Ultrasound-assisted vacuum electron beam welding method of magnesium and magnesium alloy

A technology of vacuum electron beam and welding method, applied in the field of magnesium and magnesium alloys, can solve the problems of affecting the energy density distribution of electron beam welding heat source, unable to achieve one-time welding forming effect, reducing deep penetration ability, etc. Welding quality, effect of improving densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

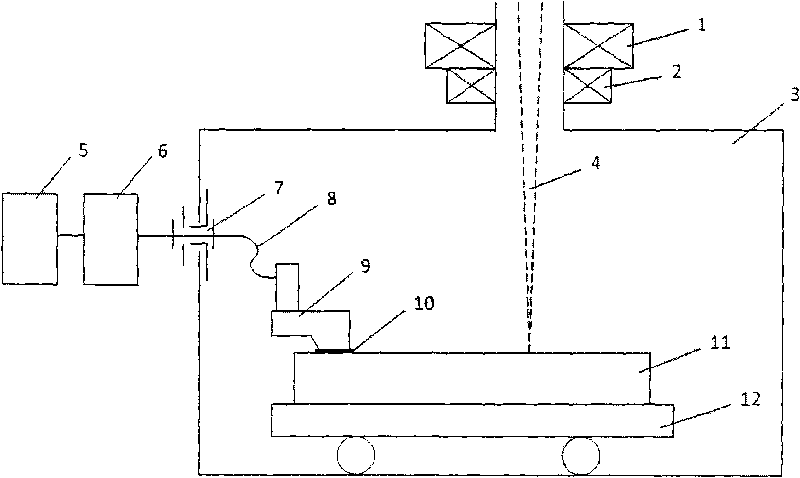

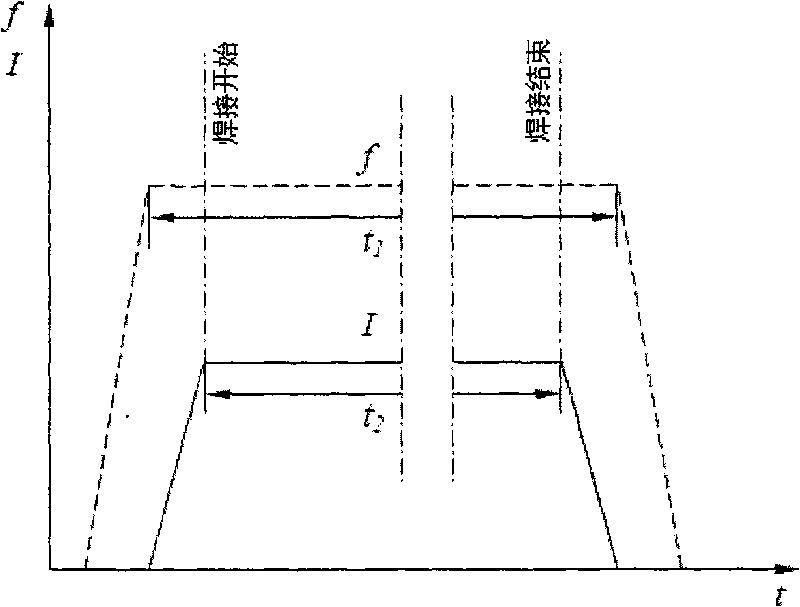

[0034] Embodiment 1: as figure 2 with image 3 As shown, the magnesium alloy weldment 11 to be welded is the butt joint of two flat plate structures with a thickness of 10 mm. Clamp the two pieces of weldment 11 on the workbench and transmission system 12 in the vacuum welding chamber 3 through the clamp, apply the coupling agent 10 on the pressing surface of the ultrasonic introduction device 9, and then put the ultrasonic introduction device 9 through the pressure of the spring The mechanism is pressed onto the surface of a weld bead of one of the workpieces to be welded. The signal wire 8 of the ultrasonic introduction device 9 is drawn out through the wire vacuum sealing structure 7 on the wall of the vacuum welding chamber, and is electrically connected with the ultrasonic vibration system inside and outside the vacuum welding chamber 3, and the stabilized power supply 5 provides power for the ultrasonic generator 6. Then close the vacuum welding chamber 3, pump the el...

Embodiment 2

[0035] Embodiment 2: as figure 2 with Figure 4 shown, with image 3 Compared with the process flow shown, Figure 4 The process flow adds the electron beam remelting process assisted by ultrasonic waves. The magnesium alloy weldment 11 is a fillet joint between a horizontal plate with a thickness of 10mm and a vertical plate with a thickness of 10mm. Clamp the two pieces of weldment on the workbench and the transmission system 12 through the fixture, apply the coupling agent 10 on the pressing surface of the ultrasonic introduction device 9, and then press the ultrasonic introduction device 9 to the workpiece to be welded by the spring pressure mechanism The weld bead surface on one side of the transverse plate. The signal wire 8 of the ultrasonic introduction device 9 is led out through the wire vacuum sealing structure 7 on the wall of the vacuum welding chamber, so that the ultrasonic vibration generator 6 inside and outside the vacuum welding chamber 3 is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com