Automatic welding device and method for vehicle console installing support

A mounting bracket and automatic welding technology, which is applied in the direction of supporting electrode clamps, electrode supporting devices, auxiliary devices, etc., can solve the problems of large fluctuations in welding quality, high production costs, and low manual welding efficiency, so as to reduce labor costs, The effect of easy operation and saving welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

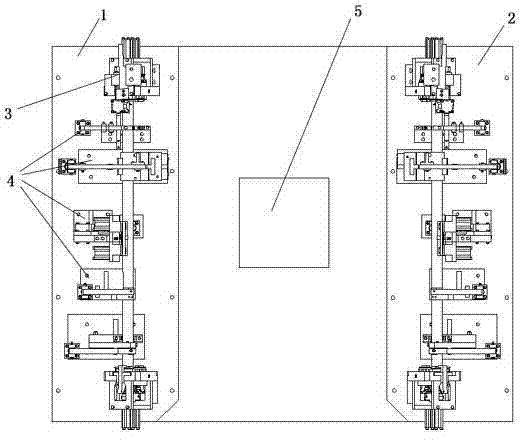

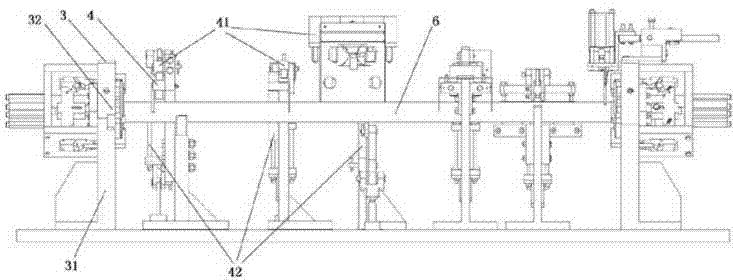

[0039] Such as figure 1 As shown, the automatic welding device for the mounting bracket of the vehicle center console in this embodiment includes workbench I1, workbench II2, pipe clamping device 3, fixture 4 and welding robot 5; the workbench I1 and workbench II2 are parallel Relatively set, the pipe clamping device 3 and the fixture 4 are respectively arranged on the workbench I1 and the workbench II2, and the pipe clamping device 3 and the fixture 4 on the workbench I1 and the workbench II2 correspond to each other in a mirror image distribution; the welding The robot 5 is set between the workbench I1 and the workbench II2, and can rotate 360 degrees in the horizontal direction. The welding torch set on it can cover the welding points of the corresponding parts of each fixture on the workbench I1 and workbench II2.

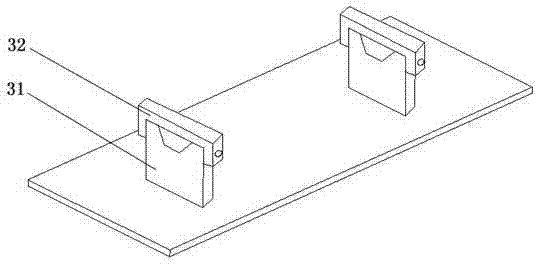

[0040] Such as figure 2 As shown, the pipe clamping device 3 includes a limiting device 31 and a clamping device 32 , and the clamping device 32 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com