Automatic tracking seam welding/cutting manipulator

An automatic tracking and manipulator technology, applied in welding/cutting auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of high production equipment cost, fast tank speed, difficult eyes and hands, etc., to achieve easy maintenance and use, use The effect of long life and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

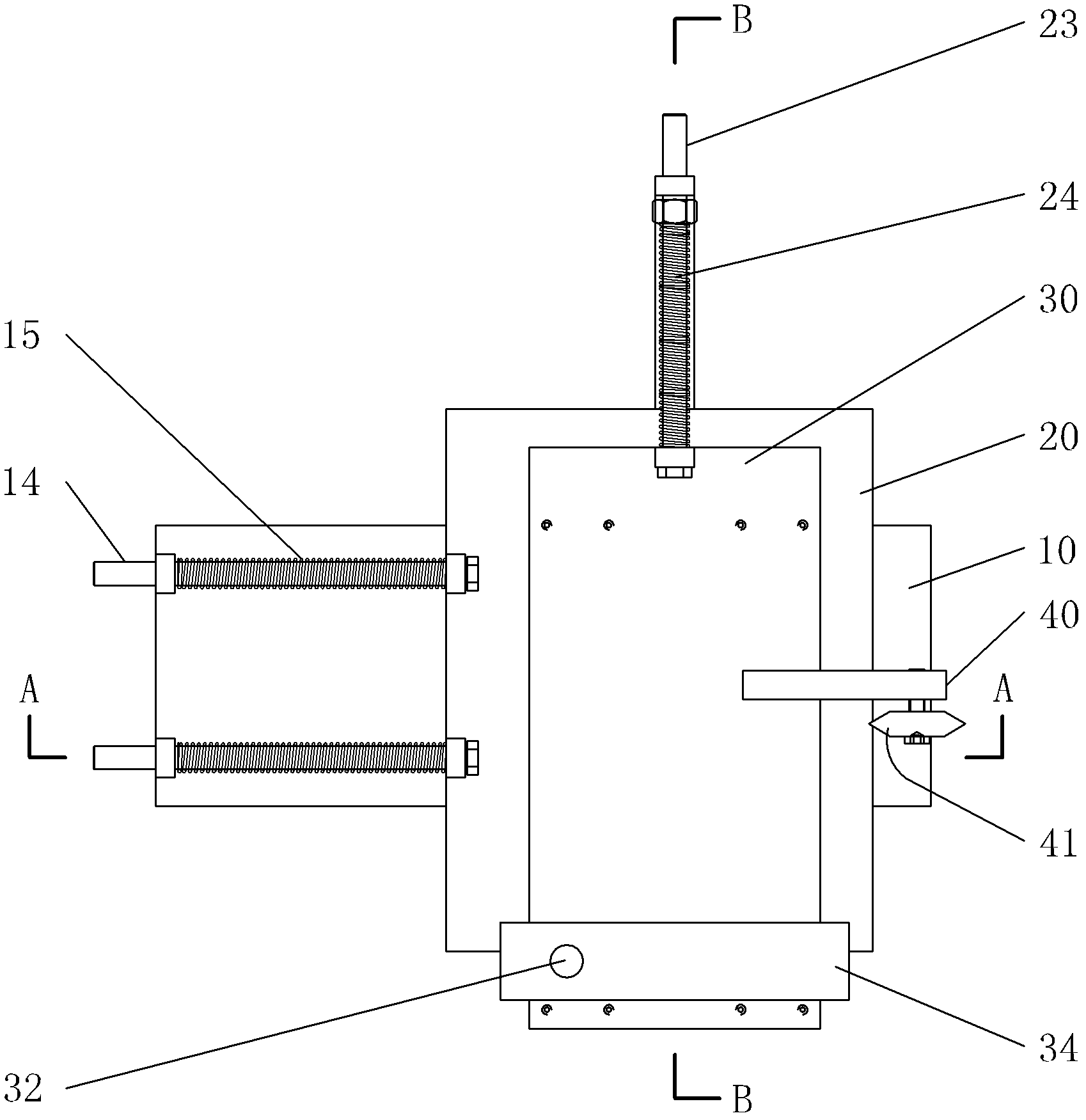

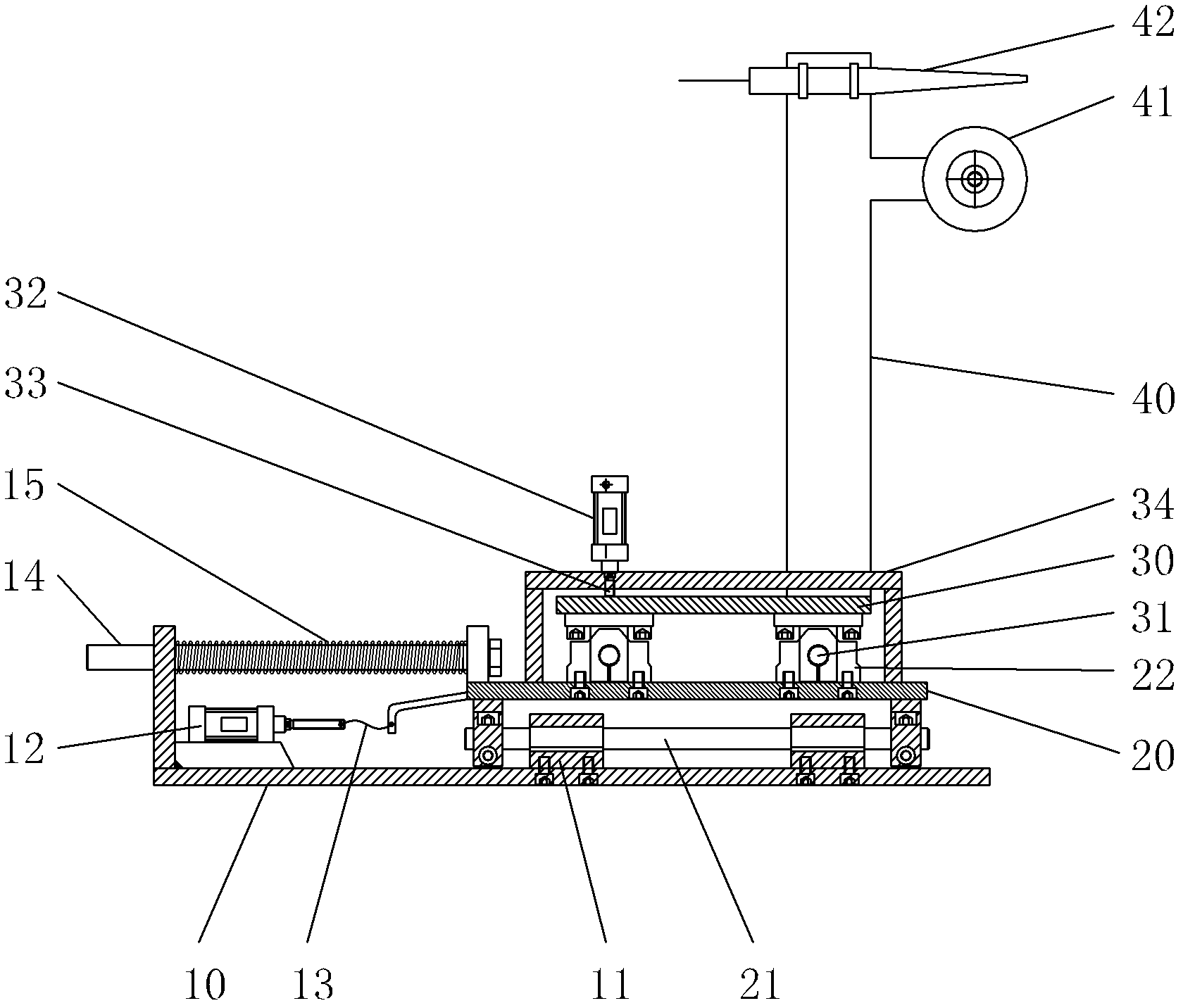

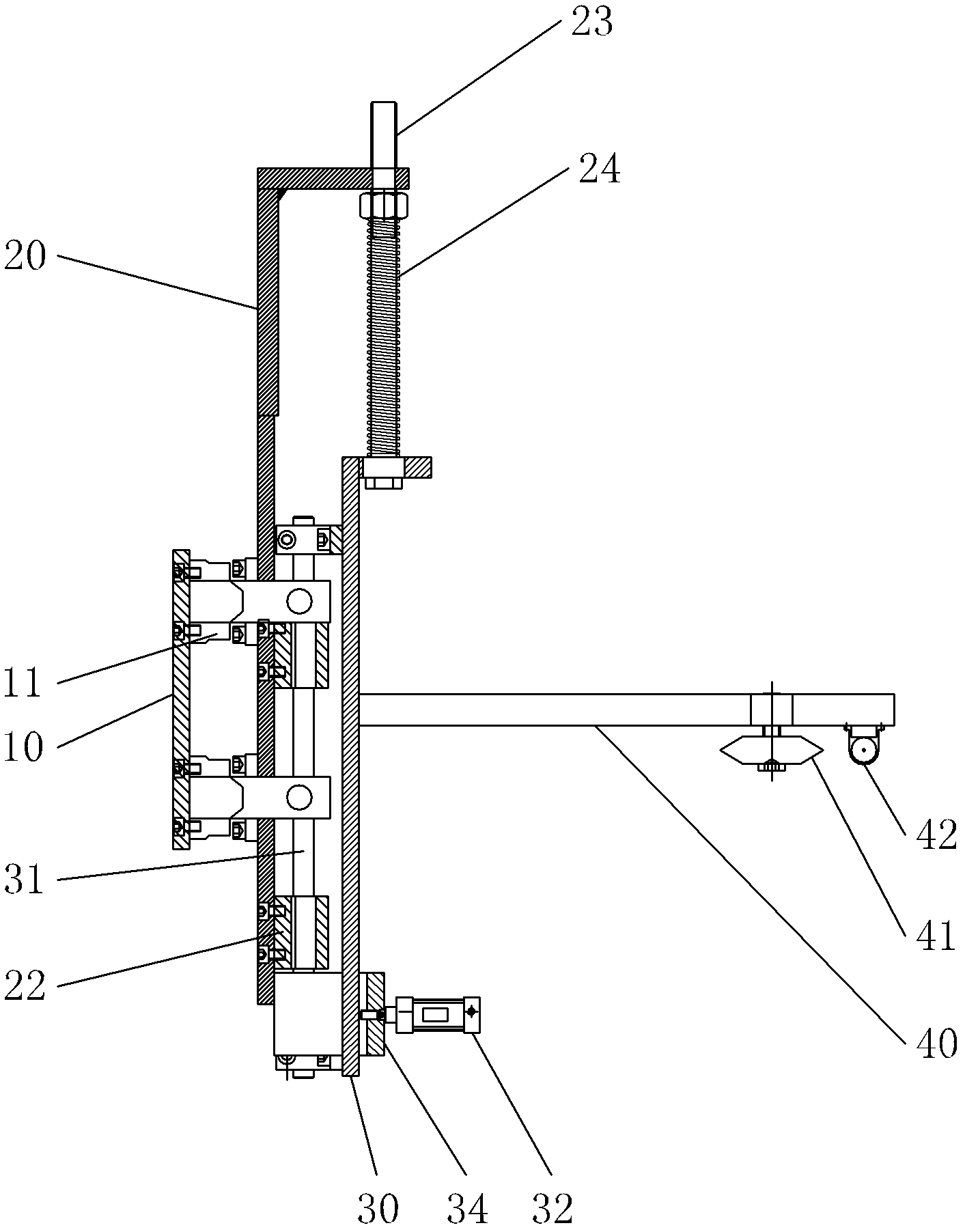

[0029] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-6 :

[0030] The automatic tracking full seam seam welding / cutting manipulator is provided with a slide plate 20 moving laterally along the base on the base 10, and a compression spring 15 is provided between the slide plate 20 and the base 10 to push the slide plate 20 to move toward the workpiece 56 to be welded. The middle part of the tight spring 15 is provided with a guide shaft 14, and the slide plate 20 is provided with a slide table 30 that moves longitudinally along the slide plate 20, and between the slide plate 20 and the slide table 30 is provided with a compression spring 24 that promotes the slide table 30 to move longitudinally. The middle part of spring 24 is provided with guide shaft 23, and slide table 30 is provided with cantilever 40, and one side of cantilever 40 outer end is provided with the roller 41 that rolls a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com