Orthodontic self-locking bracket

A technology of self-locking brackets and brackets, applied in brackets, arch wires, etc., can solve the problems of large thickness of self-locking brackets, short and blunt bracket wings, and inability to open the sliding cover, and achieves good self-locking effect. , to avoid discomfort, cover firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

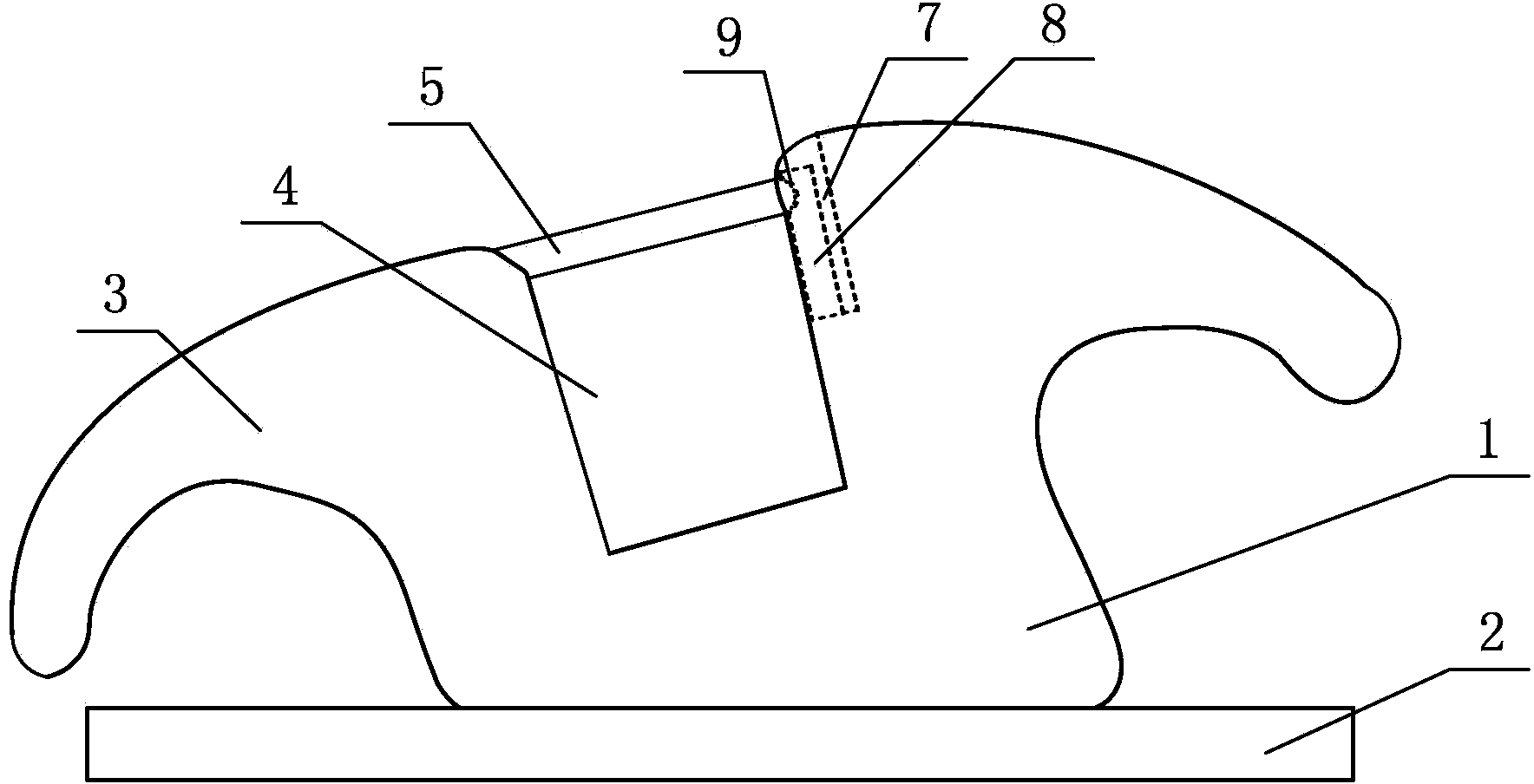

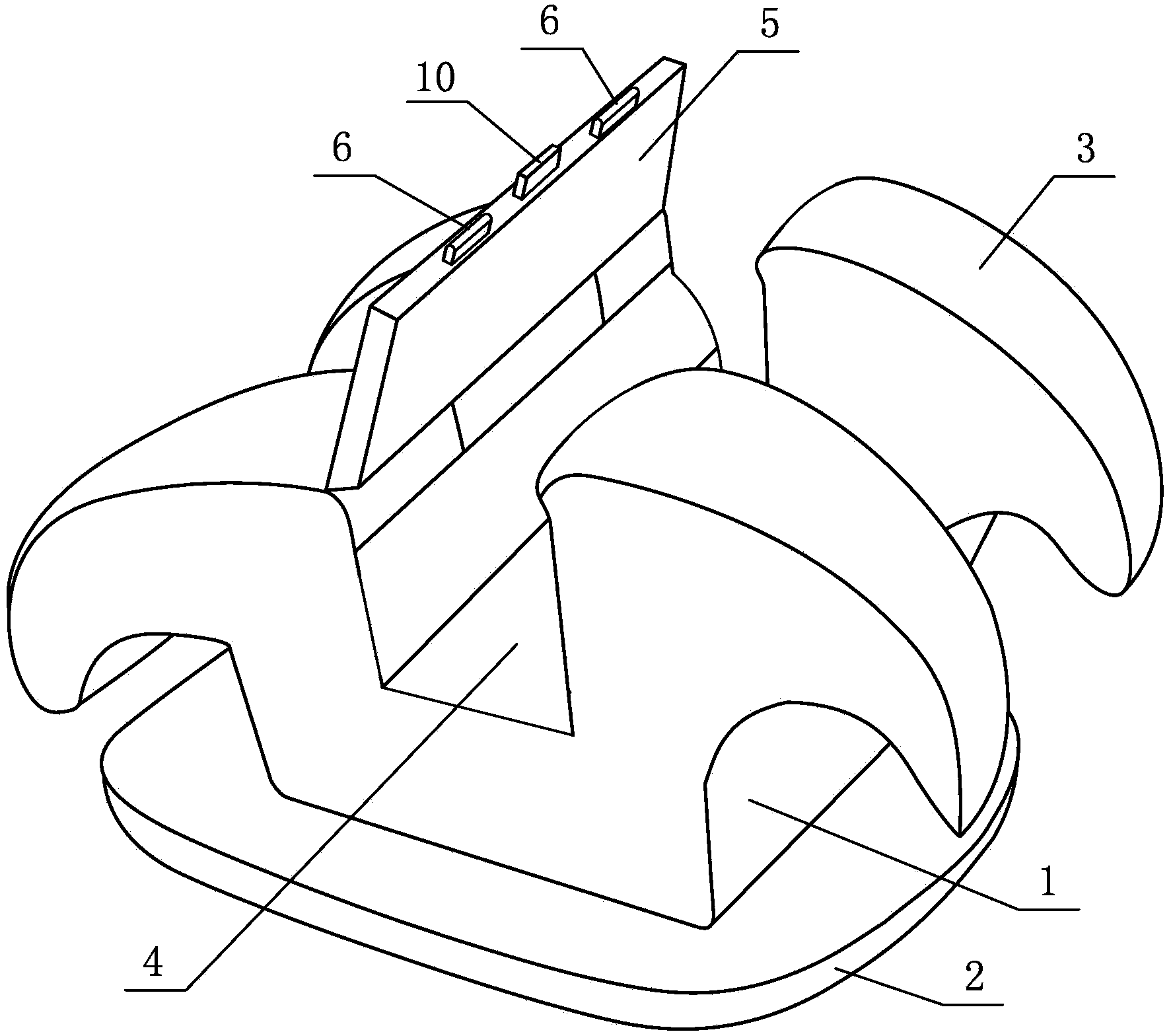

[0018] Such as Figure 1-2 As shown, an orthodontic self-ligating bracket includes a bracket base 1, a metal mesh bottom 2 is provided at the bottom of the bracket base 1, and a ligation wing 3 and an archwire groove 4 are provided on the bracket base 1. At the top of the archwire groove 4, there is a cover 5 arranged along the length direction of the archwire groove 4. One end of the cover 5 is movably connected with the top of the side wall of the archwire groove 4, and the other end of the cover 5 is A card protrusion 6 is respectively provided on both sides of the end face, a groove 7 is respectively provided on the two ligation wings 3 on the side opposite to the connecting end of the cover sheet 5, and an elastic plate 8 is respectively arranged in the two grooves 7, and an elastic plate 8 is arranged on the elastic plate 8. One side surface close to the archwire groove 4 is respectively provided with a locking groove 9 which matches with the corresponding locking protru...

Embodiment 2

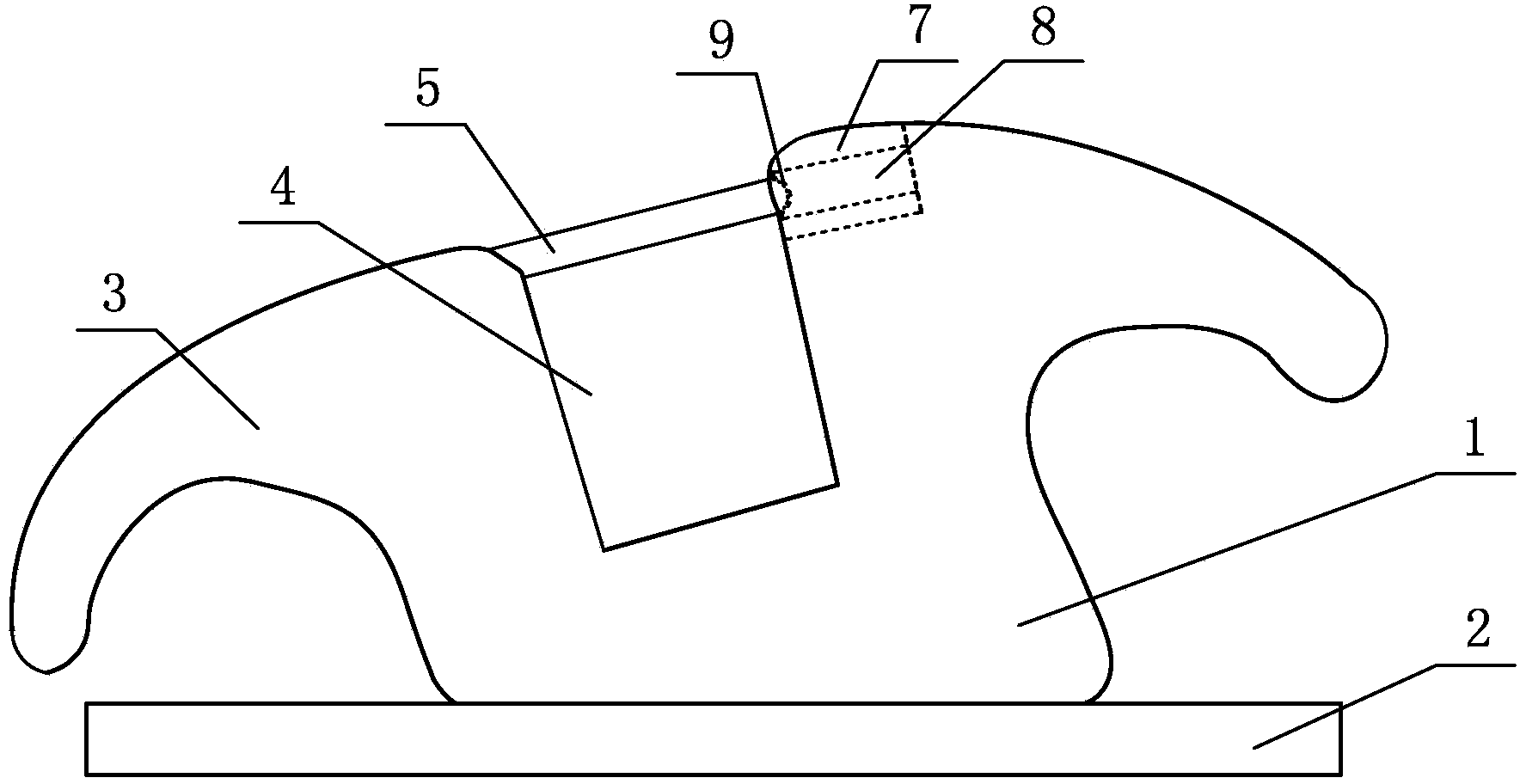

[0025] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the elastic plate 8 is horizontally arranged in the groove 7, and one end of the elastic plate 8 is elastically connected to the inner wall of the groove 7 away from the archwire groove 4, and the elastic plate 8 A gap is provided between 8 and the bottom of the groove 7 . Others are the same as in Example 1.

[0026] When in use, first use a tool to withstand the protrusion 10 on the cover 5 and lift upwards, the two card protrusions 6 exert an upward force on the top of the card slot 9, the elastic plate 8 is deformed under pressure, bends to the top of the elastic plate 8, and the card is locked. The protrusion 6 slides out from the slot 9 of the elastic plate 8. After the protrusion 6 slides out of the slot 9, the elastic plate 8 returns to its original shape, the cover 5 is opened, and the archwire is put into the groove 4 of the arch wire. Similarly, when the cover sheet 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com