Welding method for liquid injection hole of lithium ion battery threaded pole

A lithium-ion battery and welding method technology, applied in welding equipment, battery pack components, circuits, etc., can solve the problems of reducing welding efficiency, high requirements, and inability to complete fusion welding, so as to reduce heat absorption and improve welding. quality, the effect of eliminating battery scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

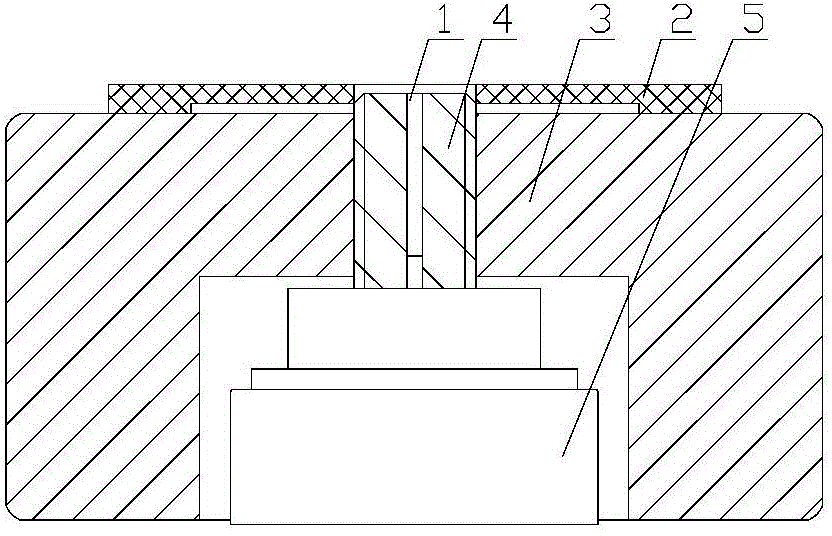

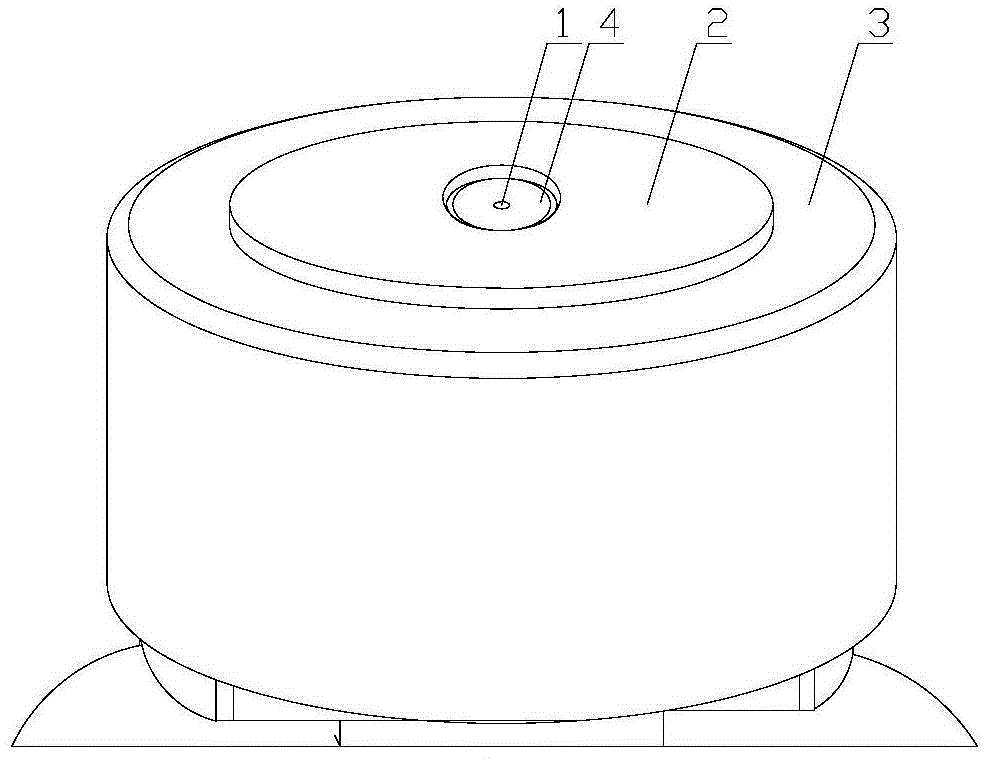

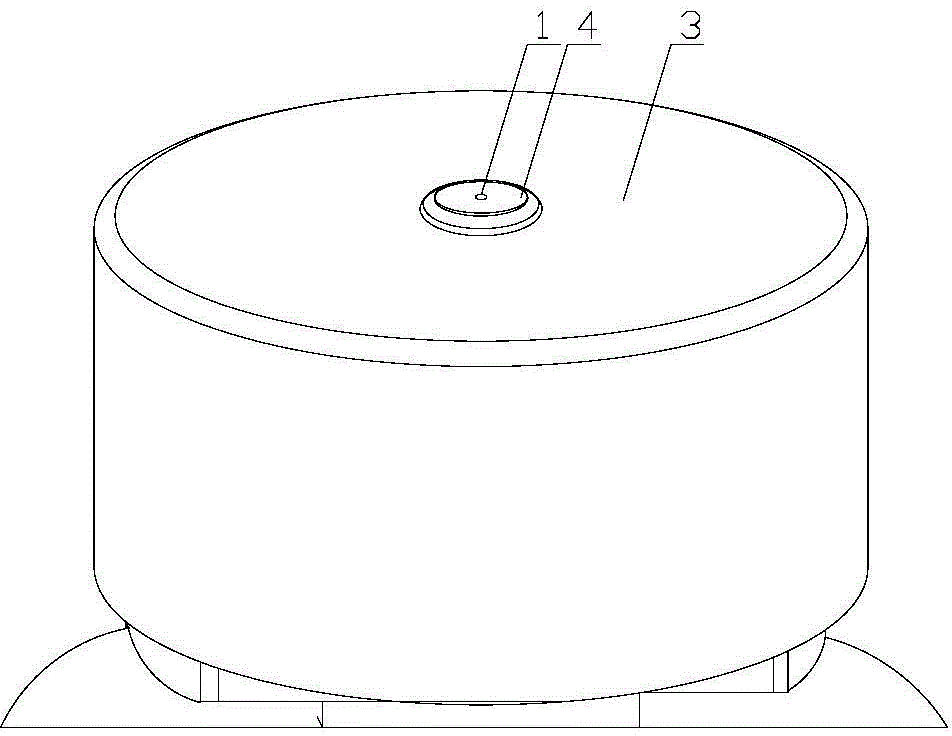

[0030] (1) After the liquid injection hole 1 on the threaded pole of the lithium-ion battery is injected with electro-liquid, the battery is placed on the workbench as the welded battery 5; according to the outer diameter of the welded battery shell and the height of the threaded pole 4 exposed on the battery and the outer diameter of the threaded pole, respectively made as Figure 1-2 The radiator 3 and the ceramic ring 2 shown in the figure; the radiator is a red copper barrel with a through hole in the center, the inner diameter of the barrel is larger than the outer diameter of the welded battery shell to be welded, and the through hole on the radiator It is the same as the outer diameter of the thread on the threaded pole of the battery to be welded; the ceramic ring is to make a through hole at the center of a ceramic sheet, and the diameter of the through hole is the same as the outer diameter of the thread on the threaded pole of the battery to be welded. A blind hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com