Symmetrical-hot-rolled composite plate blank and seal welding method thereof

A welding method and composite plate technology, applied in welding equipment, arc welding equipment, layered products, etc., can solve the problems of difficult configuration of production conditions, large weld bevel size, and low sealing welding efficiency, etc. The investment amount and sealing welding manufacturing cost, good welding consistency, and the effect of ensuring welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for sealing and welding symmetrical hot-rolled clad plate slabs, the technical scheme and steps are as follows:

[0049] 1. S1 designs and manufactures a frame with a special structure. For the specific structure and size of the frame, see figure 2 shown.

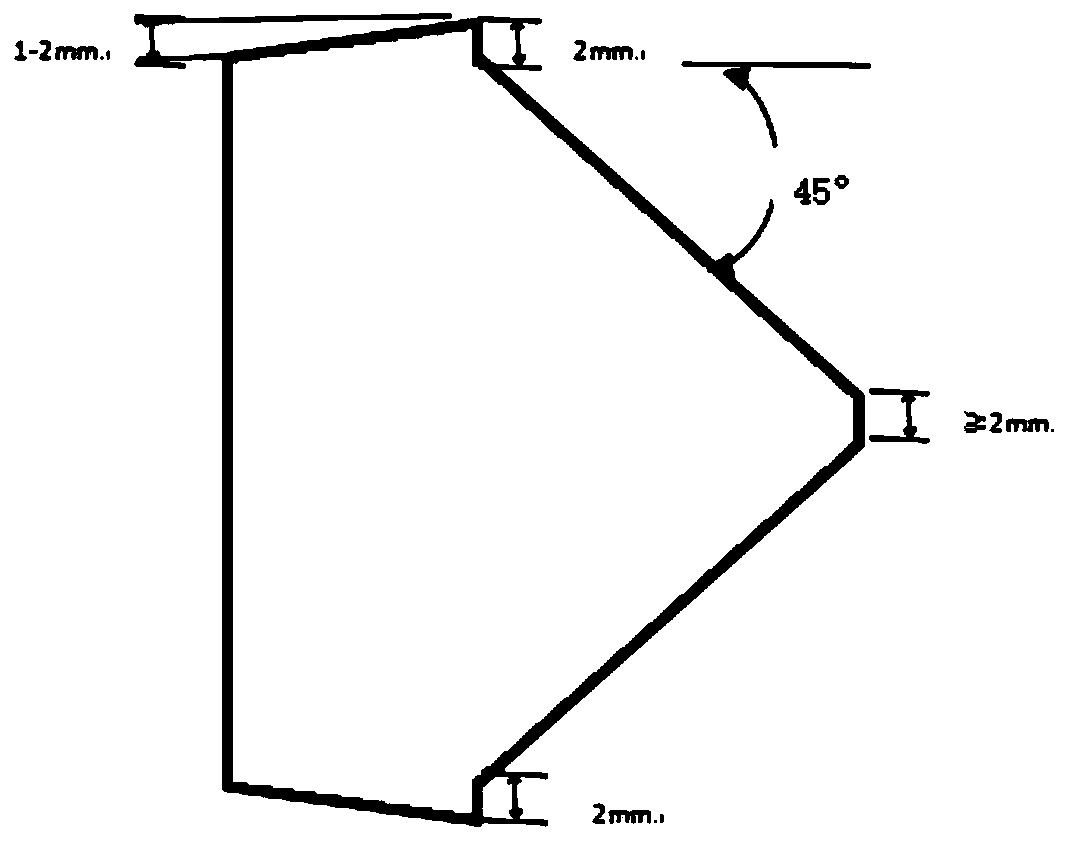

[0050] cladding side of the enclosure ( figure 2 The left side of the isosceles trapezoid is designed as an isosceles trapezoid, the length of the lower base of the isosceles trapezoid is greater than or equal to the sum of the thicknesses of the upper and lower cladding materials, and the length difference between the lower and upper bases of the isosceles trapezoid is not limited. And the preferable range is 2mm to 20mm.

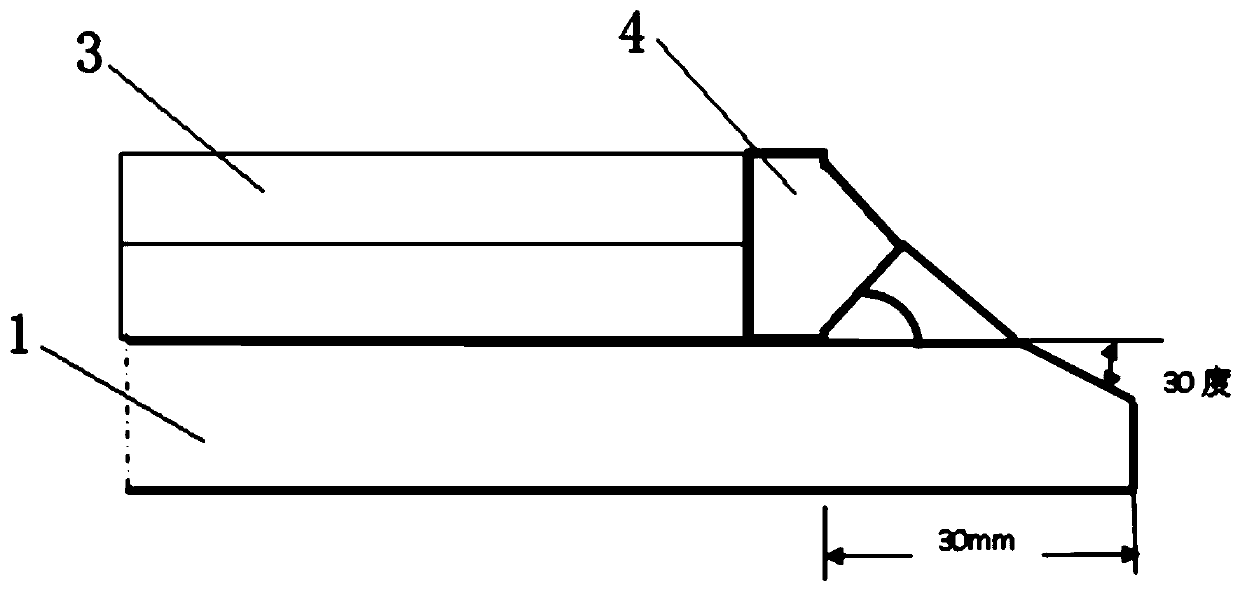

[0051] outside the frame ( figure 2 On the right side of the cross-section, a certain length is reserved on the upper and lower sides as the blunt edge of the weld bevel. The optimal range of the blunt edge length is 2-5mm, and the other parts are designed to be trapezoidal. The l...

Embodiment 2

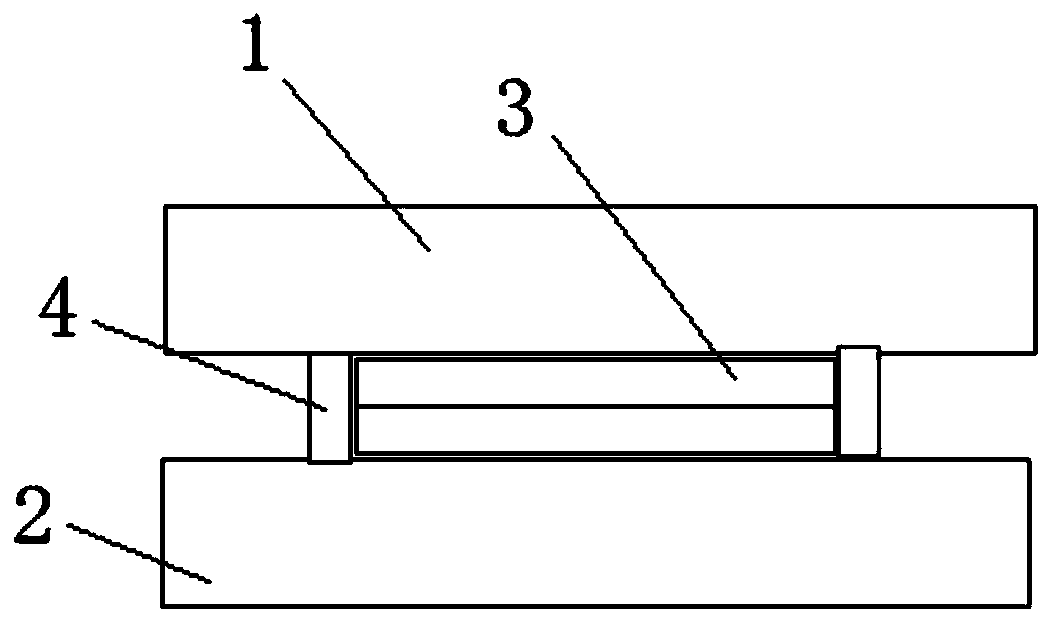

[0062] A symmetrical hot-rolled composite plate slab, the overall structure of which is as follows Figure 4 As shown, it includes an upper base material, a lower base material, a covering material and a surrounding frame. The upper base material and the lower base material cover the upper and lower sides of the covering material. The base material and the lower base material are welded separately, and the frame includes two parts, the first part constitutes the inner periphery of the frame, its cross-section is isosceles trapezoidal, the upper bottom edge is connected with the cladding material, and the second part constitutes the outer periphery of the frame , its cross-section is trapezoidal, the lower base of the second part is connected to the lower base of the first part, and the length of the lower base of the second part is smaller than the lower base of the first part, and the end of the upper substrate There is a bevel on the side close to the frame. The length of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com