A live welding compensation device under full current for aluminum electrolytic cell series

A live welding and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolysis, can solve the problems of electrolytic production impact, cumbersome connection methods, and influence on welding quality and process, so as to avoid production impact and save installation and operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

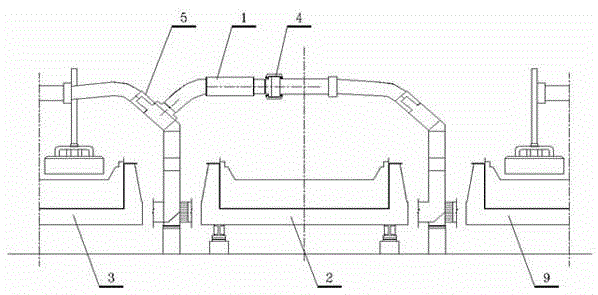

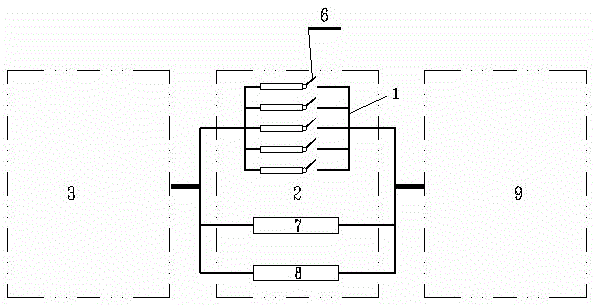

[0017] Such as image 3 As shown, aluminum electrolytic production consists of multiple electrolytic cells connected in series. Here, the electrolytic cell requiring live welding is defined as the overhaul electrolytic cell 2, the front-end electrolytic cell connected in series with it is the upstream electrolytic cell 9, and the rear end of the overhaul electrolytic cell 2 is connected in series. The electrolytic cell is defined as the downstream electrolytic cell 3, and in the overhaul electrolytic cell 2, from top to bottom, there are current drainage magnetic compensation device 1, cathode steel rod 7 and short-circuit busbar 8 at the bottom of the cell.

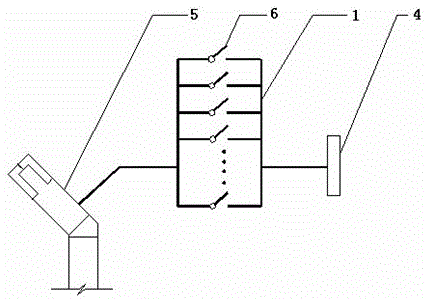

[0018] When welding the connecting plate of the cathode steel rod 7 of the aluminum electrolysis overhaul electrolytic cell 2, in order to reduce the magnetic field at the welding point, multiple sets of current-draining magnetic compensation devices 1 are installed, such as Figure 4 shown. One end is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com