Planar embedded annular structure and manufacturing process thereof

A ring-shaped structure and planar embedded technology, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., can solve the problems of low utilization rate of raw materials, large heat input, low yield, etc. Achieve the effect of small deformation of workpiece, prevent oxidation and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

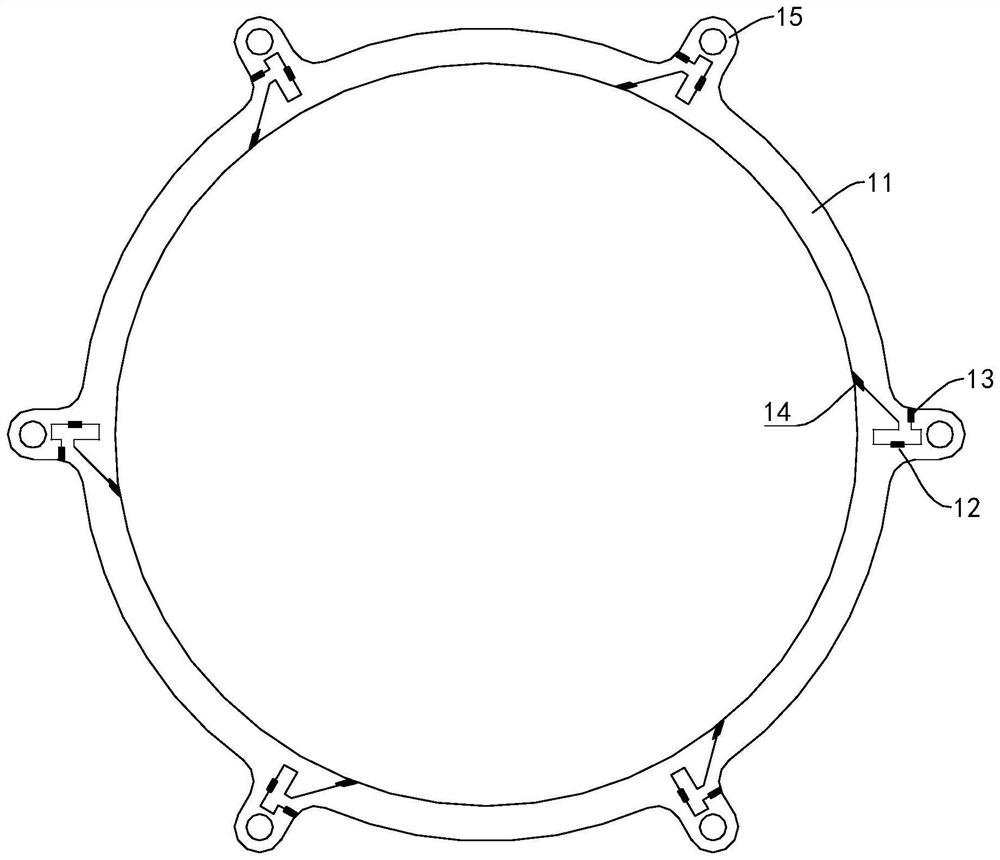

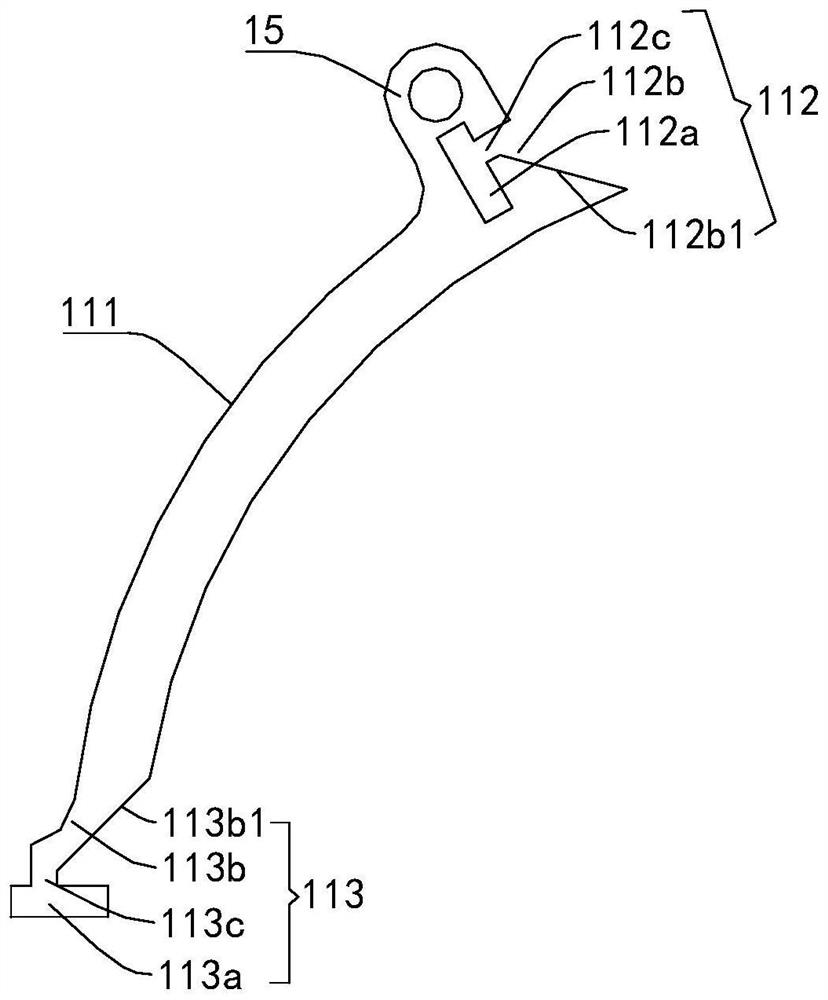

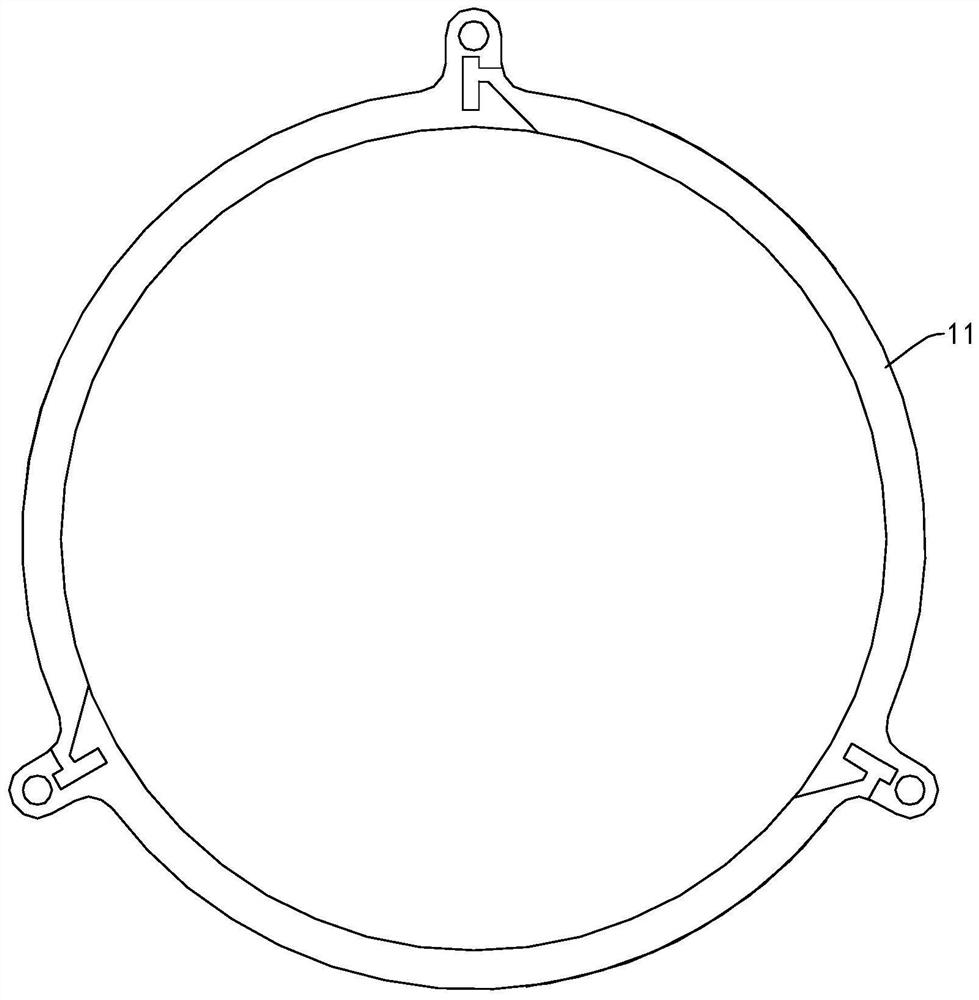

[0047] Please refer to Figure 1 to Figure 2 , the present embodiment provides a planar embedded annular structure, including several arc segment units 11, and several arc segment units 11 are sequentially connected end to end to form an annular structure, and the arc segment unit 11 includes an arc segment main body 111, and the arc segment units 11 One end of the section main body 111 is configured with a special-shaped splicing interface 112, and the other end of the arc section main body 111 is equipped with a special-shaped splicing block 113 that matches the special-shaped splicing interface 112. The special-shaped splicing block parts 113 are spliced together, and several welding points are provided at the splicing points for welding the special-shaped splicing part 112 and the special-shaped splicing block part 113 at the welding points. Through the special-shaped splicing part 112 and the special-shaped splicing block part 113, since the special-shaped splicing part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com