Turnover device for hub casting detection

A technology for turning over devices and castings, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of low safety of manual operation, easy to slip, and difficult to disassemble and assemble when turning over and clamping, so as to achieve flexible turning and improve safety. , the effect of saving adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

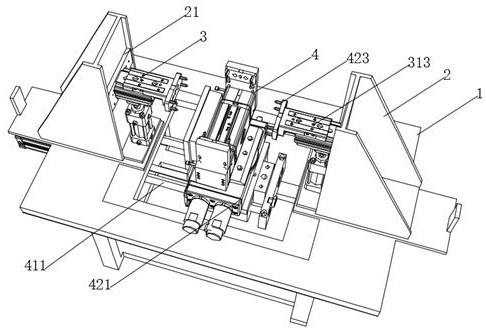

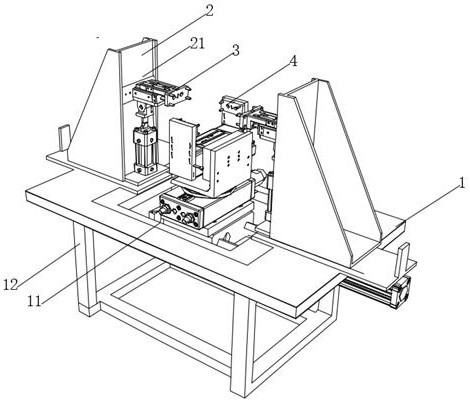

[0026] Such as figure 1 As shown, a turning device for wheel hub casting detection includes a fixed seat 1, the four corners of the bottom of the fixed seat 1 are uniformly formed with supporting legs 12, and the two sides of the top of the fixed seat 1 are fixedly installed with supporting seats 2, two supporting seats The inner side of 2 is provided with a first chute 21, the inside of the first chute 21 is slidably connected with an engaging mechanism 3, the top of the fixed seat 1 is provided with a slot 11, and the inside of the slot 11 is equipped with a turning mechanism 4. During the overturning process of the processed hub, first adjust the engaging mechanism 3 to a suitable level through the two first slide grooves 21 inside the support seat 2, and then support and fix the hub, which needs to be supported and overturned by the overturning mechanism 4 , The support seat 2 is composed of a bottom plate and two side plates symmetrically integrally formed on the top of t...

Embodiment 2

[0028] Such as Figure 2-4 As shown: the two engaging mechanisms 3 include a first slider 31 slidingly connected to the inside of the first chute 21, and one side of the two first sliders 31 is fixedly connected with a mounting block 311, and the top of the mounting block 311 is opened There is a second chute 312, the inside of the second chute 312 is slidably connected with a second slider 32, one end of the second slider 32 is fixedly mounted with a snap-in plate 313, and the four corners of the snap-in board 313 are fixedly mounted with clips. Combined column 314, one side of the middle part of the engaging plate 313 is fixedly equipped with an electric telescopic rod 33, the two sides of one end of the mounting block 311 are provided with a first groove, and the inside of the first groove is equipped with an electric telescopic rod 33, and an L-shaped base 44 One side of the top is fixedly equipped with a telescopic seat 441, and the two sides of the telescopic seat 441 ar...

Embodiment 3

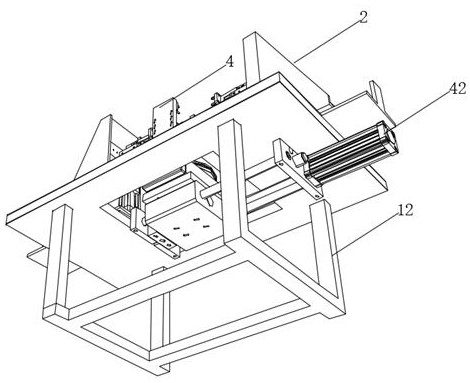

[0031] Such as Figure 5As shown: the turning mechanism 4 includes a first connecting plate 41 and a second connecting plate 412 fixedly connected with the bottom end of the fixed base 1, two guide rods 411 are fixedly installed on both sides of the first connecting plate 41, and the two guide rods 411 A second connecting plate 412 is fixedly installed at one end of the second connecting plate 412, and a second electrohydraulic rod 42 is fixedly installed on one side of the second connecting plate 412. The telescopic end of the second electrohydraulic rod 42 runs through the wall of the first connecting plate 41, and the second The shrinking end of the electro-hydraulic rod 42 is fixedly connected with a sliding seat 421, the inside of the sliding seat 421 is slidably connected with the rod columns of the two guide rods 411, the top of the sliding seat 421 is fixedly connected with an electric turntable 43, and the top of the electric turntable 43 is fixed. The L-shaped base 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com