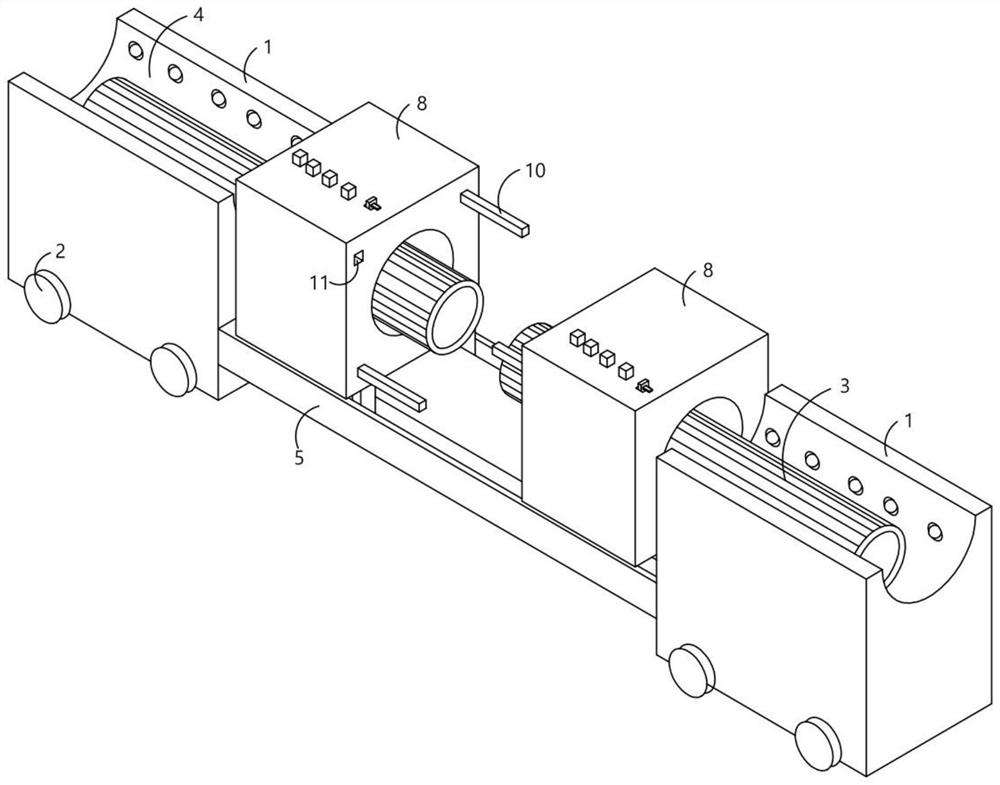

Embodiment 1

[0039] A large-diameter pipeline welding device, comprising two placing tables 1, the placing table 1 is used for placing the pipeline 3, the two placing tables 1 in this embodiment are arranged at intervals, and the side of the placing table 1 is provided with a moving wheel 2, The moving wheel 2 is a roller. In order to facilitate the subsequent movement of the placing table 1, the placing table 1 is provided with a placing slot 4 for placing the pipeline 3. The two placing platforms 1 are provided with a placing slot 4. The placing table 1 is on the same horizontal plane, and the placing groove 4 is set in an arc shape. At this time, when the pipes 3 are placed inside the placing groove 4, under the action of gravity, the lower parts of the two pipes 3 will be in the lowest section of the placing groove 4. At this time, the centers of the two pipes 3 are naturally on the same horizontal plane, and a track plate 5 is fixedly arranged between the two placing tables 1. The trac...

Embodiment 2

[0043] The fixed box 8 is provided with an inflatable block 19 that communicates with the inflator 18. The inflatable block 19 communicates with the airbag 17 and the inflation of the inflator 18 at the same time. The inflatable block 19 has a certain elasticity and can be made of elastic materials such as rubber. Inflatable objects, a one-way valve 20 and a pressure regulating valve 21 are provided at the connection between the inflator 18 and the inflatable block 19. The one-way valve 20 ensures that the gas can only enter the inflatable block 19 from the inflator 18. The pressure regulating valve 21 is The electric throttle valve model JL923W produced by Gongheng Valve Co., Ltd. can adjust the pressure regulating valve 21 to make the inflation speed into the inflatable block 19. The model of the pressure regulating valve 21 is not unique, as long as it can be used as an inflator 18 When inflating the airbag 17 and the inflatable block 19 at the same time, the air intake spee...

Embodiment 3

[0045] On the basis of the first embodiment, the structure of the control assembly in the first embodiment is disclosed. The control assembly includes a control cavity 25 opened inside the fixed box 8 , and a second electrical connection with the inflator 18 is arranged inside the control cavity 25 . The switch 26, the control cavity 25 is provided with a control rod 27 which is in active contact with the second switch 26. The control rod 27 and the second switch 26 cooperate to control the inflator 18. When the control rod 27 squeezes the second switch 26, the gas is inflated at this time. The machine 18 starts to work. On the contrary, when the control rod 27 is separated from the second switch 26, the inflator 18 stops working. One end of the control rod 27 can move out of the control cavity 25 and is blocked by the limit rod 28. The control rod 27 is fixed. A strut 271 that is in active contact with the inflatable block 19 is connected. The control rod 27 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com