Welding spatter prevention agent and preparing method

A technology of anti-splash agent and solvent oil, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc. It can solve the problems of reducing welding slag and the surface adhesion of objects, not cleaning it off, and poor welding molding. Achieve the effects of improving operation efficiency and product delicacy, reducing dust and noise pollution, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

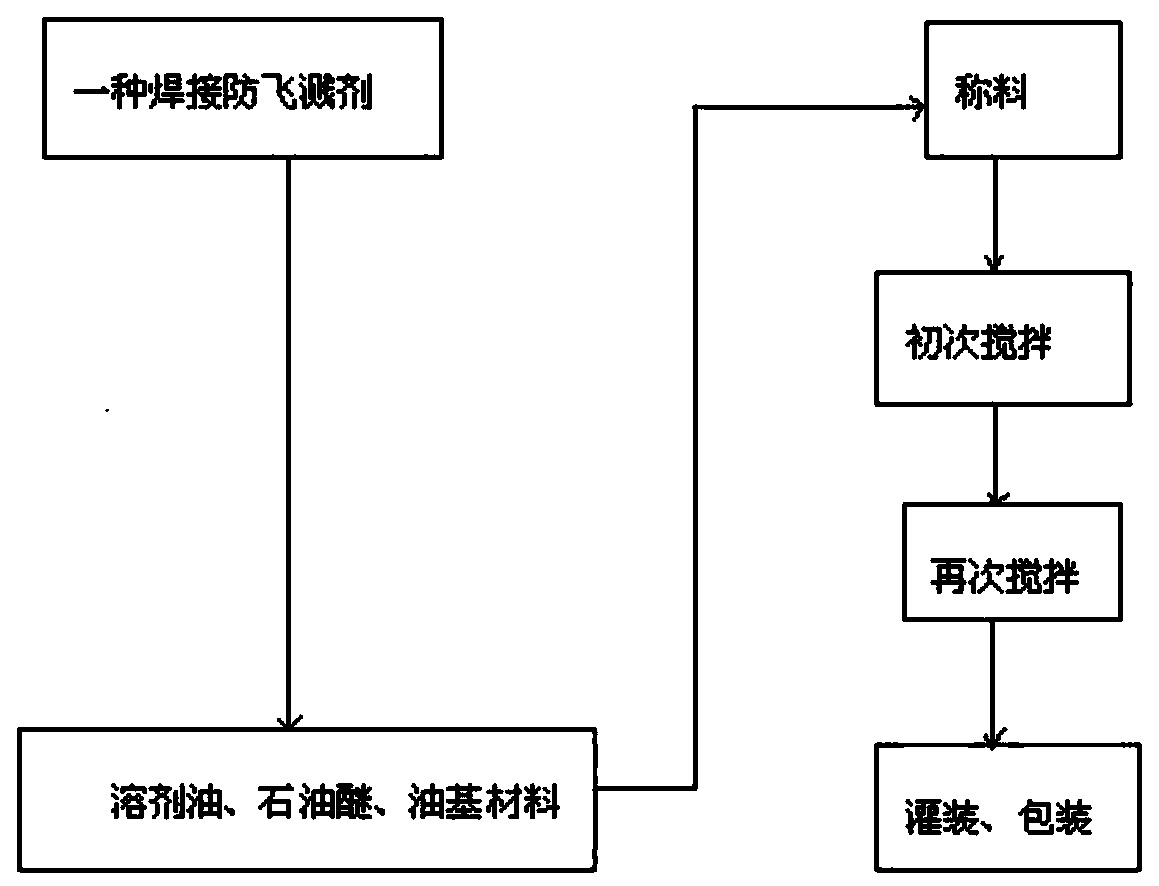

[0015] figure 1 As shown in, a welding anti-splash agent, including solvent oil (one of 6#, 120#, 200#, the present embodiment uses 6#), petroleum ether, oil-based materials; the oil-based materials are lubricating Oil, oil-based materials, solvent naphtha, and petroleum ether are three materials in equal parts per hundred, which are 70 parts, 25 parts, and 5 parts respectively. The above-mentioned raw materials are mixed and stirred at high temperature to obtain finished products; the preparation method of welding anti-splash agent includes Weighing, initial stirring, re-stirring, filling and packaging five processes.

[0016] figure 1 As shown in , in the weighing process, the oil-based material, solvent naphtha, and petroleum ether are weighed according to the proportion of each hundred equal parts, and put into containers for use. In the initial mixing process, first pour lubricating oil into the constant temperature stirring container, after the temperature inside the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com