Conveying turnover device for plastic sealing strip of integrated circuit

A technology of integrated circuits and flipping devices, applied in printed circuits, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of low efficiency, many equipment and operators, and high production costs, and achieve convenient operation, simple structure, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, it will be further described below in conjunction with the accompanying drawings and specific embodiments.

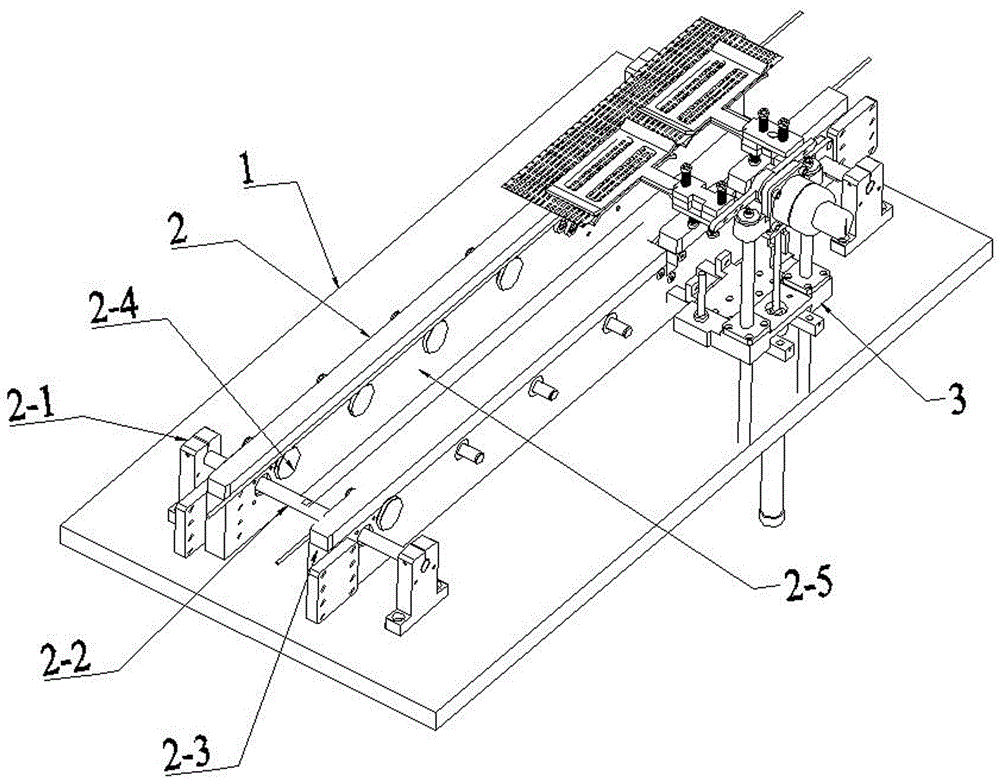

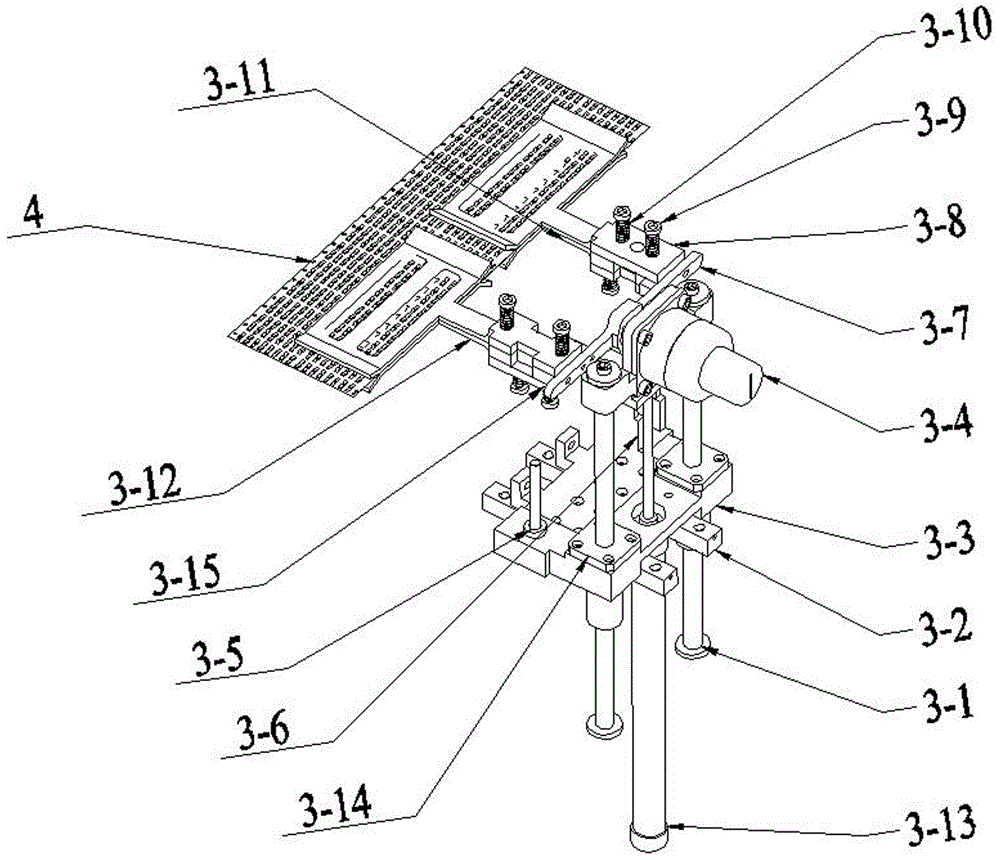

[0018] Such as Figure 1-2 As shown, a conveying and turning device for integrated circuit molding compound strips includes a conveying mechanism 2 and a turning mechanism 3, wherein the conveying mechanism 2 includes two mutually parallel guide rails 2-3, and the guide rails 2-3 are provided with pulleys 2-4 , the belt pulley 2-4 is provided with a conveyor belt 2-5, and two guide rails 2-3 are erected on the belt bearing holders 2-1 at both ends of the guide rail 2-3 through the rotating shaft 2-2, and one of the guide rails 2-3 An overturning mechanism 3 is provided on the outside, and the fixed seat 2-1 with bearings is fixed on the horizontal operating platform 1; -3 vertical setting, slide rail 3-2 is provided with fixed base 3-3, is provided with some linear bearings 3-14 on the fixed base 3-3, is respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com