Patents

Literature

158results about How to "Roll over stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

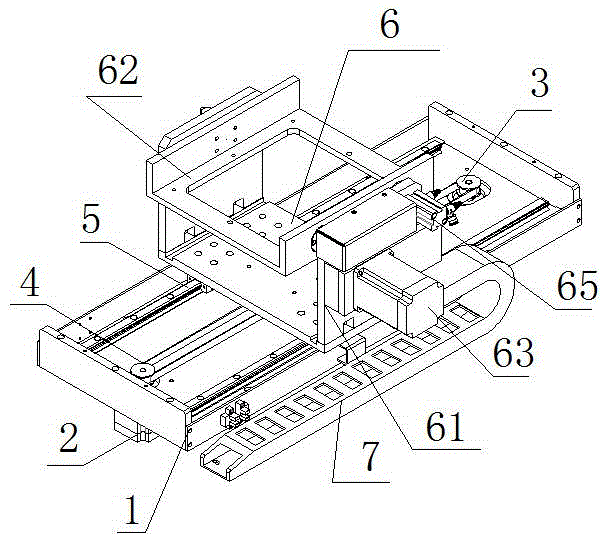

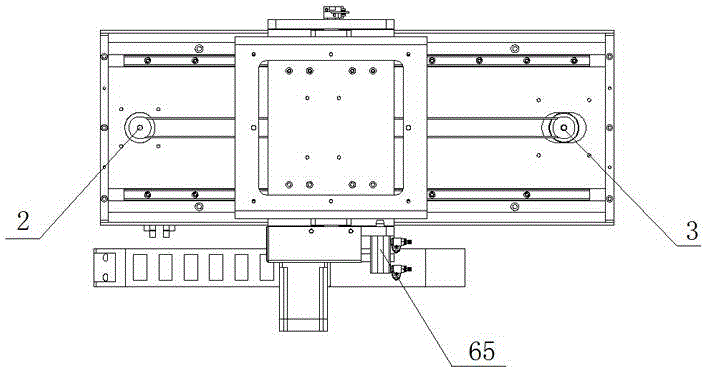

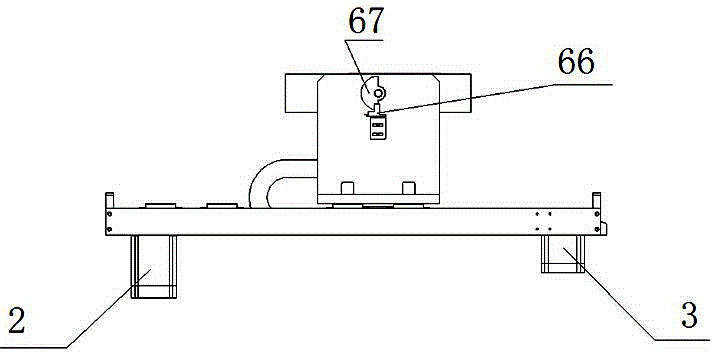

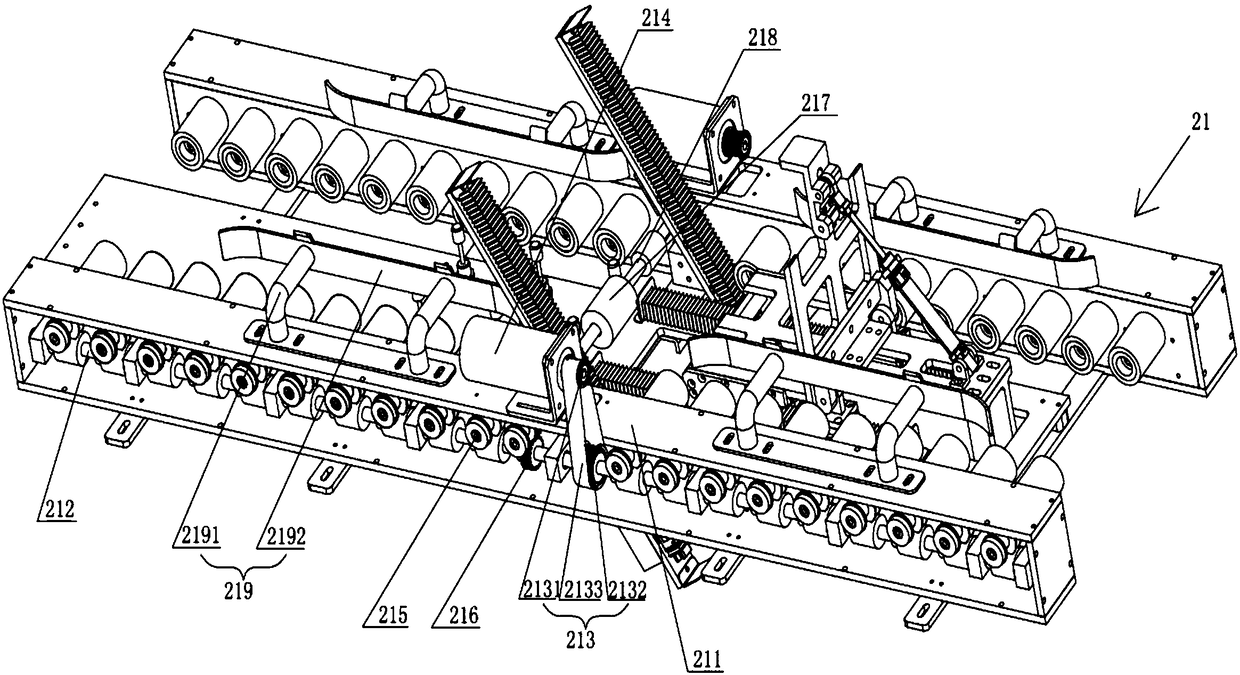

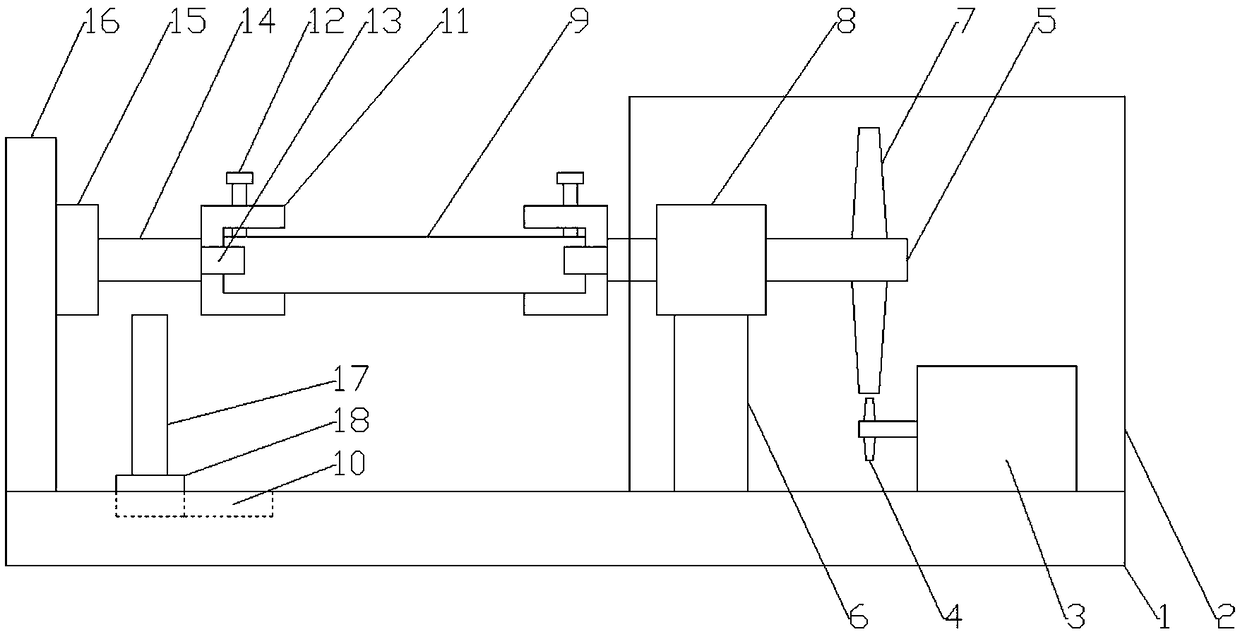

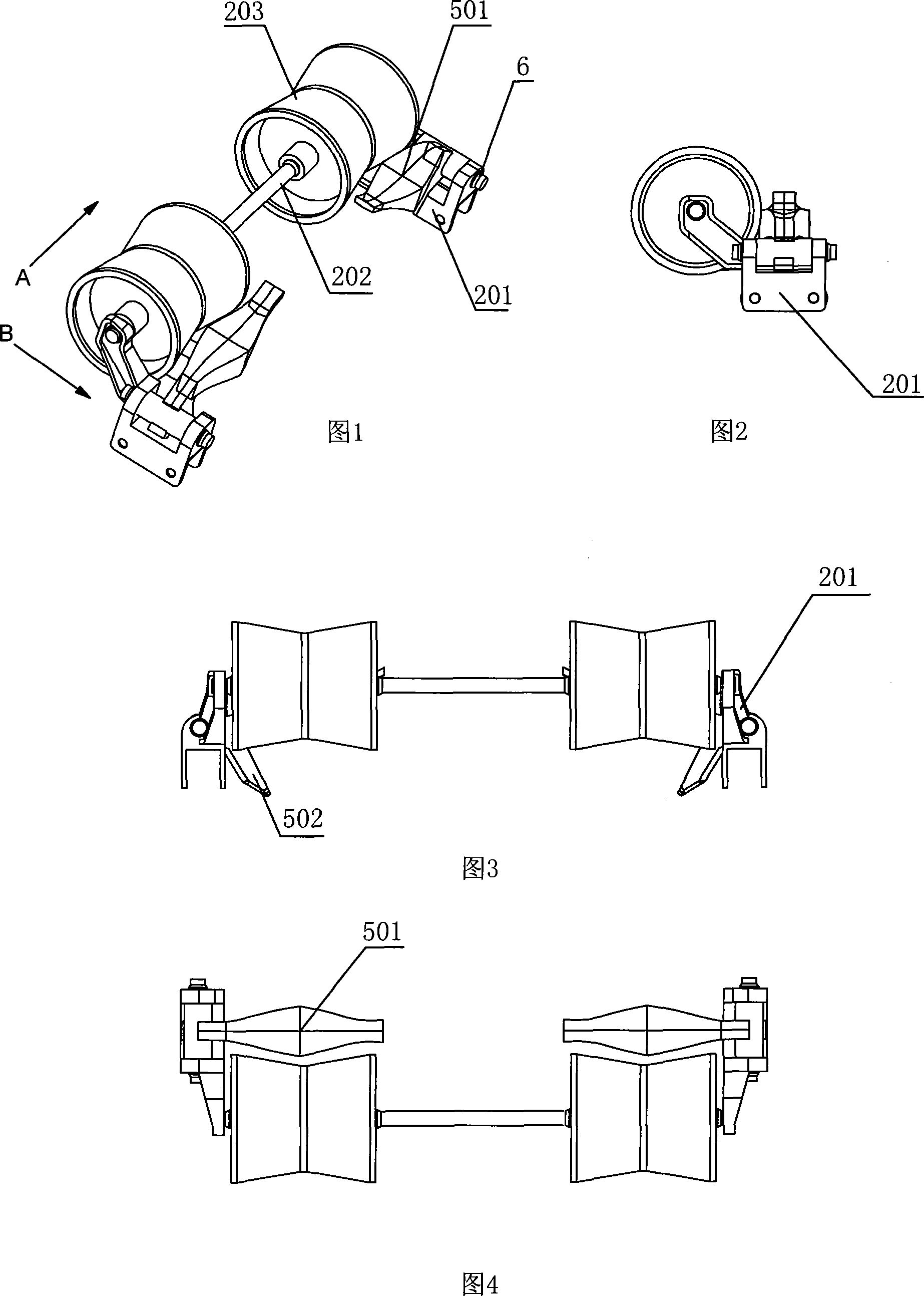

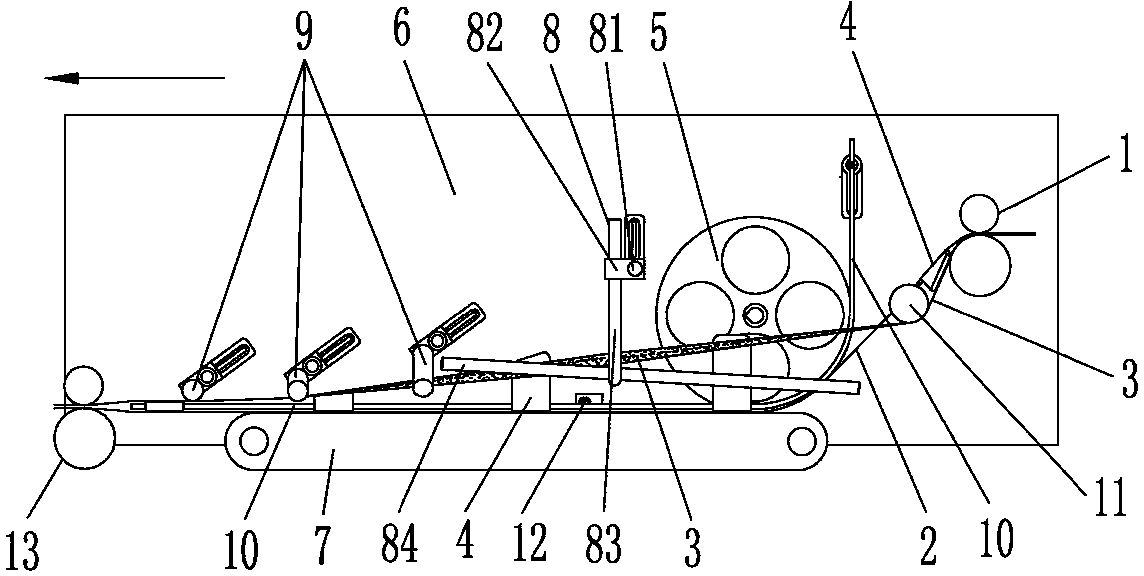

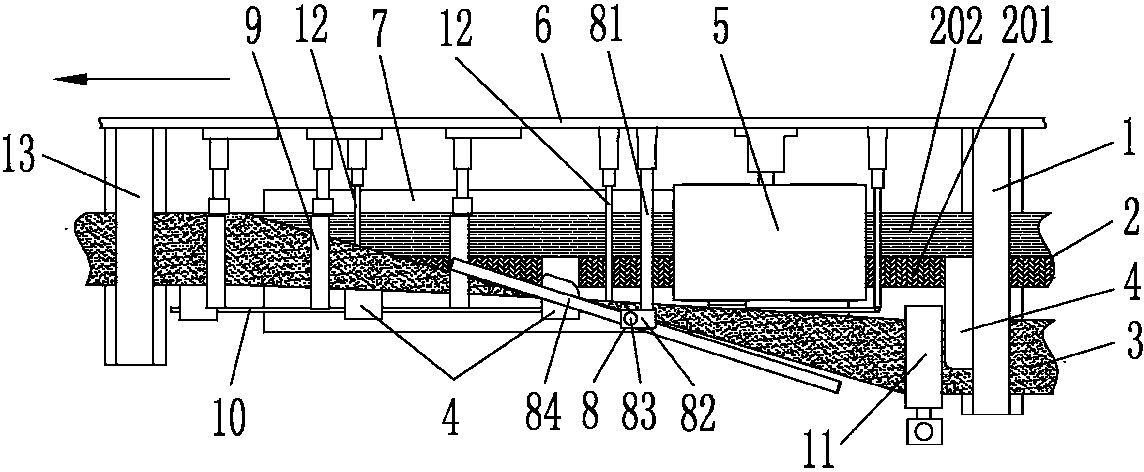

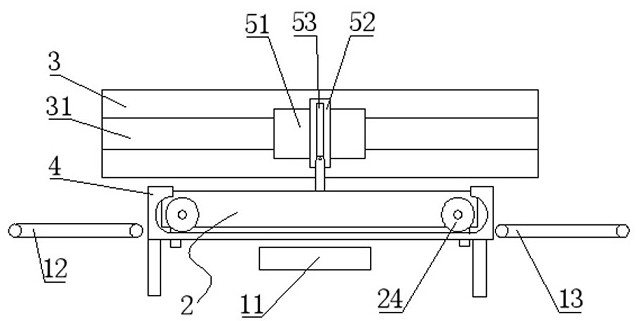

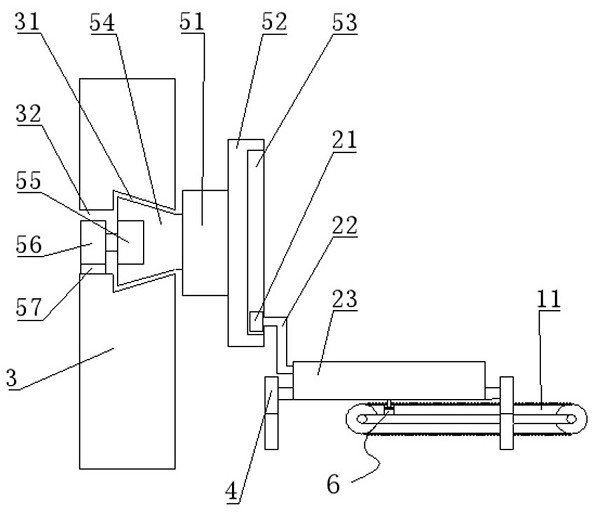

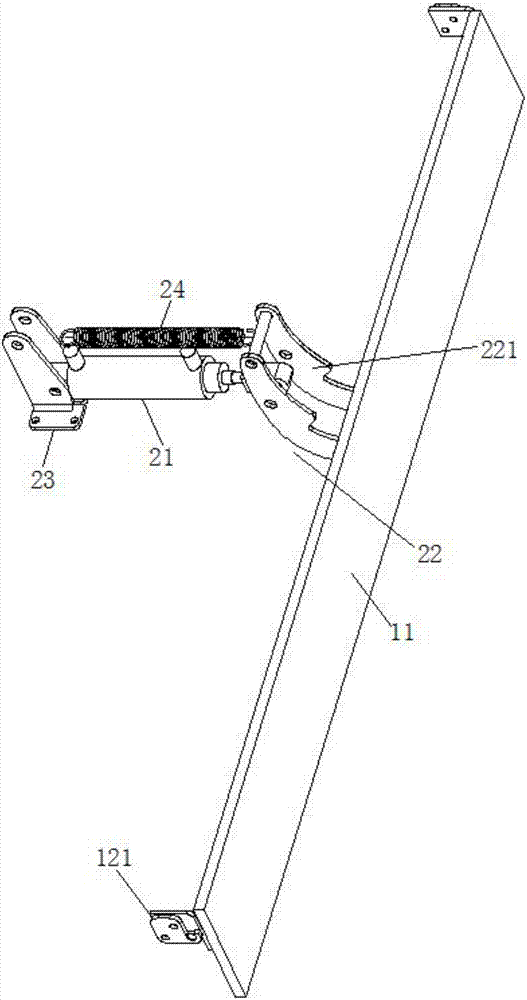

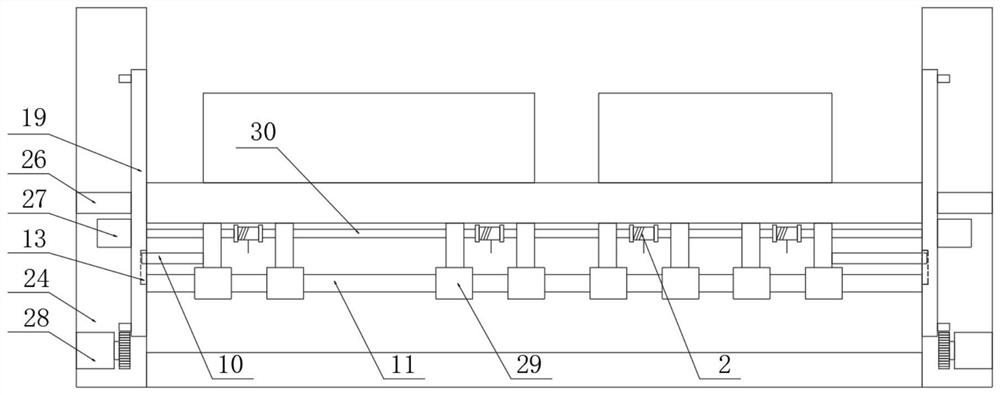

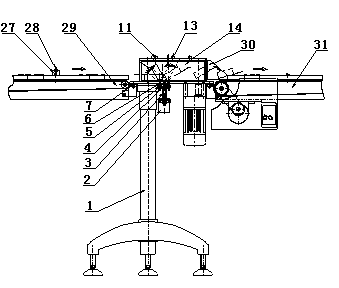

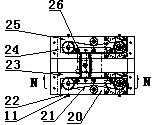

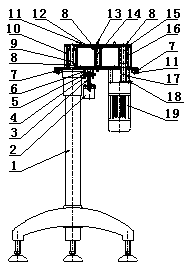

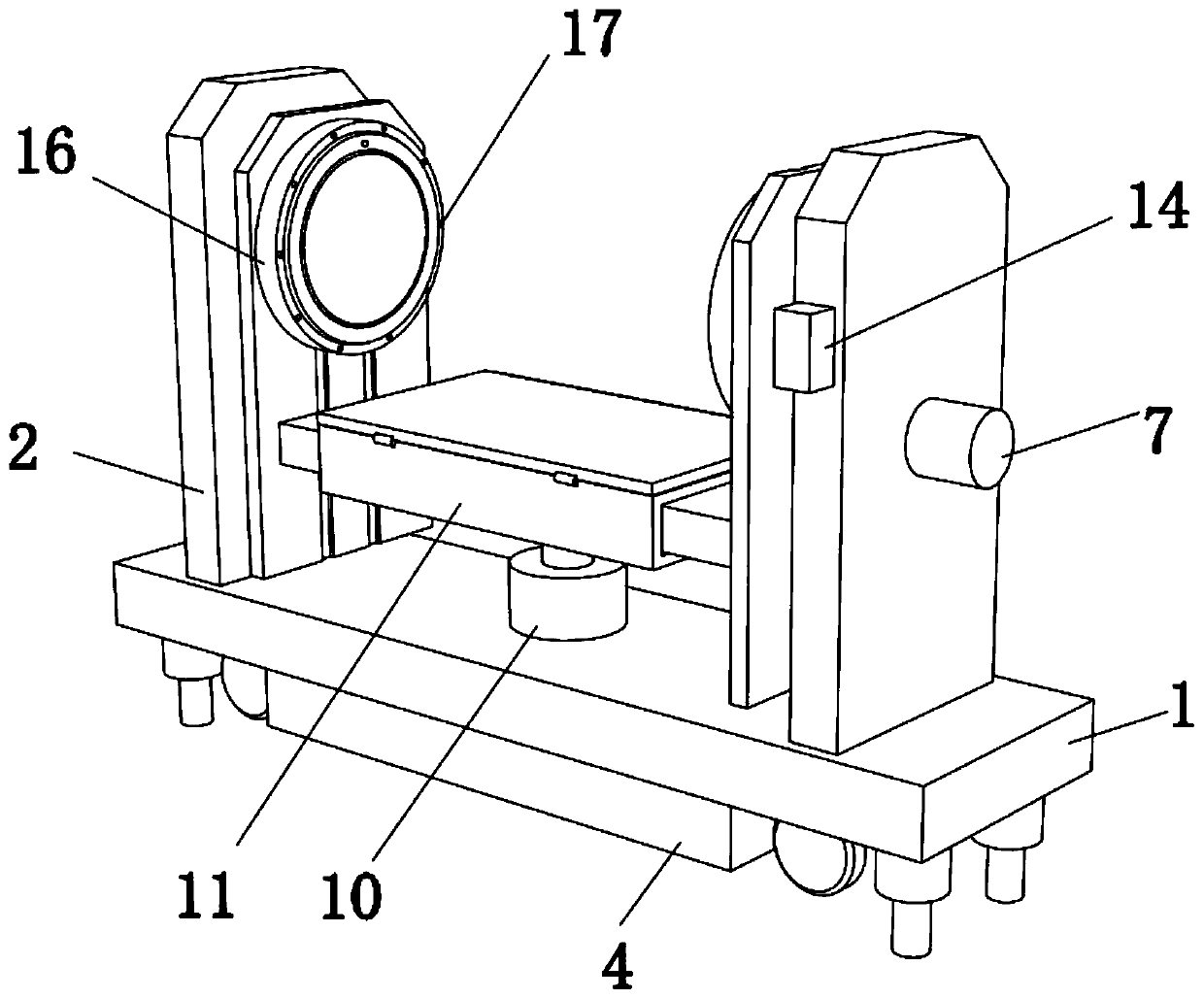

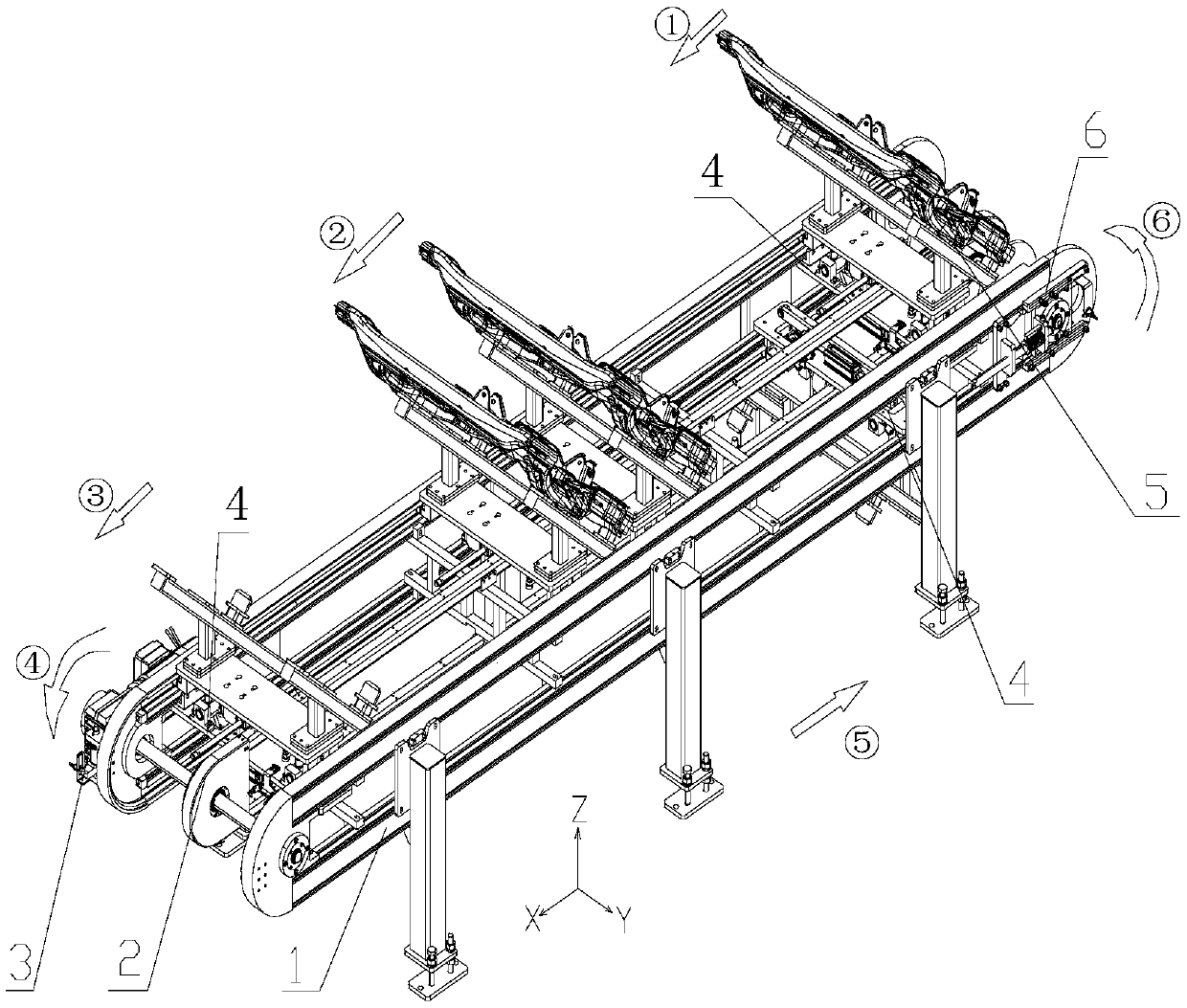

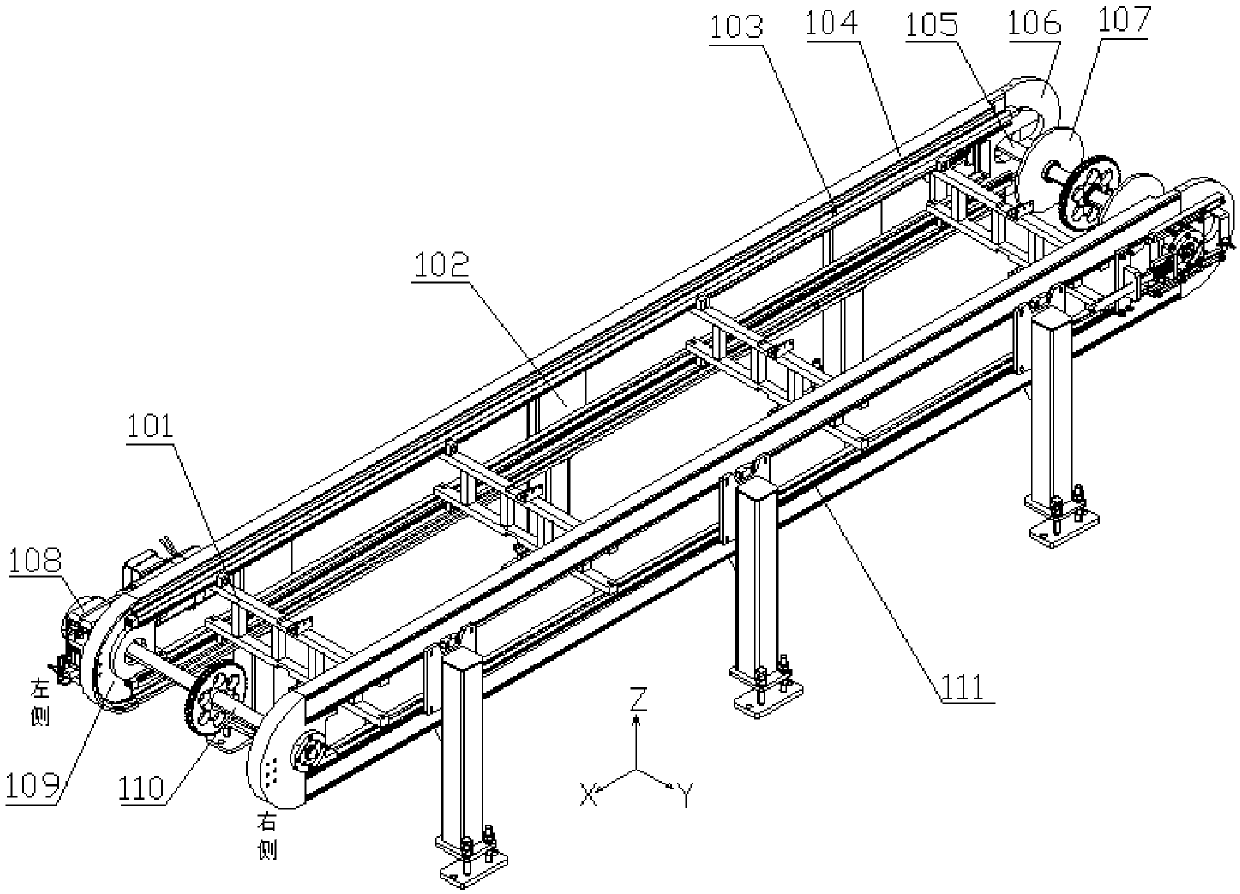

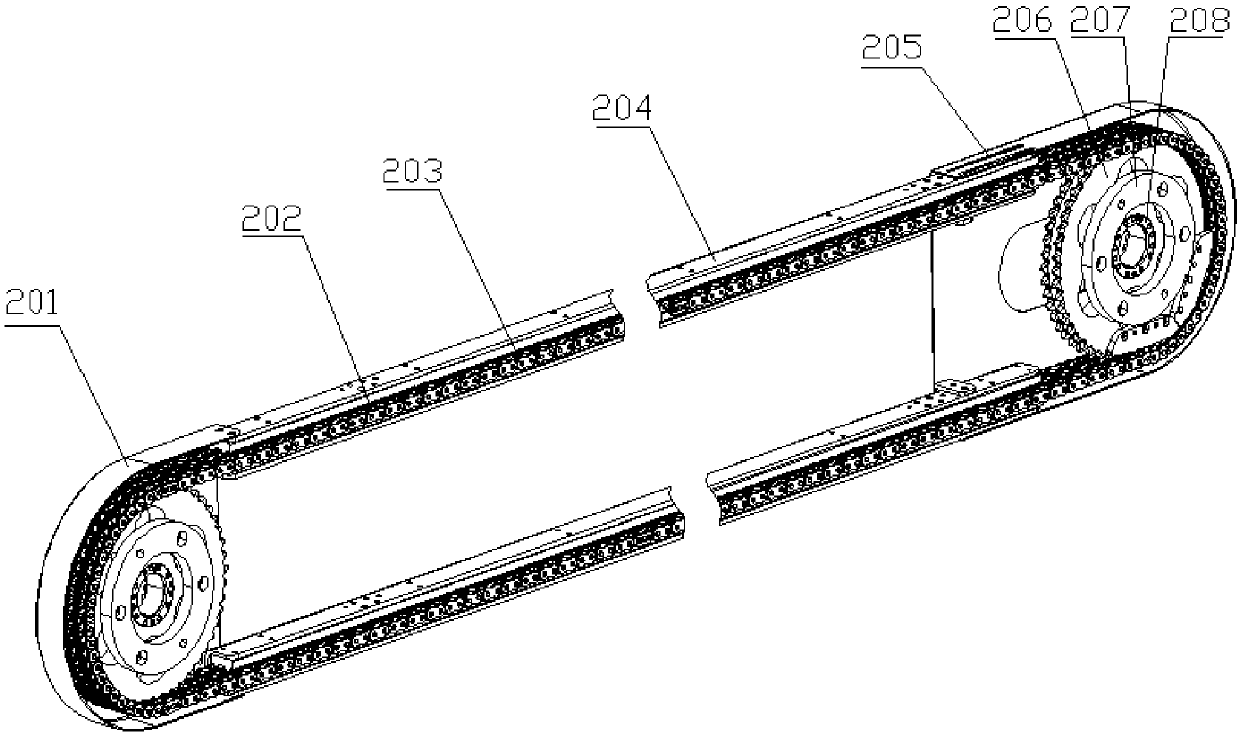

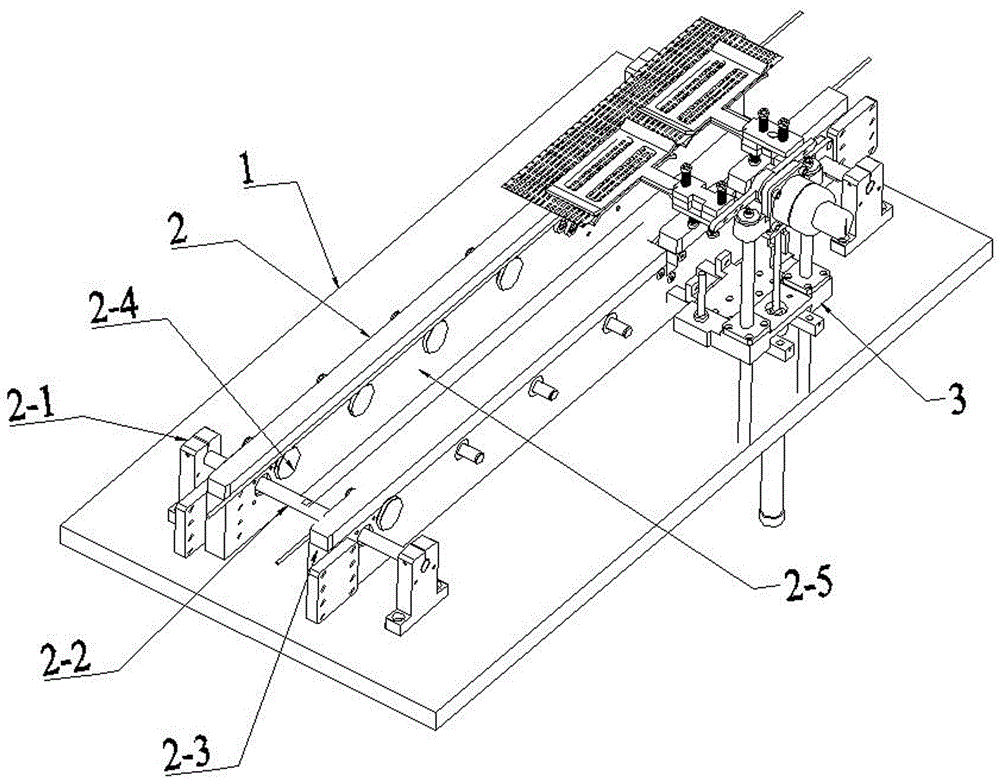

Multi-station conveying mechanism capable of overturning jigs

ActiveCN104475913AFast transmissionRoll over stabilityMetal working apparatusSoldering auxillary devicesAdhesiveEngineering

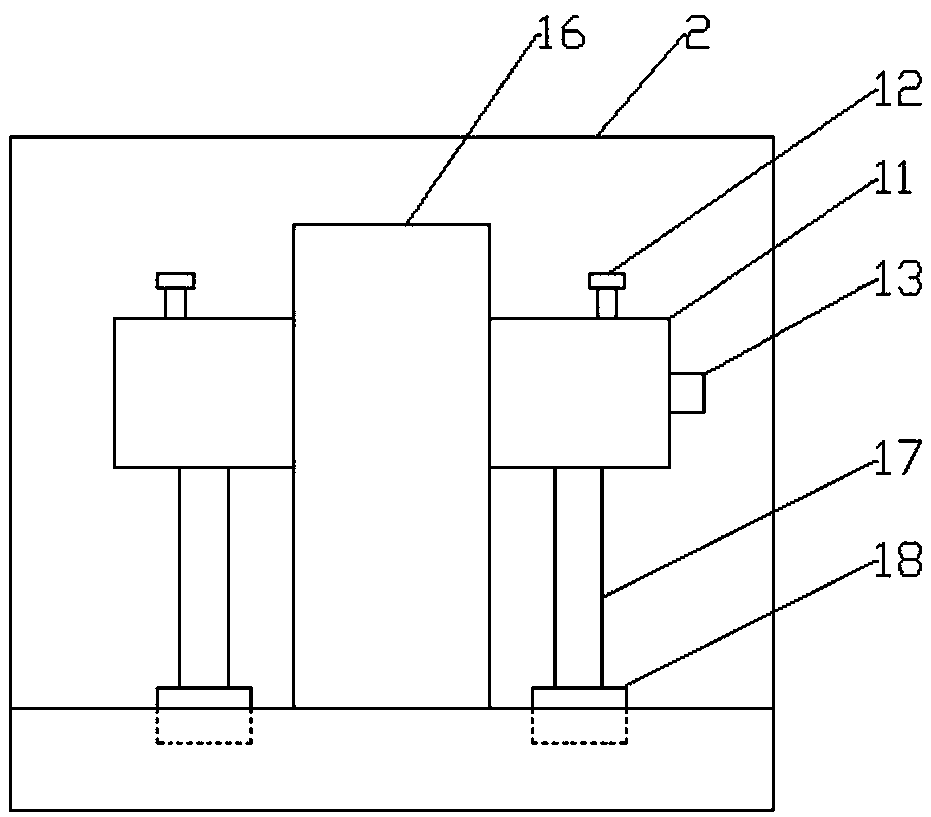

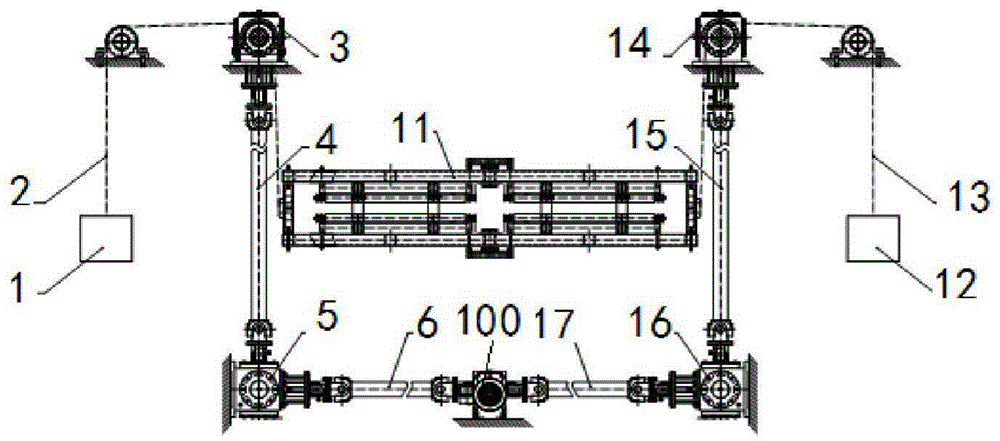

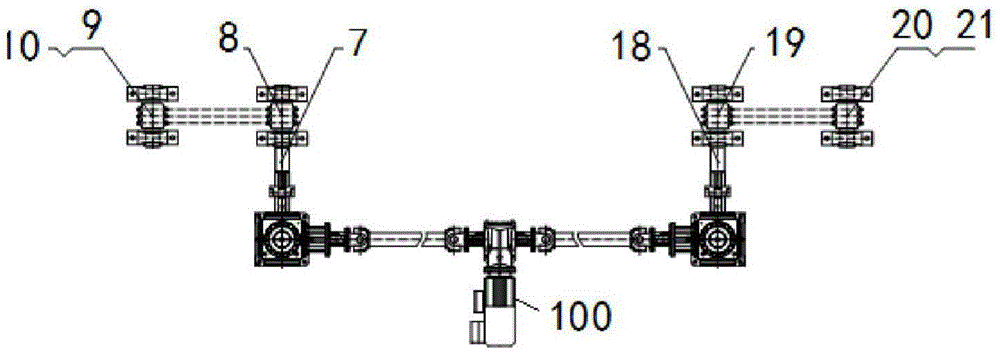

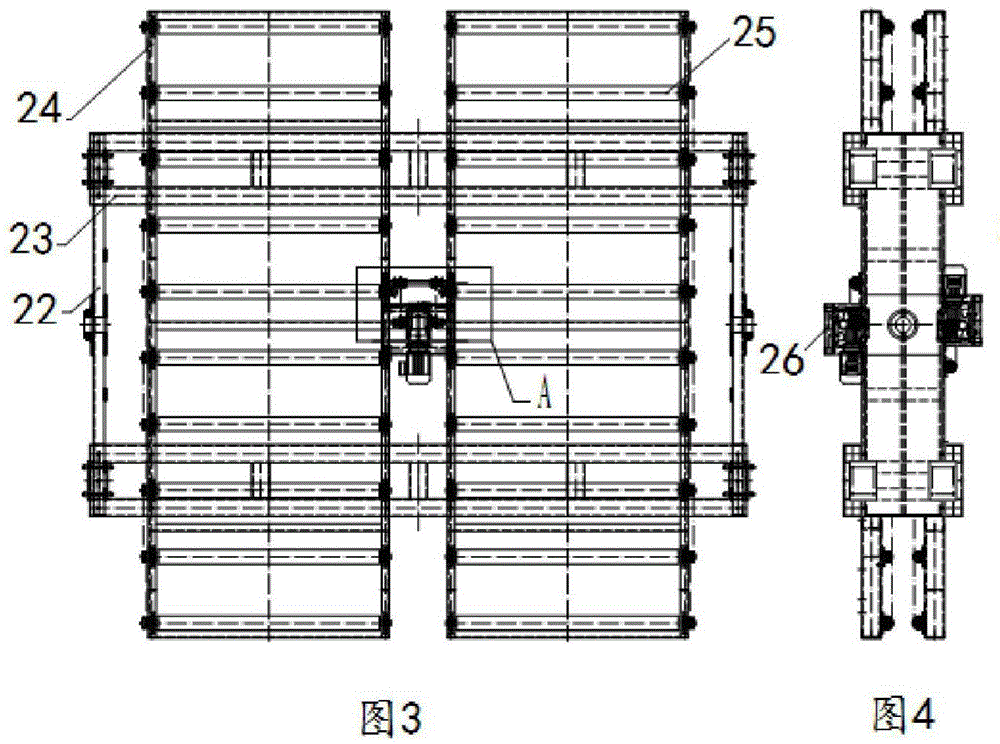

The invention relates to a multi-station conveying mechanism capable of overturning jigs, which comprises an overturning mechanism conveying frame, an overturning mechanism conveying motor, an overturning mechanism driven conveying motor, an overturning mechanism conveying belt, sliding rail assemblies, an overturning device and a drag chain, wherein the overturning mechanism conveying motor is arranged at the left end of the overturning mechanism conveying frame in a connecting manner; the overturning mechanism driven conveying motor is arranged at the right end of the overturning mechanism conveying frame in a connecting manner; the overturning mechanism conveying belt is arranged on the middle part of the overturning mechanism conveying frame and is wound at the tops of the overturning mechanism conveying motor and the overturning mechanism driven conveying motor; the sliding rail assemblies are arranged at both front and rear ends of the overturning mechanism conveying frame; the overturning device is arranged on the sliding rail assemblies; the drag chain is arranged at the front side of the overturning mechanism conveying frame. According to the multi-station conveying mechanism capable of overturning the jigs, the processing operations of a series of different manufacturing procedures, such as conveying feeding, screwing, iron soldering, tin soldering or adhesive dispensing, can be simultaneously carried out on a circuit board; the circuit board can be full-automatically overturned; the multi-station conveying mechanism capable of overturning the jigs is simple and convenient to operate, has a high intelligent degree, has good effects and is low in cost.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

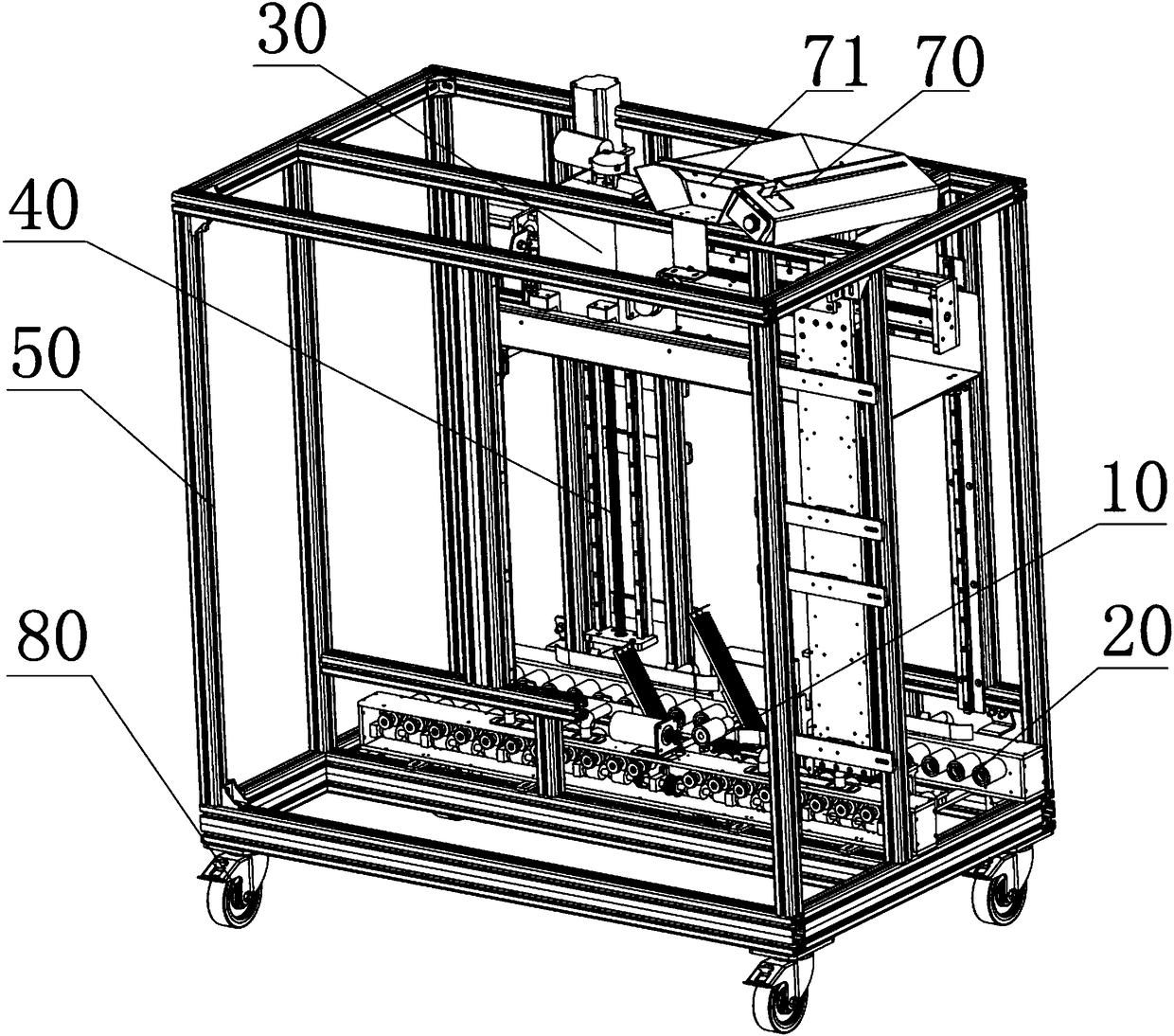

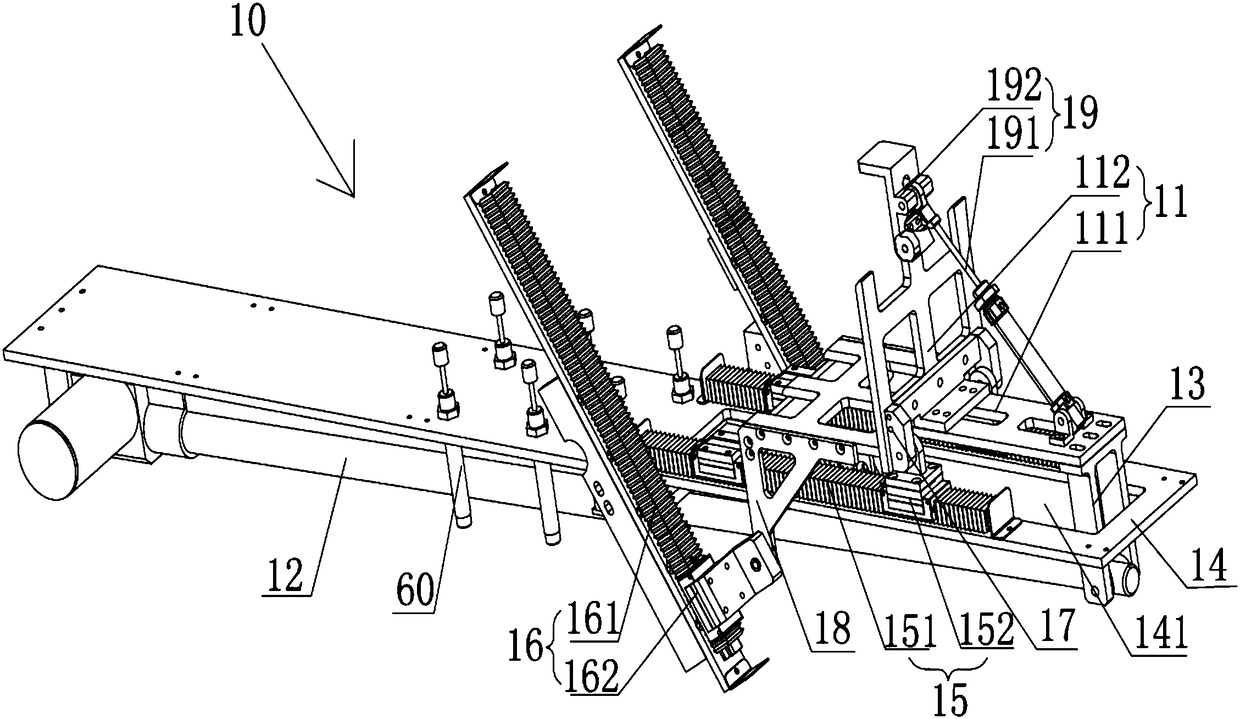

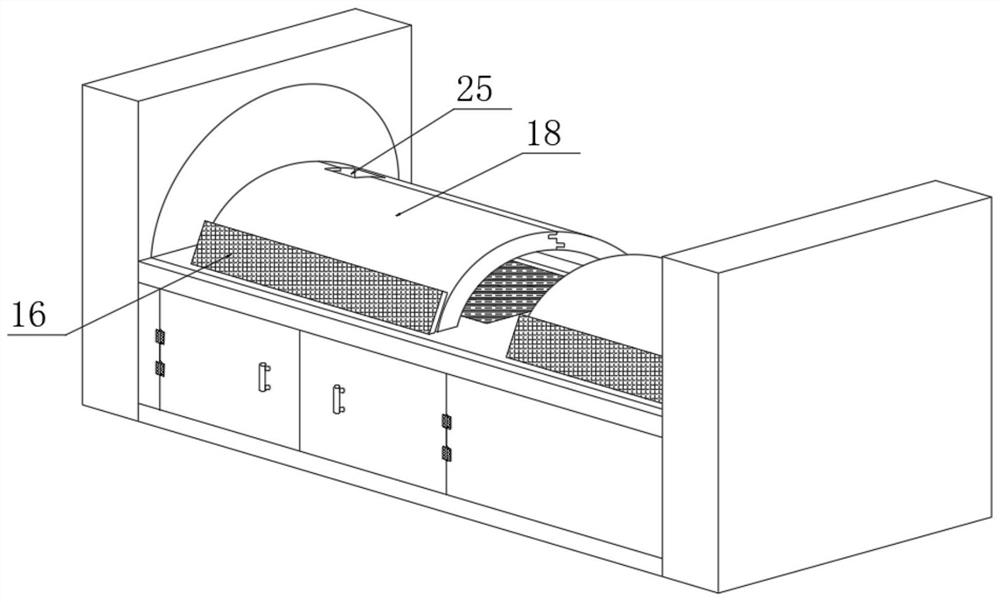

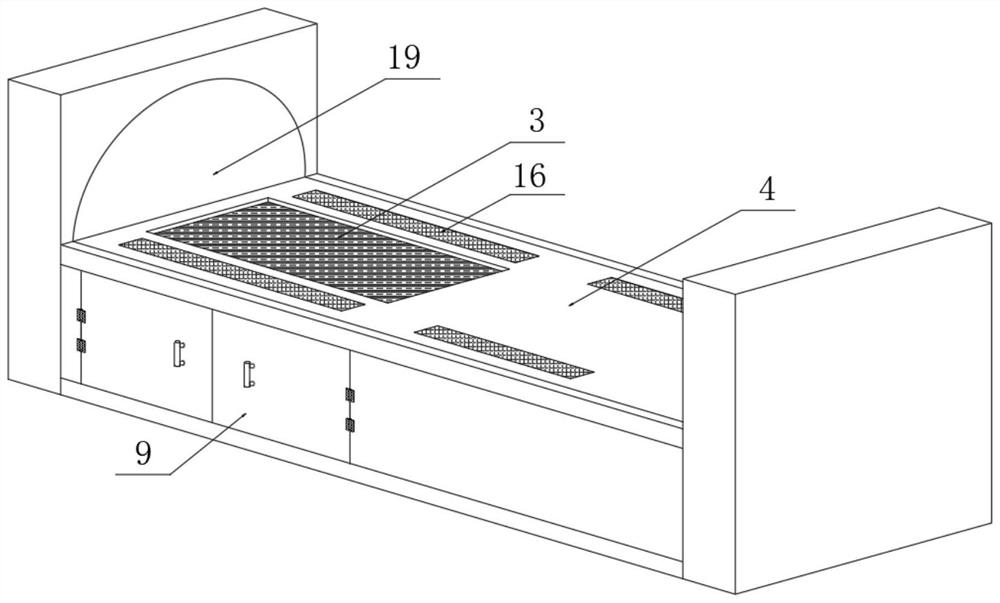

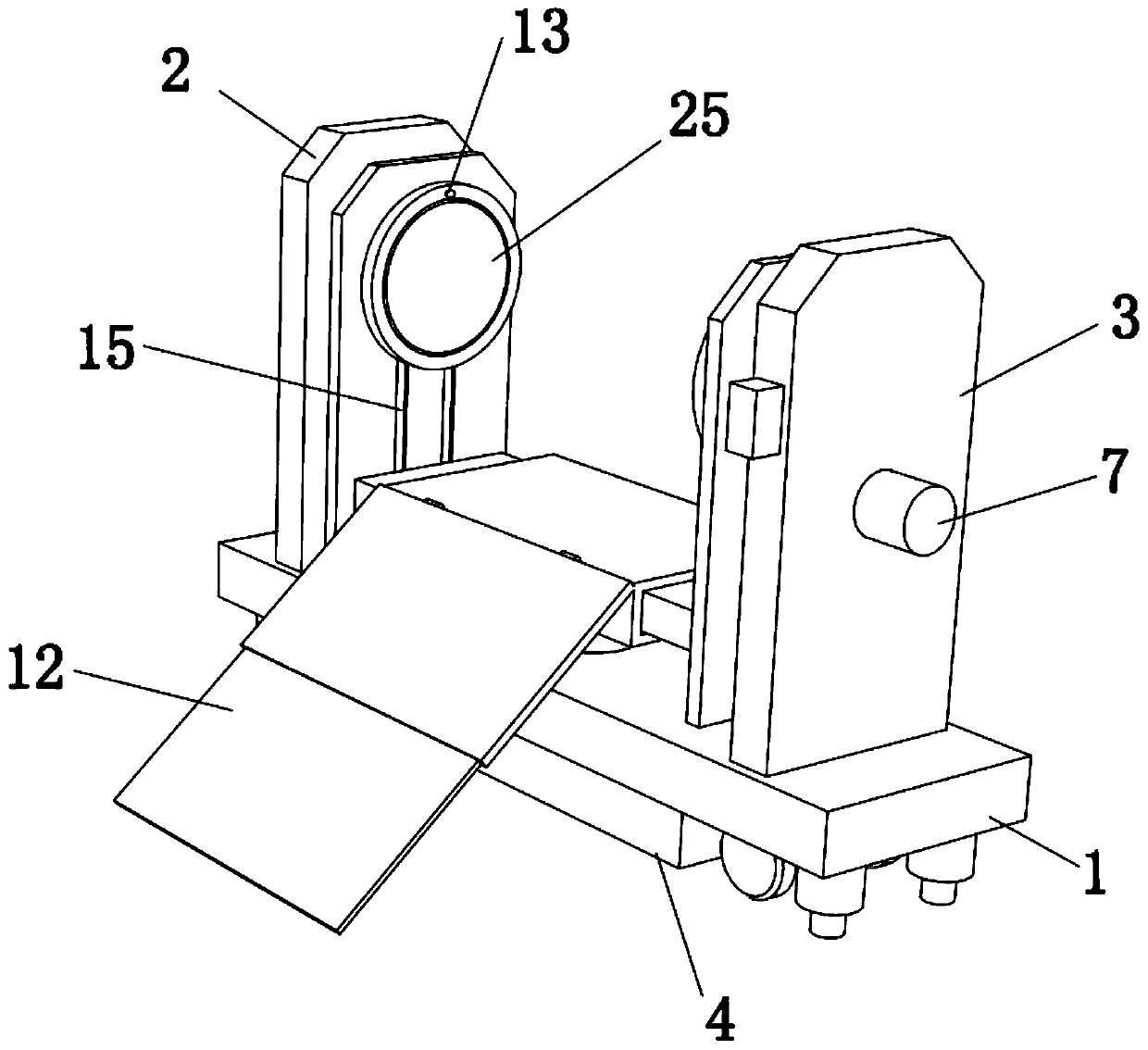

Stable printing paste robot and control method thereof

ActiveCN108071237AFunction increaseHigh printing efficiencyBuilding material handlingManipulatorBrickMechanical equipment

The invention discloses a stable printing paste robot and a control method thereof, and relates to the technical field of mechanical equipment. The stable printing paste robot comprises a turnover mechanism, a transport mechanism, a sizing mechanism, a lifting mechanism, and a support frame; the turnover mechanism is arranged in the lower part of the interior of the support frame; the turnover mechanism is used for turning over wall tiles; the transport mechanism is arranged in the lower part of the interior of the support frame; the transport mechanism comprises two conveying units; the conveying units are separately arranged at both sides of the turnover mechanism and used for conveying the wall bricks after printing paste; the sizing mechanism is arranged in the support and is located above the turnover mechanism; the lifting mechanism is vertically arranged in the support frame; and the lifting mechanism can realize the lifting of the sizing mechanism in the vertical direction. Thestable printing paste robot can ensure that the bottom surface height of the wall tiles after turning over is the same every time and can be applied to printing paste process of wall tiles with different specifications.

Owner:HUAWAY IOT TECH

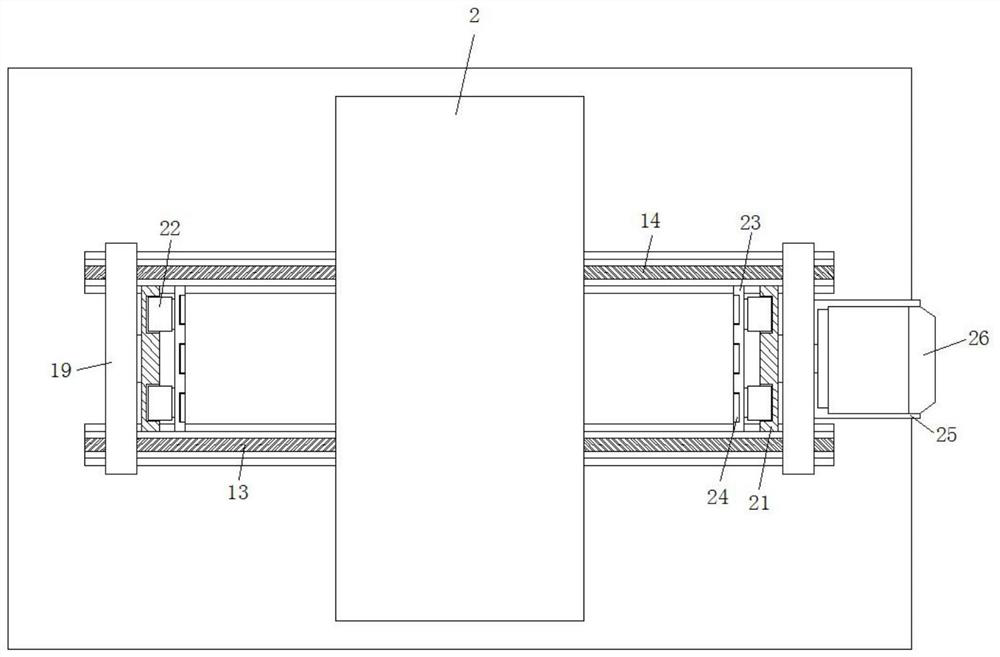

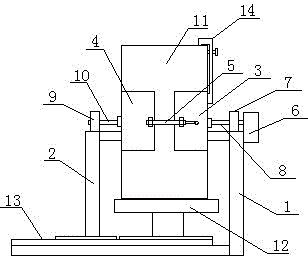

Dead-corner-free efficient drilling equipment for power distribution cabinet production

PendingCN112139542AImprove work efficiencyGuaranteed uptimeFeeding apparatusPositioning apparatusRolling-element bearingStructural engineering

The invention discloses dead-corner-free efficient drilling equipment for power distribution cabinet production. The equipment comprises a working table. An installing frame is fixed to the middle ofthe top face of the working table through screws. First installing columns are connected to the inner walls of the two sides of the installing frame through rolling bearings correspondingly. First installing plates are fixed to the ends of the first installing columns correspondingly. First grooves are formed in the upper sides and the lower sides of the ends, away from the first installing columns, of the first installing plates. First electric telescopic rods are fixedly connected to the inner walls of the first grooves through screws. First adsorption plates are fixedly connected to the output ends of the first electric telescopic rods through screws. First electromagnetic blocks are fixed in the other ends of the first adsorption plates correspondingly. First horizontal frames are fixedly connected to the sides of the first installing frames through screws. First servo motors are fixedly connected to the top faces of the first horizontal frames through screws. The equipment is stable in operation, reasonable in design and high in automation degree, dead-corner-free drilling operation on the six faces of an electric control cabinet can be achieved after one-time feeding, and theworking efficiency of drilling of the electric control cabinet is greatly improved.

Owner:ANHUI LANRUN AUTOMATION INSTR

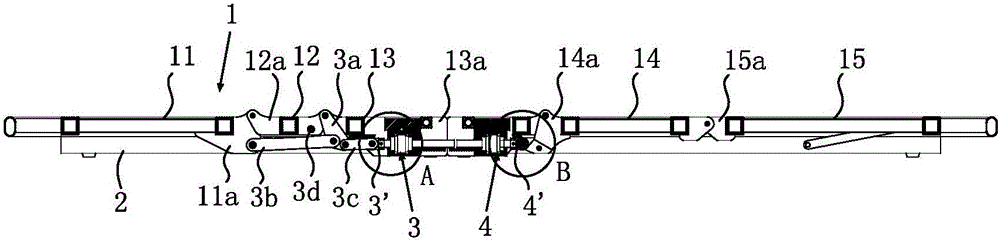

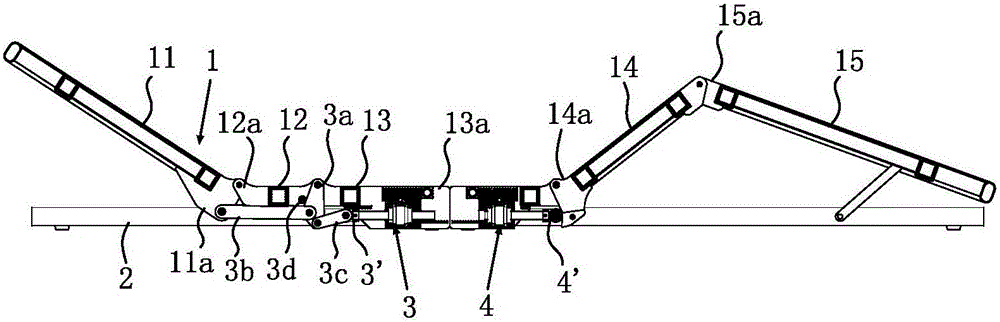

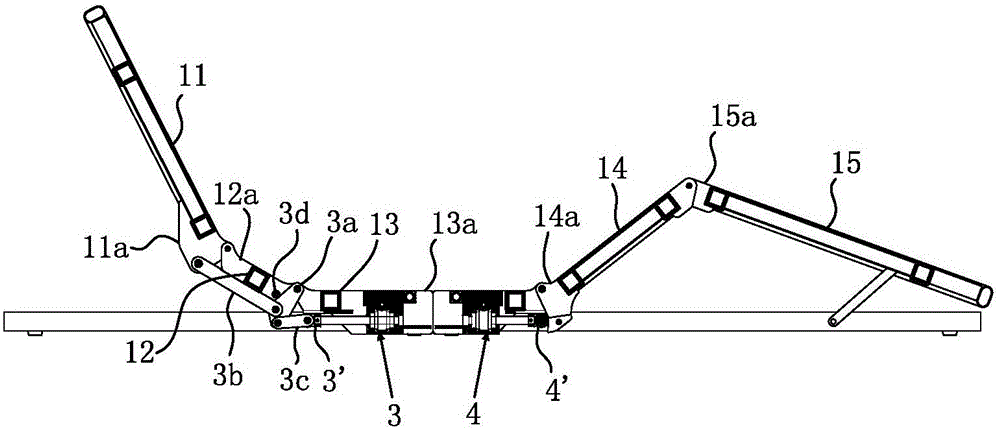

Intelligent mattress

The invention, which belongs to the technical field of the mattress, discloses an intelligent mattress comprising a bed body and a bed frame for supporting the bed body. The bed body consists of a back frame, a waist frame, and a seat frame, wherein the frames are in a hinge joint successively. The seat frame is fixed on the bed frame. A first driver with a driving end is arranged at the bed frame; a first connecting rod is in hinge joint with the bed frame; and a second connecting rod is arranged between the first connecting rod and the back frame. The driving end of the first driver makes stretching movement to drive the first connecting rod to swing. One end of the second connecting rod is linked to the first connecting rod and the other end can apply a force to the back frame to enable the back frame to overturn up and down relative to the waist frame. A pin shaft arranged in a swinging region of the first connecting rod is arranged at the waist frame; and the first connecting rod can apply a force to the waist frame by the pins shaft, so that the waist frame can overturn up and down relative to the seat frame. The intelligent mattress has the advantage: the loading force applied on the driver can be reduced.

Owner:NINGBO KANGMAILONG MEDICAL APP

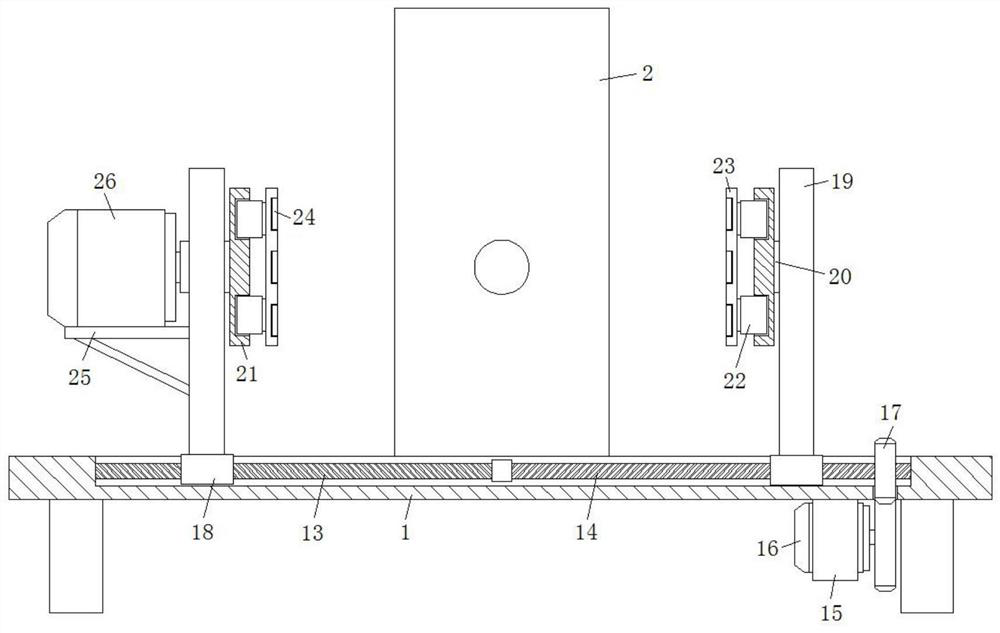

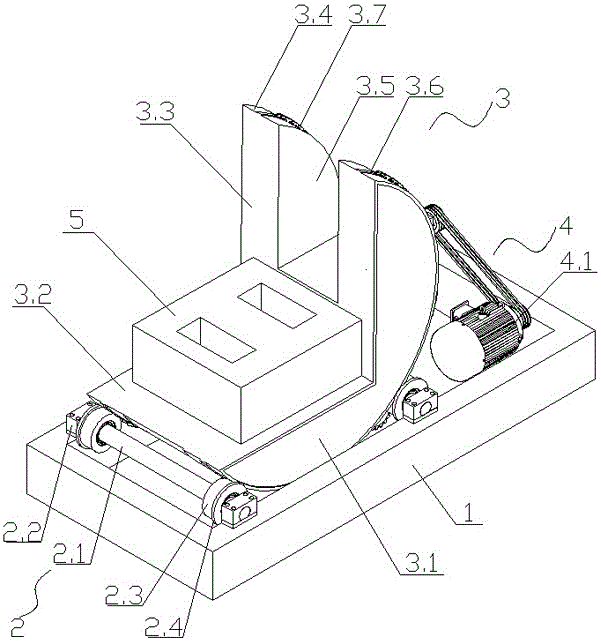

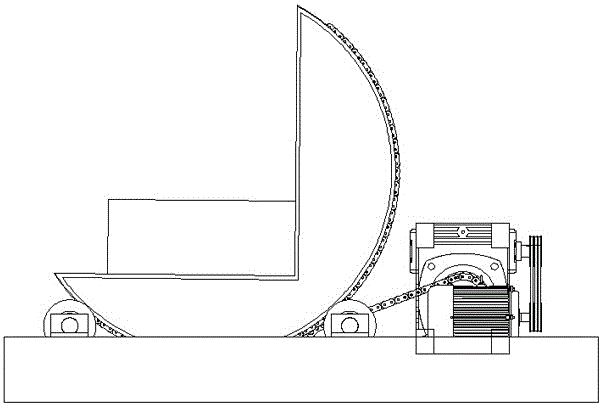

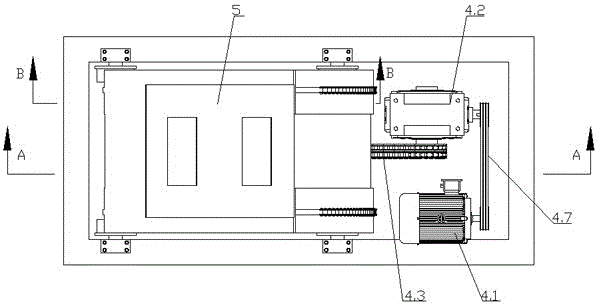

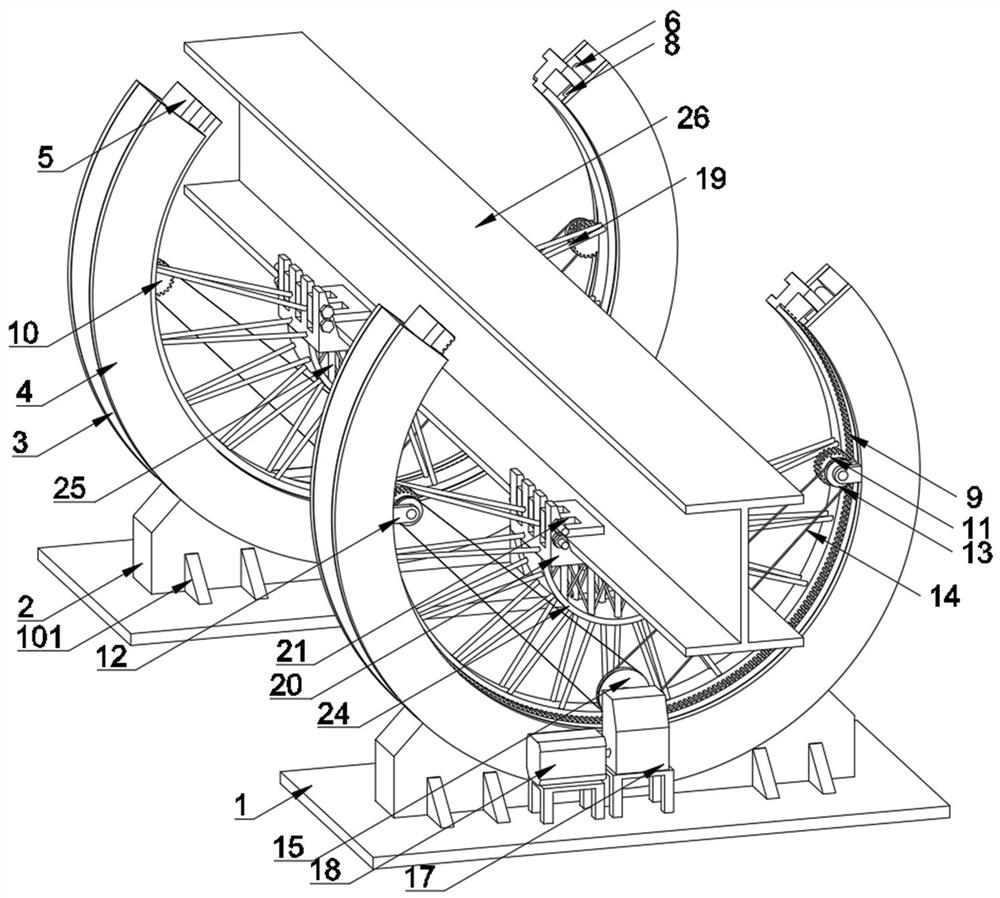

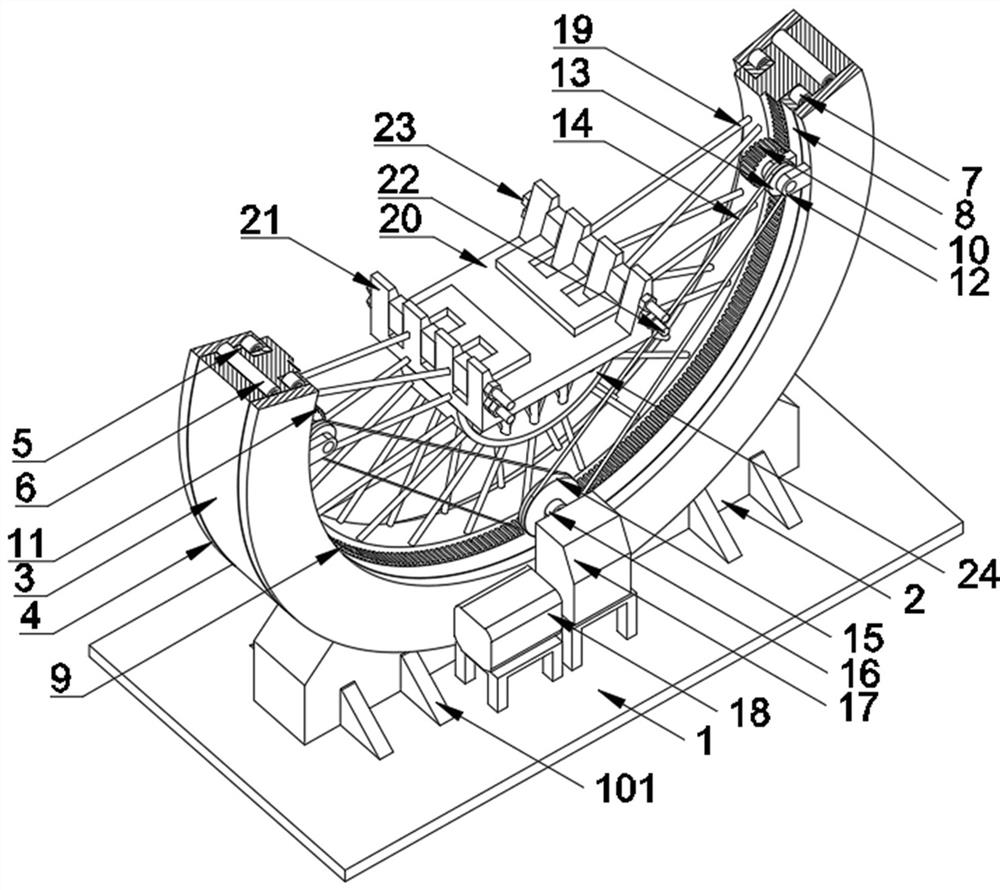

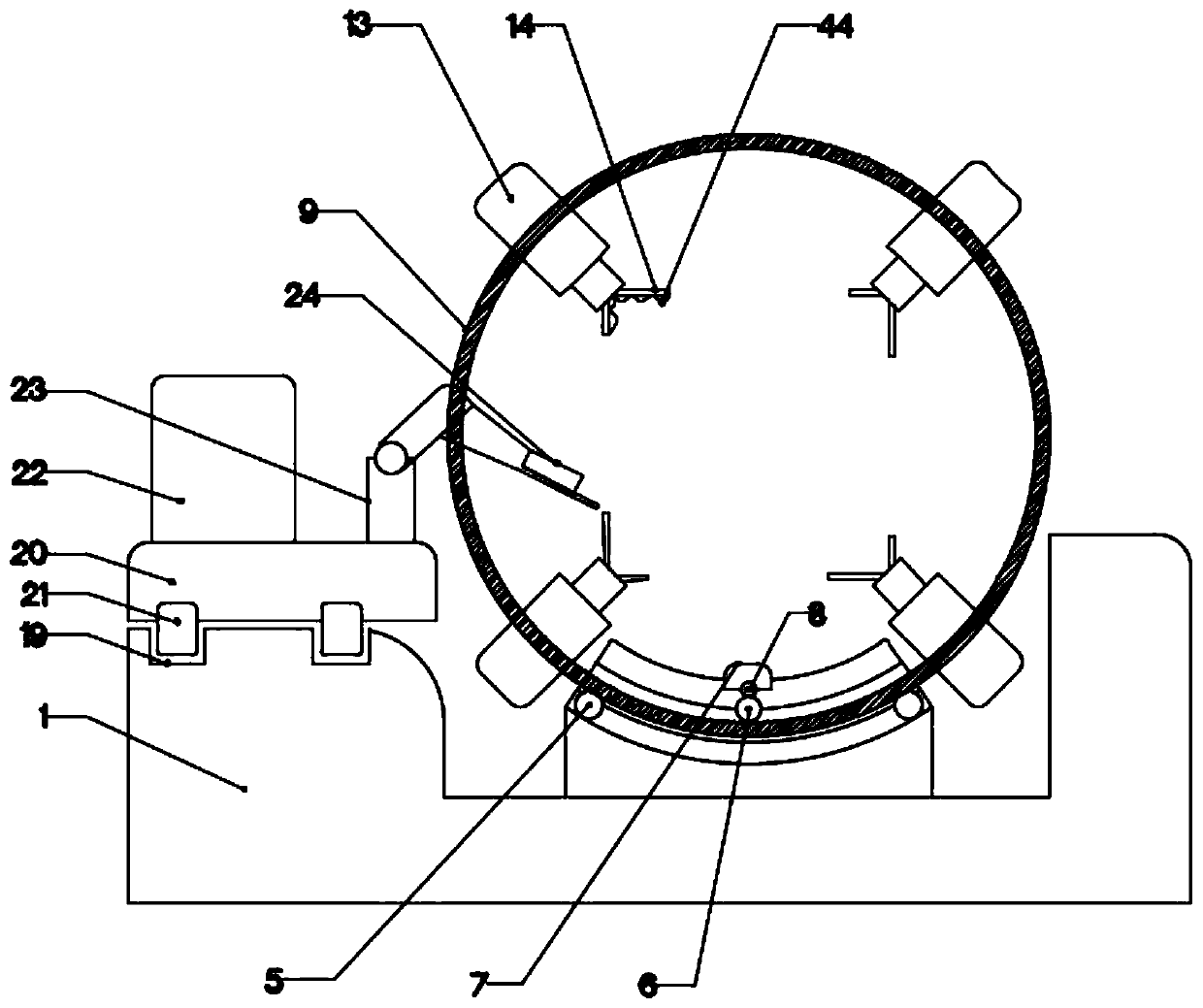

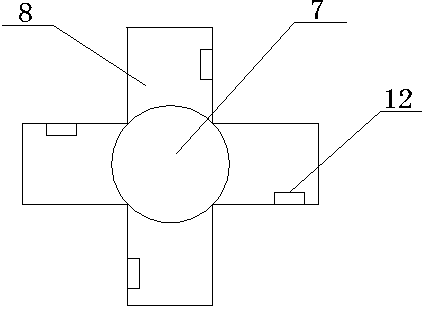

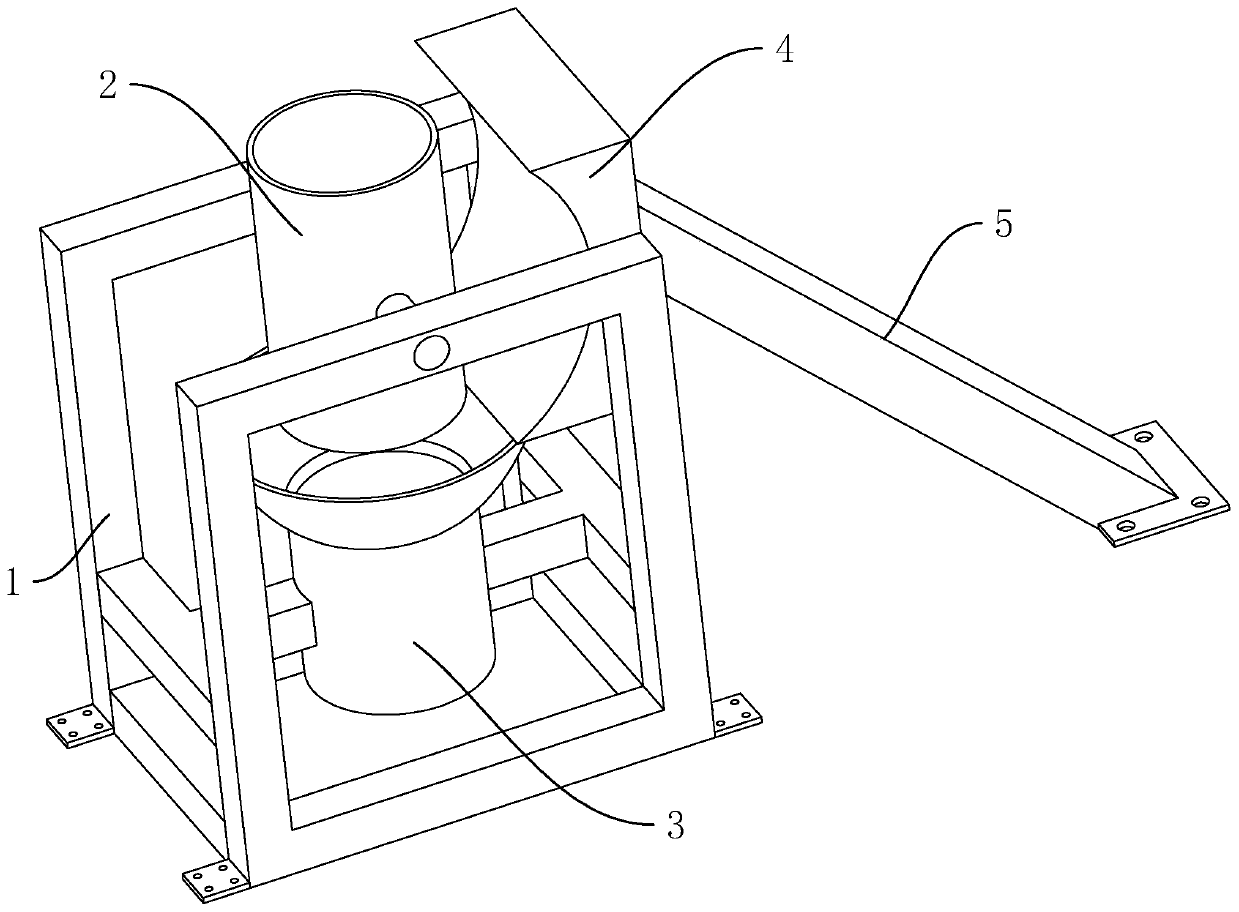

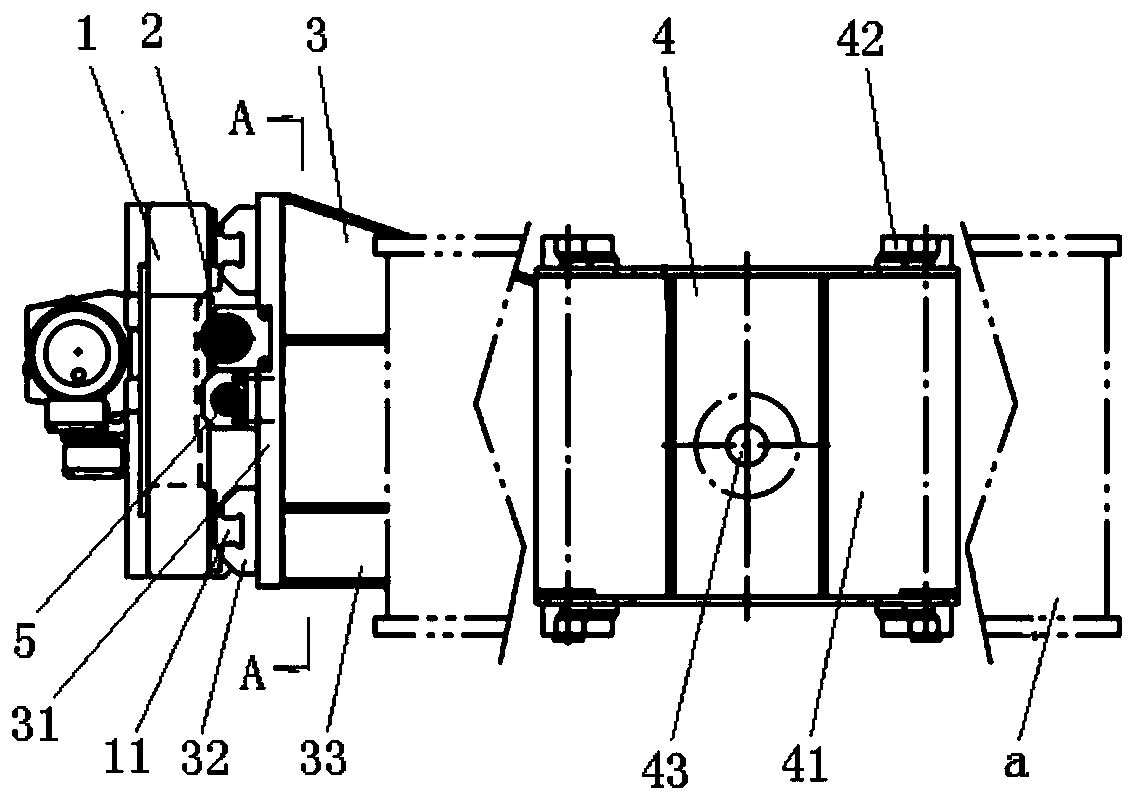

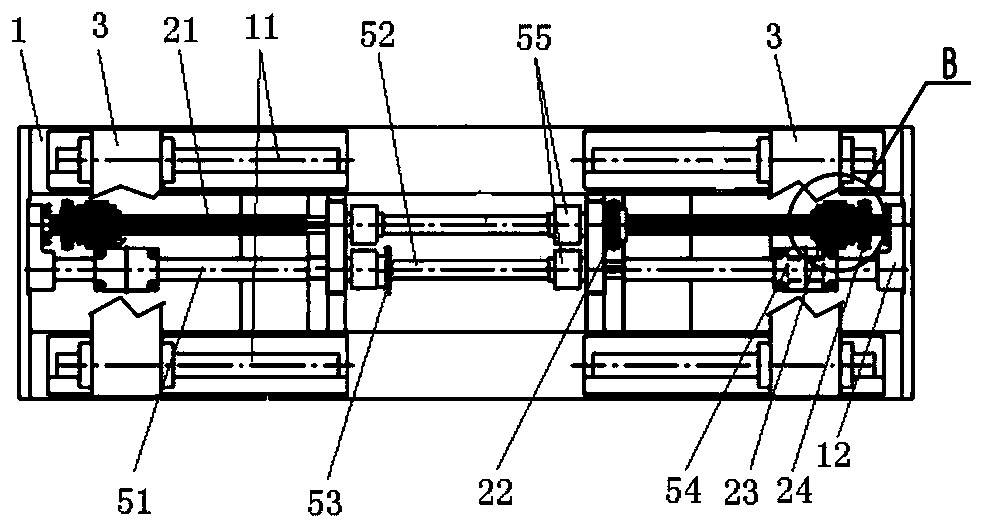

Transformer iron core overturning device and operating method thereof

ActiveCN106298222ARealize semi-automatic operationReduce labor intensityInductances/transformers/magnets manufactureTransformerSemi automatic

The invention relates to a transformer iron core overturning device which comprises a base (1), a bracket (2), an overturning frame (3) and a power mechanism (4), wherein the bracket (2) comprises a left supporting shaft (2.1) and a right rotary supporting shaft (2.1) which are arranged longitudinally; two supporting wheels (2.3) are mounted on the front segment and the back segment of each rotary supporting shaft (2.1) in a sleeving manner respectively; the overturning frame (3) comprises an overturning frame main body (3.1); the overturning frame main body (3.1) is provided with a first supporting plane (3.2) and a second supporting plane (3.3) which are perpendicular to each other; the overturning frame main body (3.1) is also provided with an arc segment driving plane (3.4); a driving chain (3.7) on the driving plane (3.4) is driven by the power mechanism (4). The transformer iron core overturning device provided by the invention has the advantages of realizing semi-automatic operation, reducing labor intensity and realizing stable overturning.

Owner:JIANGYIN HONGHENG ELECTROMECHANICAL TECH CO LTD

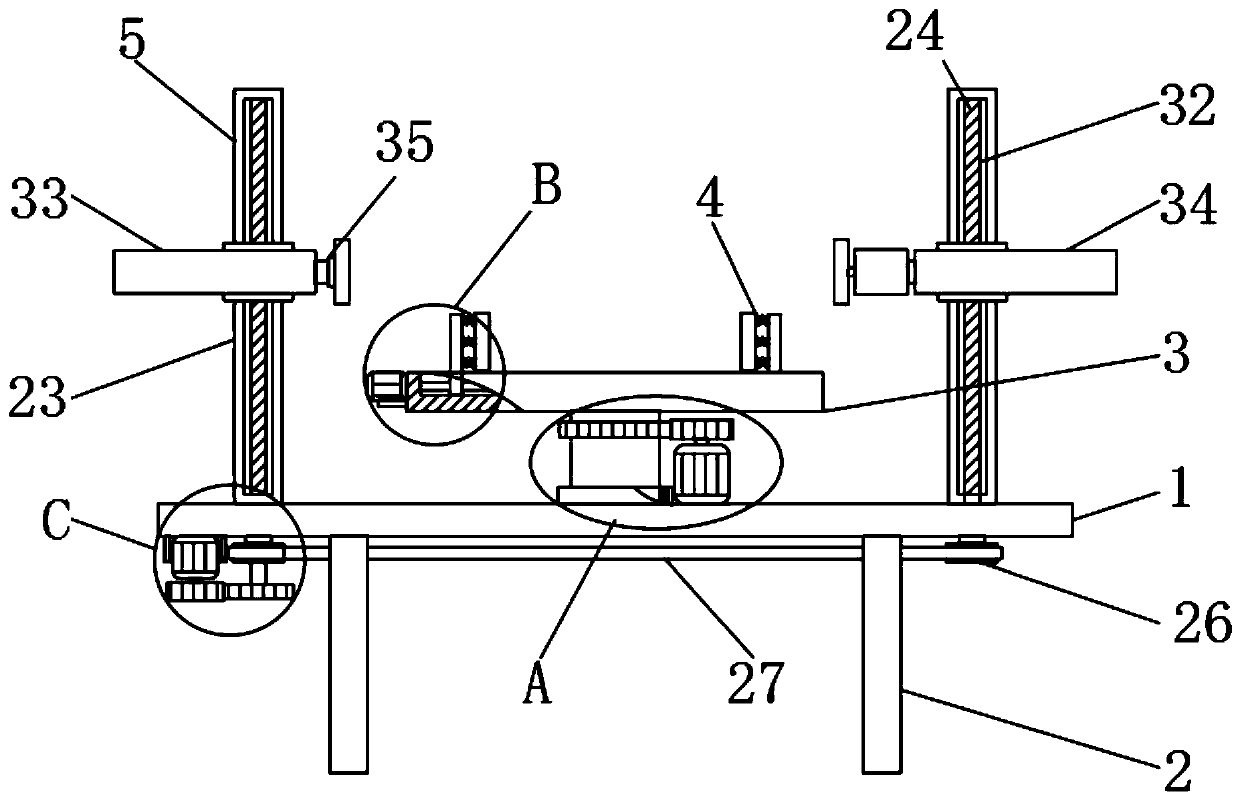

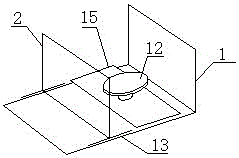

Sand box turnover device for butterfly valve casting

InactiveCN108405835AReduce bumpsIntegrity guaranteedMould handling equipmentsEngineeringButterfly valve

The invention discloses a sand box turnover device for butterfly valve casting. The sand box turnover device comprises a bottom plate, wherein a supporting plate and a support column are correspondingly arranged at the two ends of the bottom plate, a rotating seat II is arranged on the side face of the supporting plate, and a rotating rod II is arranged in the rotating seat II; two sliding groovesin the length direction of the bottom plate are formed below the rotating rod II, sliding blocks are arranged in the sliding grooves, and a supporting columns are fixed at the upper ends of the sliding blocks; a rotating seat I is arranged at the upper end of the support column, a rotating rod I is arranged in the rotating seat I, and C-shaped chucks are arranged at the front end of the rotatingrod I and the front end of the rotating rod II; a sand box is arranged between the chucks, clamping bolts which are in threaded connection with the chucks are arranged at the upper ends of the chucks,and the lower ends of the clamping bolts are in contact with the upper end of the sand box; and limiting blocks are arranged at the front ends of the chucks, a large gear is arranged at the rear endof the rotating rod I, a stepping motor is further arranged on the bottom plate, and a pinion meshed with the large gear is arranged on a main shaft of operation is simple, the turnover process is gentle, the collision occurring in the sand box is reduced, and the integrity of an internal sand mold is ensured.

Owner:WUHU HUABANG FLUID TECH CO LTD

Lift type reciprocating automatic plate turnover machine and method

The invention discloses a lift type reciprocating automatic plate turnover machine and a method, and belongs to the technical field of machinery. One end of a double-output shaft of a speed reducing motor is connected with a first universal coupling; the speed reducing motor is fixed on the ground; the first universal coupling is connected with a first lower reversing box; the first lower reversing box is fixed on a frame, and is connected with a second universal coupling; the second universal coupling is connected with a first upper reversing box; the first upper reversing box is fixed on the frame, and is connected with a first driving shaft through a coupling; the first driving shaft is fixed on the frame through a plummer block, and is connected with a first driving chain wheel; a first driven shaft is connected with a first driven chain wheel; two ends of a first chain are respectively connected with a first counterweight and a double-layer conveying roller way; and the first chain is connected with the first driving chain wheel and the first driven chain wheel. The lift type reciprocating automatic plate turnover machine can quickly overturn curtain wall frames; and a one-way adjustable baffle plate mechanism can realize overturning of the curtain wall frames with different specifications.

Owner:中联装备集团北新机械有限公司

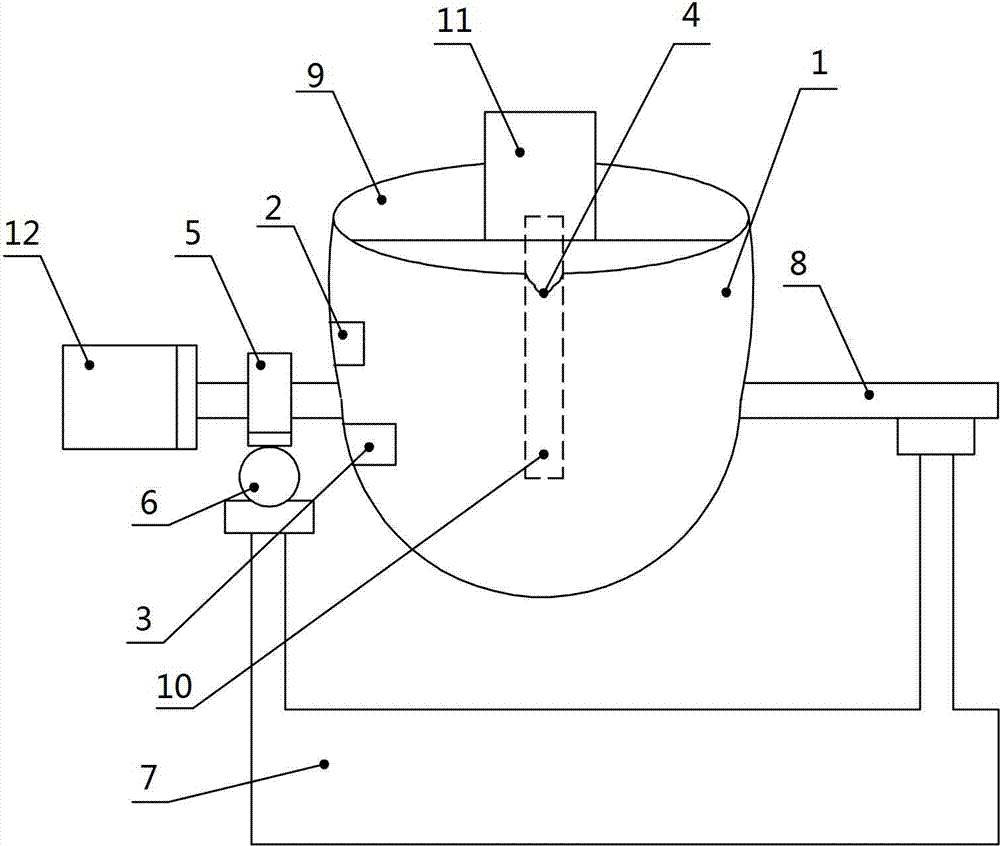

Syrup heating tank

InactiveCN103757145AEasy to cause blockageSolve the blockageGlucose productionEngineeringFood processing

The invention belongs to the field of food processing equipment, and especially relates to a syrup heating tank. The syrup heating tank comprises a syrup heating tank main body; the syrup heating tank main body is provided with a feed inlet, a steam inlet, a dumping mouth, and a dumping device; the dumping mouth is arranged at an opening of the syrup heating tank main body; the dumping device is fixedly arranged on the syrup heating tank main body, and comprises a worm wheel, a worm rod, a pedestal, a turnover shaft, and a motor; the worm rod and the pedestal are fixed together; the worm rod and the worm wheel cooperates with each other; the turnover shaft and the worm wheel are fixed together, and the ends of the turnover shaft are arranged on the syrup heating tank main body; and the worm wheel is driven by the motor. The syrup heating tank main body is not provided with a discharge port, but the opening of the syrup heating tank main body is provided with the dumping mouth; and the whole syrup heating tank can be inclined by the dumping device, so that syrup in the syrup heating tank is discharged via the dumping mouth, and blocking of the discharge port is avoided.

Owner:重庆市合川区川洲桃片有限公司

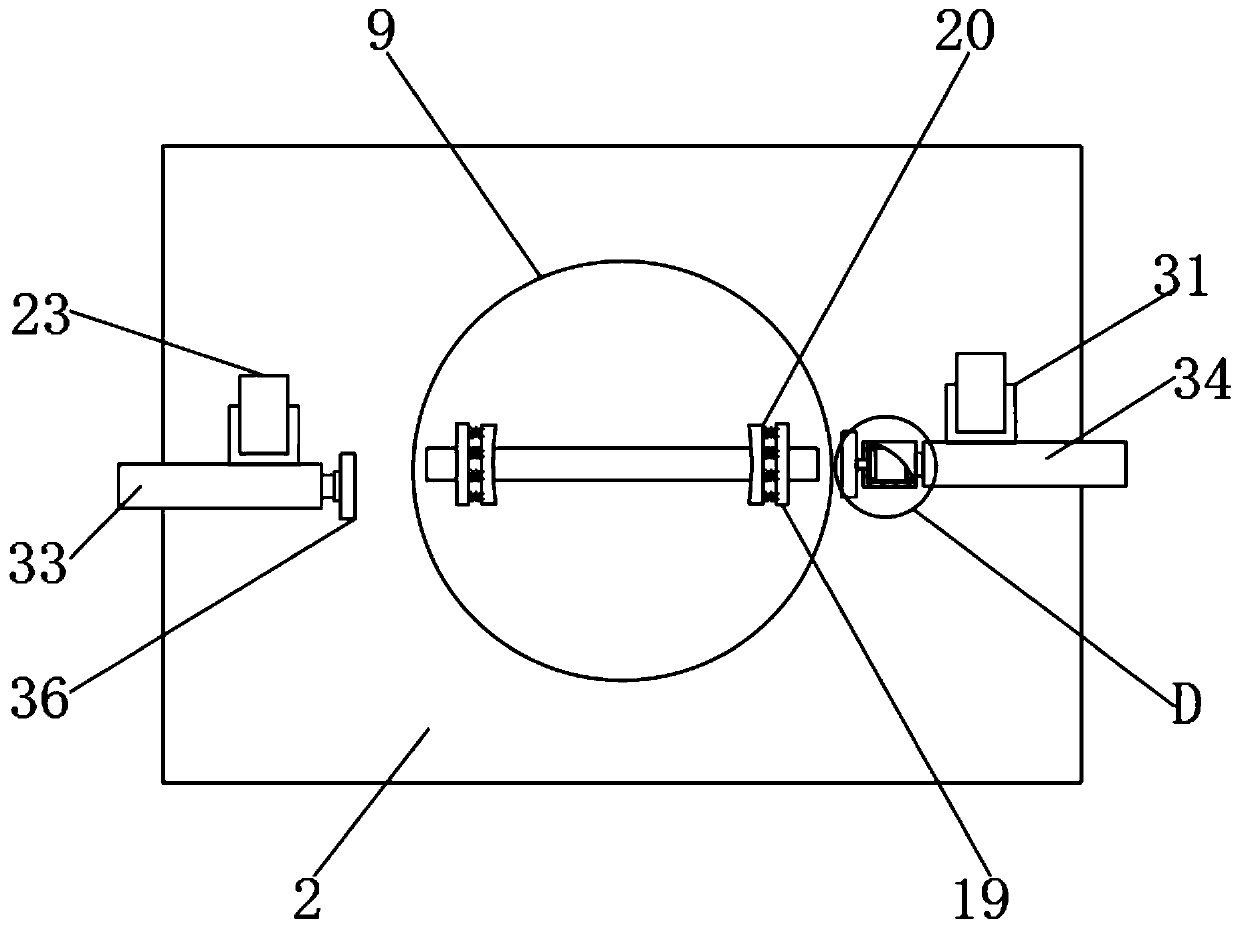

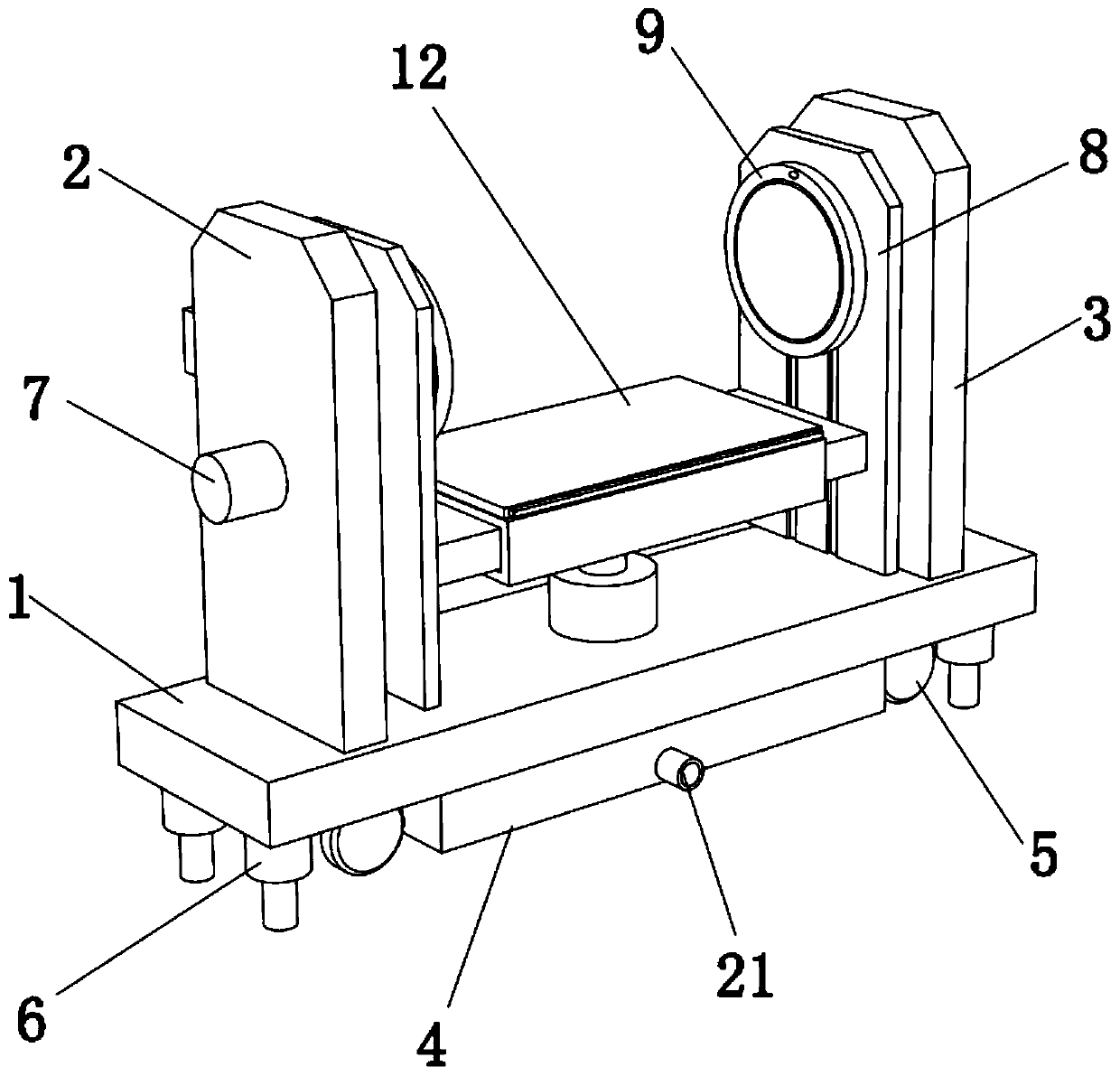

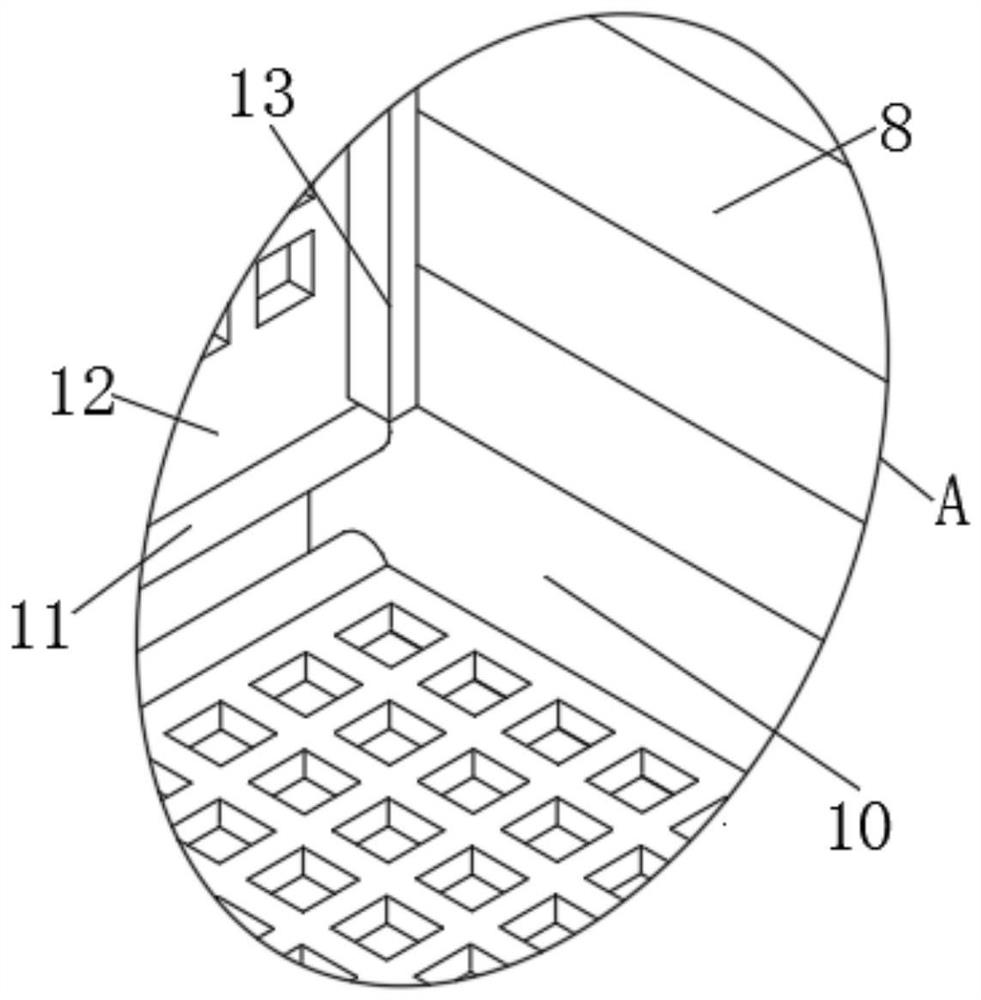

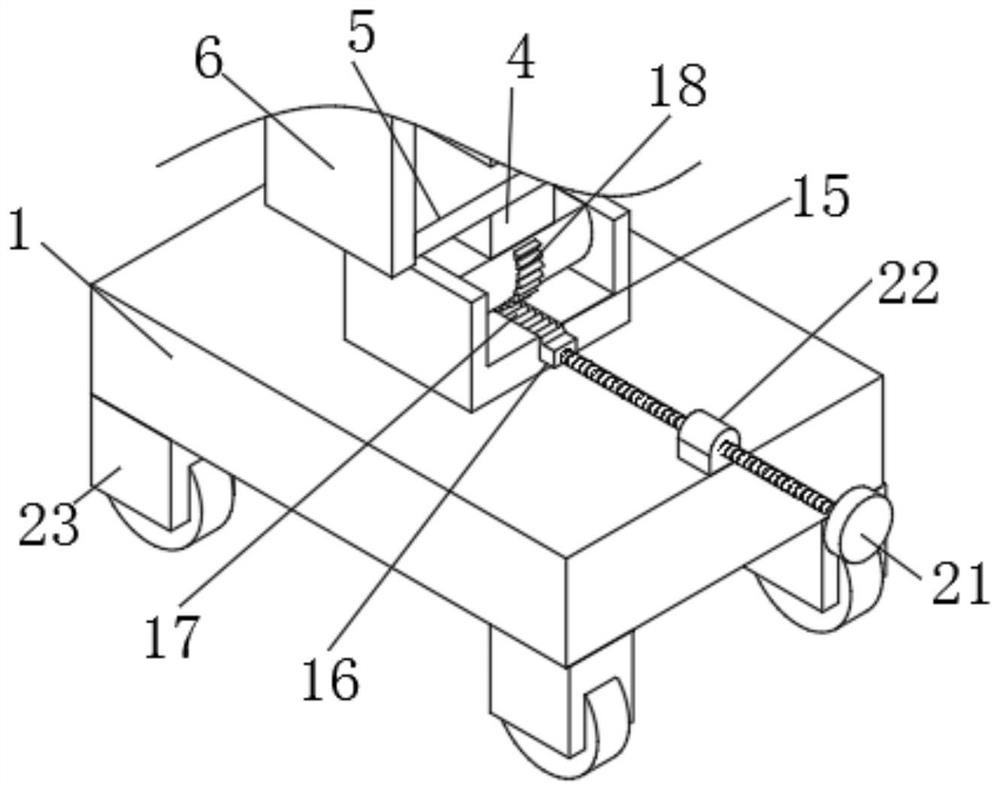

New energy automobile air conditioner assembly and machining device thereof

The invention discloses a new energy automobile air conditioner assembly and a machining device thereof. The assembly comprises a hybrid compressor assembly, a condenser assembly, a liquid reservoir dryer assembly, an evaporator assembly and a control circuit. The hybrid compressor assembly, the condenser assembly, the dryer assembly and the evaporator assembly are sequentially connected through the control circuit. A compressor shell in the hybrid compressor assembly performs machining assistance through auxiliary positioning and overturning equipment. According to the new energy automobile air conditioner assembly and the machining device thereof, the auxiliary positioning and overturning equipment is arranged on a workbench, so that in the process of manually finishing and detecting thehybrid compressor shell, the hybrid compressor shell is stably positioned, and the phenomenon that the hybrid compressor shell is unstable and slips during machining is avoided. Meanwhile, the hybridcompressor shell can rotate on the workbench, stable overturning can be achieved, and the effect of full-automatic adjustment of the hybrid compressor shell is achieved.

Owner:杭州众川科技有限公司

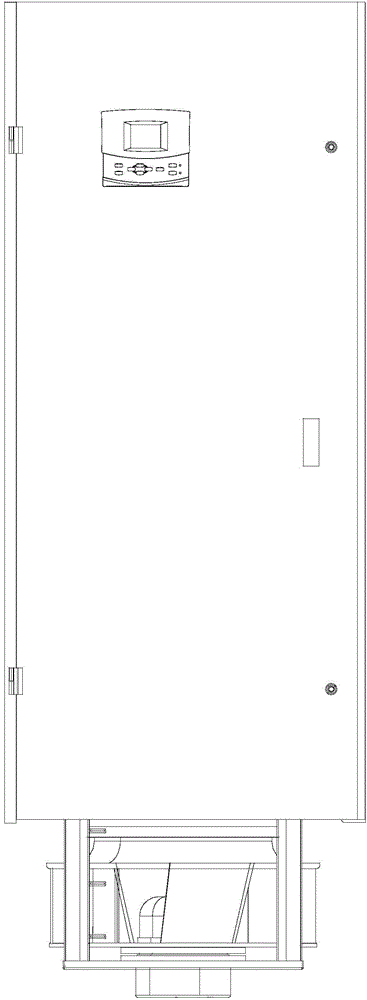

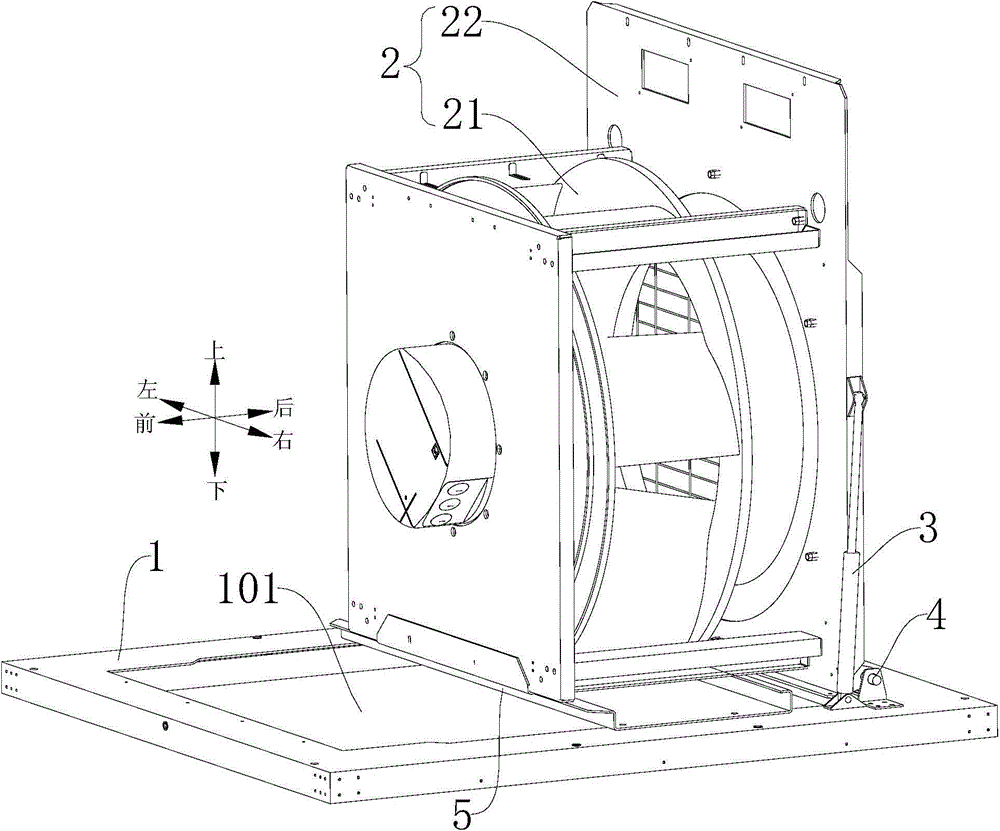

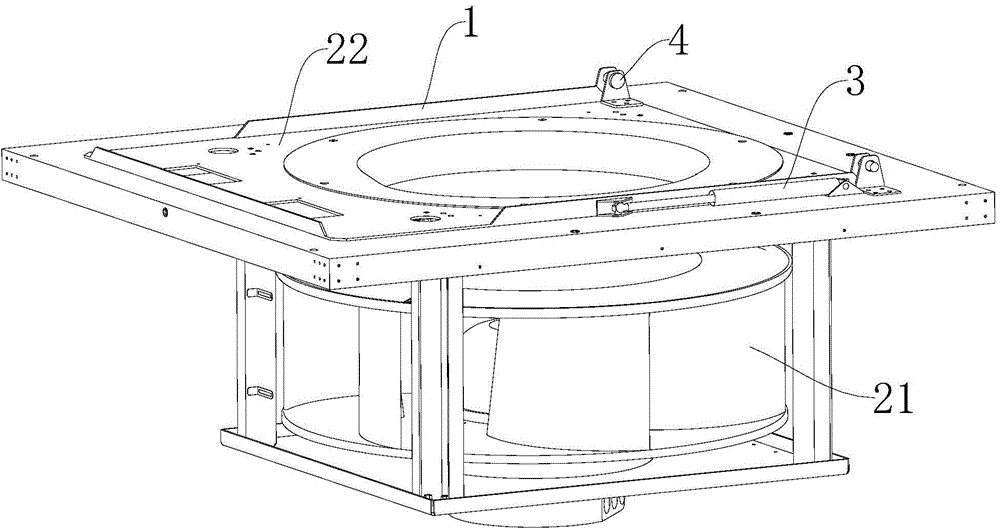

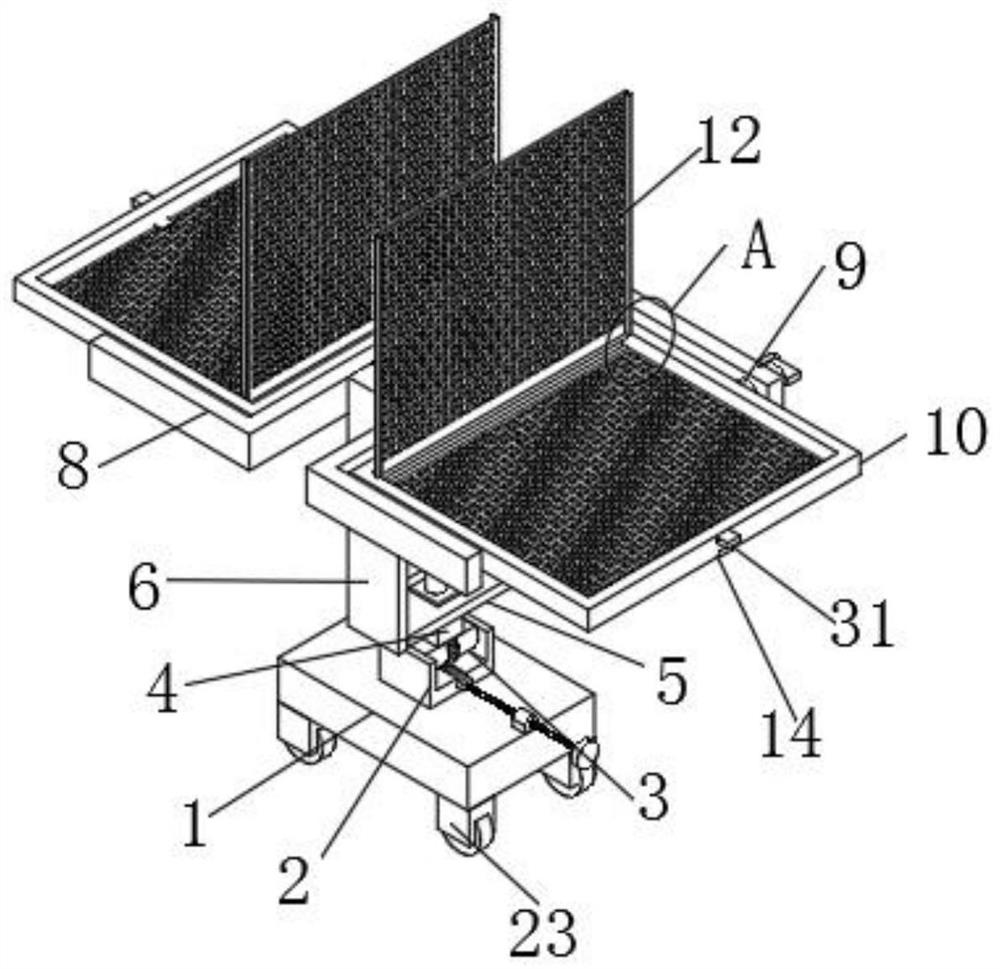

Air conditioning unit

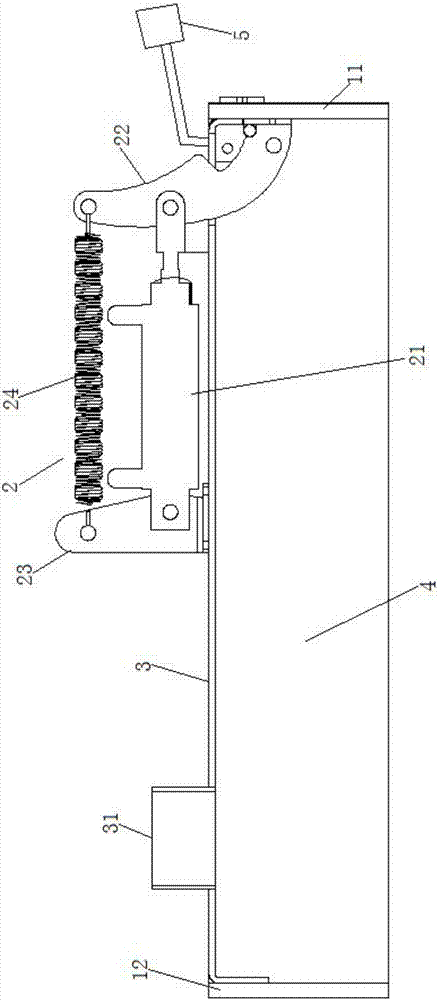

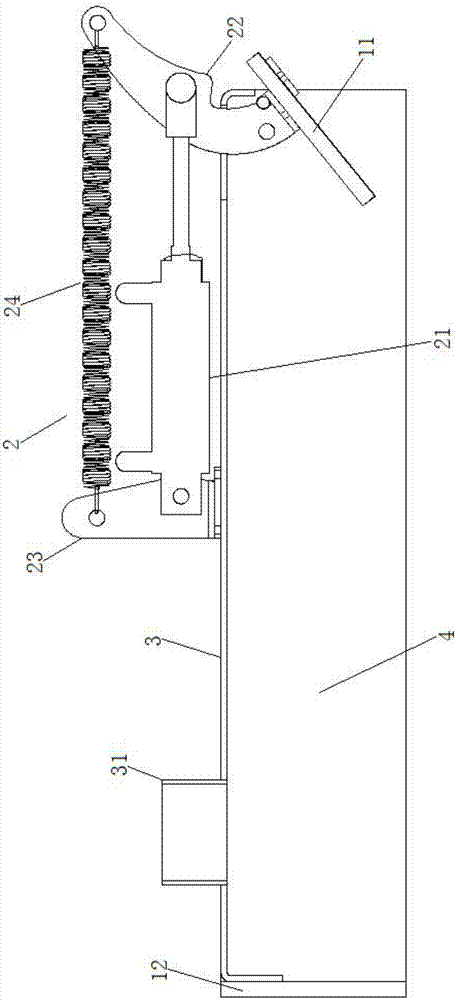

InactiveCN104819518AEasy flipRoll over stabilityLighting and heating apparatusSpace heating and ventilation detailsElastic componentGravitational force

The invention discloses an air conditioning unit. The air conditioning unit comprises a cabinet, a draught fan component and an elastic component; the draught fan component is connected with the cabinet between a first position and a second position in a pivotal mode; when the fan component is arranged at the first position, the fan component is arranged inside the cabinet; when the fan component is arranged at the second position, the fan component downward extends out of the bottom of the cabinet; the elastic component is connected between the fan component and the cabinet and has acting force on the fan component; the acting force can offset at least a part of the gravitational force of the fan component during pivot of the fan component. According to the air conditioning unit of an embodiment, the elastic embodiment can offset the acting force applied to the fan component, the acting force and at least a part of the gravitational force can be offset, and accordingly the fan component is easy to turn upward and stable to turn downward, the turning convenience of the fan component is greatly improved, and the safety and reliability are improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

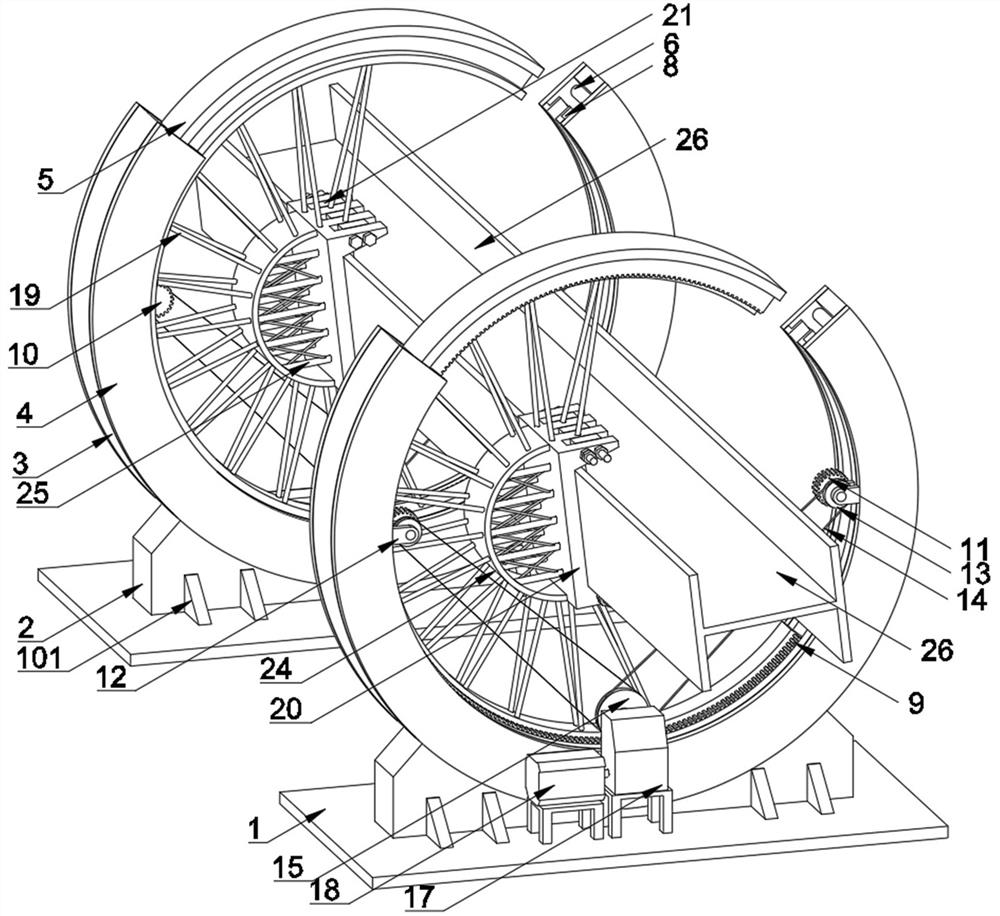

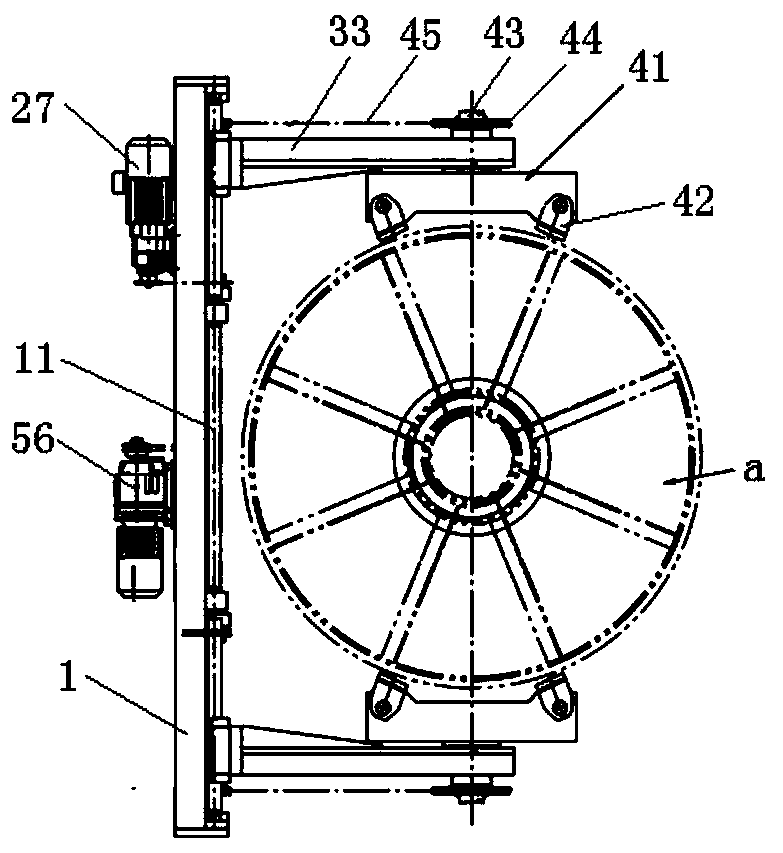

Auxiliary turnover device for steel member welding

InactiveCN112658569AShorten the lengthStable supportWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention belongs to the technical field of steel member machining, and particularly relates to an auxiliary turnover device for steel member welding. The device comprises bottom plates, wherein side fixed plates are fixedly connected to the front side face and the rear side face of each outer fixed plate mounted on the top face of each bottom plate through a fixing seat, the side fixing plates are rotatably connected with outer supporting pieces and inner supporting pieces, an inner gear ring is arranged at one side of the inner side face, rotationally connected with the corresponding outer supporting piece, of each rotating frame, a driven chain wheel fixedly mounted on a rotating shaft of a first gear and a second gear which are connected with each inner gear ring in a meshed mode is in transmission connection with a driving chain wheel through a transmission chain, a clamping plate and an arch frame are connected to the inner side face, at one side of the corresponding inner gear ring, of each rotating frame through supporting spokes, pressing pieces are rotationally mounted on the clamping plates through fixing shafts, and the clamping plates and the pressing pieces are provided with pin shafts in a sliding mode. An operator can vertically put down the two ends of a workpiece from the upper portions of openings of the rotating frames through crane hoisting and fix the two ends of the workpiece to the clamping plates to be clamped and fixed for turnover work, so that the occupied area of the device is effectively reduced, and operational safety is improved.

Owner:安徽宇艳智能机械科技有限公司

Highly-efficient overturning, laminating and packing machine

The invention discloses a highly-efficient overturning, laminating and packing machine. The highly-efficient overturning, laminating and packing machine comprises a frame, an overturning device, a packing device and a conveying device. The overturning device, the packing device and the conveying device are arranged on the frame. The overturning device is arranged in the middle of the conveying device. The packing device is located at the back portion of the conveying device and comprises a continuous film-sending mechanism, a thin film-forming mechanism, a sealing mechanism and a cutting mechanism. The highly-efficient overturning, laminating and packing machine has following beneficial effects: food can overturn at 180 degrees by means of the multi-position overturning device; due to multi-position overturning, packaged food can be stably, rapidly and reliably overturned; overturned food and non-overturned food can be conveyed in a laminating mode and then packed by means of the packing device; the packing device adopts the continuous film-sending mechanism so that operation cannot be stopped due to replacement of film rolls during a packing process, thereby enhancing working efficiency of an overall production line; and the highly-efficient overturning, laminating and packing machine is used for production equipment of food.

Owner:FOSHAN RUIPUHUA PACKING MACHINERY CO LTD

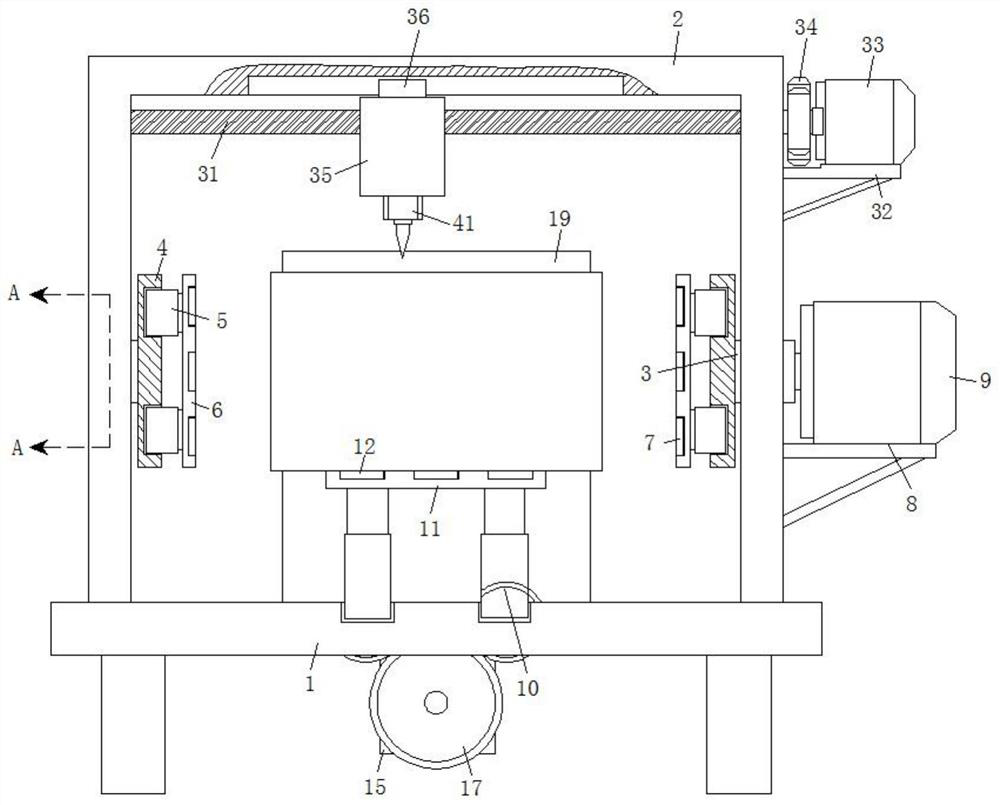

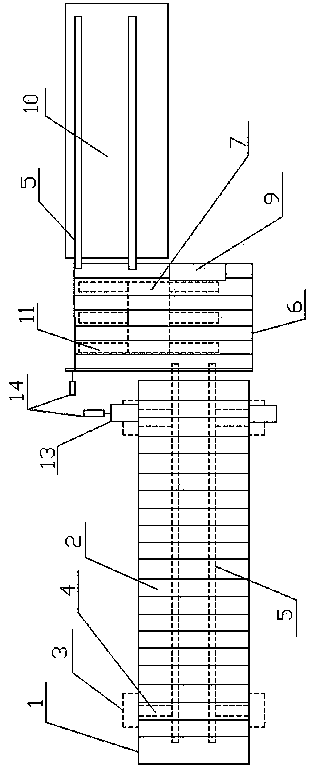

Forming welding equipment for I-steel production

ActiveCN110039248ARoll over stabilityFlexible distance adjustmentWelding/cutting auxillary devicesAuxillary welding devicesSteel platesArchitectural engineering

The invention discloses forming welding equipment for an I-steel production. The forming welding equipment comprises a rectangular base, wherein a welding slag collecting device is arranged above therectangular base, a full-angle turnover welding device is arranged on the upper surface of the rectangular base, the I-steel forming device is arranged at one end of the I-shaped steel turnover device; the full-angle turnover welding device drives a rotating drum through a motor, the rotating drum drives the I-steel to rotate, steel plates are fixed through the combined action of the telescopic rods and the hydraulic cylinders, and the steel plates are formed and welded through the action of the welding machine. The forming welding equipment has the beneficial effects of being simple in structure and high in practicability.

Owner:山东华泰钢结构工程有限公司

Unilateral fixation folding device for diapers

ActiveCN104337622ALow costSimple structureAbsorbent padsBaby linensEngineeringMechanical engineering

The invention aims to provide a unilateral fixation folding device for diapers. The device comprises a feeding component, a first conveying belt, a second conveying belt and a discharging component, wherein the first conveying belt and the second conveying are both arranged in the feeding component and the discharging component in a penetrating manner in sequence and are both wide belts; the second conveying belt and the first conveying belt at the position of the feeding component are arranged in parallel; viewed from the feeding component to the discharging component, the second conveying belt twists clockwise; the second conveying belt at the position of the discharging component is overlapped above the first conveying belt, and the back face of the second conveying belt faces upwards; a press roll for pressing the first conveying belt is arranged between the feeding component and the discharging component; a folding rod is arranged on the side of the first conveying belt. The device has a simple structure, continuous and stable folding of products can be realized, and good neatness of the folded products is guaranteed.

Owner:JINJIANG SHUNCHANG MACHINE MFG

Storage battery transporting line with turnover device

InactiveCN104355096ARoll over stabilityRealize automatic flipConveyor partsEngineeringElectrical and Electronics engineering

The invention provides a storage battery transporting line with a turnover device. The storage battery transporting line comprises a transporting line, rolling shafts are arranged on the transporting line, seat plates are arranged on the transporting line, movable rods are arranged on the seat plates, guide rods are arranged on the movable rods, a machine frame is arranged at the tail end of the transporting line, rolling shafts are arranged on the machine frame, rotating shafts and rotating plates are arranged on the machine frame, the rotating plates are arranged on the peripheries of the rotating shafts, a partition is arranged at the right end of each rotating plate, a storage battery output line is arranged at the right end of the machine frame, and the guide rods are arranged on the storage battery output line. The storage battery transporting line has the benefits that the structure is simple, the automatic turnover of a storage battery is realized, and the working efficiency is greatly improved.

Owner:TIANNENG BATTERY WUHU

Circuit board turning over machine

InactiveCN106429551ARoll over stabilitySmooth flipOverturning articlesEngineeringMechanical engineering

The invention provides a circuit board turning over machine. The circuit board turning over machine includes a first conveying table connected to a front device, a second conveying table connected to a back device, and a turning over device arranged between the first conveying table and the second conveying table; the turning over device includes a rotation shaft, support rods and turning over boxes; the support rods are evenly arranged in the peripheral direction of the rotation shaft; and the front ends of the support rods are fixedly connected to the turning over boxes. The beneficial effects of the invention are that the circuit board turning over machine is simple in structure, is stable in working, is high in safety, and can complete turning over and cooling of printed circuit boards well.

Owner:TIANJIN MINNING ELECTRONICS

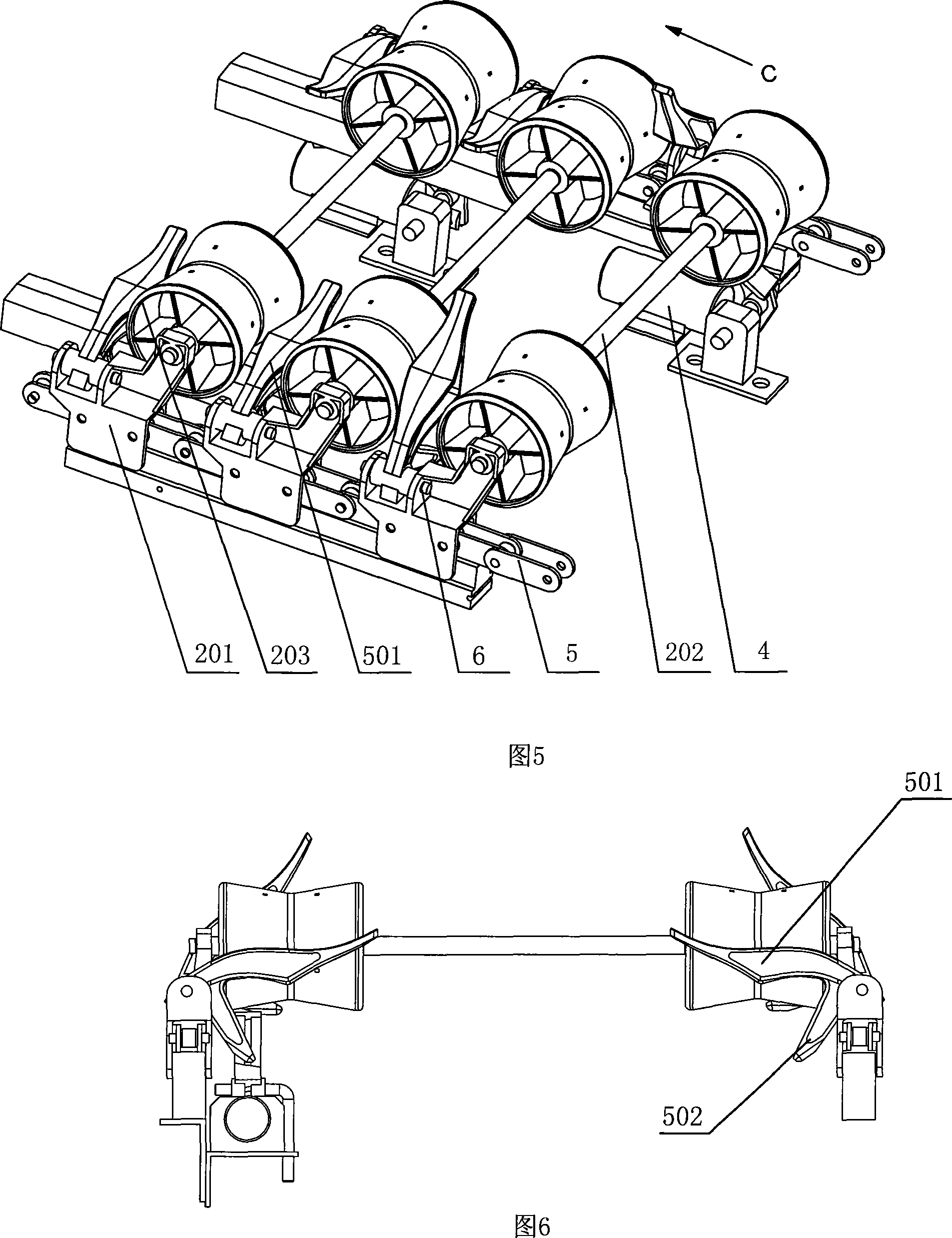

Overturning, distributing and conveying device

ActiveCN113460638ARealize interval deliveryRoll over stabilityConveyor partsEngineeringTransfer line

The invention is applicable to the technical field of square workpiece conveying, and provides an overturning, distributing and conveying device. The overturning, distributing and conveying device comprises a supporting seat arranged on the upper portion of the tail end of a first conveying assembly, wherein a distributing and conveying assembly is arranged on the supporting seat; a second conveying assembly is arranged on the left side of the distributing and conveying assembly; a third conveying assembly is arranged on the right side of the distributing and conveying assembly; the side, opposite to the first conveying assembly, of the distributing and conveying assembly is fixedly connected with an overturning driving assembly; and the overturning driving assembly is movably connected to a supporting plate. Therefore, the overturning, distributing and conveying device is simple in structure and low in cost, stable overturning of square workpieces can be achieved, the square workpieces on the same conveying line can be divided into two conveying lines, the conveying direction of the square workpieces can be changed, and interval conveying of the square workpieces can be achieved.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

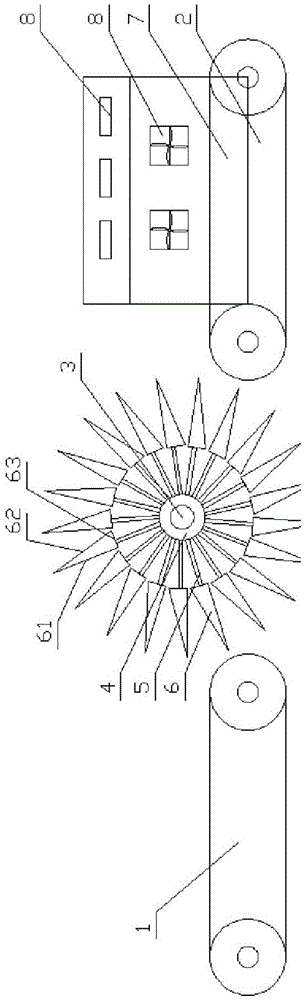

Turnover avoiding mechanism for rubber plates of sucking disk of dust collection vehicle

The invention relates to a turnover avoiding mechanism for rubber plates of a sucking disk of a dust collection vehicle. The turnover avoiding mechanism comprises the rubber plates and at least one turnover driving mechanism, wherein the rubber plates include the first rubber plate and second rubber plates; the first rubber plate is arranged at the front side of the sucking disk in a rotating mode; the second rubber plates are arranged at the rear side and two sides of the sucking disk in a surrounding mode; the lower end of the first rubber plate and the lower ends of the second rubber plates are positioned below the sucking disk and are flush mutually; an air suction chamber of which the lower end is opened is formed between the first and second rubber plates and the sucking disk; the at least one turnover driving mechanism is mounted at the front side of the upper end of the sucking disk; and the driving end of the turnover driving mechanism is fixedly connected with the first rubber plate and can drive the lower end of the first rubber plate to turn into the air suction chamber or turn to the normal position. The turnover avoiding mechanism provided by the invention has the advantages of being simple in structure and convenient to use; and the turnover driving mechanism can be used for driving the first rubber plate to turn so as to avoid obstacles, so that larger abrasion of the first rubber plate can be avoided, and the obstacles can be favorably cleaned.

Owner:HUBEI JULI AUTOMOTIVE TECH CO LTD

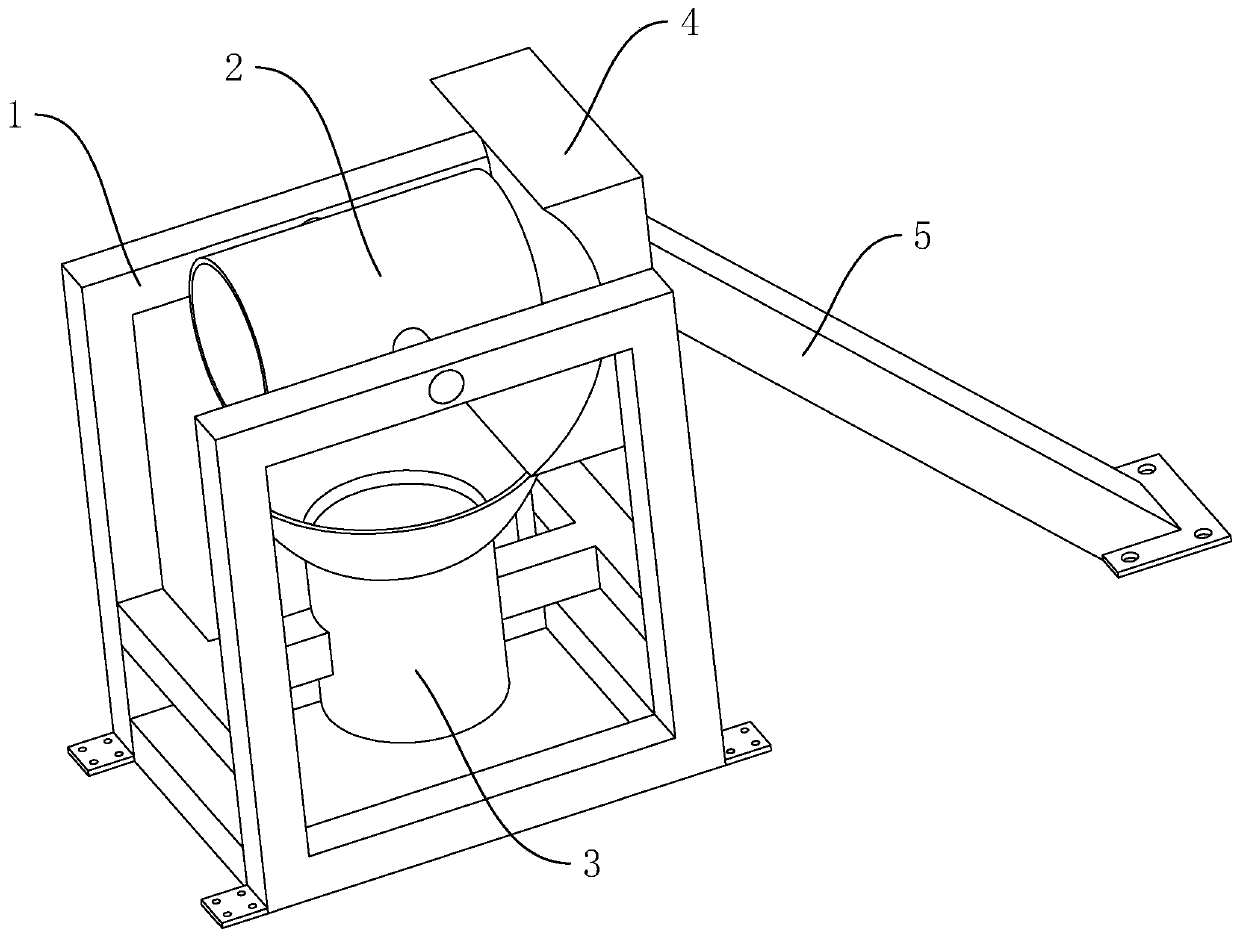

Feeding mechanism for garbage truck and garbage truck

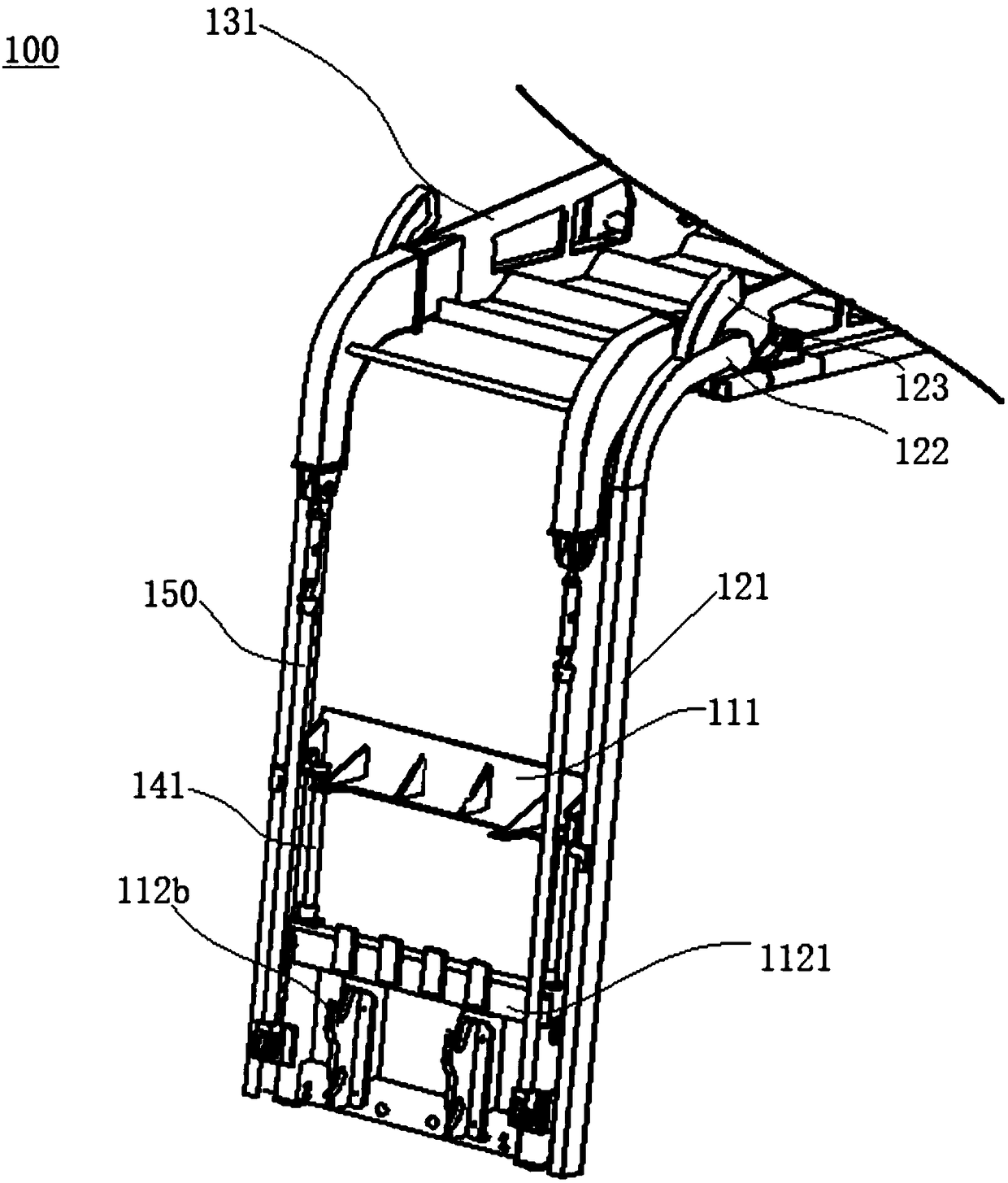

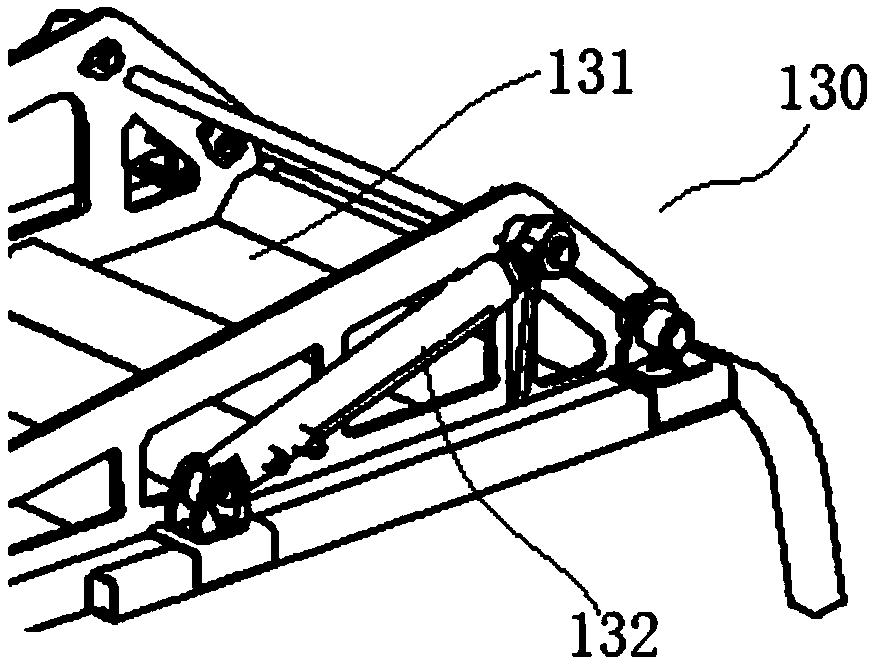

InactiveCN108861252ASimple structure and good stabilityPrevent leakageRefuse vehiclesEngineeringTruck

The invention discloses a feeding mechanism for a garbage truck and the garbage truck. The feeding mechanism for the garbage truck comprises a dustbin overturning mechanism, a guide rail and a drive mechanism. A dustbin is suitable for being installed on the dustbin overturning mechanism. The dustbin overturning mechanism is provided with first guide pieces and second guide pieces, wherein the first guide pieces and the second guide pieces are spaced in the vertical direction. The guide rail comprises guide bodies, first guide rails and second guide rails, wherein the first guide rails and thesecond guide rails are arranged at the tail ends of the guide rail bodies, the first guide rails and the second guide rails both extend backwards, and the first guide rails are arranged below the second guide rails. The drive mechanism is connected with the dustbin overturning mechanism so as to drive the dustbin overturning mechanism to move along the guide rail. When the first guide pieces andthe second guide pieces both move along the guide rail bodies, the first guide pieces are located above the second guide pieces. After the first guide pieces and the second guide pieces move to the tail ends of the guide rail bodies, the first guide pieces enter the first guide rails, the second guide pieces enter the second guide rails, and then the dustbin overturning mechanism drives the dustbin to turn over. The feeding mechanism moves stably, and generated impact force is small.

Owner:长沙普罗科环境装备有限责任公司

Urological postoperative rehabilitation device capable of adjusting multi-directional angles

ActiveCN112704610ALess discomfortAvoid shakingNursing bedsSpittle receiving devicesRotational axisPhysical medicine and rehabilitation

The invention discloses a urological postoperative rehabilitation device capable of adjusting multi-directional angles. The postoperative rehabilitation device includes a recovery device body, circular rotating plates and transmission cabins; the transmission cabins are arranged on the two sides inside the recovery device body; the circular rotating plates are arranged in the transmission cabins; and the circle centers of the circular rotating plates are rotatably connected to the surfaces inside the transmission cabins through first rotating shafts. Second servo motors can drive gears to rotate to act on the circular meshing tooth tracks on the surfaces of the circular rotating plates, so that the circular rotating plates can be driven to rotate in the transmission cabins through the first rotating shafts, and a bed plate can be driven to turn over; the patients cannot be greatly moved due to the compression of an inflatable airbag; limit blocking blocks can support the bed plate again after turning over, and a sliding plate can slide to one side, so that the bed plate can be opened; and therefore, cleaning can be conveniently performed on the patients, labor intensity can be reduced, and the turning-over efficiency during nursing the patients can be enhanced.

Owner:NORTHWEST WOMEN & CHILDREN HOSPITAL

Conveying upright turnover device for boxes

InactiveCN104071561AReasonable structureConveyor adjustment is simple and convenientControl devices for conveyorsEngineeringBelt conveyor

The invention provides a conveying upright turnover device for boxes and relates to the technical field of the conveying mechanism. The conveying upright turnover device for boxes comprises a front belt conveyor, an upright turnover device and a rear belt conveyor, all of which are orderly mounted and connected; the upright turnover device comprises clamping belts at two sides, a driving wheel, a driven wheel, a motor, and baffle plates of two stages and cylinders under the belts of the two sides; an optical fiber sensor is mounted on the front belt conveyor. The conveying upright turnover device for boxes has the advantages of simple and reasonable structure, convenient adjustment, stable conveying, high efficiency, low self-weight and low cost.

Owner:山东奇润机械设备有限公司

Overturning device for mechanical part production

The invention belongs to the technical field of overturning devices, and particularly relates to an overturning device for mechanical part production. Aiming at solving the technical problem that mechanical parts are prone to falling in the overturning process, and consequently, large potential safety hazards exist, the following scheme is currently put forward, specifically, the overturning device comprises an overturning base, the two sides of the upper end of the overturning base are connected with a first side support and a second side support correspondingly, a lifting device is arrangedbetween the first side support and the second side support, clamping pushing plates are arranged on the sides, close to each other, of the first side support and the second side support correspondingly, the ends, away from each other, of the first side support and the second side support are connected with extrusion driving devices correspondingly, the power output ends of the extrusion driving devices penetrate through the first side support and the second side support and are fixedly connected with the clamping pushing plates, the clamping pushing plates are connected with rotating devices,and each rotating device comprises a rotating driving device and a pair of clamping rotating discs. The clamping degree of the mechanical parts can be guaranteed, later stable overturning of the mechanical parts is guaranteed, and the safety factor is increased.

Owner:ZHUZHOU HUAXIN PRECISION IND

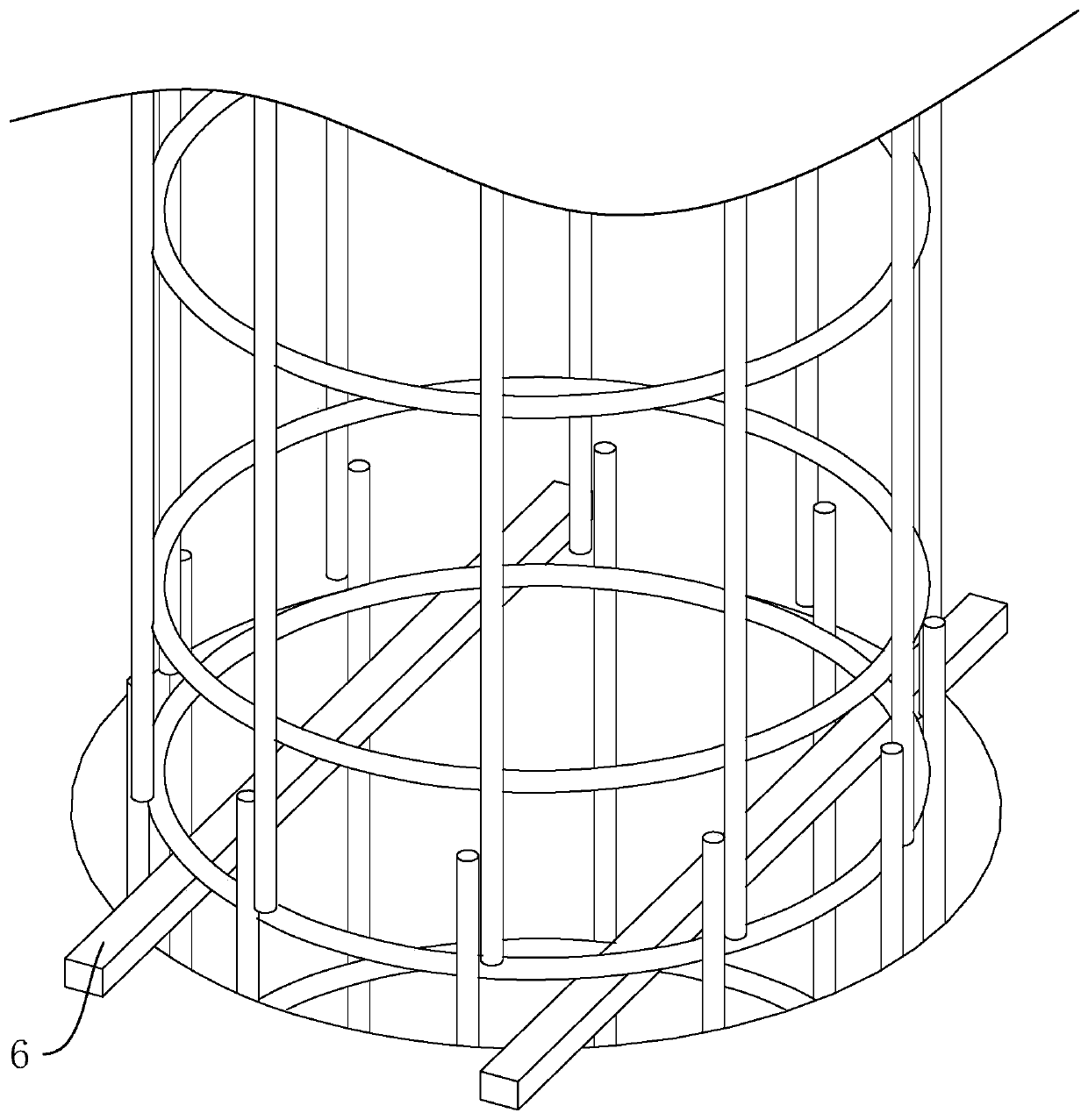

Drilled pile construction method

PendingCN111119169AAvoid the hassle of butt weldingEasy to operateBulkheads/pilesButt weldingArchitectural engineering

The invention discloses a drilled pile construction method, and relates to the field of constructional engineering. The drilled pile construction method comprises the following steps of S1, performingconstruction preparation; S2, burying a protective cylinder; S3, arranging a mud pool; S4, performing drilling machine drilling, namely, drilling by using a drilling machine; S5, performing primary hole cleaning, namely, cleaning a hole after the hole is drilled to a designed depth; S6, placing a steel reinforcement cage, namely, after the steel reinforcement cage passes acceptance inspection andwhen pre-operation is performed, splicing the steel reinforcement cage according to a designed size by an operator; and when the steel reinforcement cage is required to be placed, lifting the splicedsteel reinforcement cage to the position above a hole opening, and placing vertically and slowly; S7, placing a guide pipe; S8, performing secondary hole cleaning, after the guide pipe is placed, performing secondary hole cleaning through the guide pipe; S9, pouring underwater concrete; and S10, pulling up the protective cylinder. The trouble in performing butt welding on the steel reinforcementcage at the hole opening when the steel reinforcement cage is placed is avoided, so that the operation of placing the steel reinforcement cage is more convenient; and the construction period of the drilled pile is also shortened.

Owner:CHENGTONG KAISHENG ECOLOGICAL CONSTR CO LTD

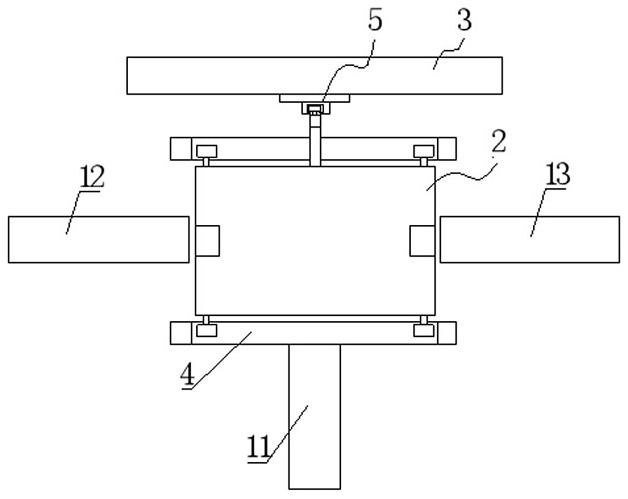

Solar cell module synchronous turnover device

The invention provides a solar cell module synchronous turnover device and relates to synchronous turnover devices used in automatic packaging production line for solar cell modules. The solar cell module synchronous turnover device is reasonable, simple and practical in structure, accurate in turnover angle, low in cost, convenient to maintain and adjust and high in automation degree. The solar cell module synchronous turnover device comprises a rack and is characterized in that L-shaped turnover frames are arranged on the rack through a rotary shaft, and turnover power devices of the turnover frames are arranged on the rack.

Owner:YINGKOU JINCHEN MACHINERY

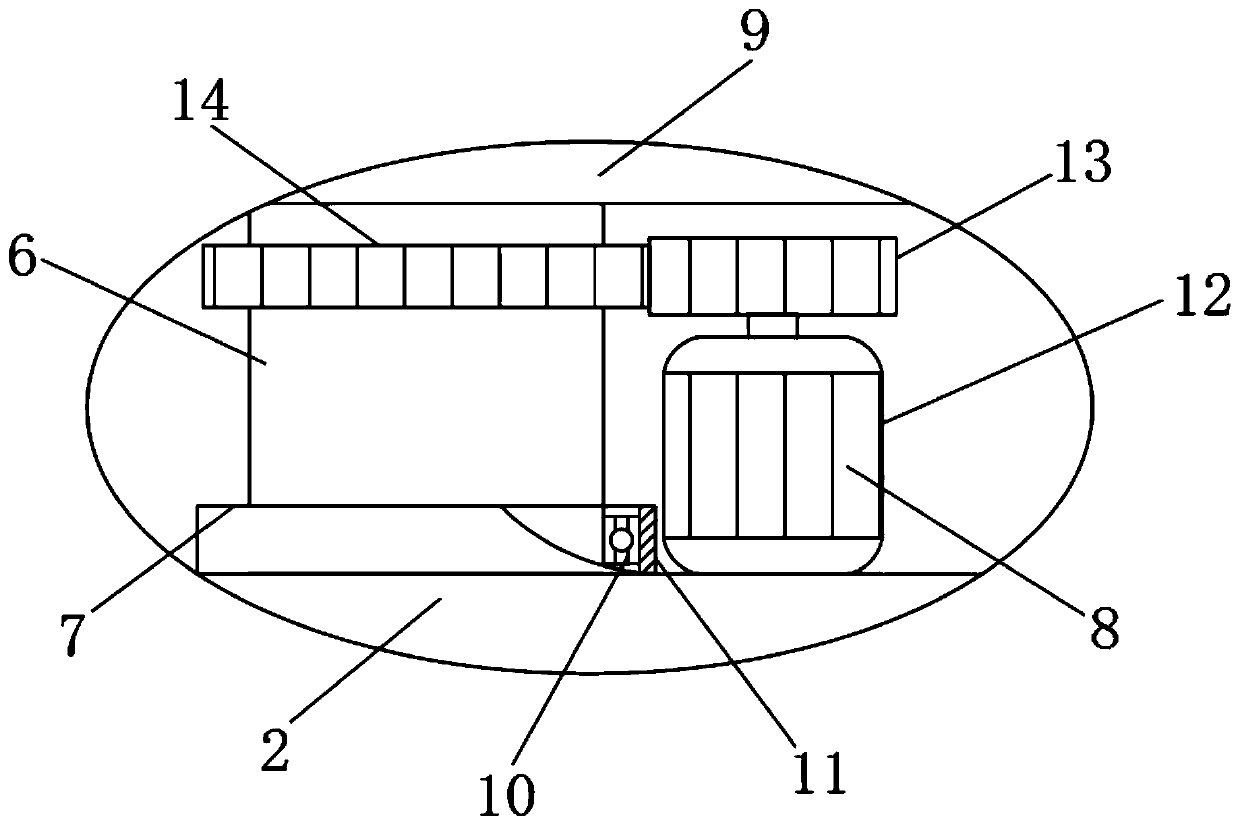

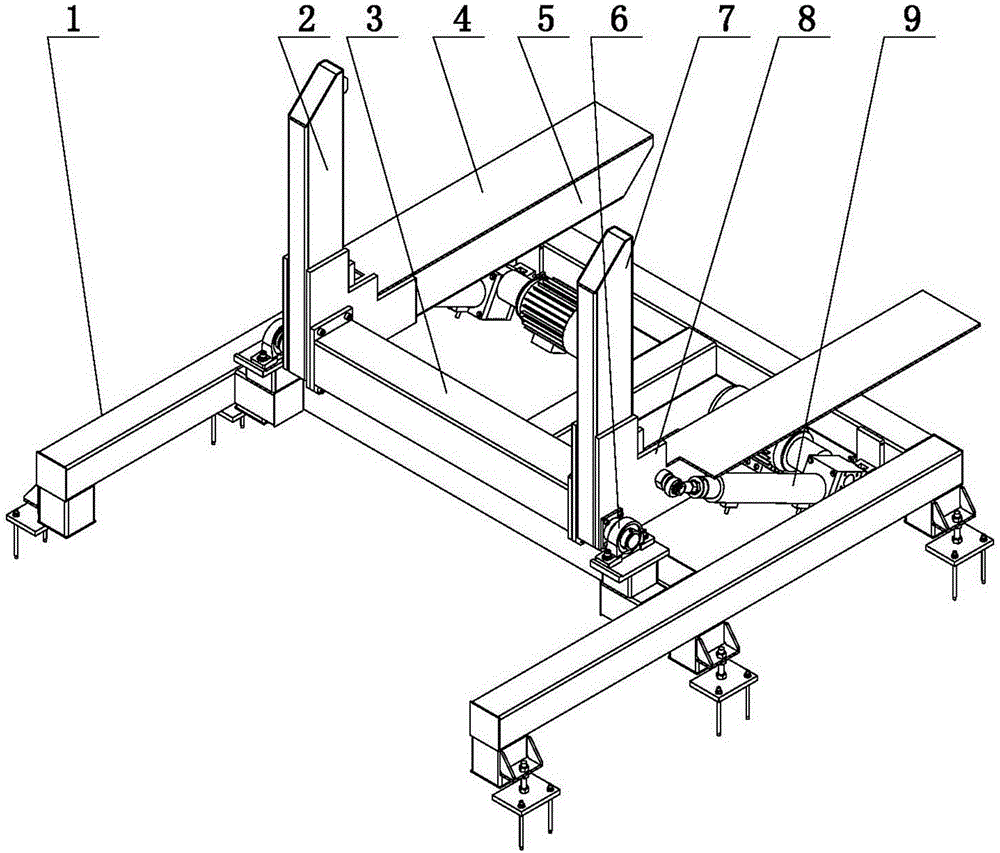

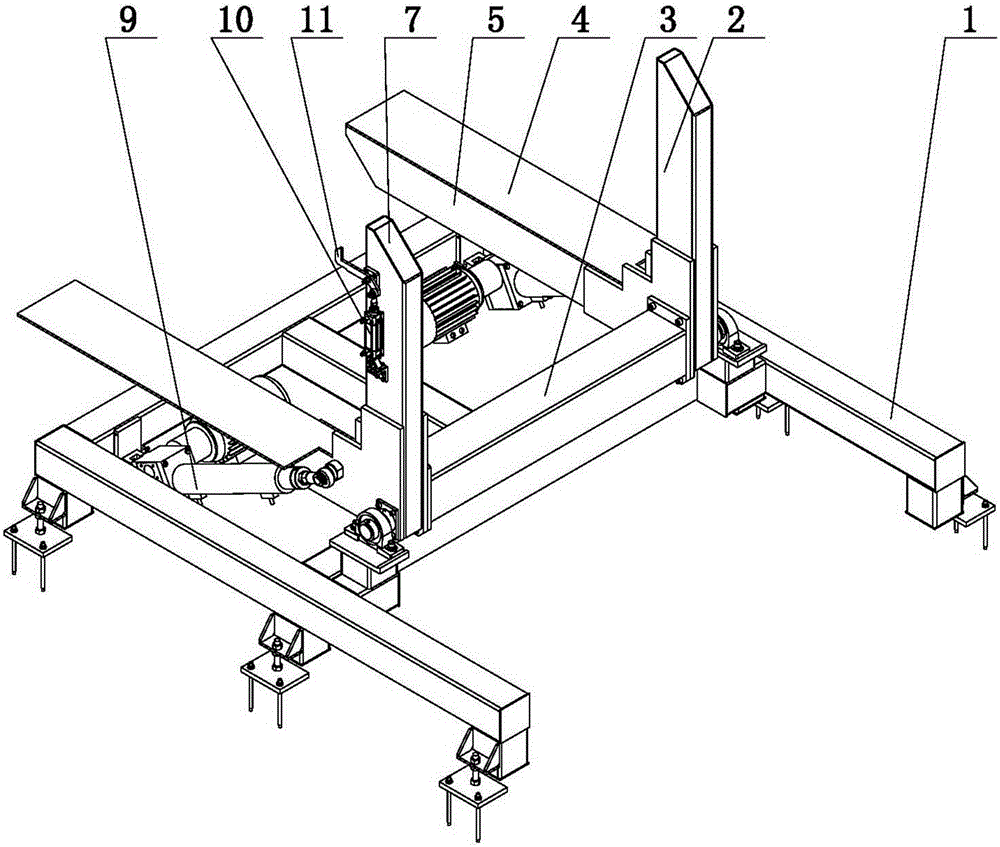

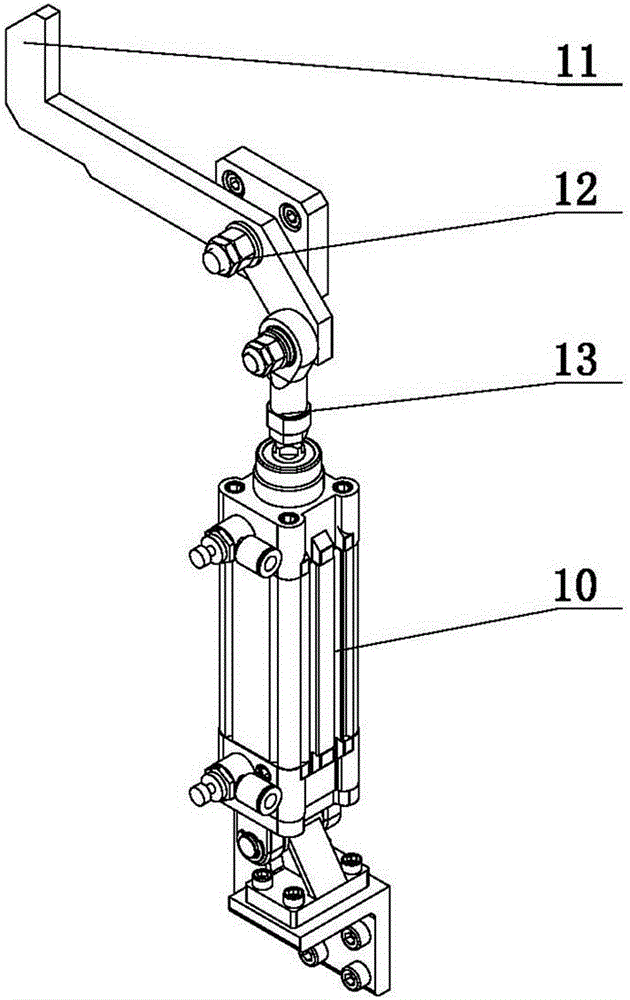

Shake device for large barrel

ActiveCN105921041ARoll over stabilityPromote shakingShaking/oscillating/vibrating mixersTransportation and packagingLeft halfFixed frame

The invention discloses a shake device for a large barrel. The shake device comprises a base, a support, a motor, a lifting device and a clamping device, the support comprises a fixed frame on the right and a movable frame on the left, a slide rail is arranged on the base, the movable frame and the lifting device can move left and right along the slide rail to be close to or far away from the fixed frame, the clamping device comprises a left half hoop and a right half hoop which are on the same horizontal line and are each shaped like a semicircle, the left half hoop and the right half hoop can be combined to form a non-closed concentric barrel, and the left half hoop is connected with the right half hoop through a binding tensioning device. Compared with a traditional artificial shaking mode, the shake device for the large barrel is high in shaking efficiency, stable in tank overturn and capable of fully shaking liquid in the tank to be uniform.

Owner:TAICANG TAIBANG ELECTRONICS TECH

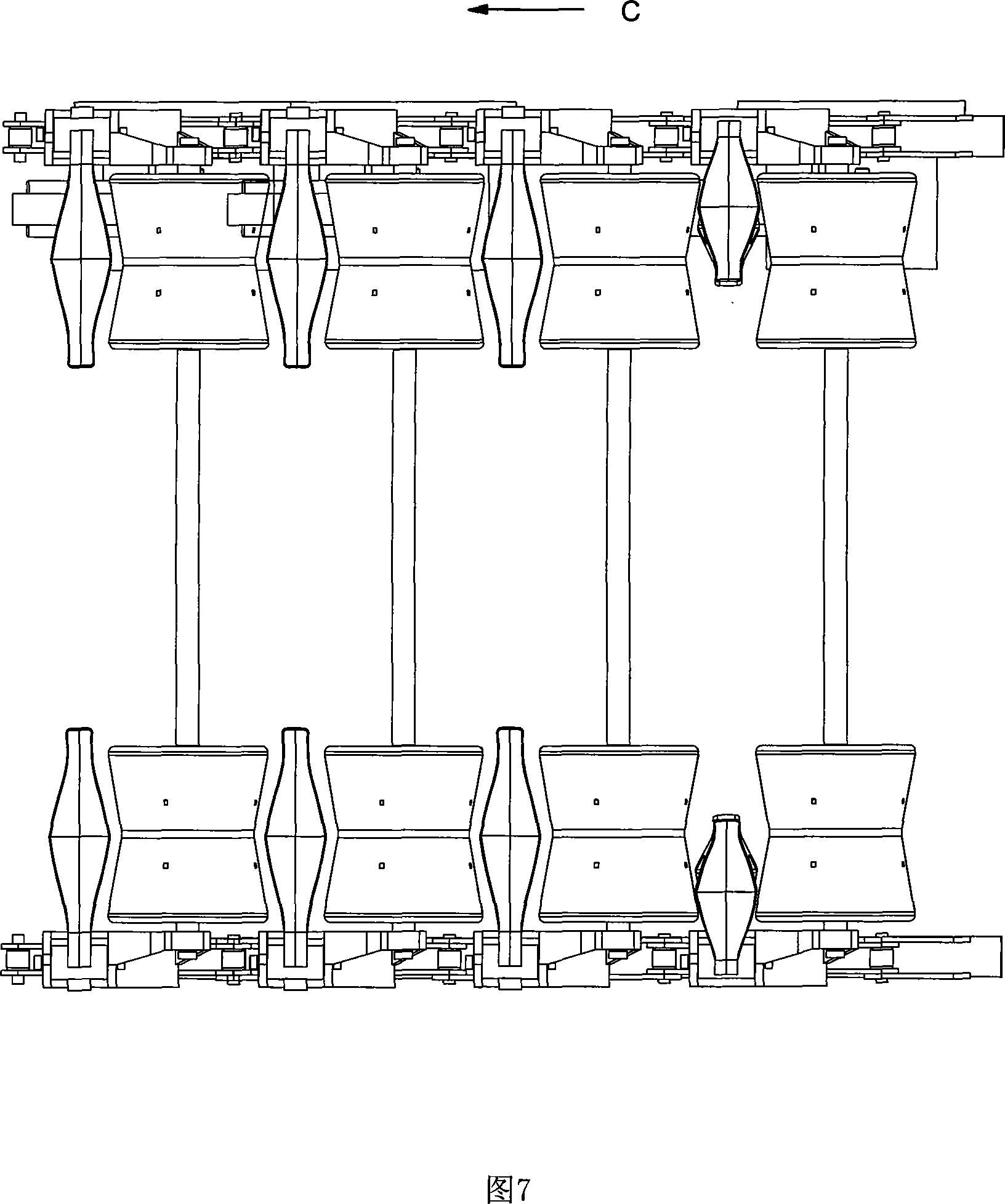

Accumulation conveyor

The invention discloses an accumulation conveyor which comprises a machine body, a sprocket drive mechanism and at least one conveying trolley. Drive wheel shafts are arranged at the front end and theback end of the machine body, and comprise a drive wheel shaft arranged at the front end of the machine body, and a driven wheel shaft at the back end of the machine body; the sprocket drive mechanism is arranged on the drive wheel shaft and the driven wheel shaft through a sprocket; a gear motor capable of driving the sprocket on the drive wheel shaft to rotate is arranged on the drive wheel shaft; a guiding rod is arranged on the machine body and is used as a track for providing a motion trail of the conveying trolley; and the conveying trolley can move along the track through rollers. Theaccumulation conveyor provided by the invention has the advantages of compact structure, low cost, convenience in installation and maintenance, stability in turning over and the like.

Owner:广州德恒汽车装备科技有限公司

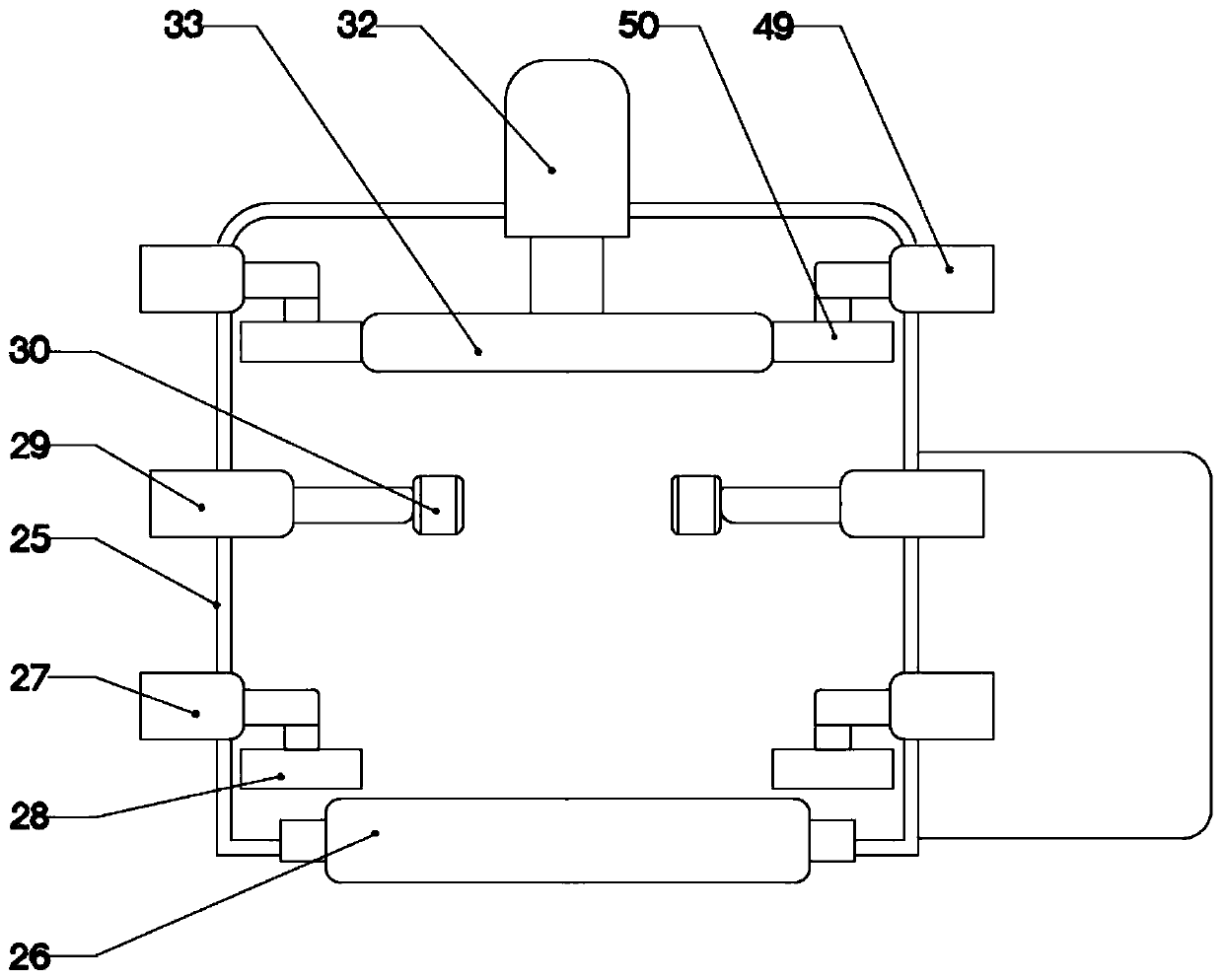

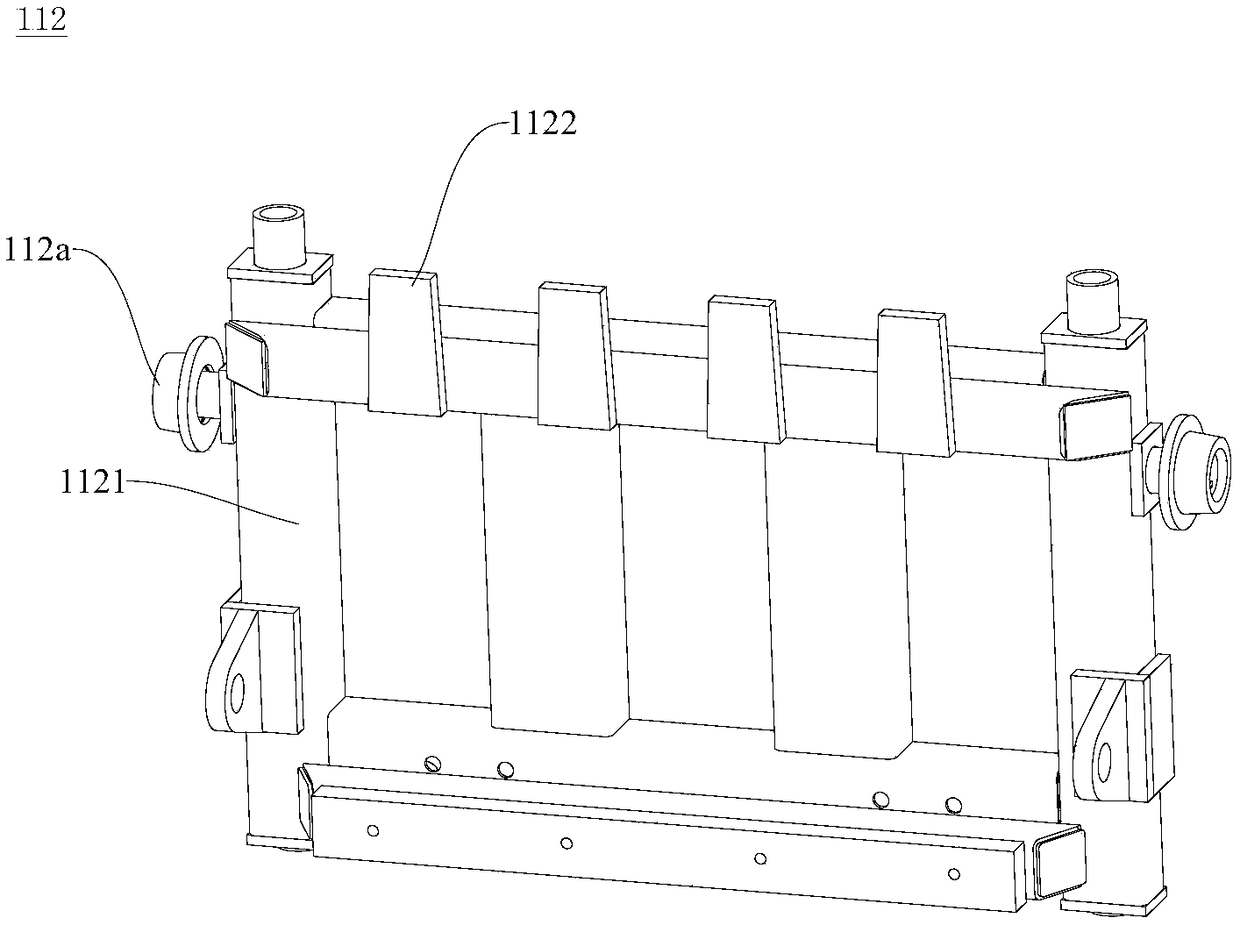

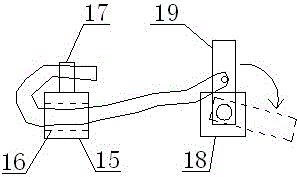

Synchronous clamping and turnover mechanism

PendingCN111017550AStable clampingRoll over stabilityConveyorsConveyor partsMedicinePharmaceutical drug

The invention provides a synchronous clamping and turnover mechanism, which comprises a support. The mechanism is characterized in that clamping mechanisms, a clamping driving mechanism, turnover mechanisms and an turnover driving mechanism are arranged on the support, wherein the number of the clamping mechanisms is two, the two clamping mechanisms are both connected to the support in a sliding mode and connected with the same clamping driving mechanism; each clamping mechanism is rotationally connected with the corresponding turnover mechanism; and the two turnover mechanisms are both connected with the same turnover driving mechanism. The two clamping mechanisms are driven by the same clamping driving mechanism to slide in a face-to face manner to synchronously clamp an object, and movein a back-to-back manner to synchronously loosen clamping of the object; and two turnover mechanisms are driven by the same turnover driving mechanism to overturn the clamped object, so that clampingis firm and reliable, turnover is flexible, and no pollutant is generated; and the synchronous clamping and turnover mechanism is suitable for clamping various articles, especially for clamping of amedicine extraction basket and turnover of medicines or extracts on the turnover face.

Owner:KUNMING XUBANG MACHINERY

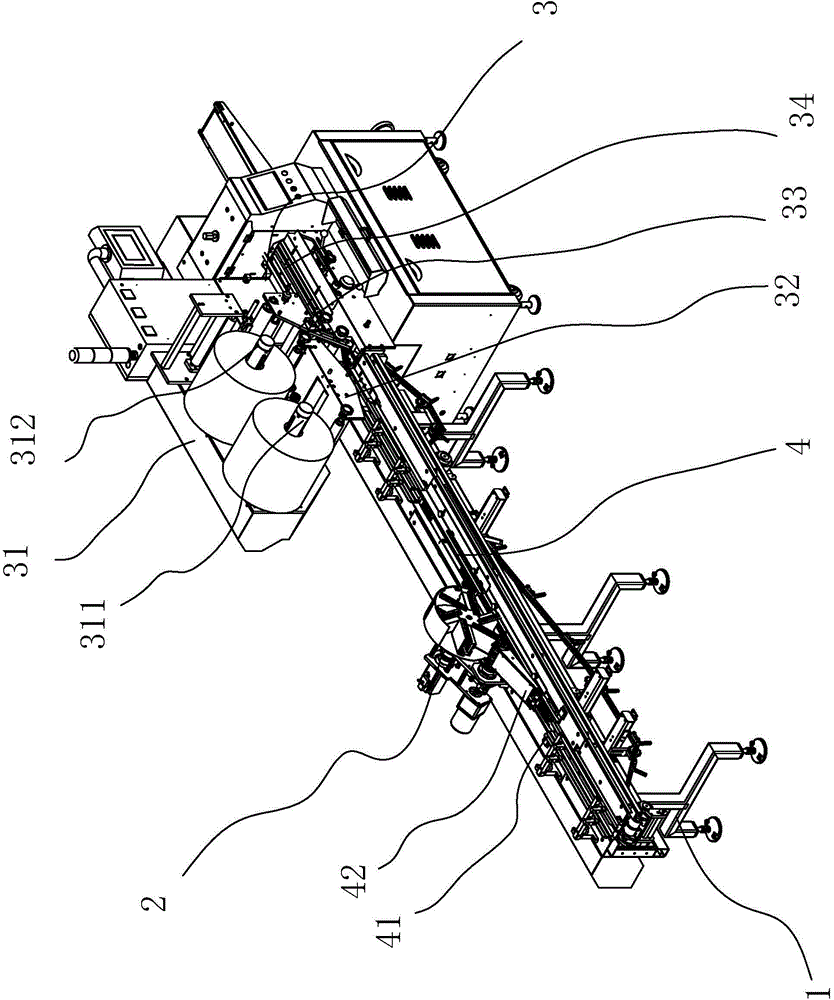

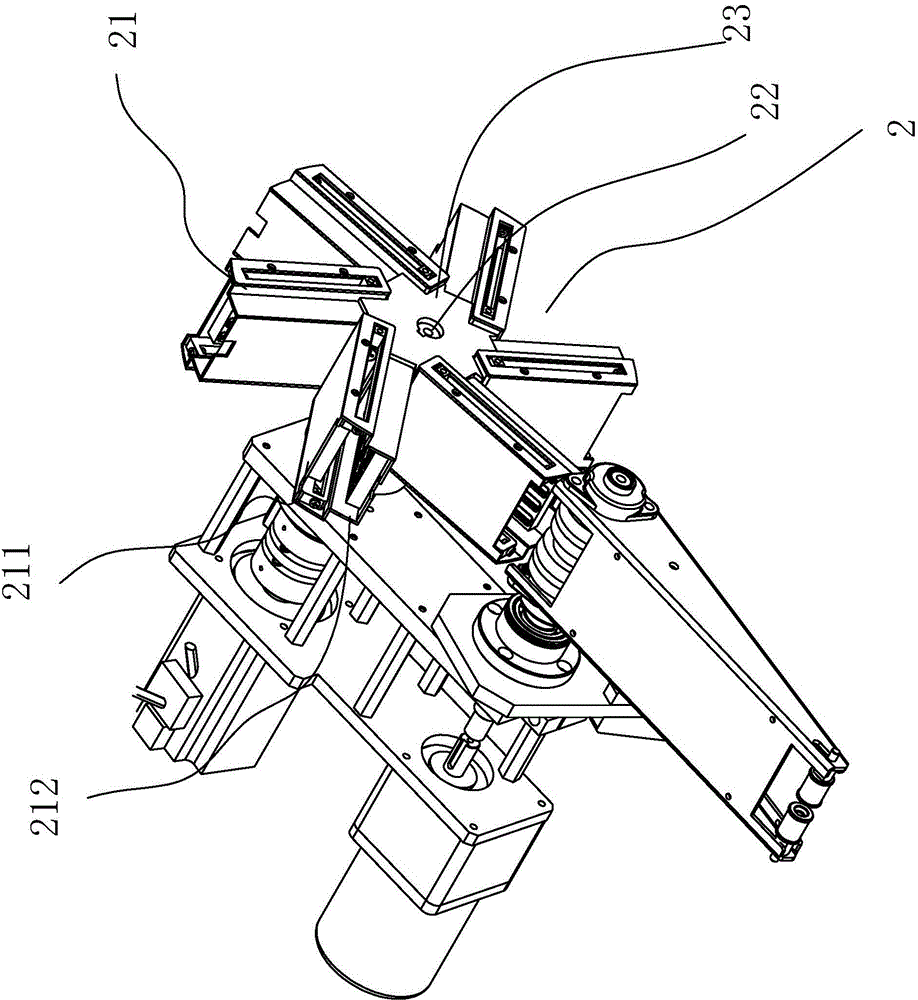

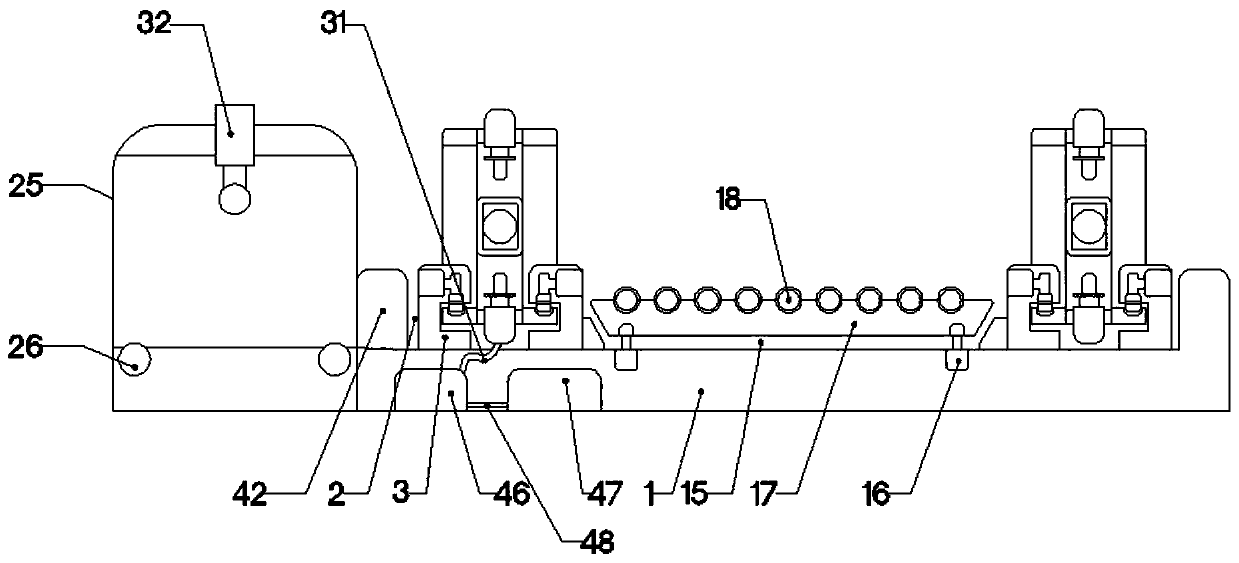

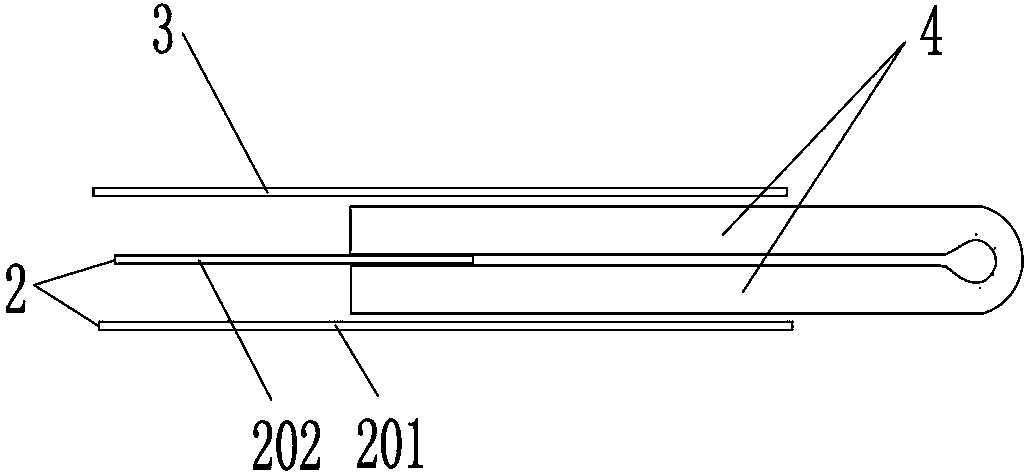

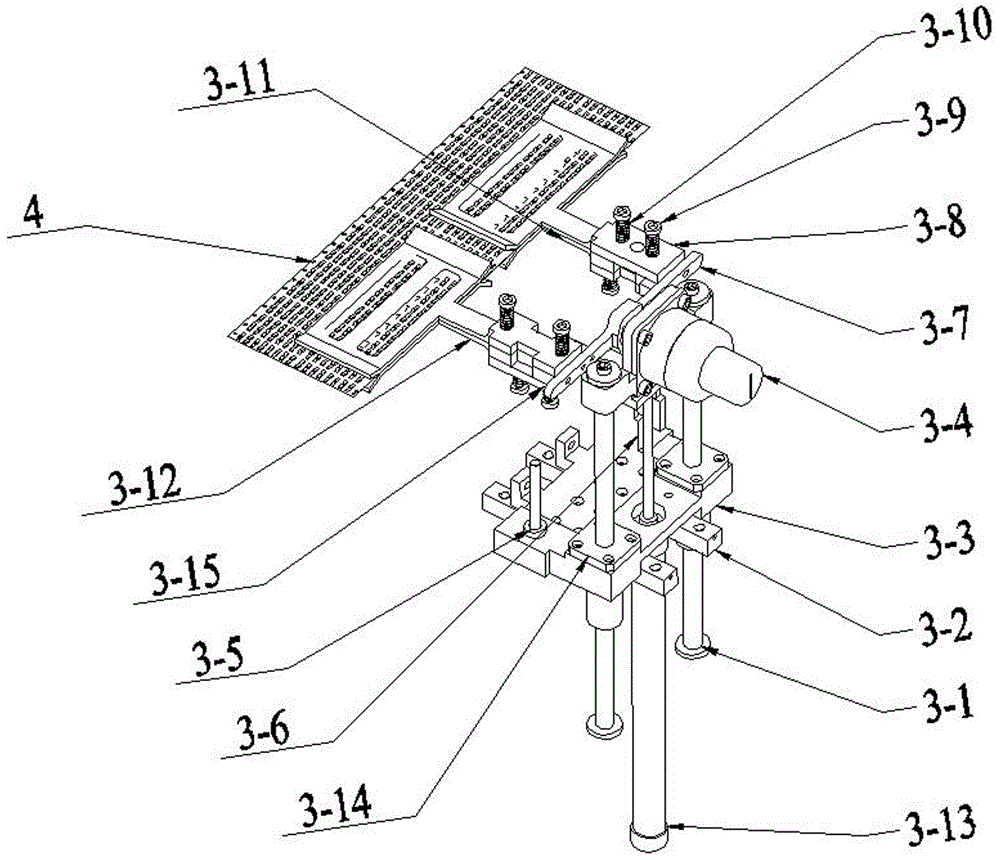

Conveying turnover device for plastic sealing strip of integrated circuit

ActiveCN106271131AReduce manufacturing costIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a conveying turnover device for a plastic sealing strip of an integrated circuit and belongs to the field of integrated circuit package auxiliary equipment. The conveying turnover device mainly comprises a horizontal operation platform, a belt conveying mechanism and a strip turnover mechanism. The packaged integrated circuit strip is conveyed to a front side marking position; after the front side is marked, the strip is conveyed to the strip turnover mechanism for overturning for 180 degrees; and then, the strip is conveyed to a rear side marking position for marking the rear side. According to the invention, the positive and negative laser marking for the integrated circuit strip is simultaneously performed on a same device, so that the production cost of the products is effectively lowered and the production efficiency of the products is increased; the structure is simple and the operation is convenient; and the conveying turnover device is suitable for the marking operation of the plastic sealing strips of the integrated circuits in different sizes by adjusting the heights of a reset spring and a reset rod on an upper flipper-shaped clamp plate and a lower flipper-shaped clamp plate.

Owner:华天科技(宝鸡)有限公司

Adjustable windproof cotton airing equipment

InactiveCN112432452AEasy to hold downKeep from blowing awayDrying solid materials with heatDrying chambers/containersHydraulic cylinderAgricultural engineering

The invention discloses adjustable windproof cotton airing equipment, and relates to the field of airing equipment. The adjustable windproof cotton airing equipment comprises a moving base, a U-shapedplate is fixedly installed at the top of the moving base, the same rotating shaft is fixedly installed on the inner walls of the two sides of the U-shaped plate, a large semi-cylinder is rotatably installed on the rotating shaft, a telescopic hydraulic cylinder is fixedly installed at the top of the large semi-cylinder, a telescopic column is fixedly installed at the output end of the telescopichydraulic cylinder, two storage rods are rotatably installed at the top end of the telescopic column, a sleeving plate is fixedly connected to the telescopic hydraulic cylinder in a sleeve mode, supporting plates are fixedly installed on the two sides of the sleeving plate, and two storage shafts are rotatably installed on the sides, close to each other, of the two supporting plates. The adjustable windproof cotton airing equipment is easy to operate, adjustable, capable of enabling cotton to be fully illuminated, capable of being turned over, convenient to air, convenient to collect and storeafter airing is completed and convenient to use.

Owner:德清凯晶光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com