Metal pipeline welding device for water conservancy construction and using method thereof

A technology of metal pipes and welding devices, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of metal pipe welding angle adjustment, metal pipe welding efficiency reduction, etc., to ensure quality, guarantee effectiveness and pass rate, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

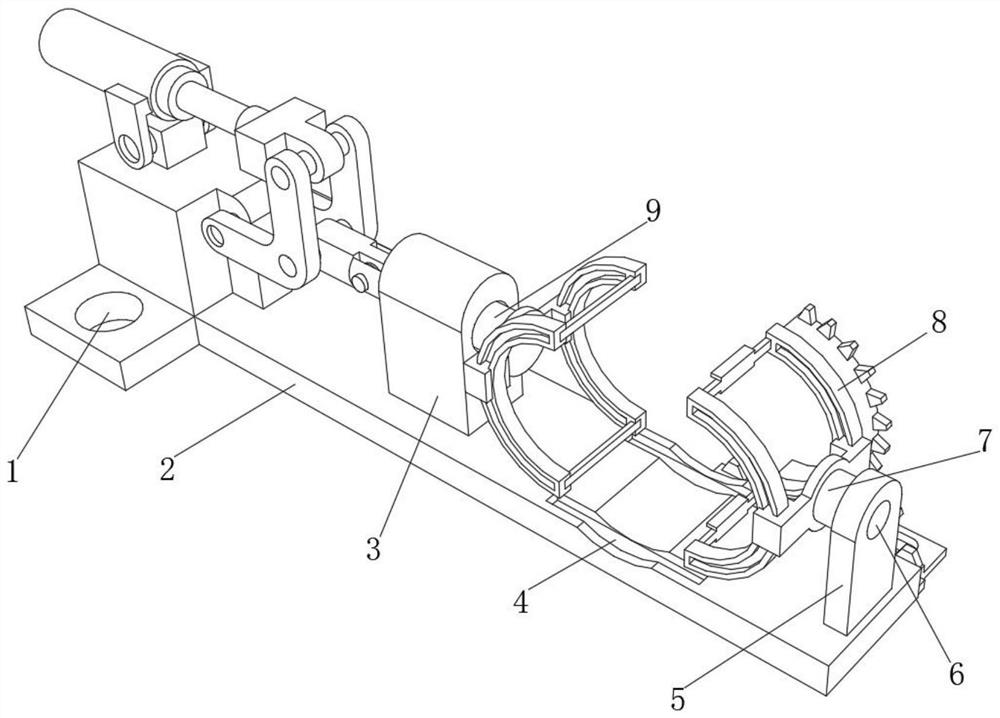

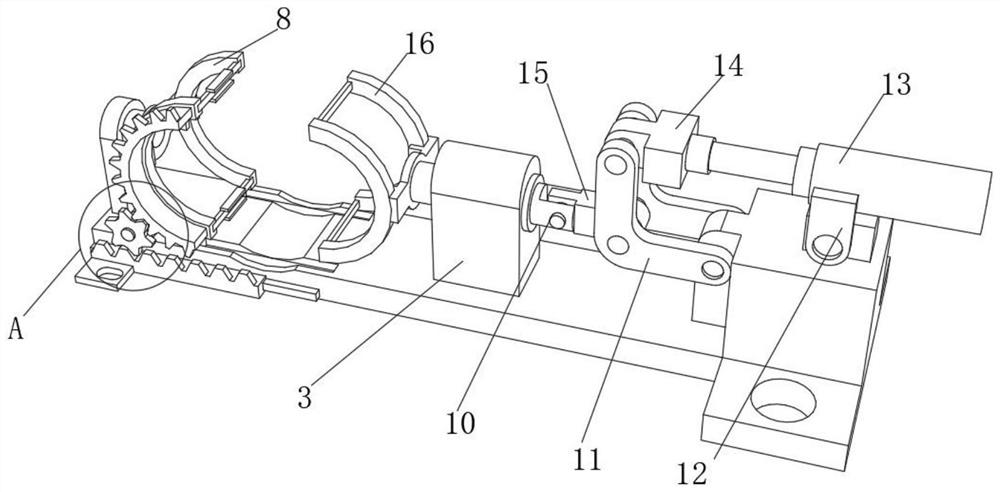

[0041] A metal pipeline welding device for water conservancy construction, such as Figure 1-4 As shown, it includes a bottom plate 2, the outer walls on both sides of one end of the bottom plate 2 are respectively fixed with a mounting plate 1 by bolts, and the top side of the bottom plate 2 is fixed with a support plate by bolts, and the outer wall on the top side of the support plate is fixed by a rotating plate 12 There is a hydraulic rod 13, and the extended end of the hydraulic rod 13 is connected with a guide block 14 through a screw thread. Two L-shaped guide plates 11 are connected to the outer wall of one side of the support plate through a rotating shaft. The two sides of 14 are connected, and the middle sections of the two L-shaped guide plates 11 are connected to the connecting plate 15 through the rotation of the guide shaft respectively. The outer wall of the top middle of the bottom plate 2 is fixed with a support 3 by bolts, and a slide hole is opened on one si...

Embodiment 2

[0048] A metal pipeline welding device for water conservancy construction, such as Figure 5 As shown, two guiding protrusions 24 are welded on the outer walls of both sides of the connecting plate 22, and rubber undercuts 26 are respectively provided on both sides of the guiding protrusions 24, and a clamping hole 25 is opened on one side of the connecting plate 22, and the clamping The holes 25 and the guide protrusions 24 are compatible with each other; when the guide protrusions 24 are clamped in the clamping holes 25, the rubber undercuts 26 of the guide protrusions 24 can engage the clamping holes 25, ensuring the fixation of the two relative connecting plates 22 The effect is to improve the stability of the connection of metal pipes.

Embodiment 3

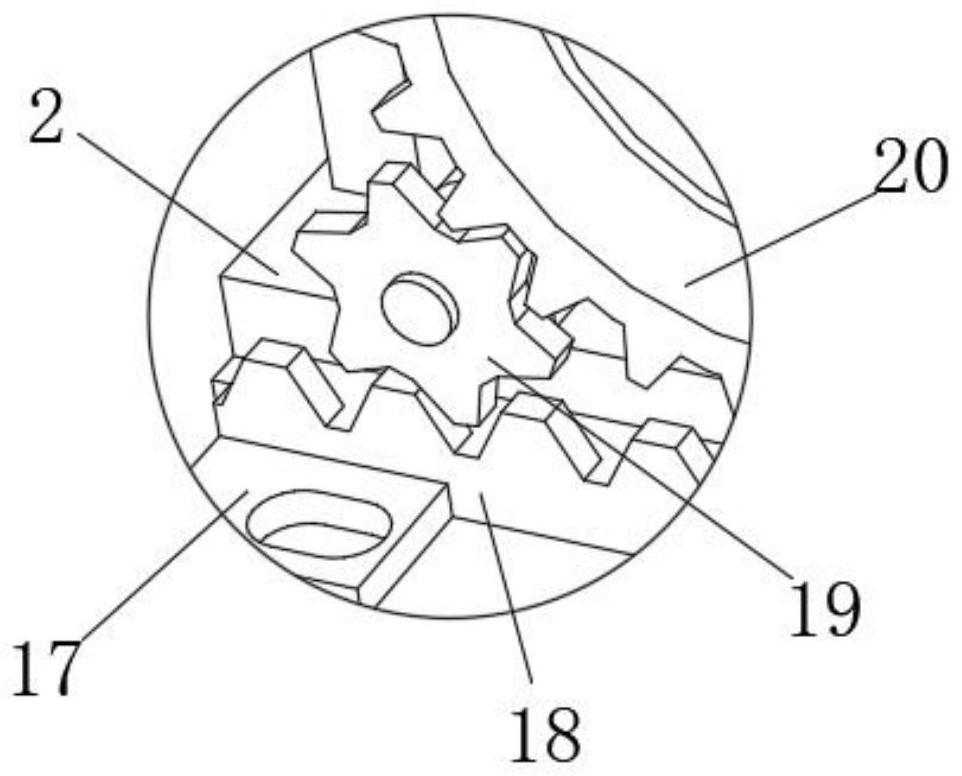

[0050] A metal pipeline welding device for water conservancy construction, such as Figure 6-8 As shown, one side of the rack plate 18 is provided with a reciprocating mechanism, and the reciprocating mechanism includes a support plate 27, a motor 28, a turntable 29, a horizontal guide plate 30, a guide rod 31, a guide column 32, a guide plate 33, and a fixed column 34 and a T-shaped plate 35, and the horizontal guide plate 30 is connected to one side of the rack plate 18 through a connecting block, the guide post 32 is fixed to one side of the horizontal guide plate 30 by threads, and the support plate 27 is slidably connected to the horizontal guide plate through a slider 30, the T-shaped plate 35 is fixed on the outer wall of the middle side of the horizontal guide plate 30 by bolts, the outer wall of the bottom side of the support plate 27 is provided with a guide groove 36, and the turntable 29 is connected to one side of the support plate 27 through a rotating shaft. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com