Patents

Literature

139results about How to "Realize semi-automatic operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

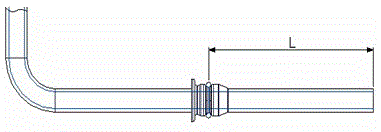

Corrugated pipe cut-off machine

ActiveCN102601443AShort tripReduce labor intensityTube shearing machinesShearing machine accessoriesDouble-timeSemi automatic

The invention relates to a corrugated pipe cut-off machine, which comprises a base. A boss is arranged at one end of the base, a cut-off cylinder and a first guide pipe are disposed on the boss, a second clamping cylinder is arranged on one side of the first guide pipe, a cutter is connected onto the cut-off cylinder and matches with a groove on the first guide pipe, a second guide pipe and an adjustable cylinder are arranged at the other end of the base, a linear guide track is disposed between the adjustable cylinder and the cut-off cylinder, and a first clamping cylinder is arranged on the linear guide track. The corrugated pipe cut-off machine has the advantages that electric elements including the four cylinders, a double-time setting relay, a counter, an electromagnetic valve and the like are integrated, and functions of an automatic corrugated pipe feeding device are realized by means of linkage of the cut-off cylinder, the adjustable cylinder and the two clamping cylinders. In addition, strokes of the cylinders are short, the running speed is fast, labor intensity of staffs is greatly reduced, semi-automatic pipe cutting operation is realized, cost investment is low, production efficiency is high, consumed working hours per capita can be reduced, and potential safety hazards caused by operational fatigue are eliminated.

Owner:TIANJIN GREAT WALL LEAN AUTOMOTIVE PARTS CO LTD

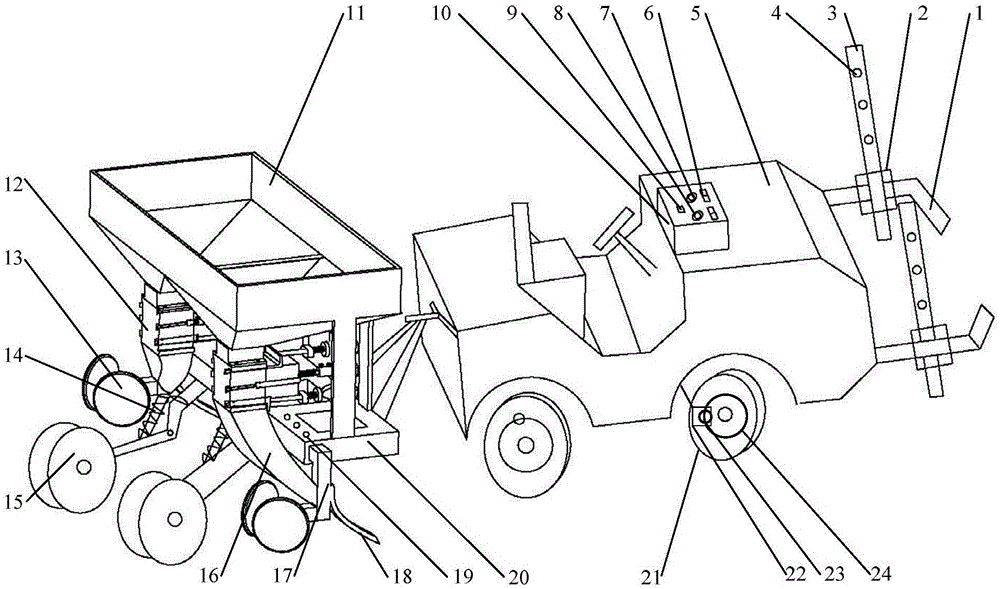

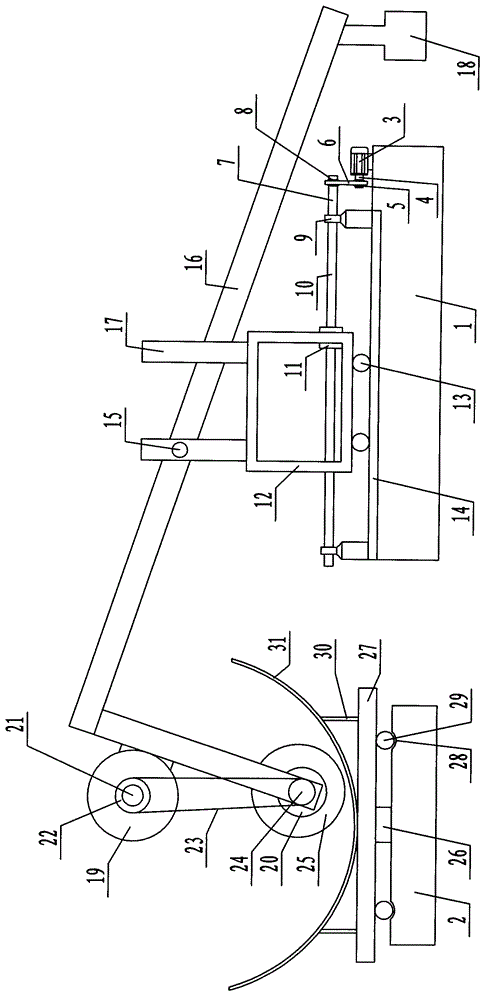

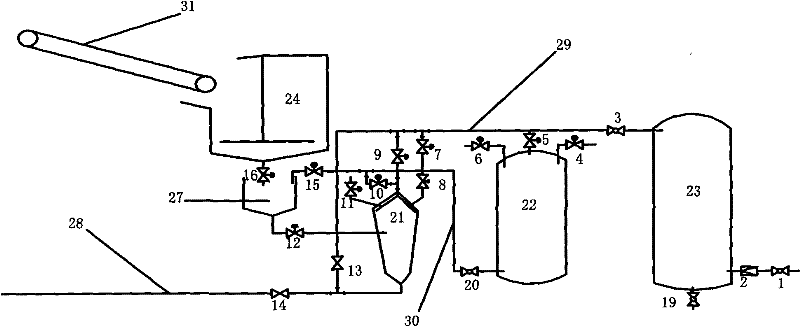

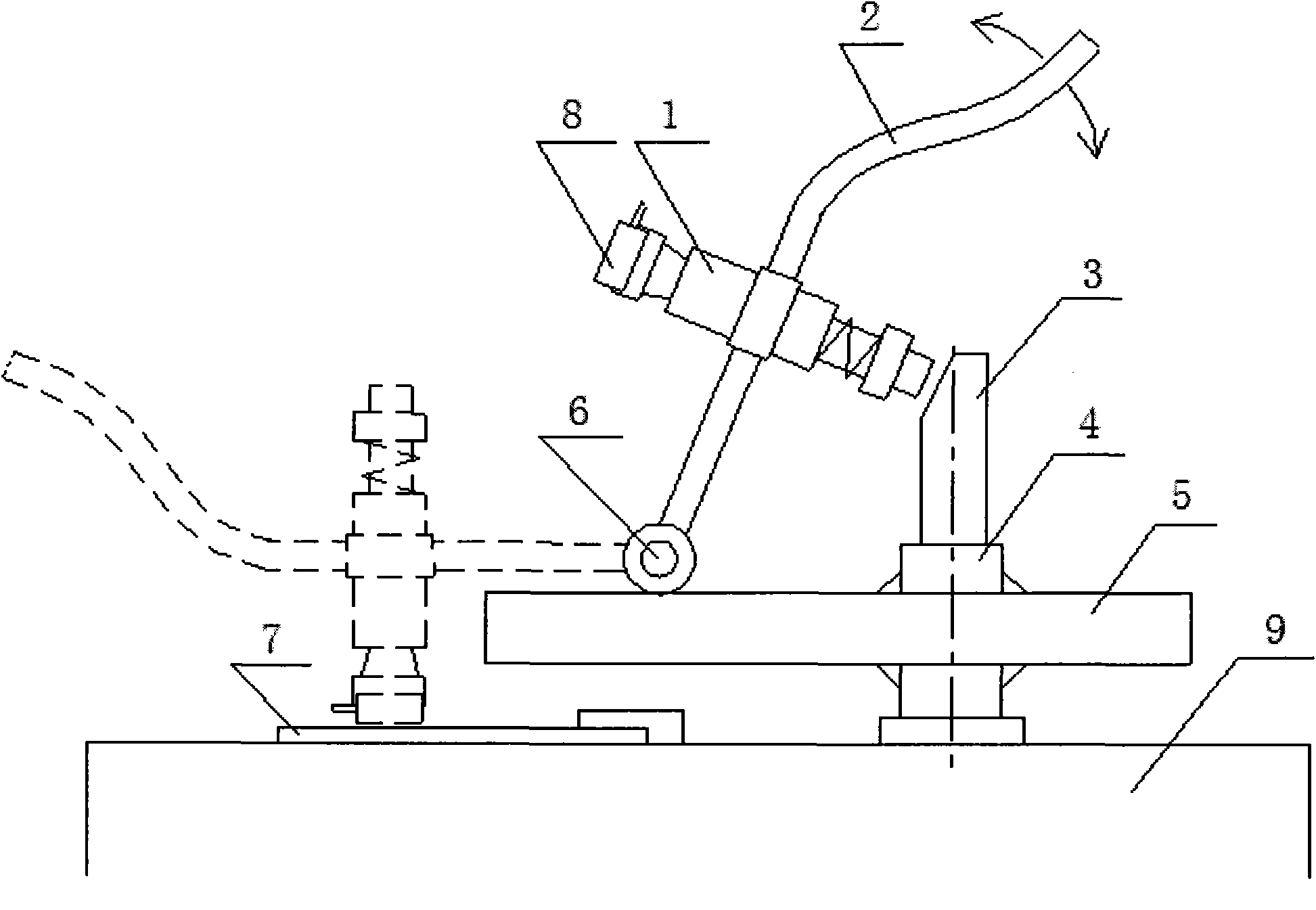

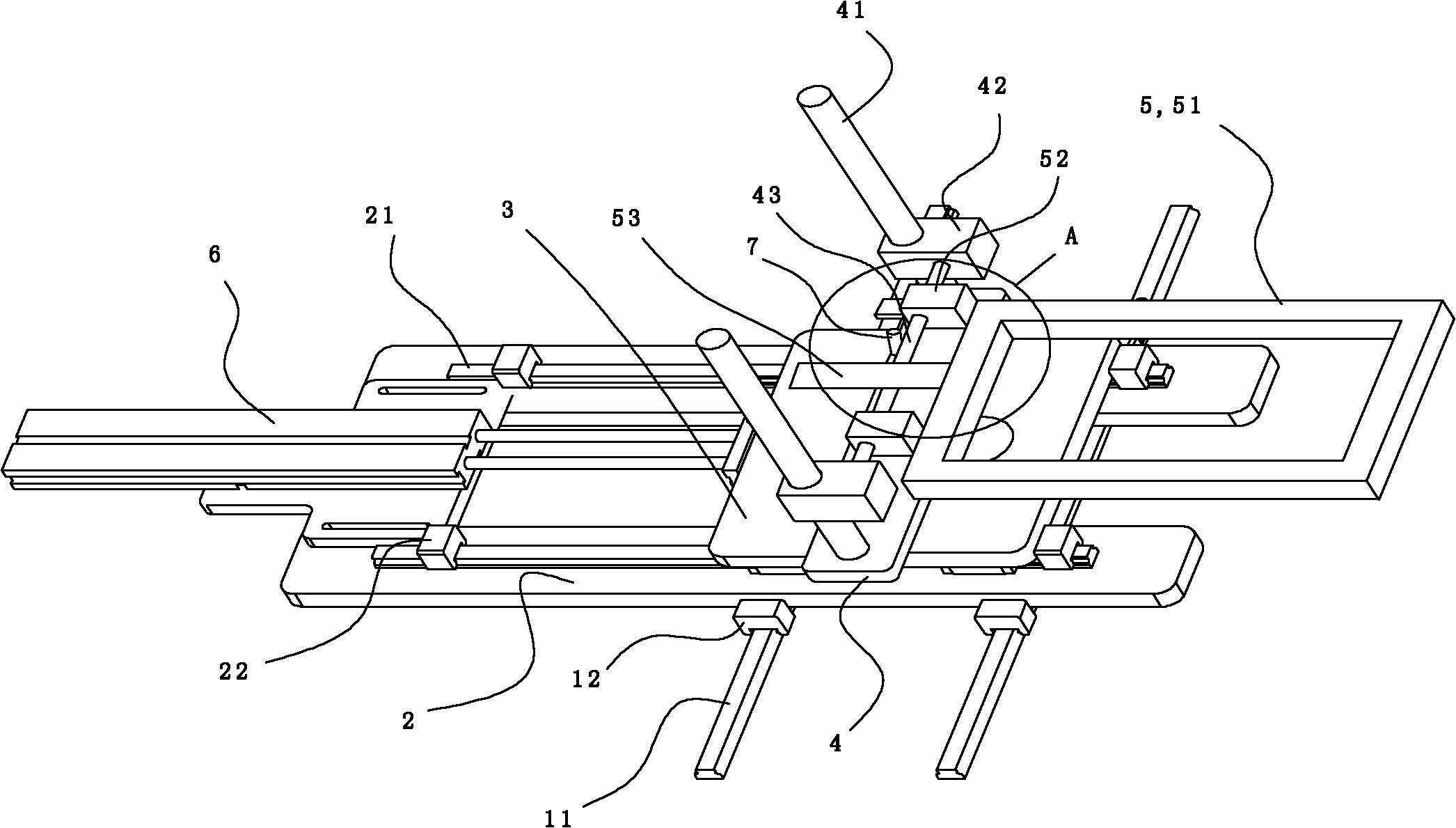

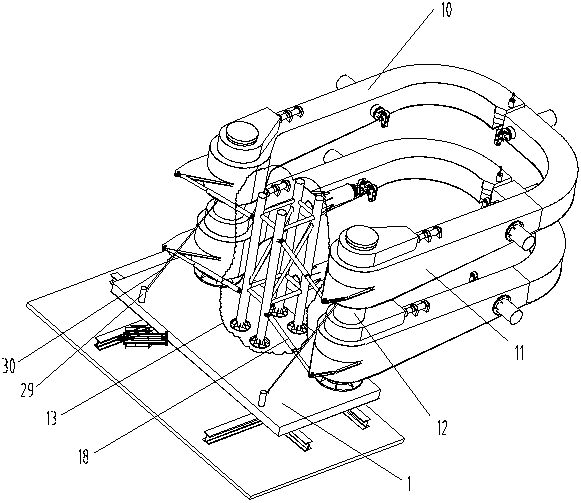

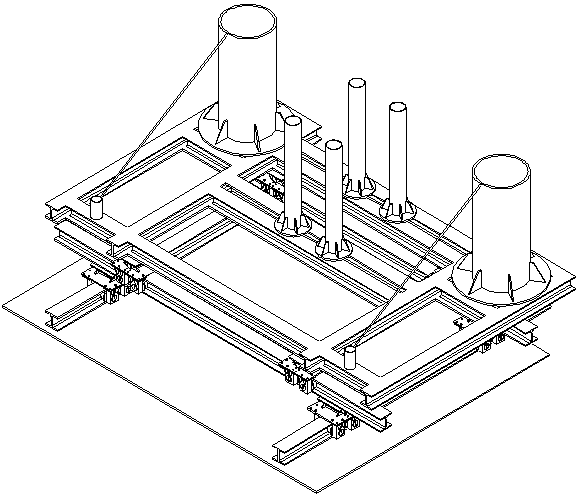

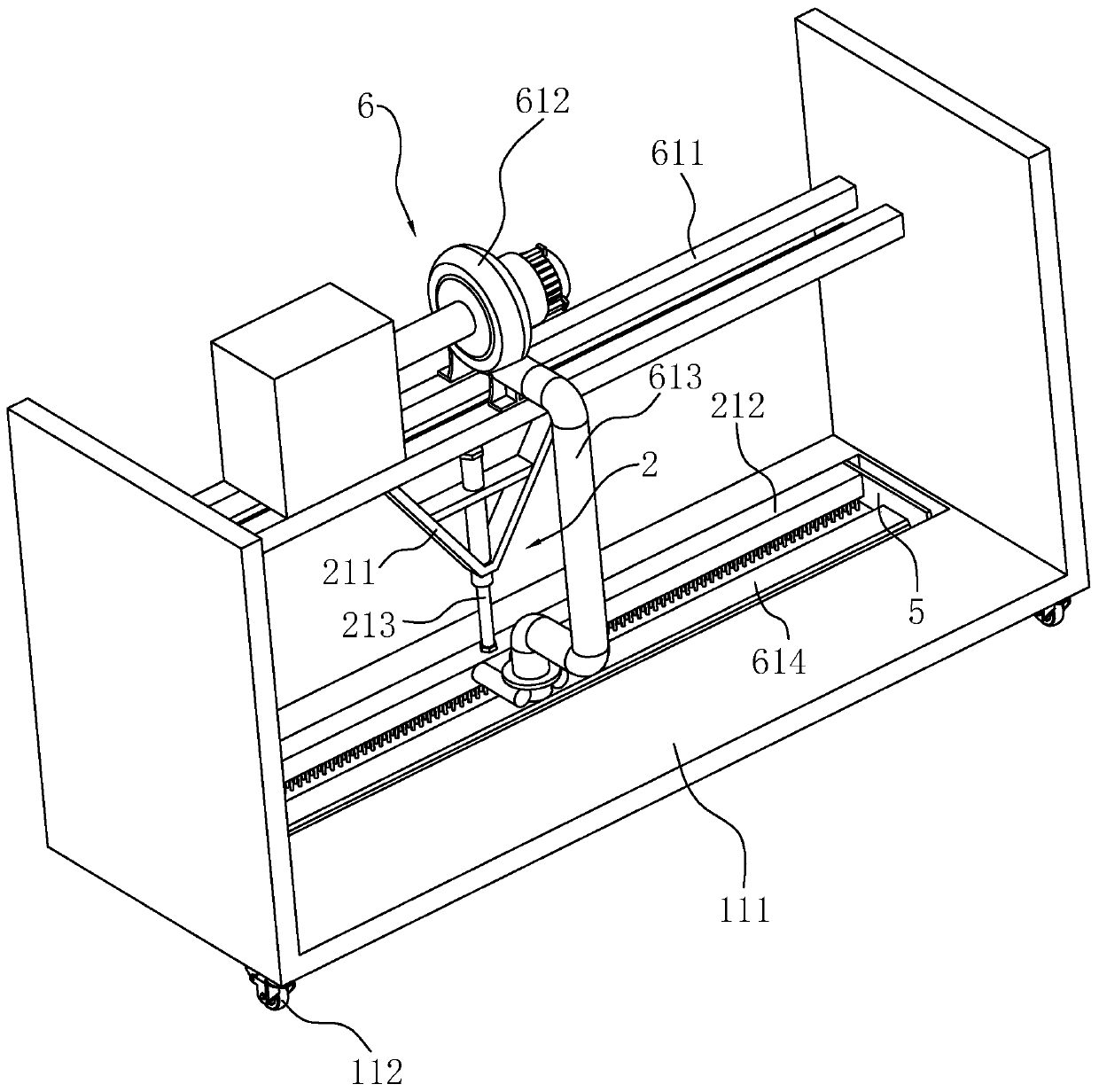

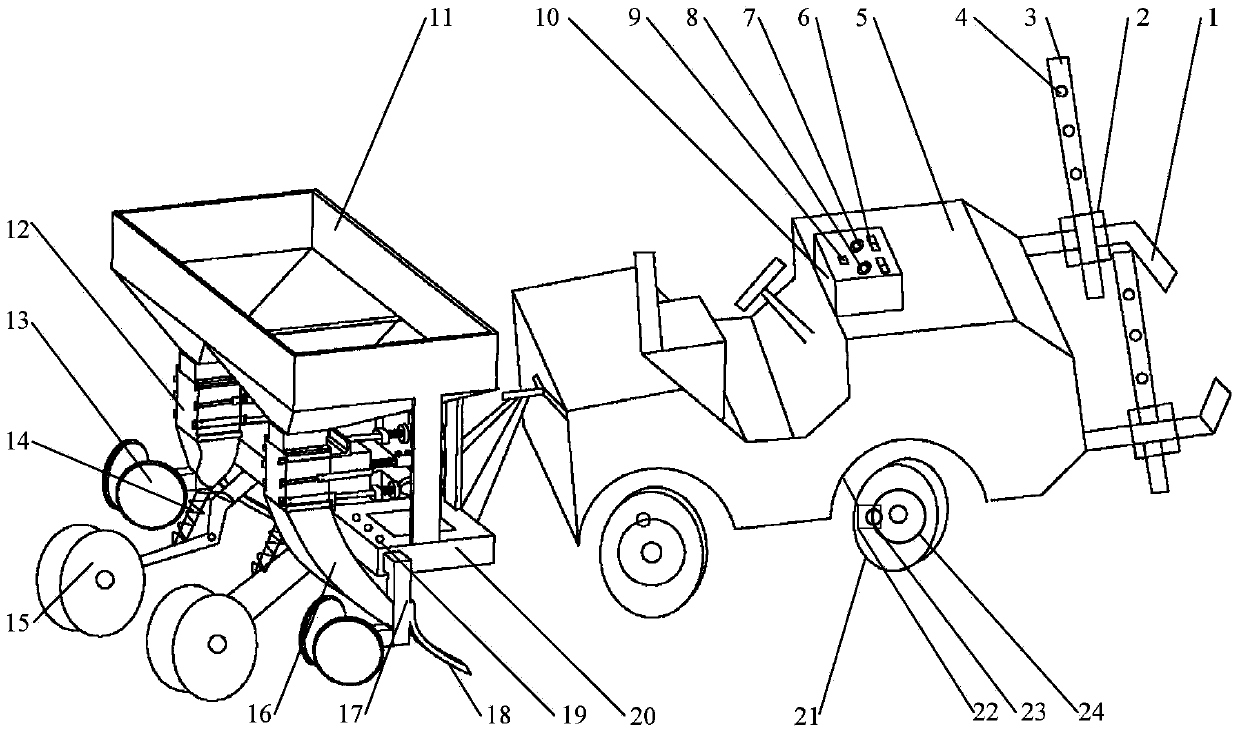

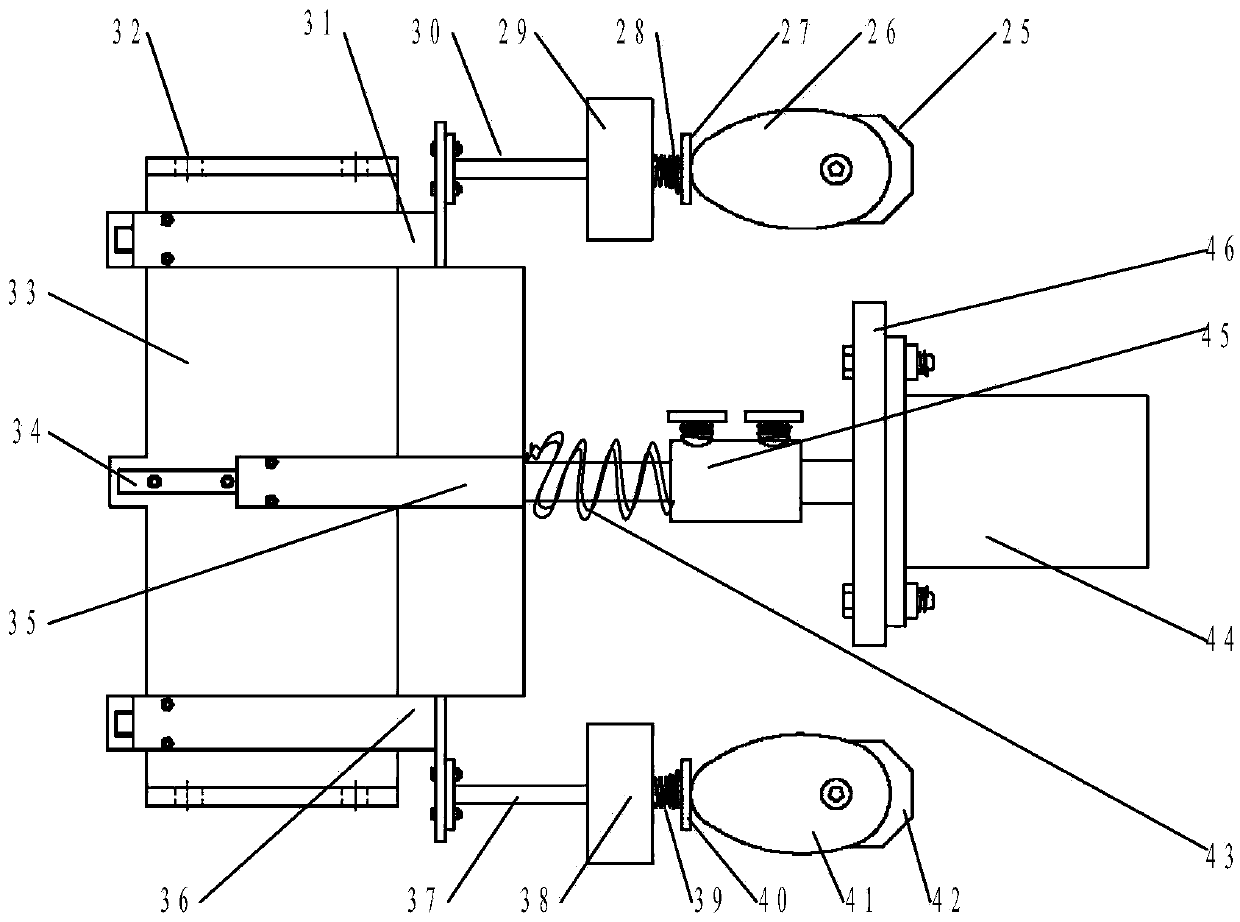

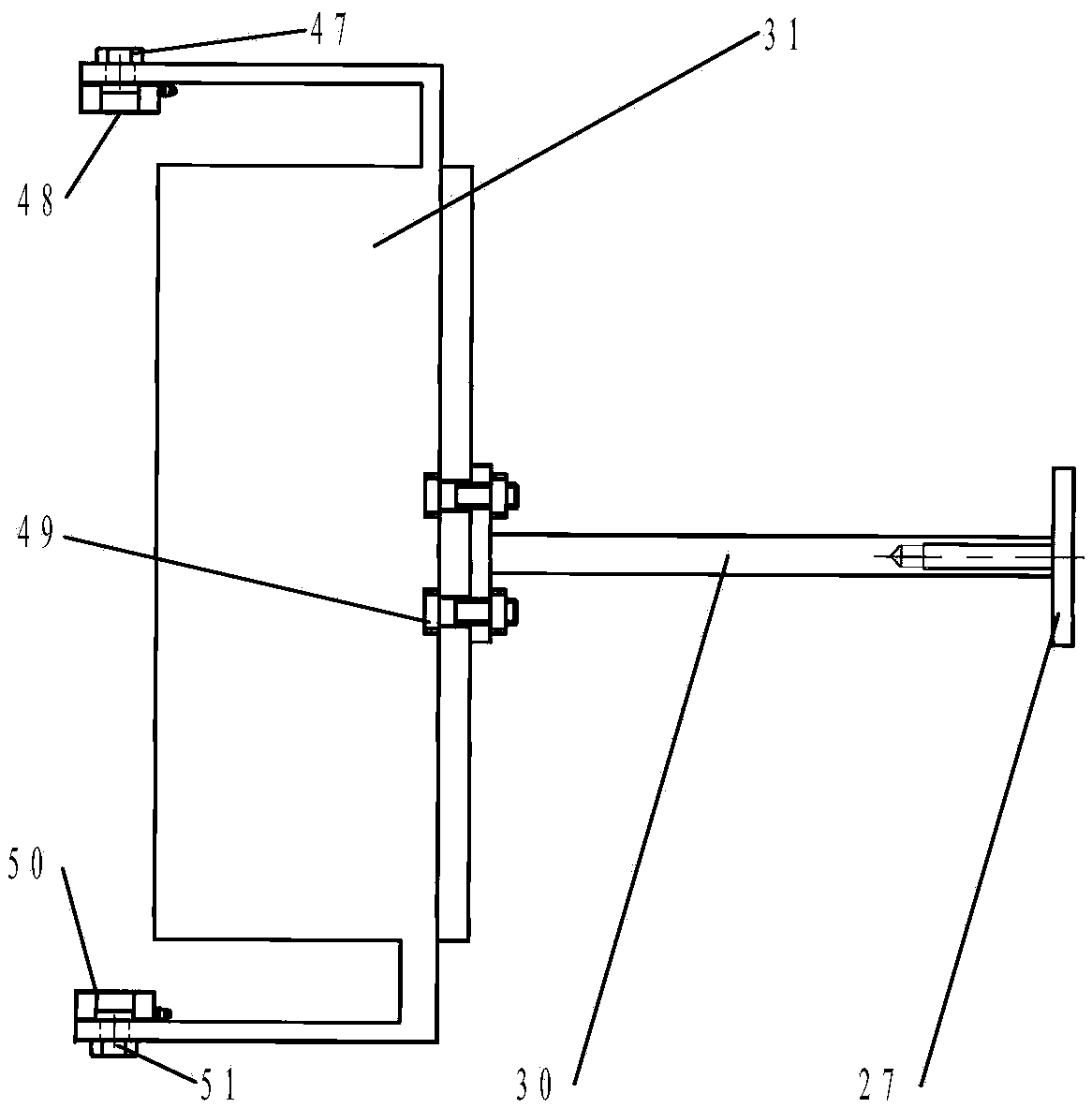

Device and method for trip-type ditching toward-target hole fertilization in orchard

ActiveCN105144918AImprove the efficiency of fertilization operationsIncrease profitPlantingFertiliser distributersFruit treeAgricultural engineering

The invention provides a device and method for strip-type ditching toward-target hole fertilization in an orchard. The device comprises ditching equipment, hole fertilizer feeding equipment, detecting equipment and a controller for fertilization amount adjustment, wherein the hole fertilizer feeding equipment comprises a fertilizer box and hole fertilizer feeders, and is used for realizing precise control of the fertilizer feeding amount and a fertilizer feeding position; the detecting equipment comprises a machine traveling speed detecting unit and a fruit tree target detecting unit, and is used for acquiring machine traveling speed information and fruit tree position information; the controller takes a single chip microcomputer as a core, is used for setting fertilizer feeding information of each tree and crown width information, processing the fruit tree position information and the machine traveling speed information, and controlling the hole fertilizer feeder to perform quantitative hole fertilizer feeding. According to the device and the method, a center position of each fruit tree can be calculated according to fruit tree target information and the traveling speed of the fertilizer distributor; aiming at center control of fruit trees on the two sides, the fertilizer feeders are correspondingly controlled to realize toward-target precision fertilization to improve the orchard fertilization operation efficiency, so that an approach for solving the orchard fertilization labor shortage problem in some regions in China.

Owner:NORTHWEST A & F UNIV

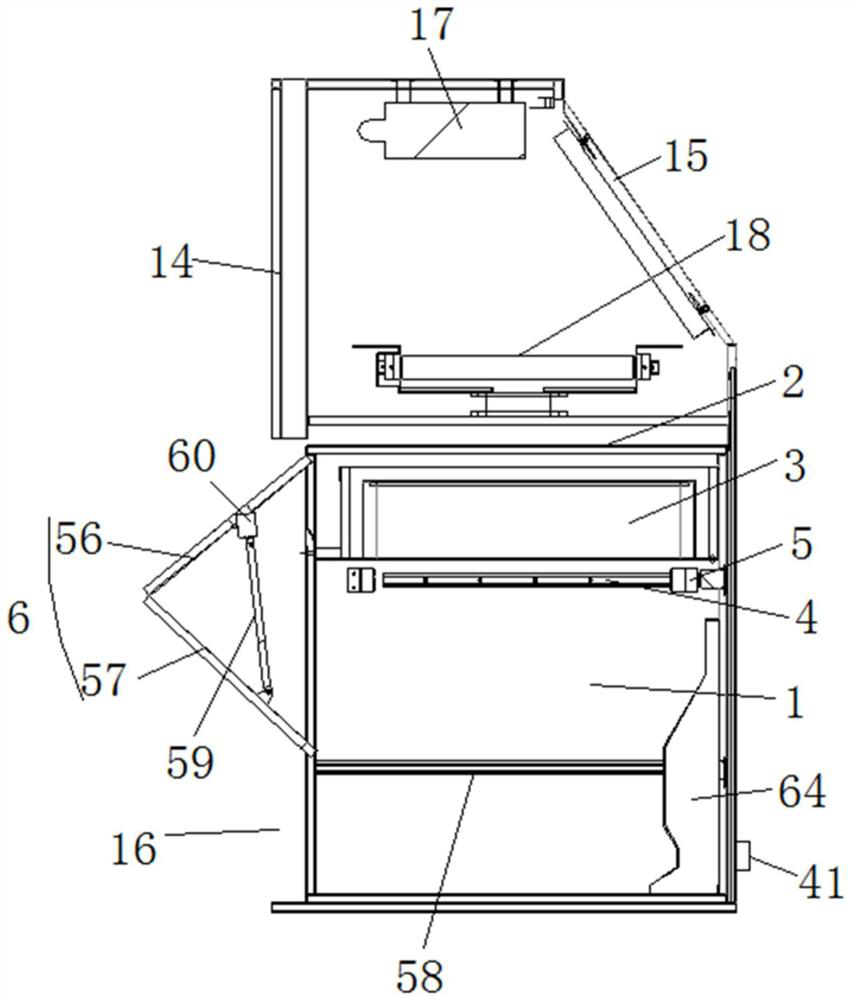

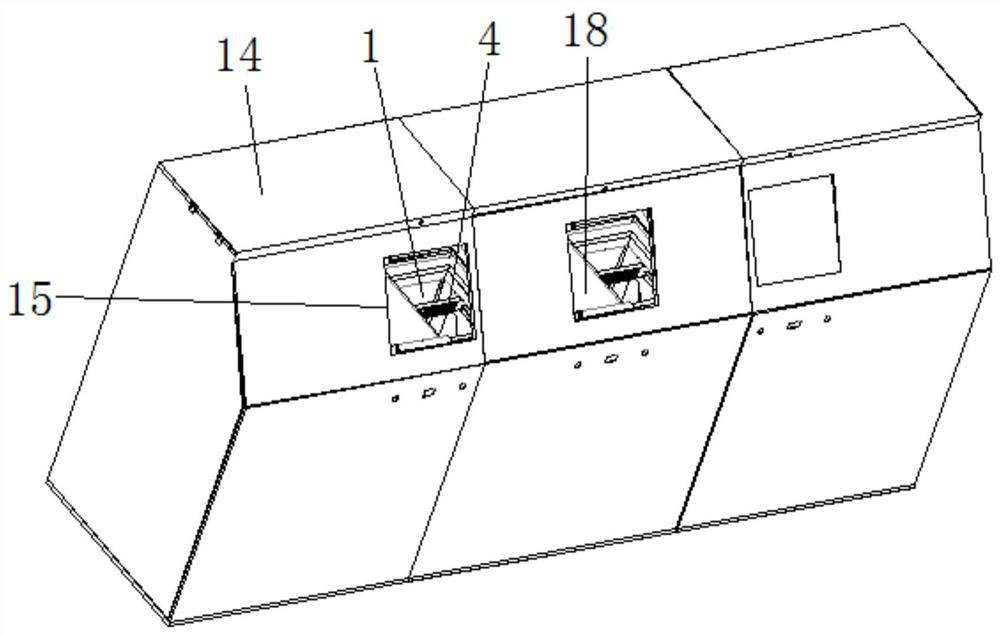

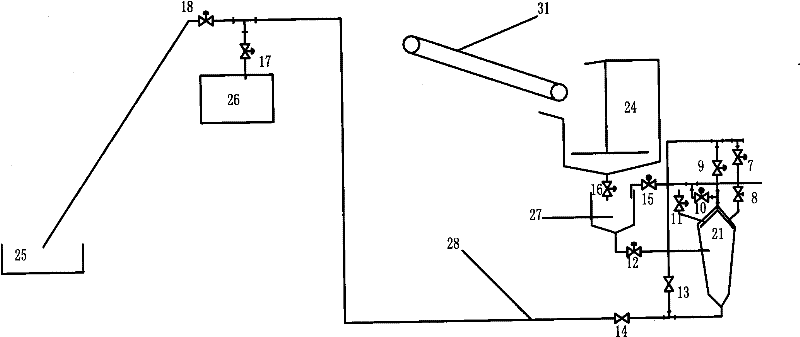

Automatic sealing and bag pushing garbage can

ActiveCN112573044AReduce configurationLow costRefuse receptaclesWrapper twisting/gatheringRefuse collectionSoftware engineering

The invention relates to an automatic sealing and bag pushing garbage can. The garbage can comprises a shell, and the shell corresponds to a set of independent garbage bins. The garbage capacity in the shell is detected through a garbage capacity detection system, the purposes of automatically packaging full-load garbage bags and automatically pushing the packaged garbage out of the shell are achieved through a sealing mechanism and a pushing mechanism, and the situations that in the traditional garbage collection work process, the full-load garbage bags are manually sealed and taken out of the garbage can are completely replaced; according to the intelligent classification garbage can, the purposes of automatically sealing the bags, packaging the garbage and pushing the bags out of the garbage can are further achieved while the garbage is intelligently thrown and intelligently recognized, and configuration of garbage collection workers in a community is further reduced; the purpose ofreducing the personnel allocation cost is achieved, the situation that personnel make contact with the garbage in the packaging process is avoided, and the body health of garbage transportation workers is effectively guaranteed.

Owner:广州东软科技有限公司

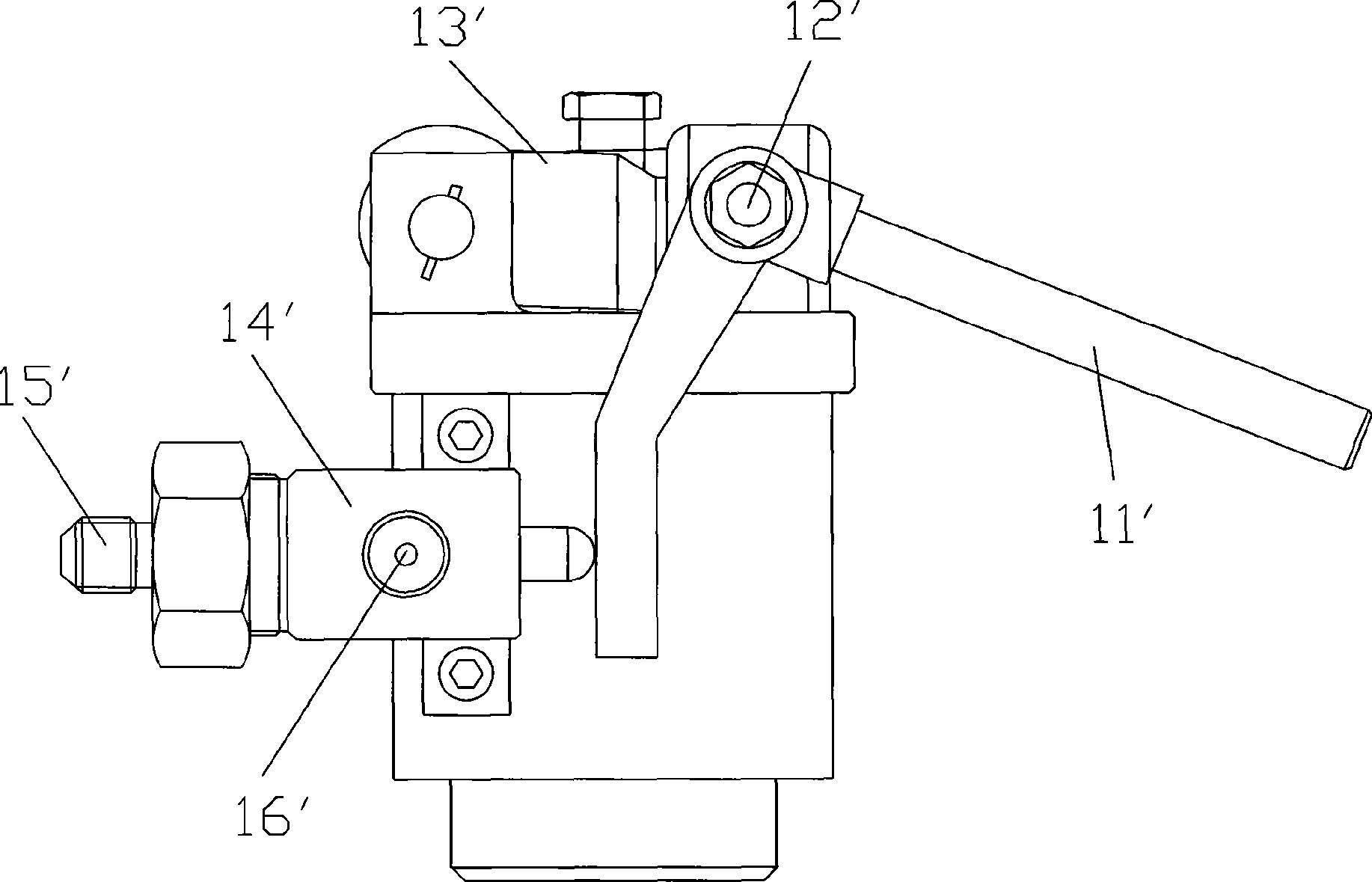

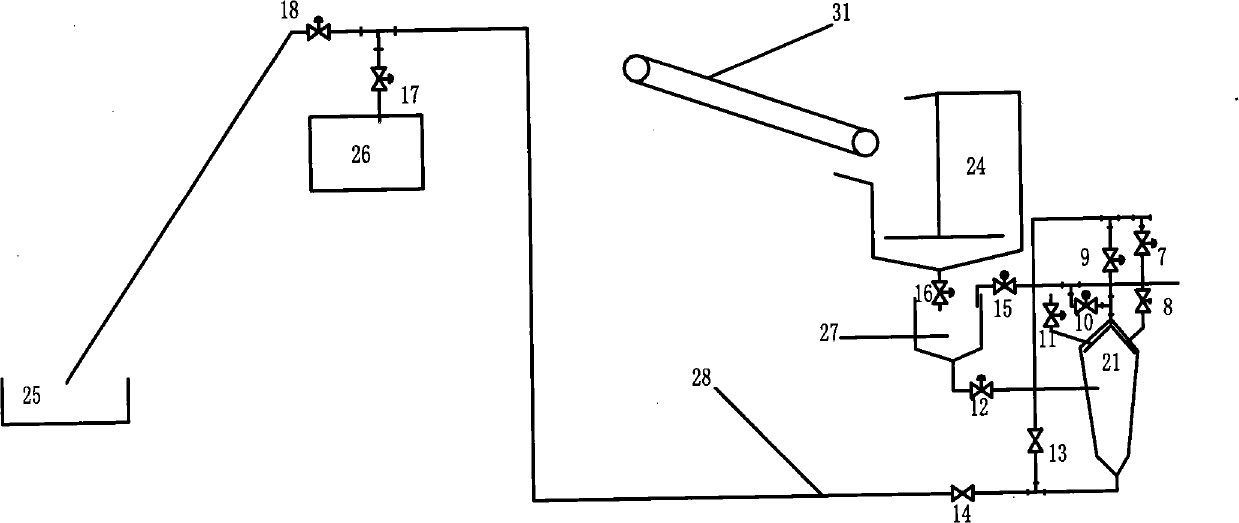

Electric control selection valve and active bottle control distribution method using the valve

ActiveCN101507869ATurn on smoothlyLow costOperating means/releasing devices for valvesFire rescueDistribution methodBottle

The invention discloses an electric control selection valve and an active bottle control and distribution method using the same. The electric control selection valve is combined by connecting an electric control driving device and a selection valve, wherein the inside of the electric control driving device is provided with a metal sealing film which divides the interior of the electric control driving device into an upper space and a lower space, and the electric control driving device is also provided with a driving gas outlet; and the body of the selection valve is provided with a main air inlet and a main air outlet. The method comprises that a plurality of fire-extinguishing and storing bottles and the electric control selection valves are arranged, and the main air outlet of each electric control selection valve is respectively opposite to a protection area; and one of the fire-extinguishing and storing bottles is used as an active bottle, and the other fire-extinguishing and storing bottles are used as passive bottles. The electric control selection valve has the advantages of reliably and steadily opening a valve port, and combining the electric control driving device and the selection valve into a whole. The method has the advantages of reducing control links, improving the control reliability, using one fire-extinguishing bottle as the active bottle, turning on the selection valve and the passive bottles thereof according to needs, and directly starting by electric control.

Owner:浙江信达可恩消防实业有限责任公司

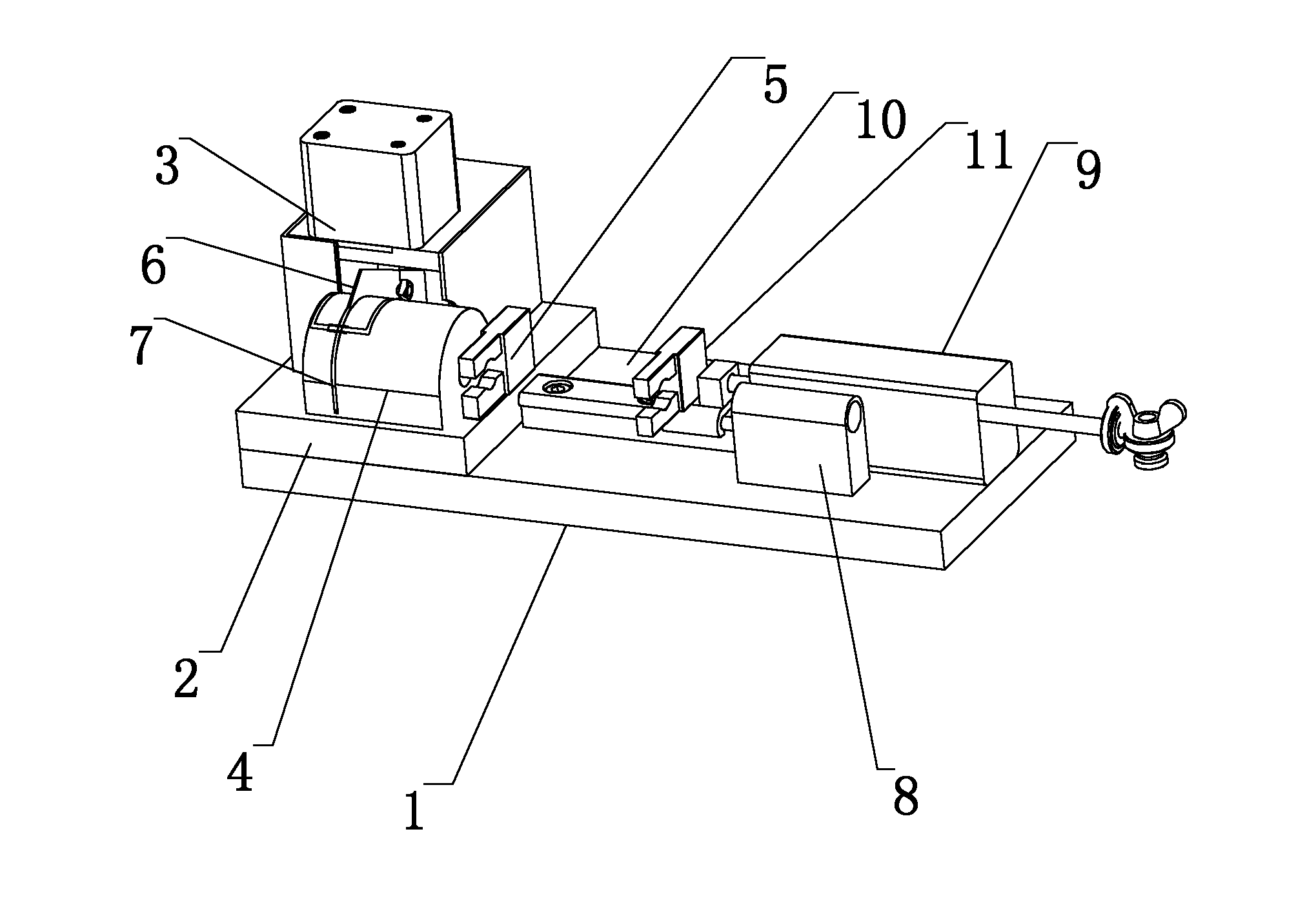

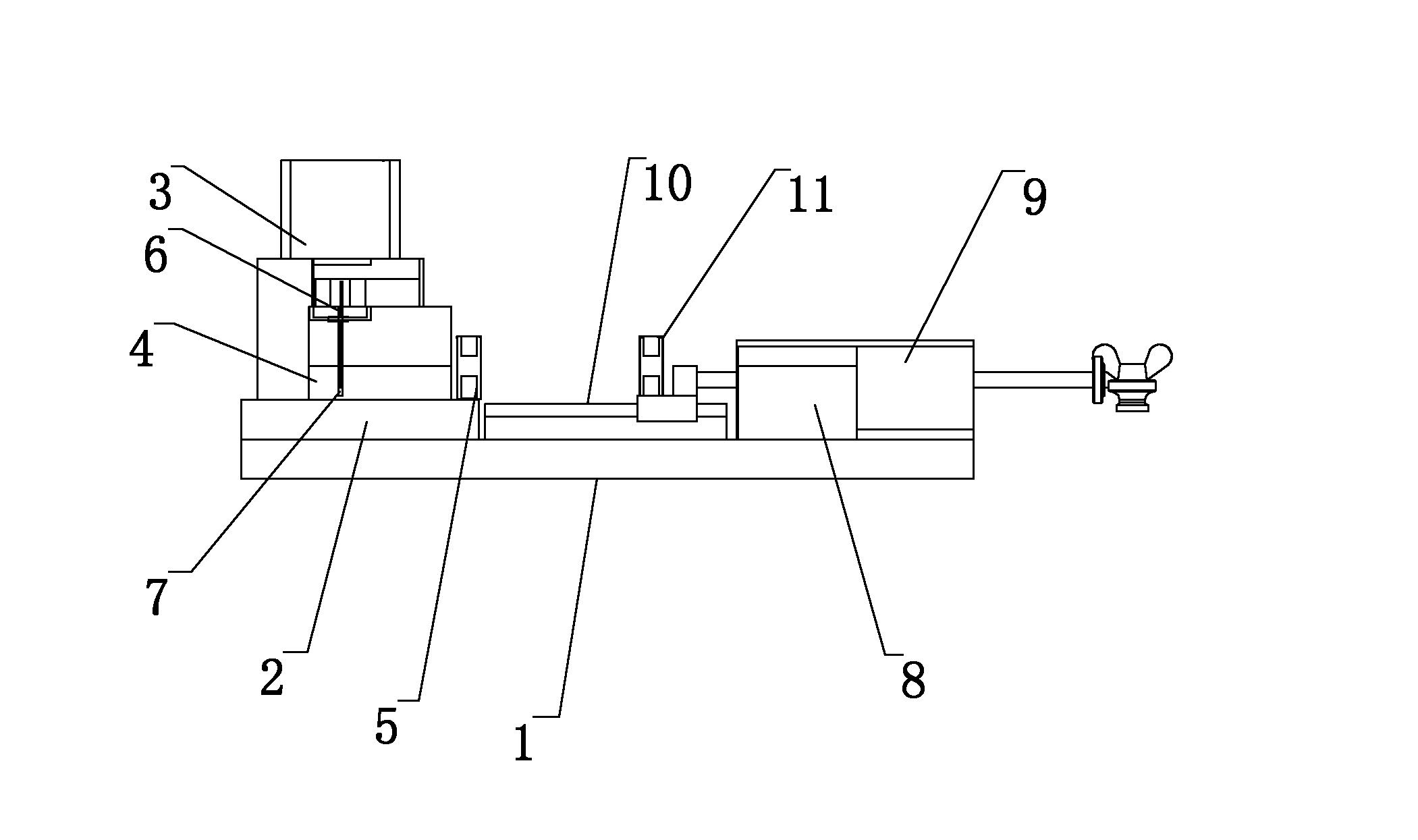

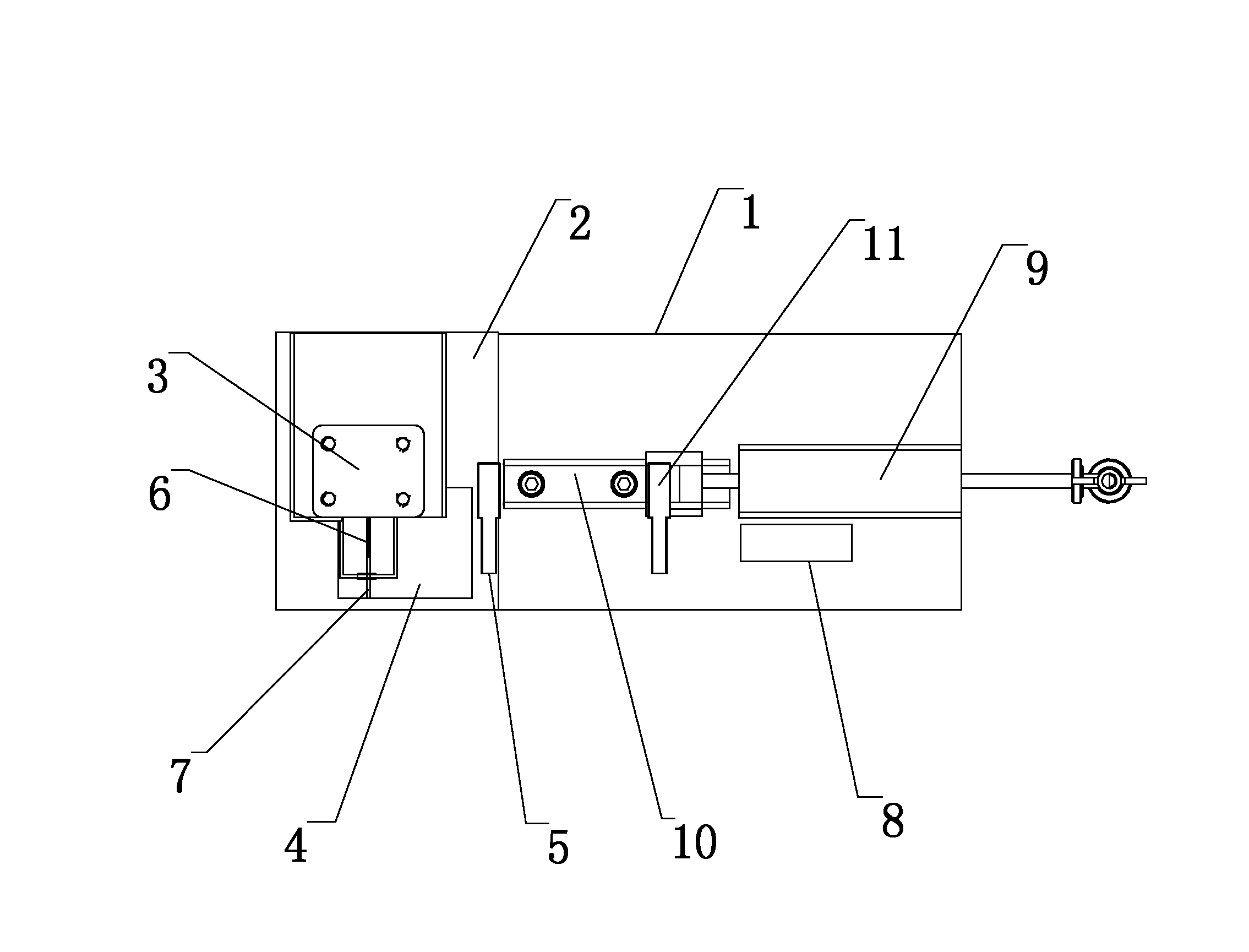

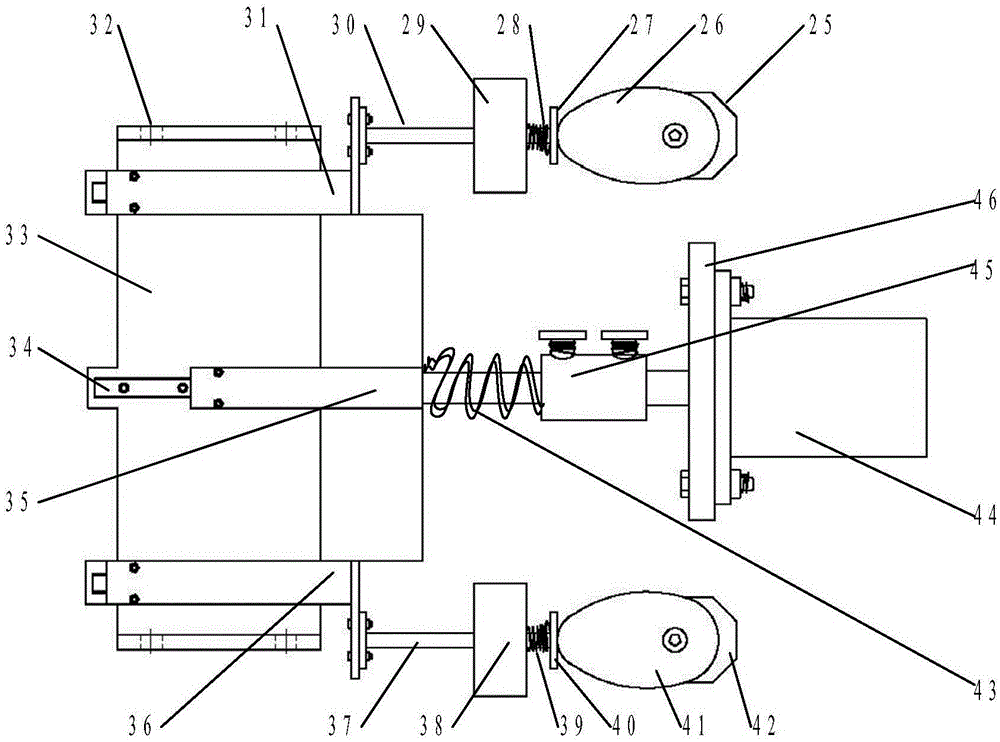

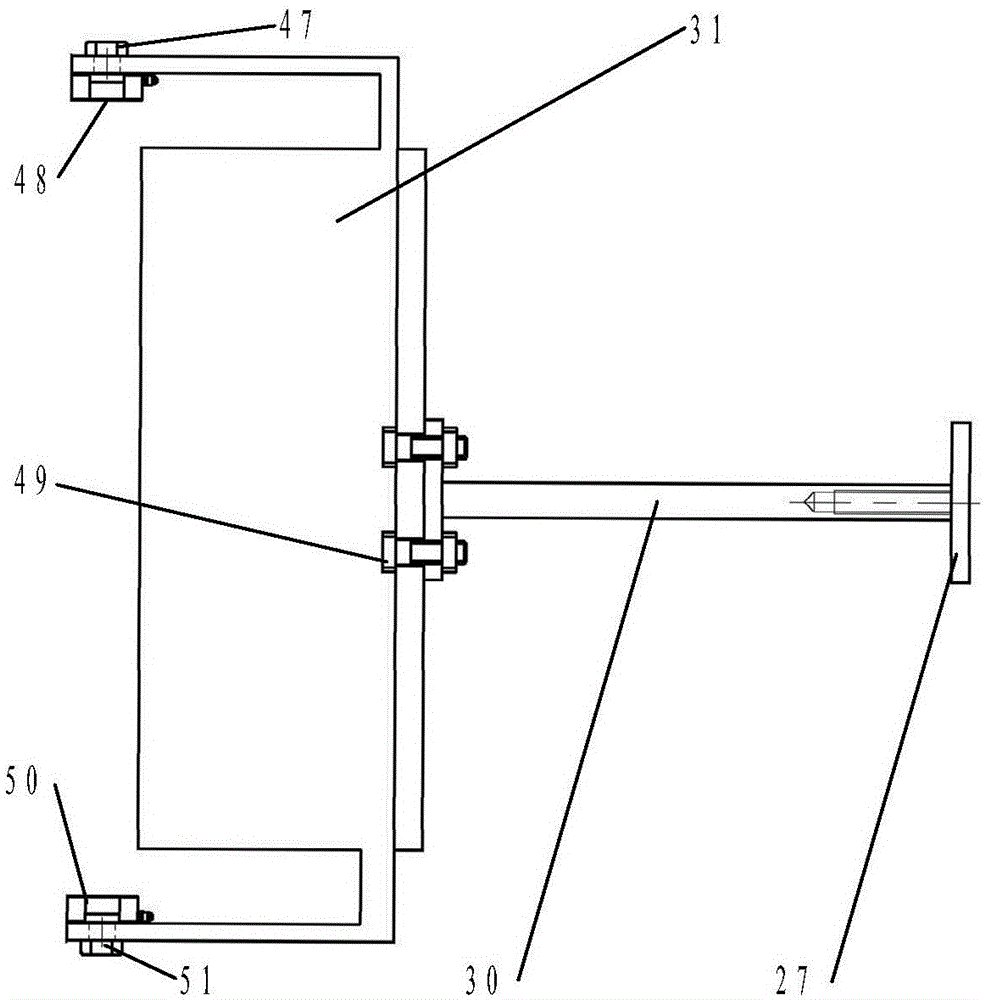

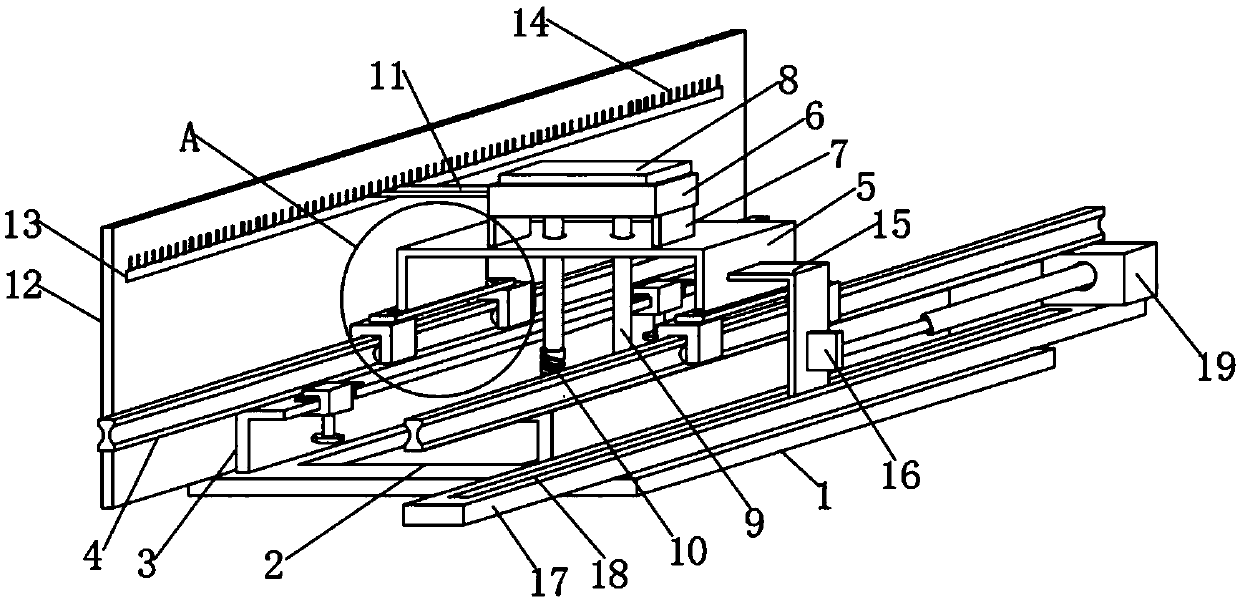

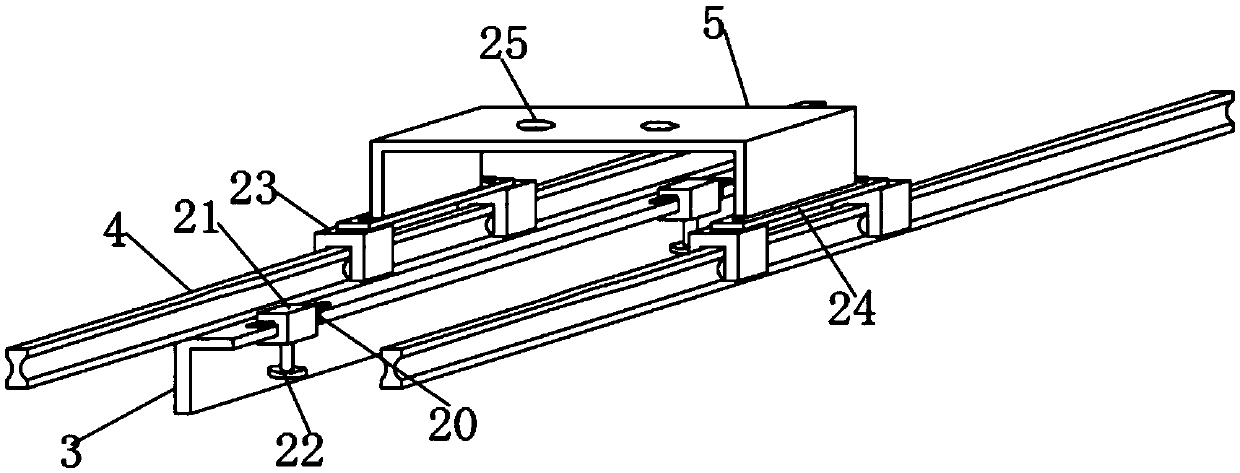

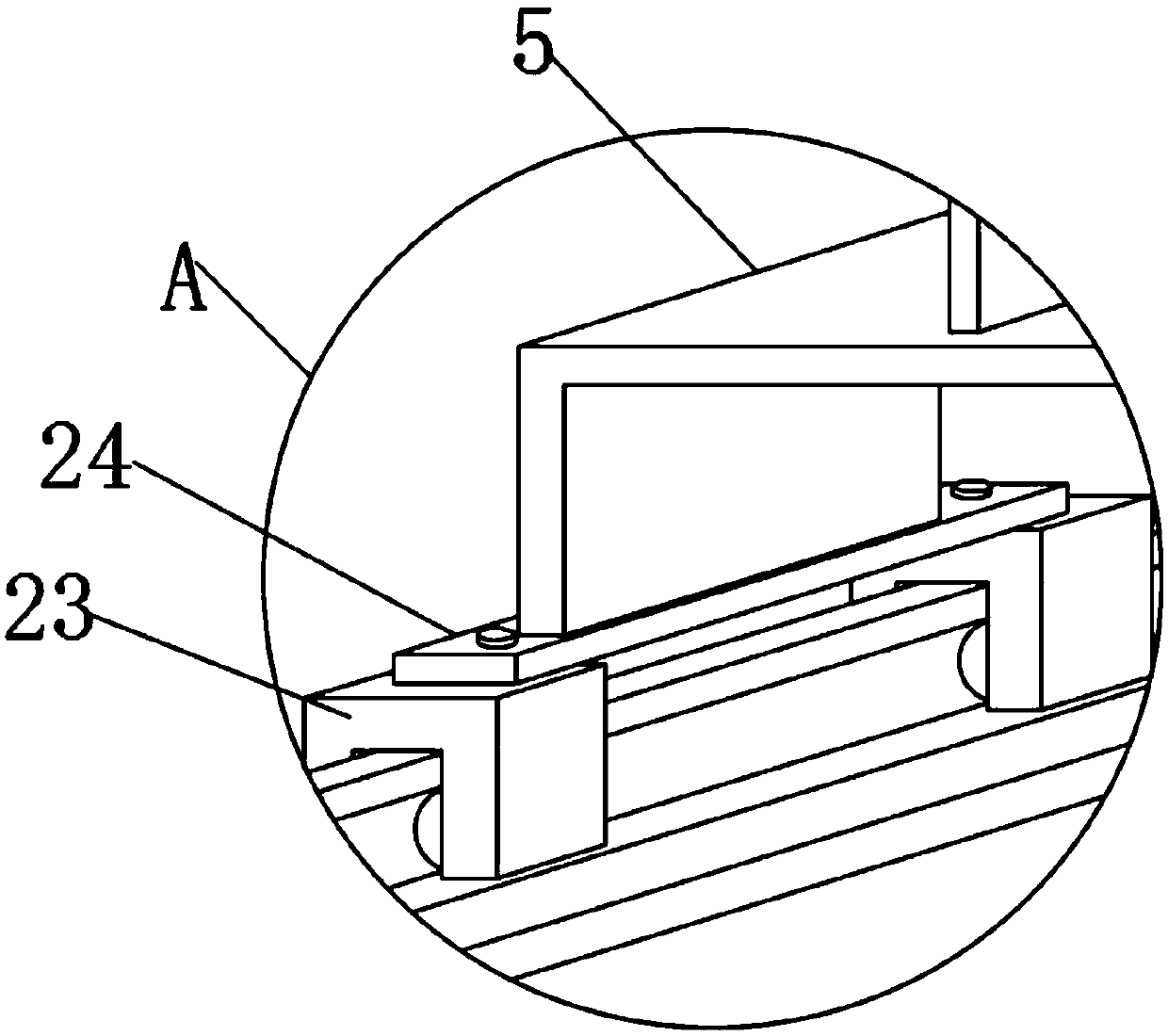

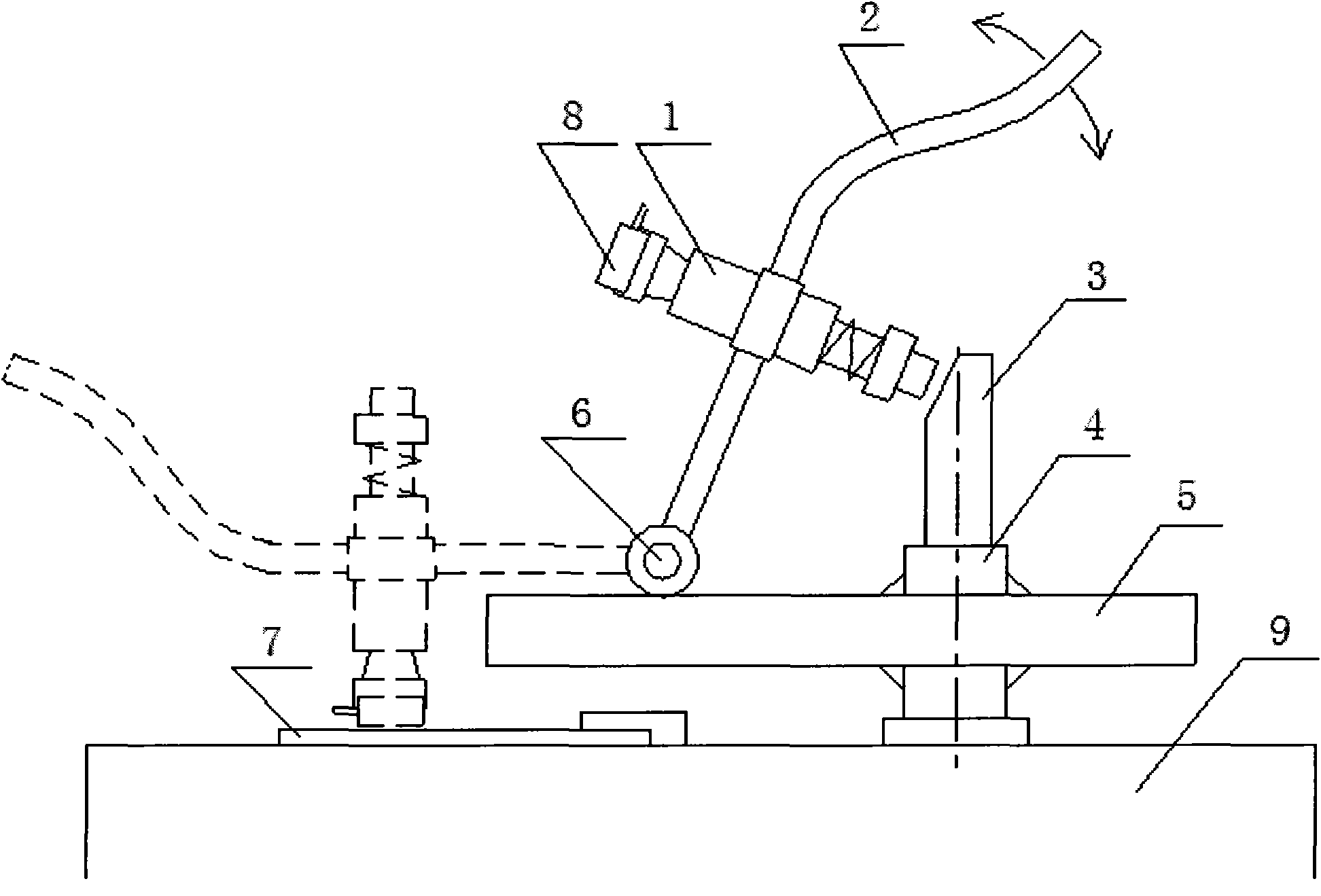

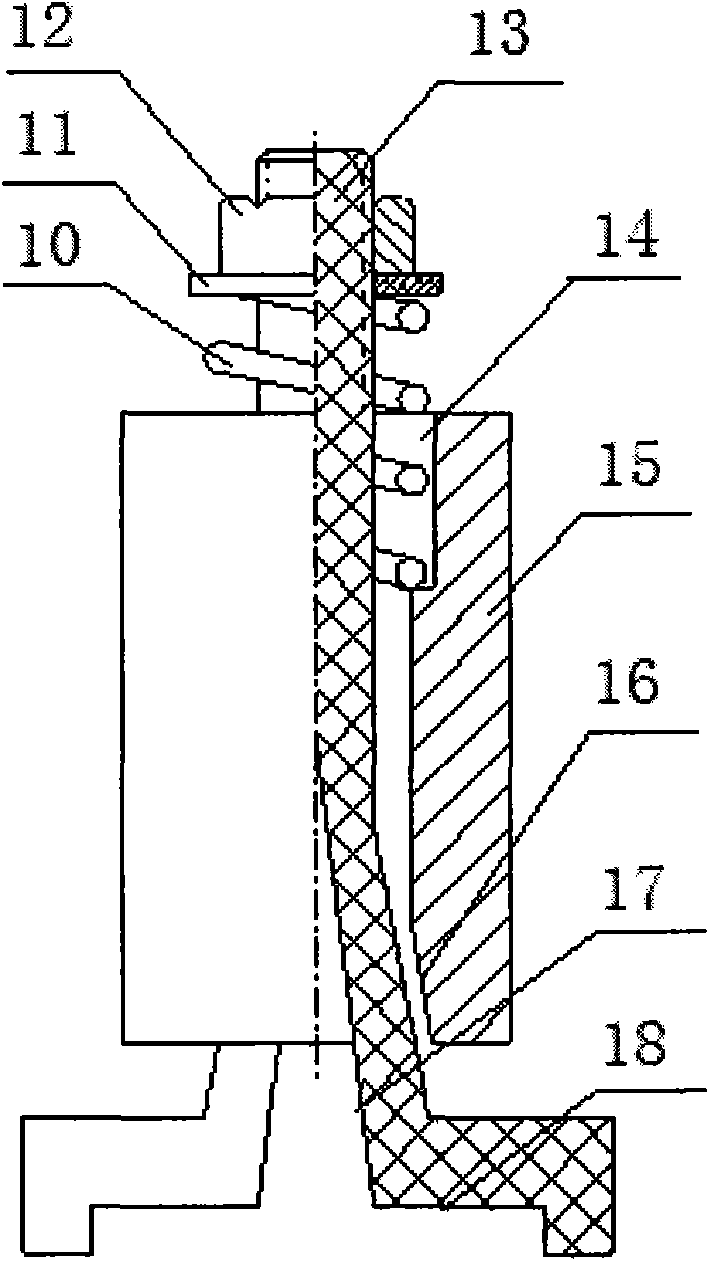

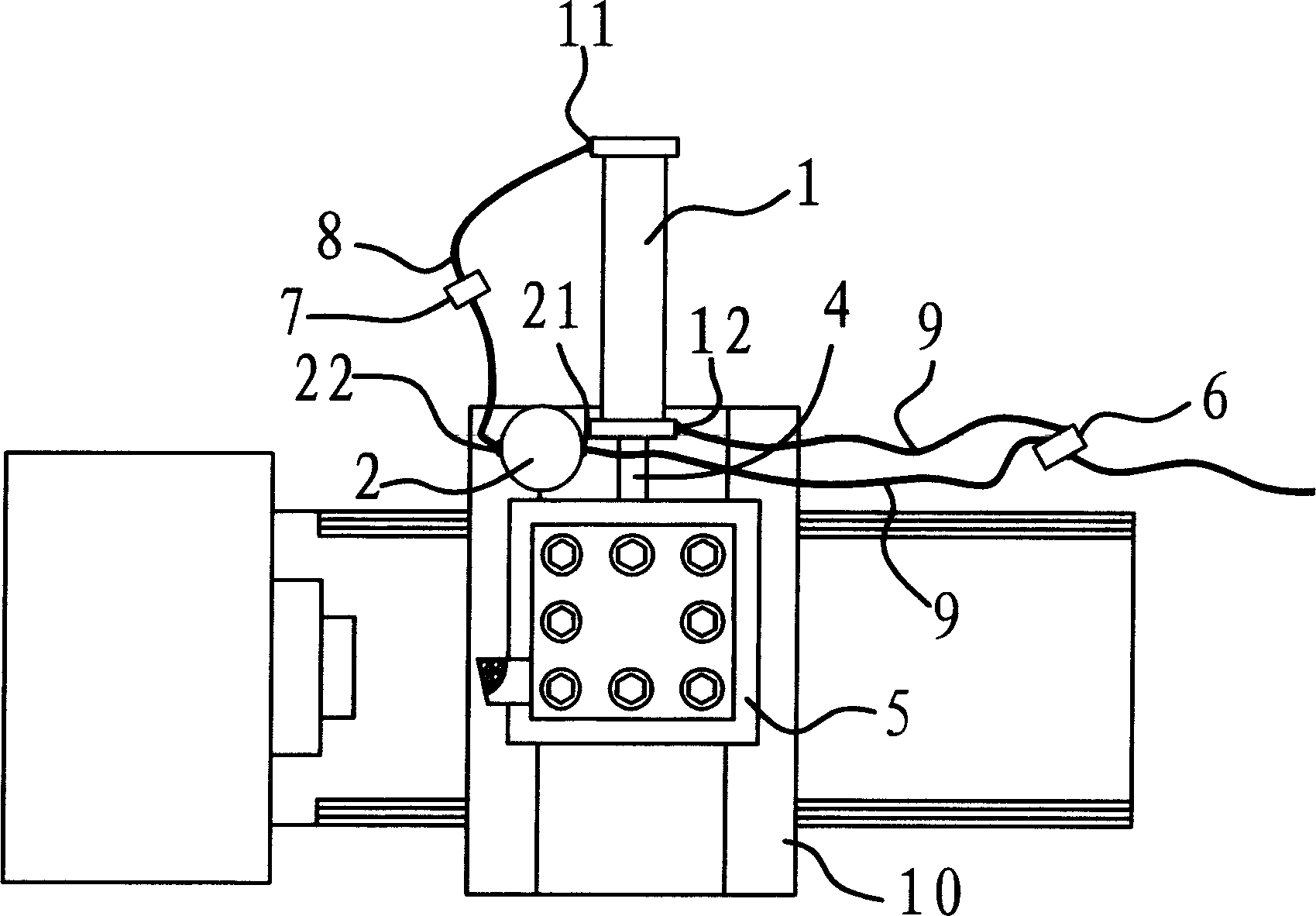

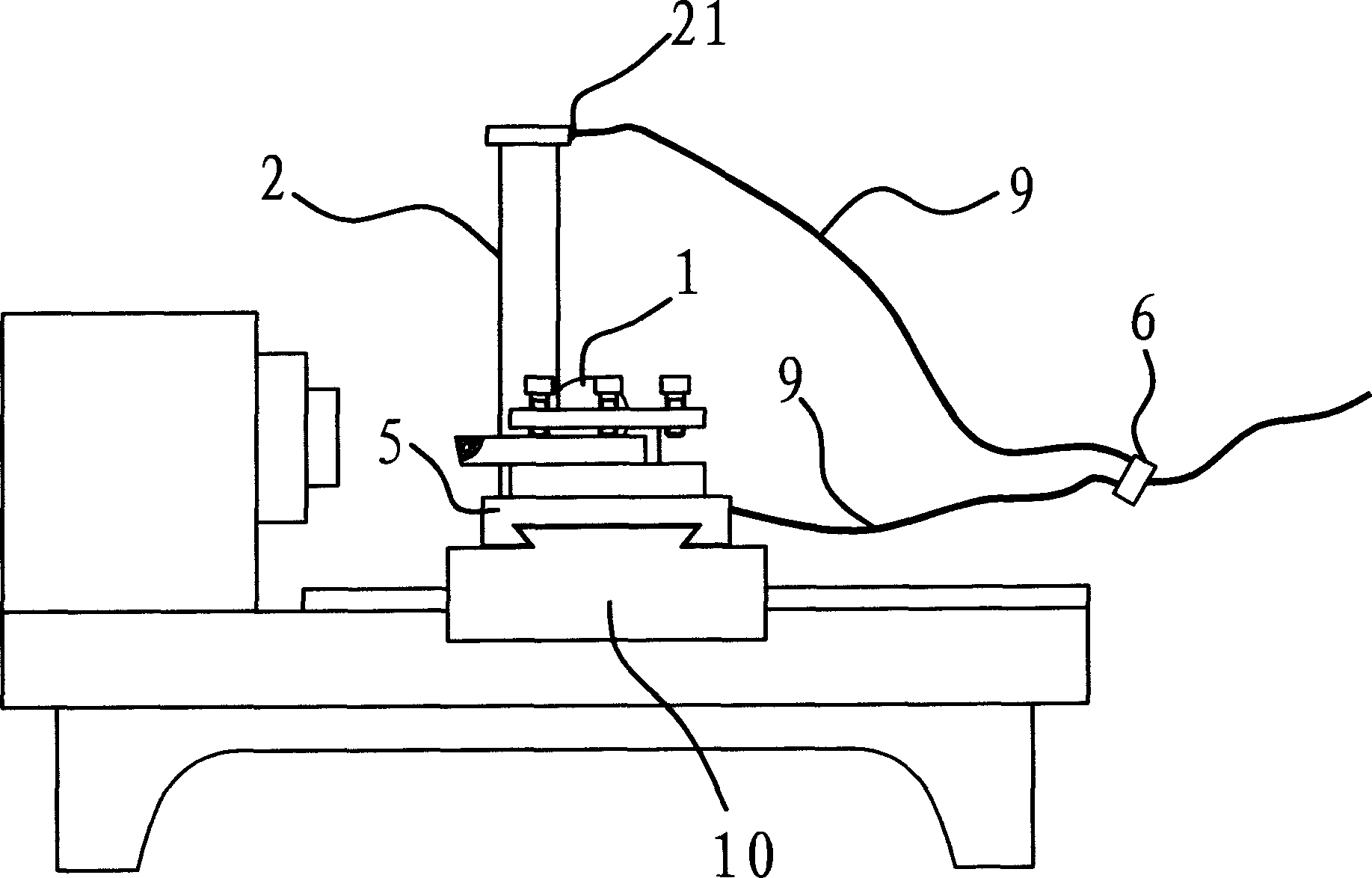

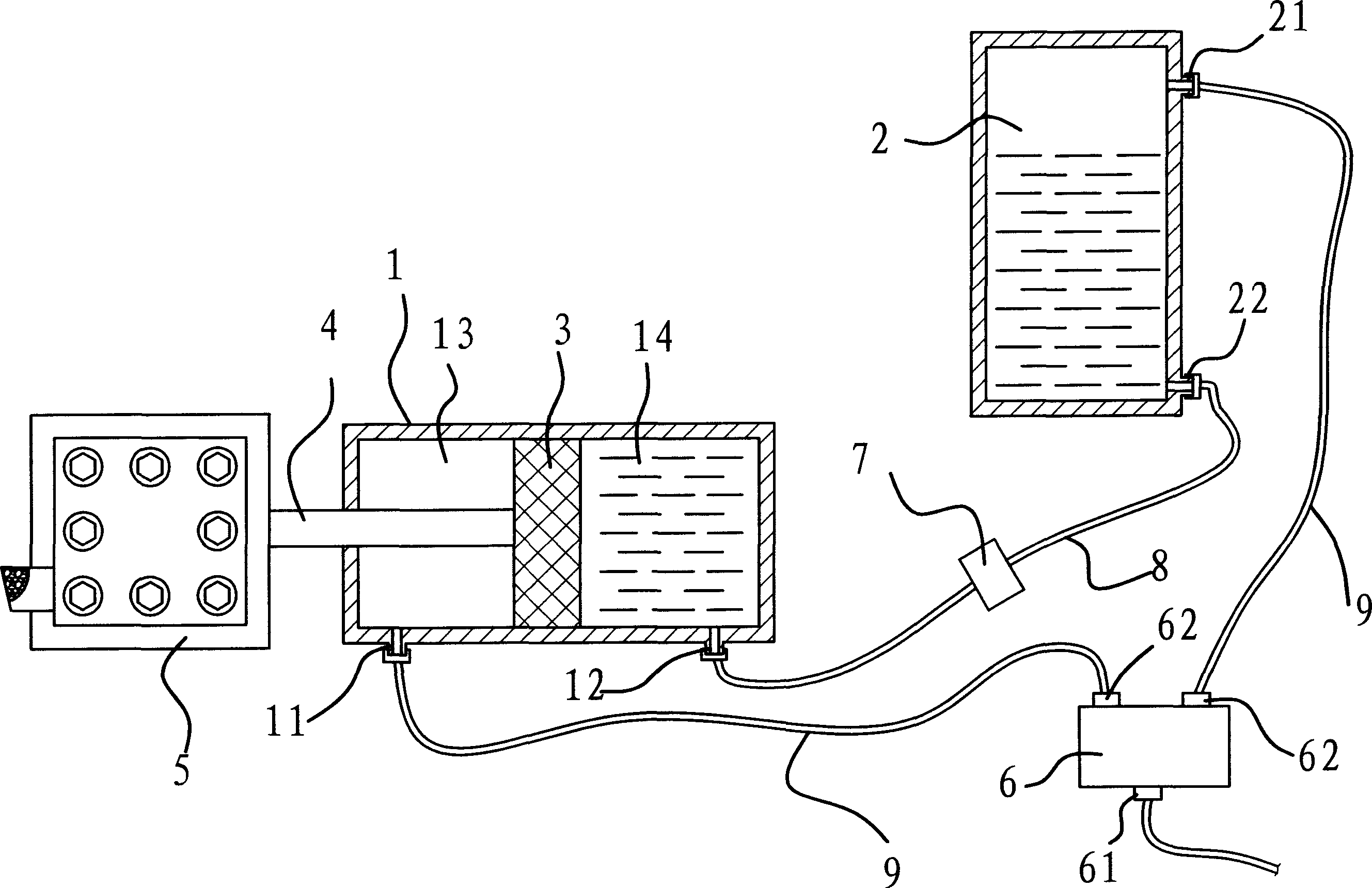

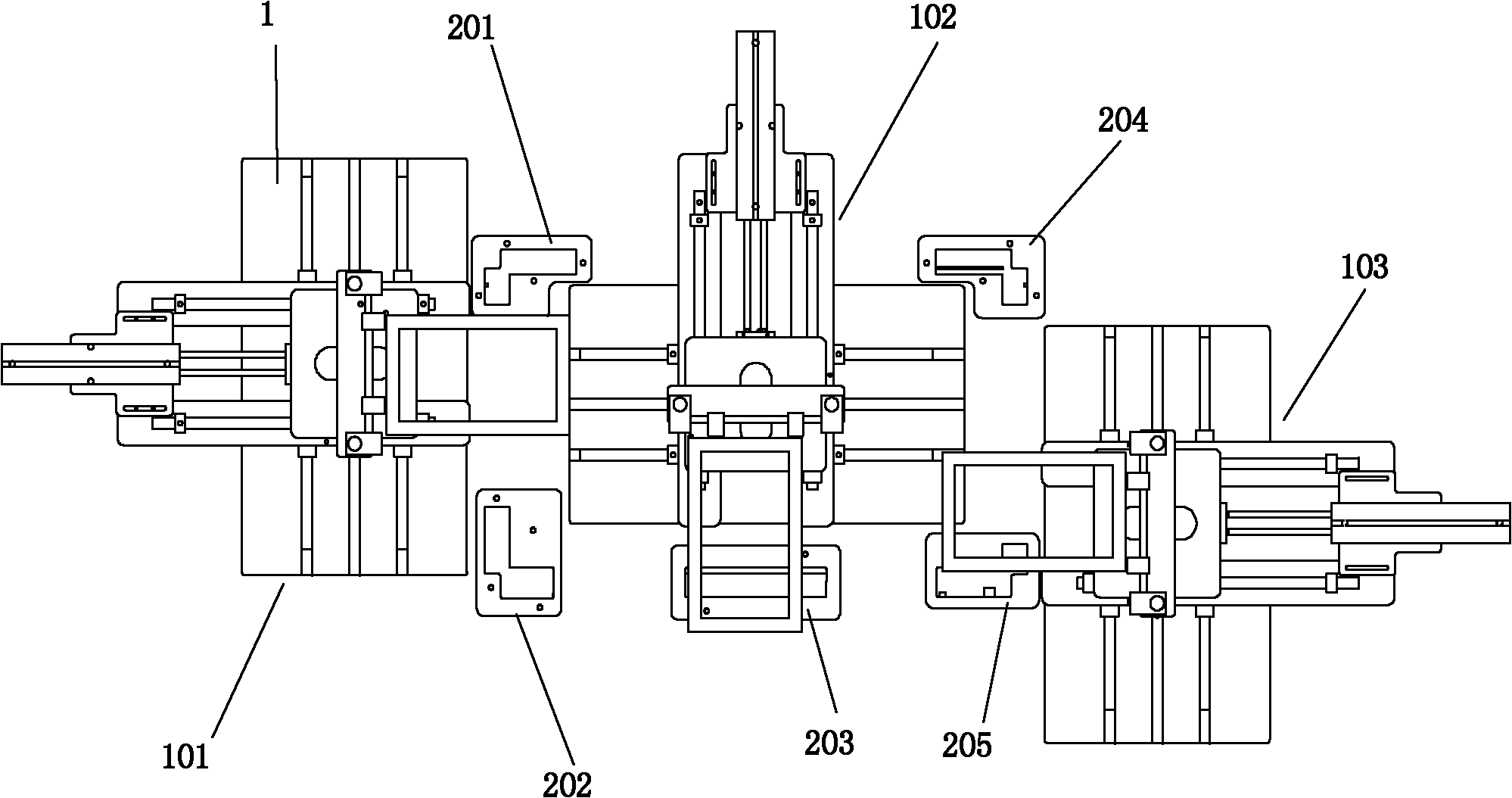

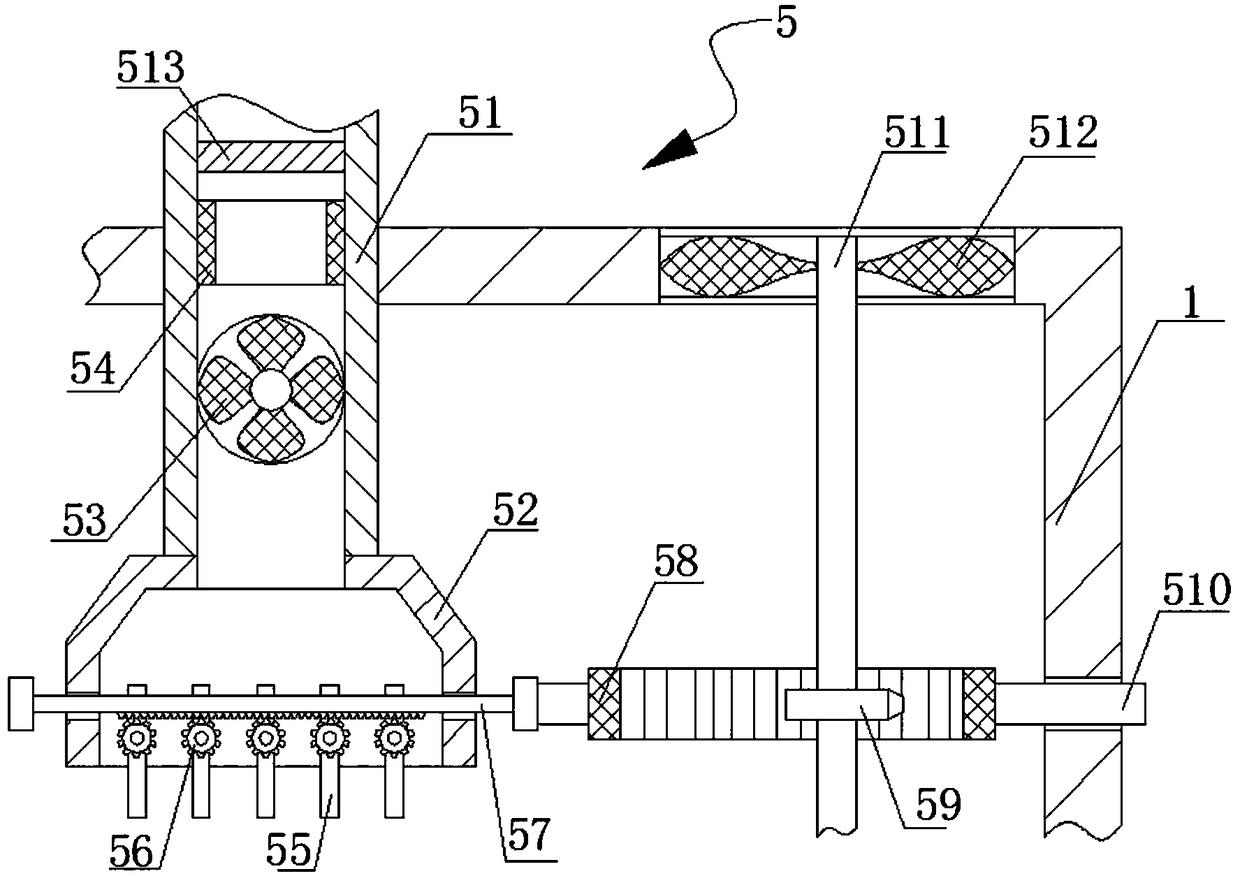

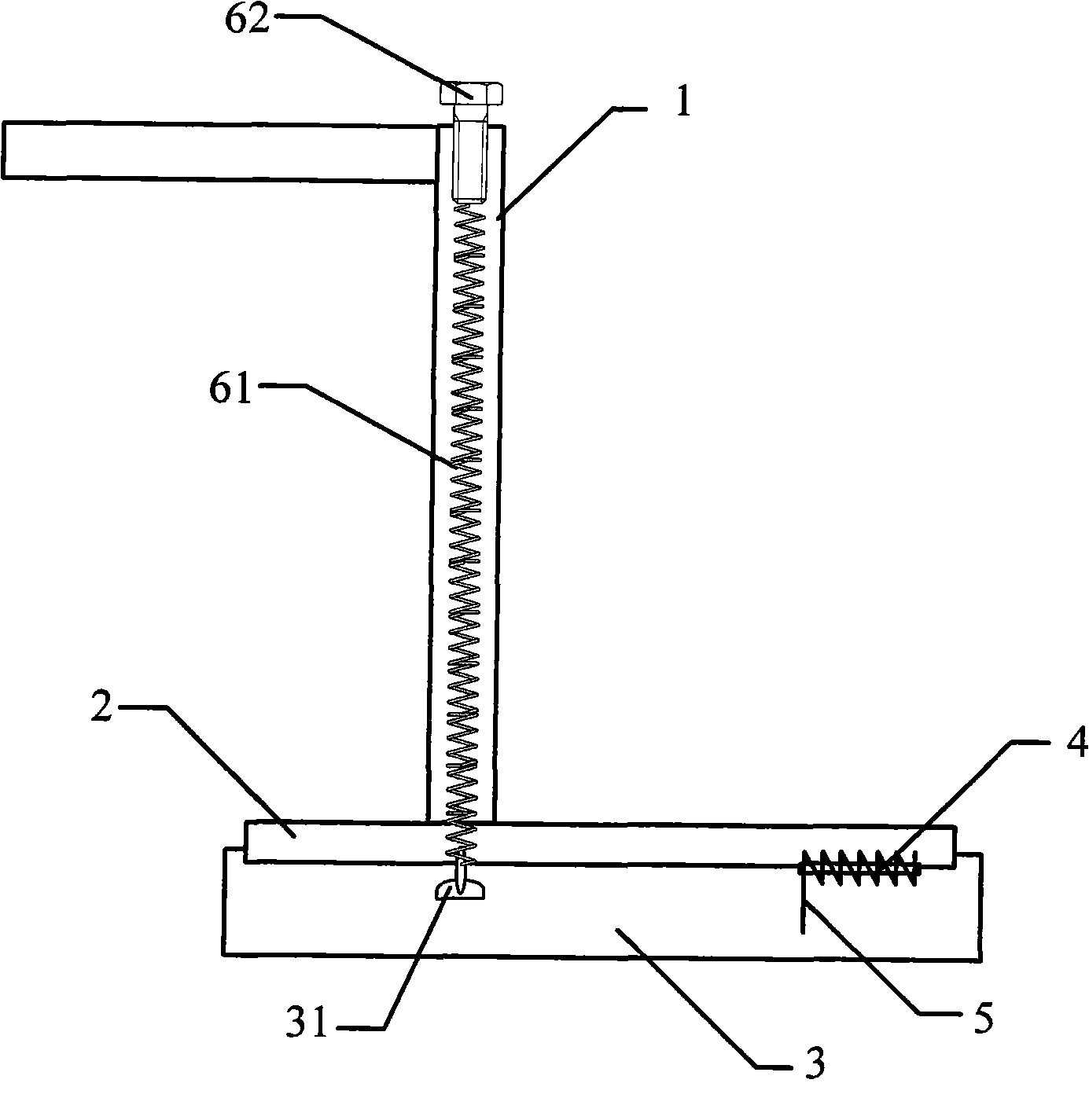

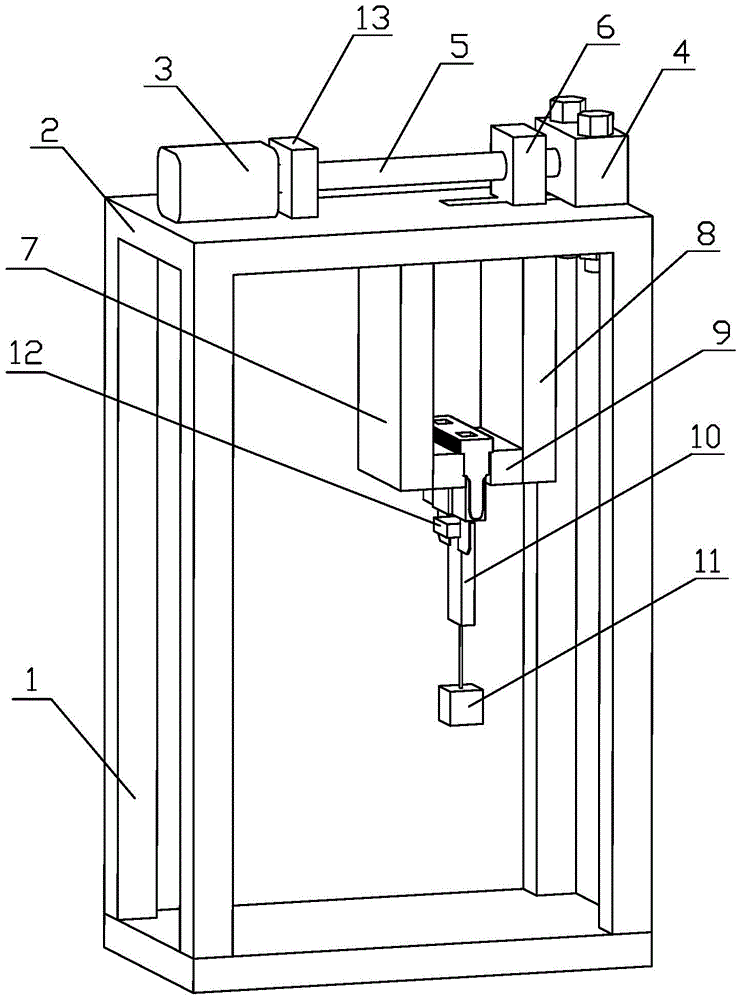

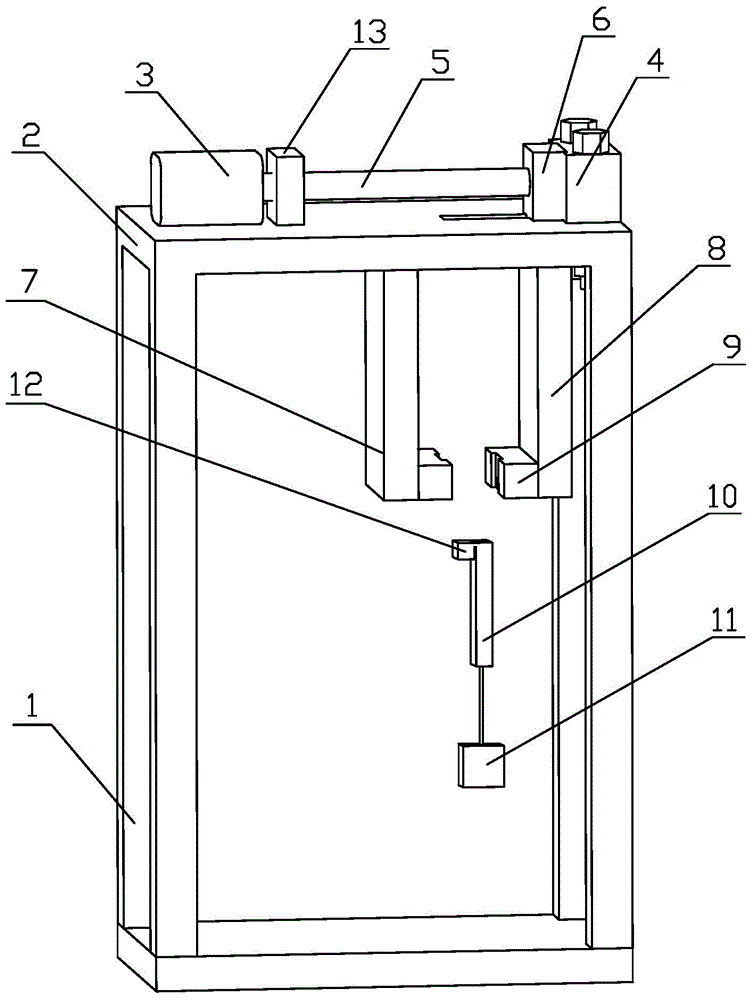

Pneumatic feeding mechanism

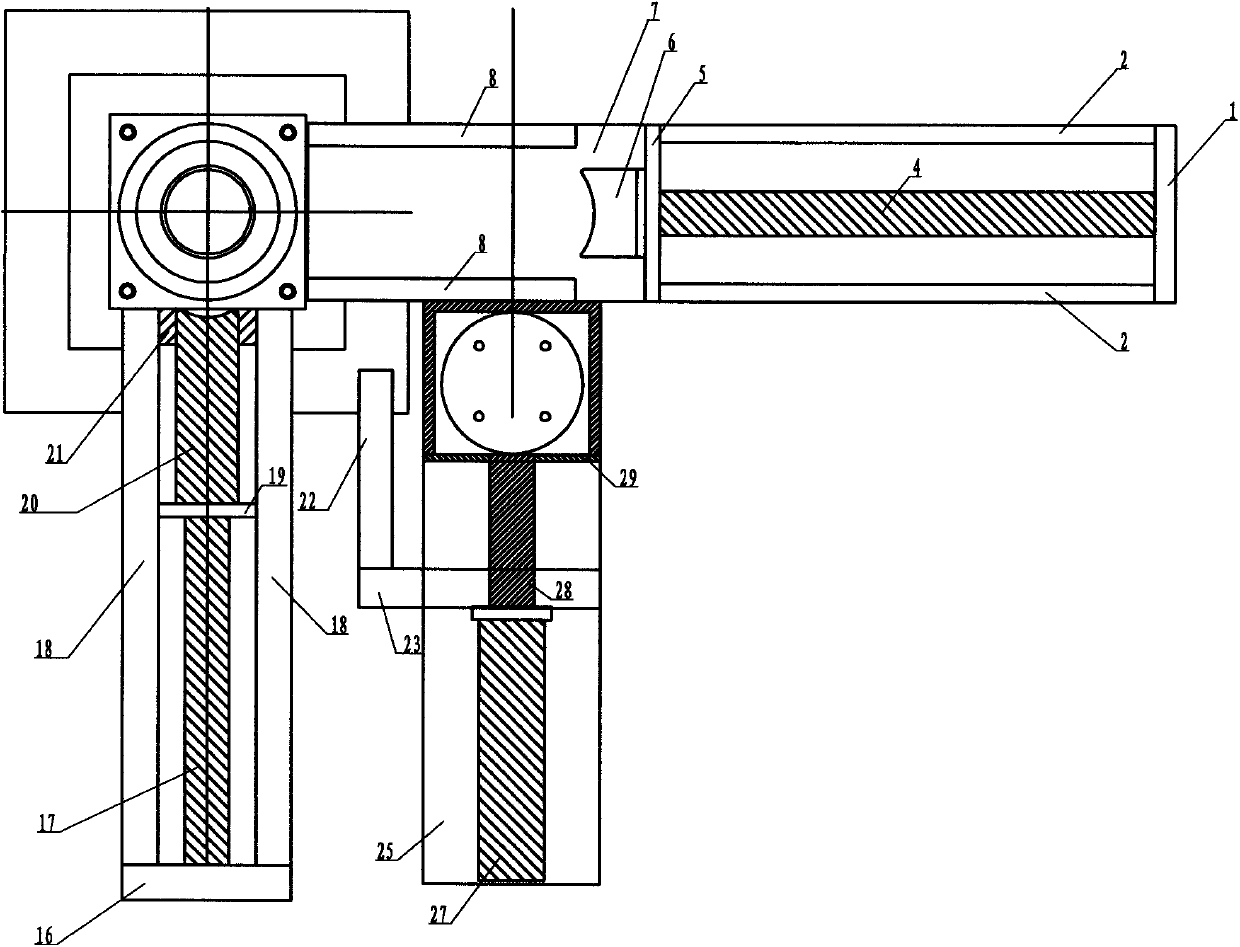

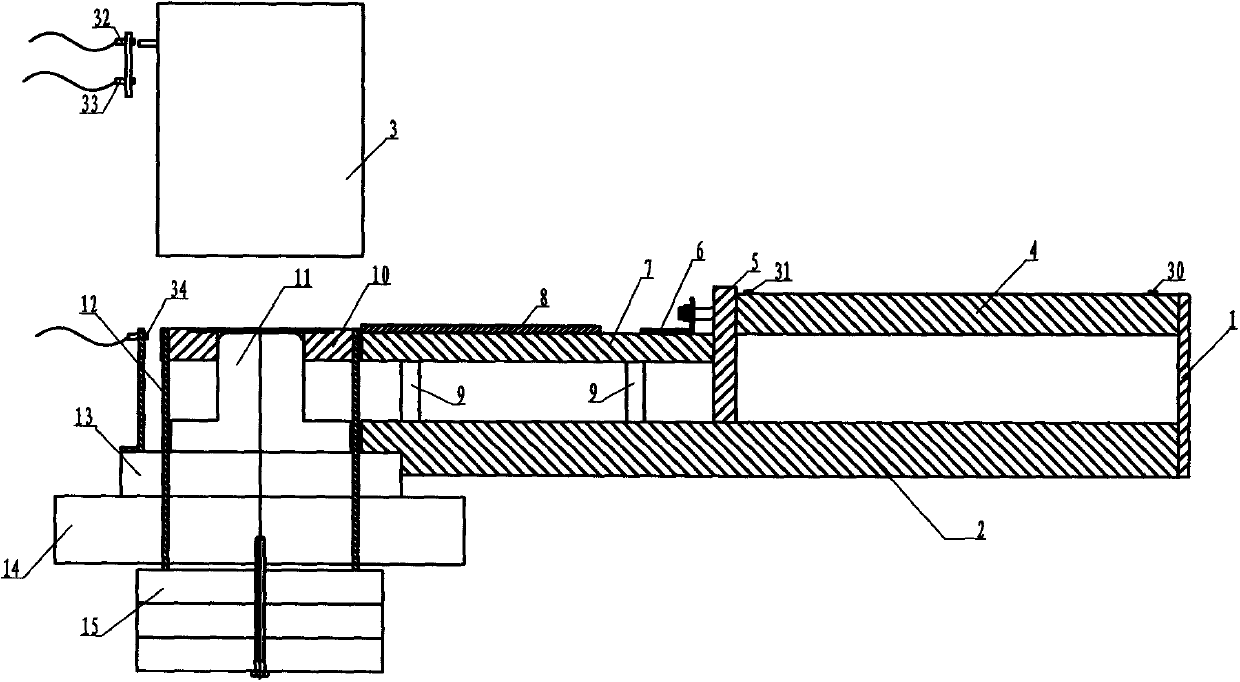

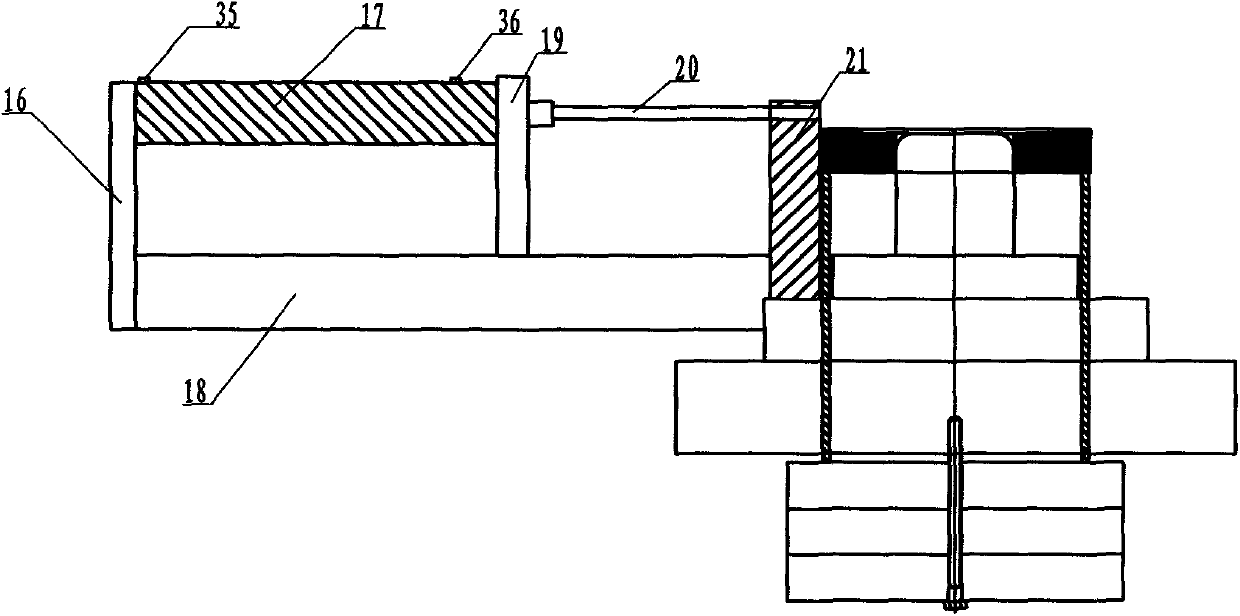

ActiveCN103464558ARealize semi-automatic operationReduce labor intensityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:QIJING MACHINERY

Seal head polishing machine

InactiveCN104690629AIncrease brightnessImprove smoothnessPolishing machinesGrinding machinesDrive shaftElectric machinery

The invention discloses a seal head polishing machine. The seal head polishing machine comprises a rack and a rotary center base which are arranged on the ground, wherein a reducing motor is arranged at one end of the rack; a driving chain wheel is arranged on a motor shaft of the reducing motor and is connected with a driven chain wheel through a transmission chain, and the driven chain wheel is arranged at one end of a transmission shaft; two ends of the transmission shaft are rotationally arranged on the rack through bearing blocks; a lead screw is arranged on the transmission shaft between the two bearing blocks and sleeved with a lead screw sleeve matched with the lead screw; the lead screw sleeve is fixedly arranged on a horizontal moving rack; the lower end of the horizontal moving rack is glidingly arranged in a horizontal track through horizontal rollers; the horizontal track is arranged on the rack; an L-shaped control rod is rotationally arranged at the upper end of the horizontal moving rack through a pin shaft.

Owner:JIANGSU YAFENG TECH GRP CO LTD

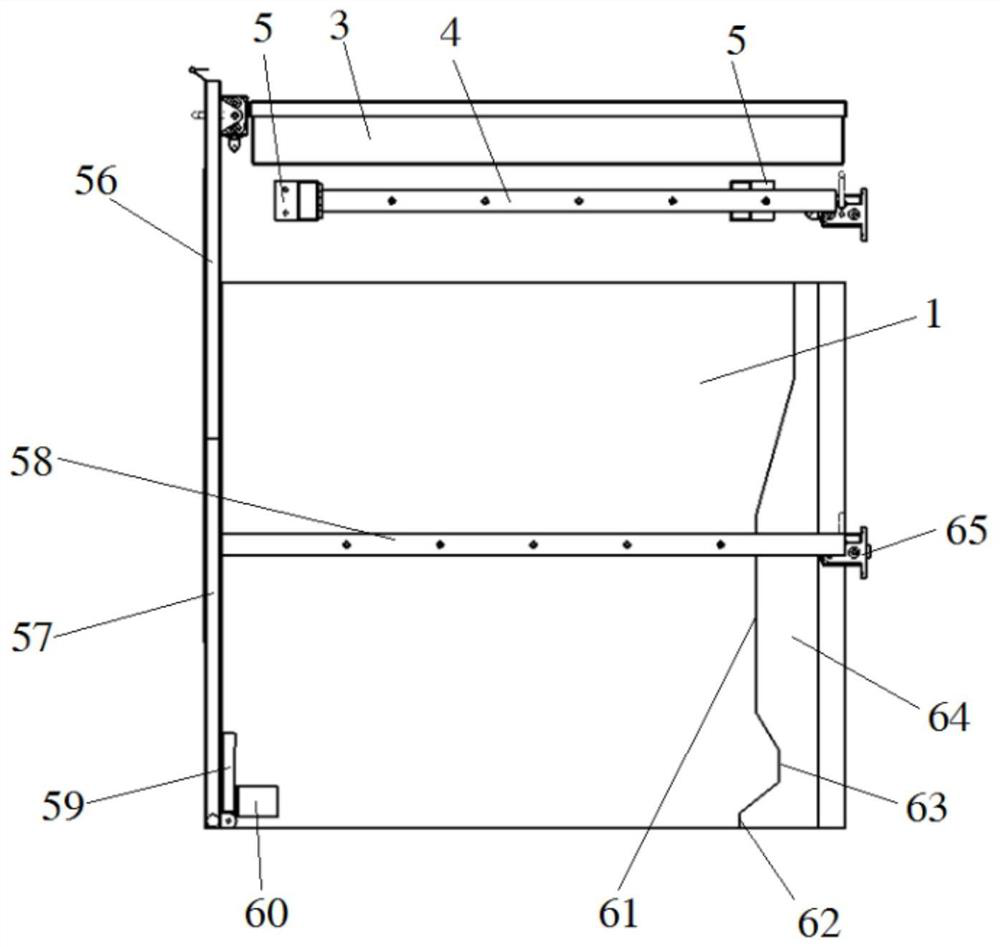

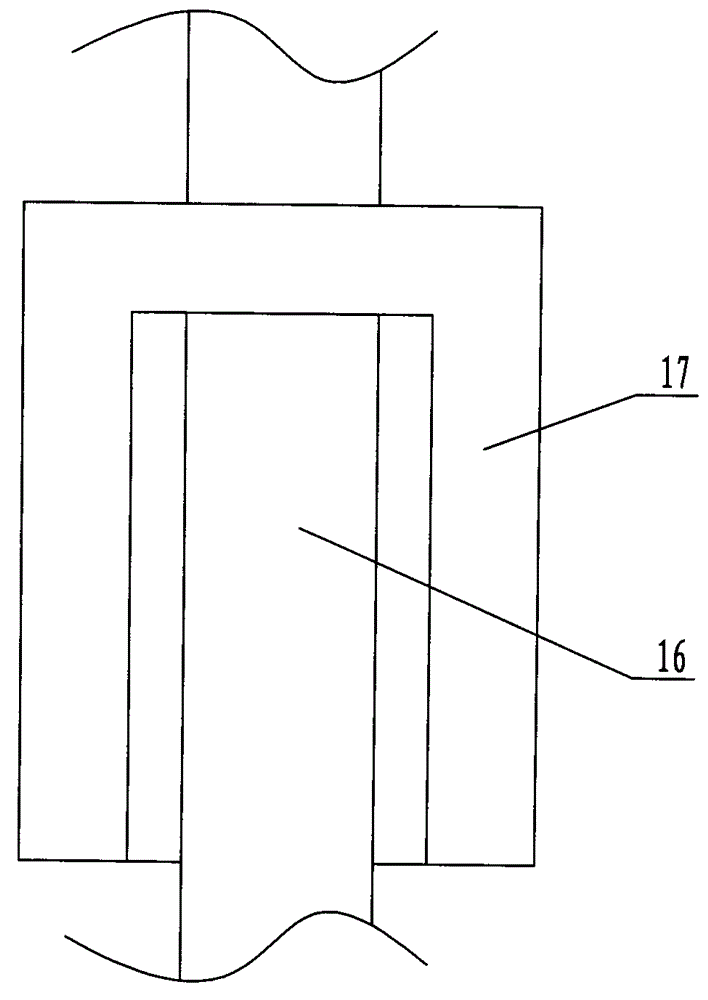

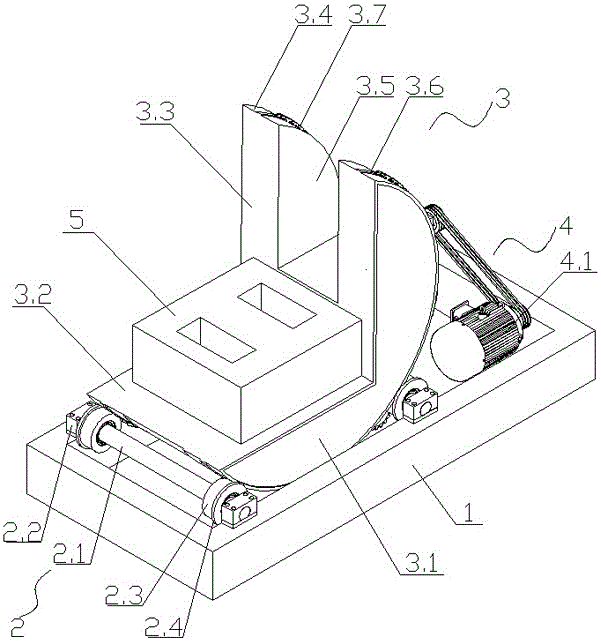

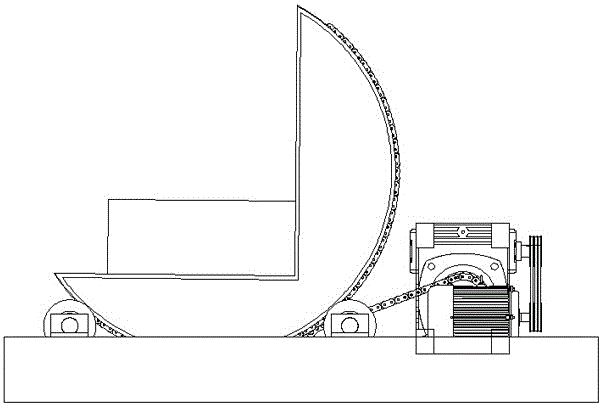

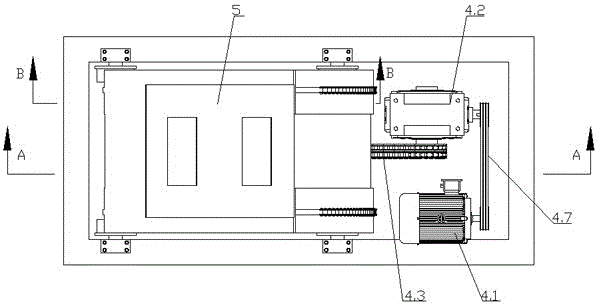

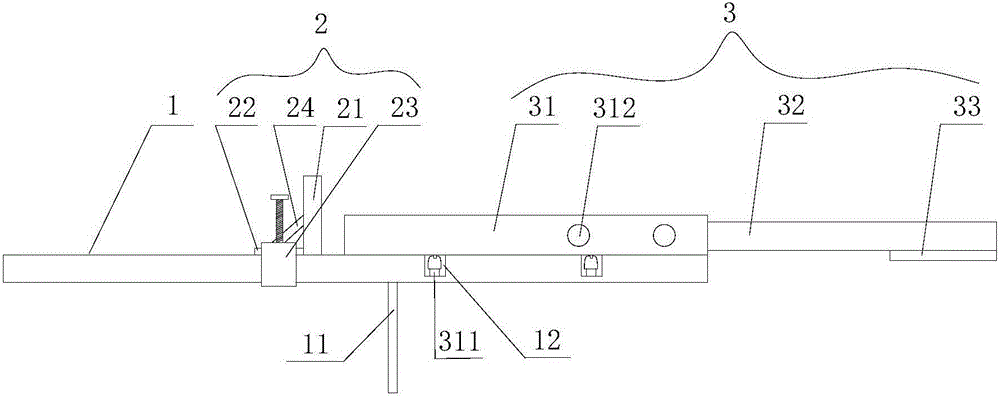

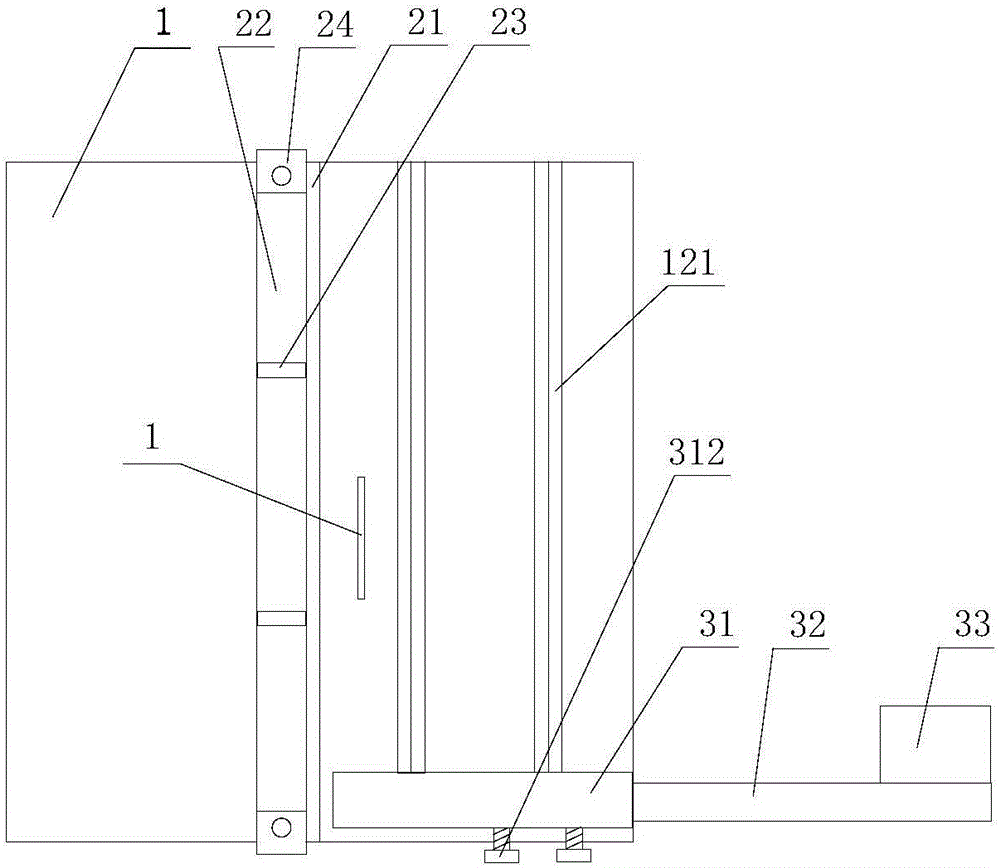

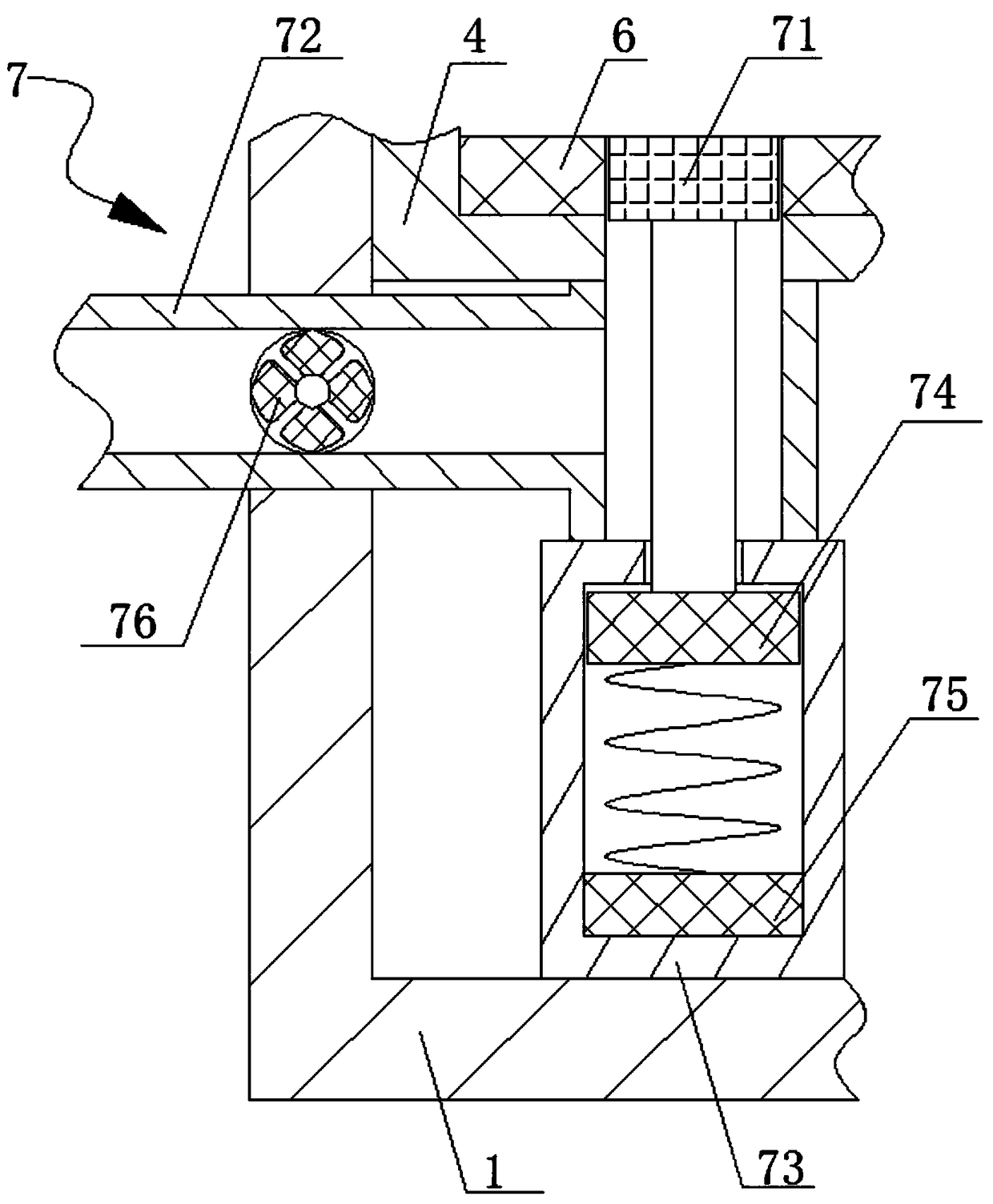

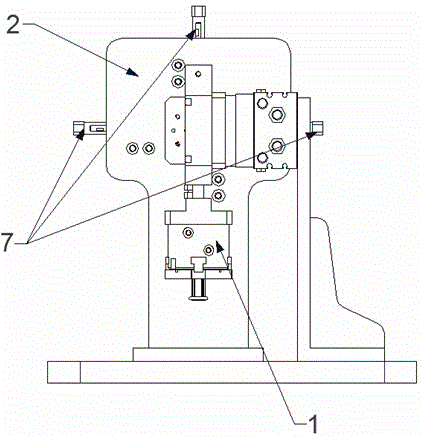

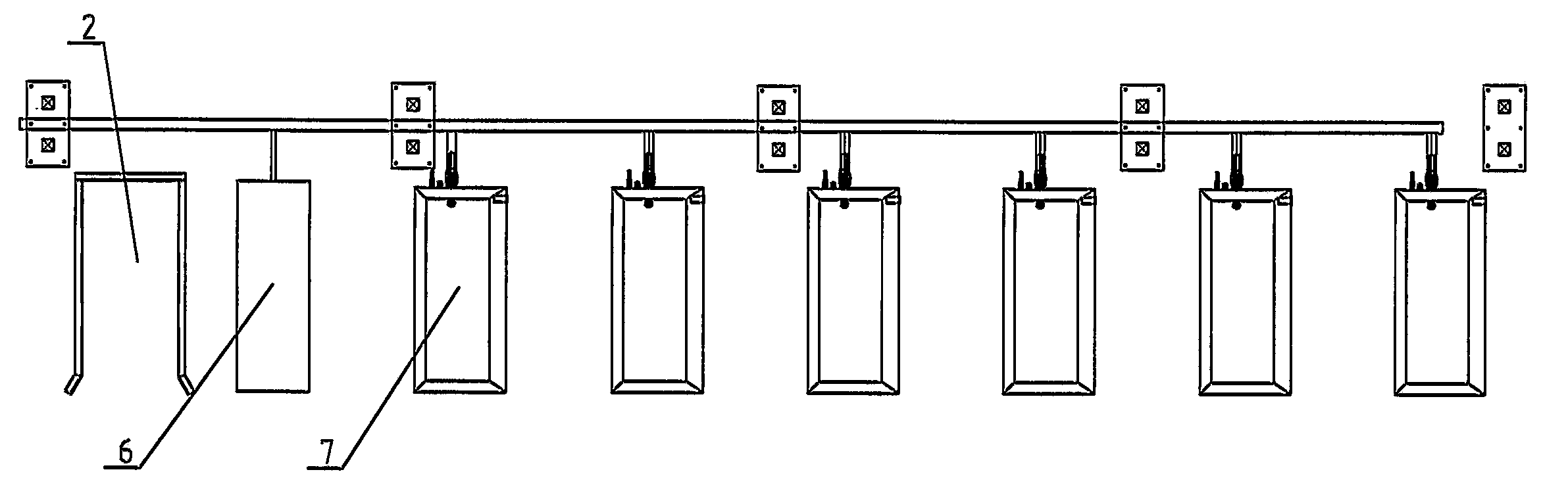

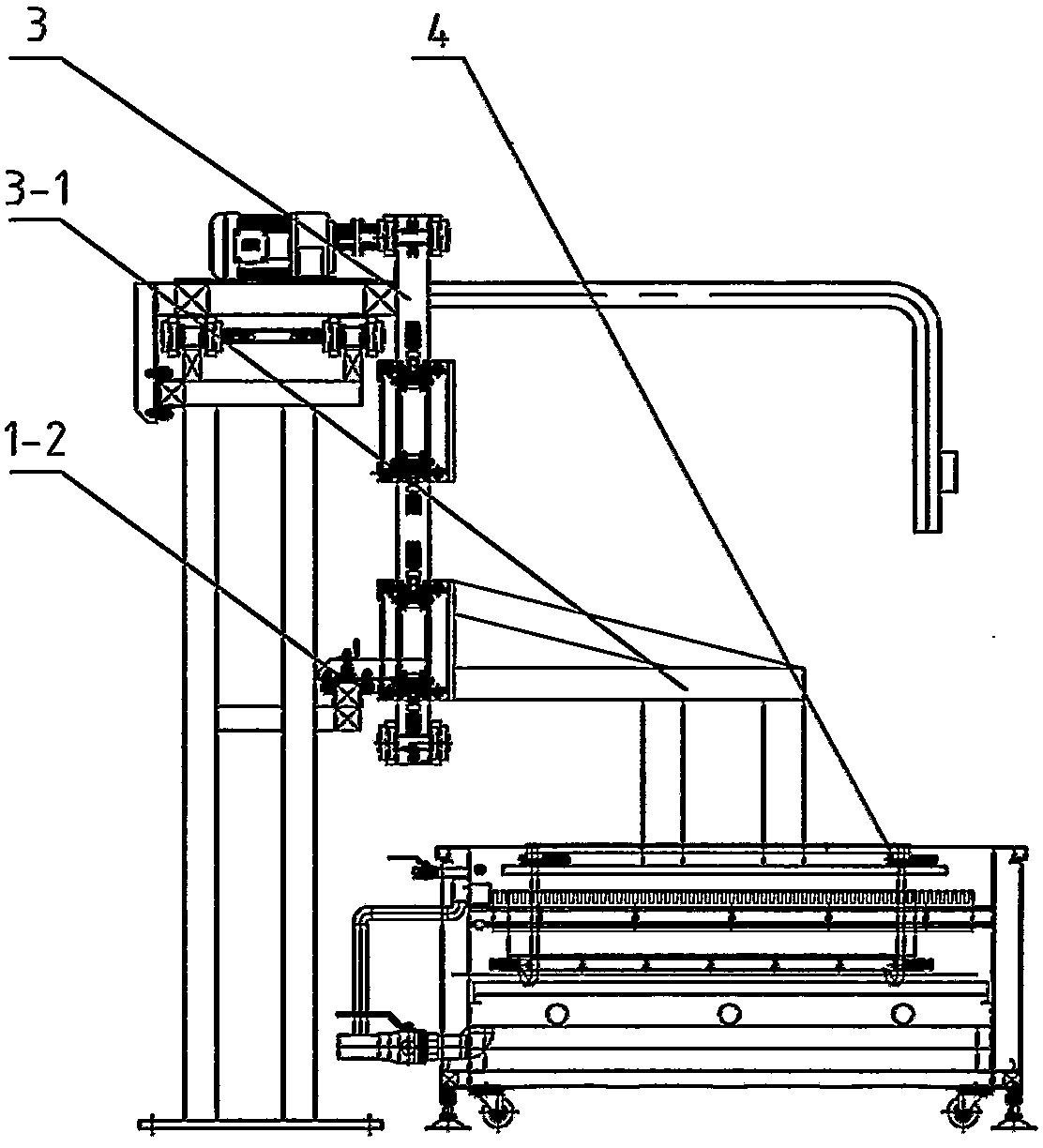

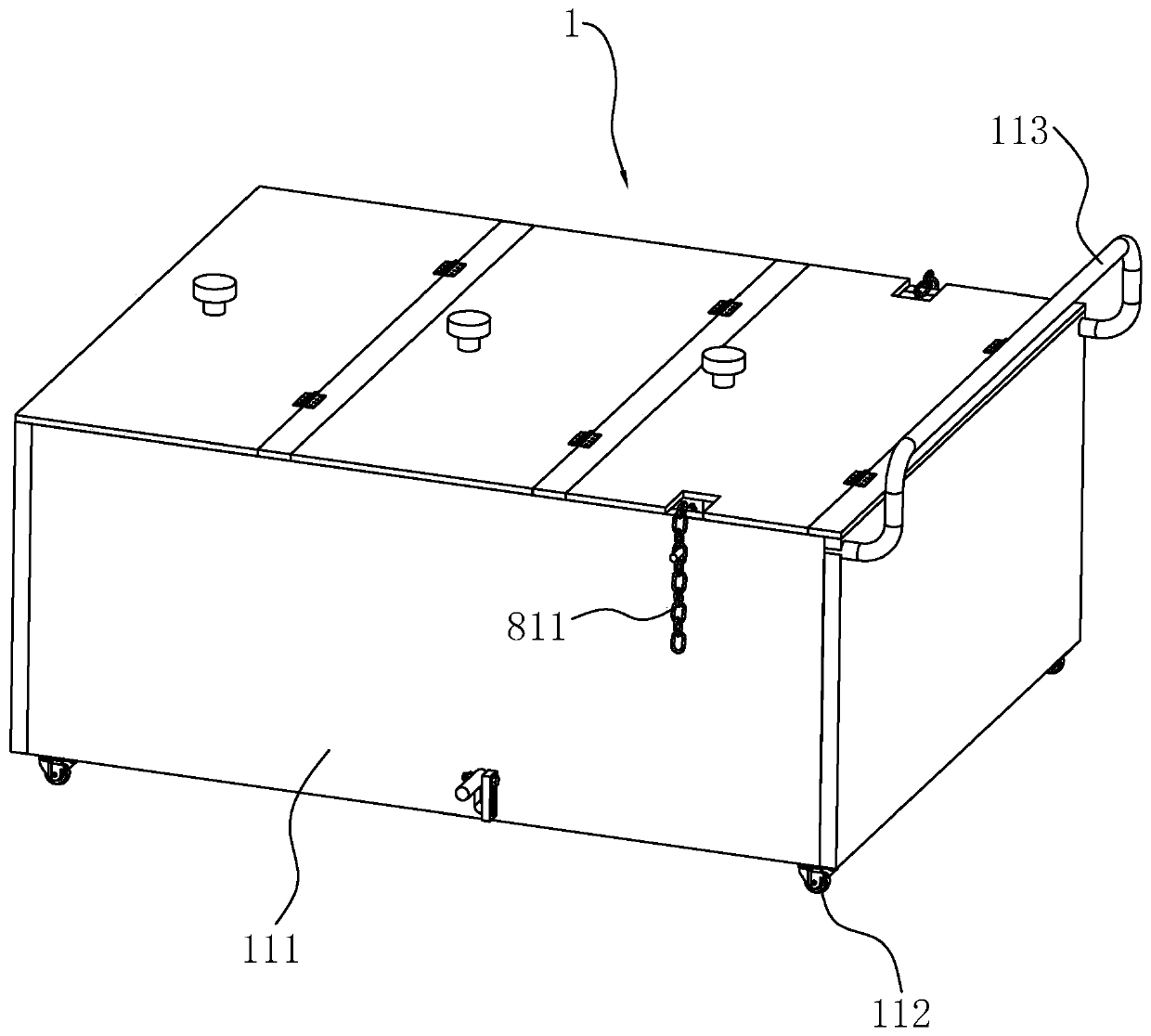

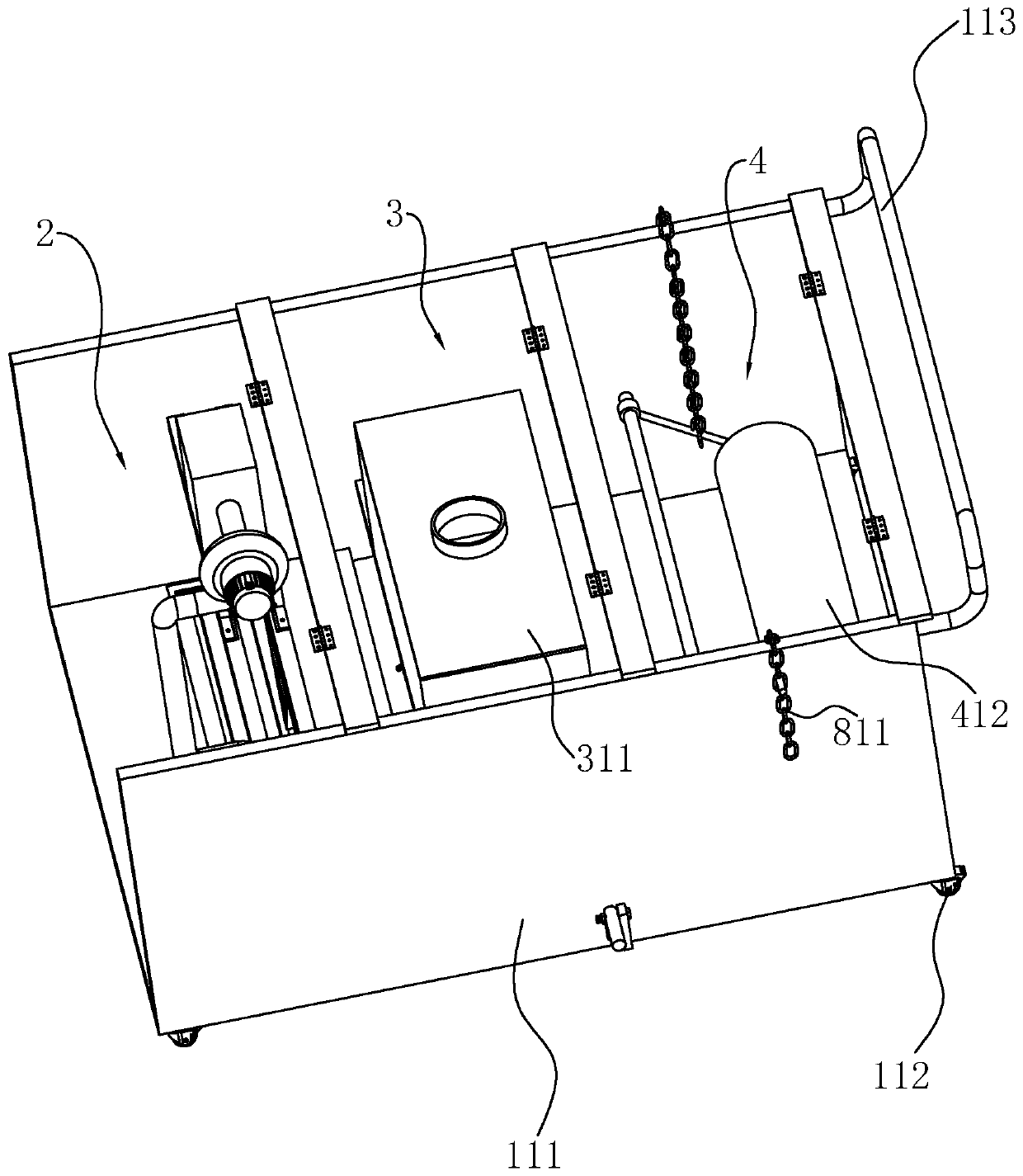

Transformer iron core overturning device and operating method thereof

ActiveCN106298222ARealize semi-automatic operationReduce labor intensityInductances/transformers/magnets manufactureTransformerSemi automatic

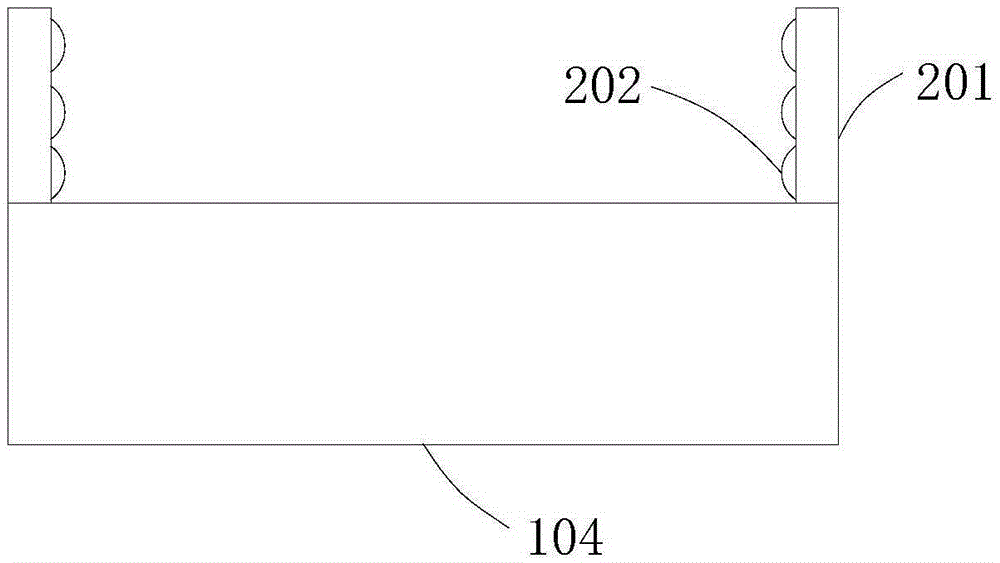

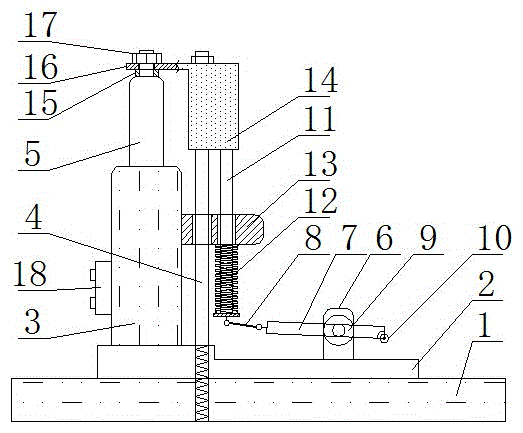

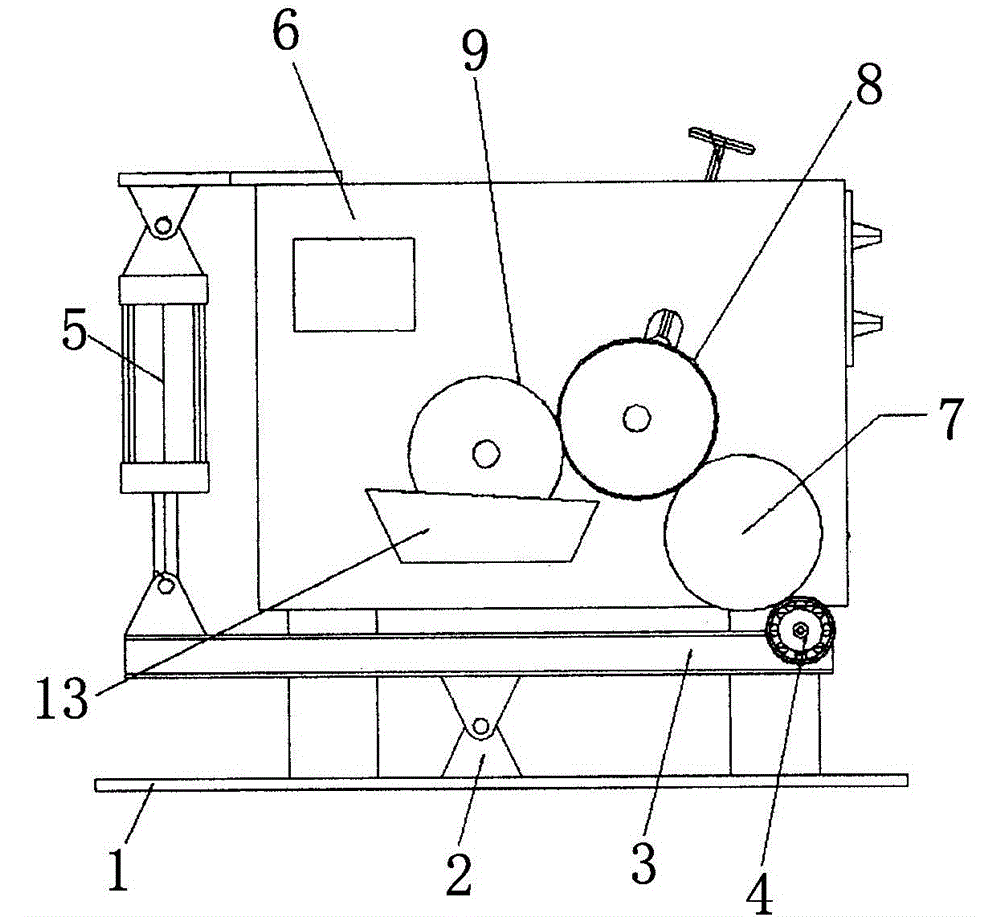

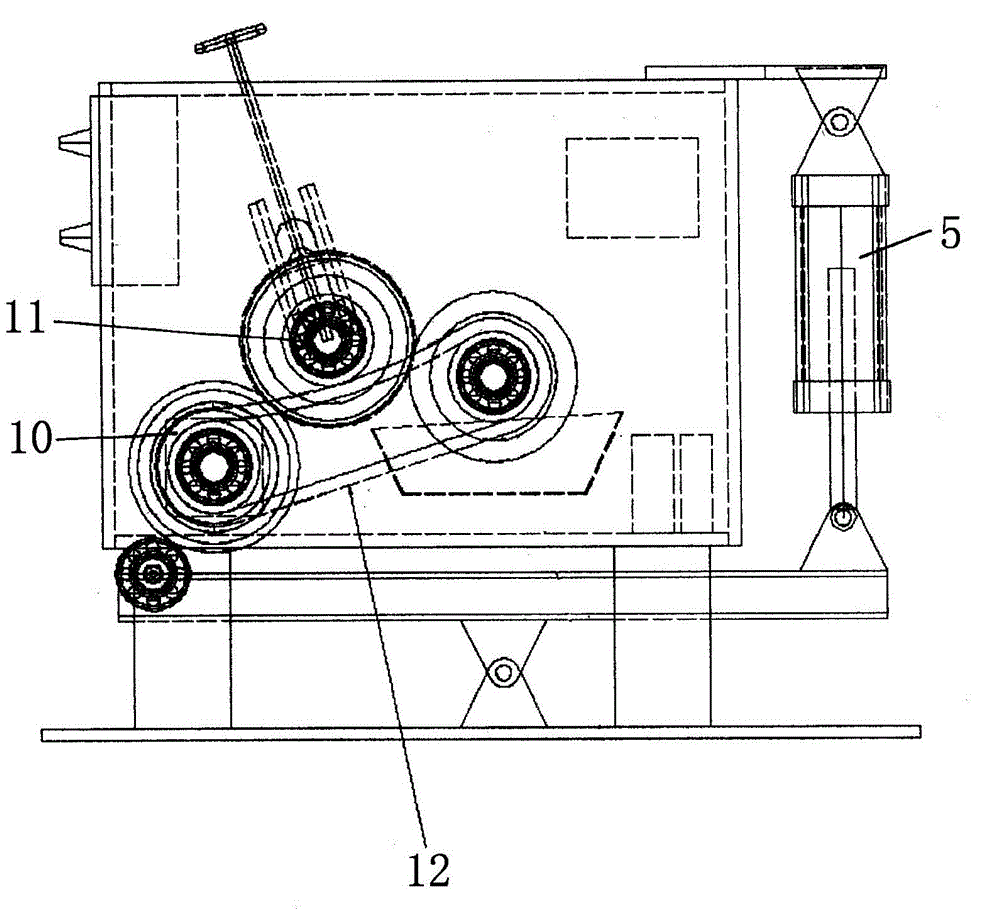

The invention relates to a transformer iron core overturning device which comprises a base (1), a bracket (2), an overturning frame (3) and a power mechanism (4), wherein the bracket (2) comprises a left supporting shaft (2.1) and a right rotary supporting shaft (2.1) which are arranged longitudinally; two supporting wheels (2.3) are mounted on the front segment and the back segment of each rotary supporting shaft (2.1) in a sleeving manner respectively; the overturning frame (3) comprises an overturning frame main body (3.1); the overturning frame main body (3.1) is provided with a first supporting plane (3.2) and a second supporting plane (3.3) which are perpendicular to each other; the overturning frame main body (3.1) is also provided with an arc segment driving plane (3.4); a driving chain (3.7) on the driving plane (3.4) is driven by the power mechanism (4). The transformer iron core overturning device provided by the invention has the advantages of realizing semi-automatic operation, reducing labor intensity and realizing stable overturning.

Owner:JIANGYIN HONGHENG ELECTROMECHANICAL TECH CO LTD

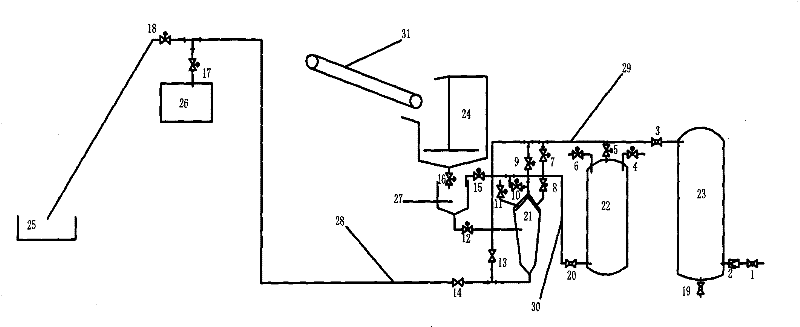

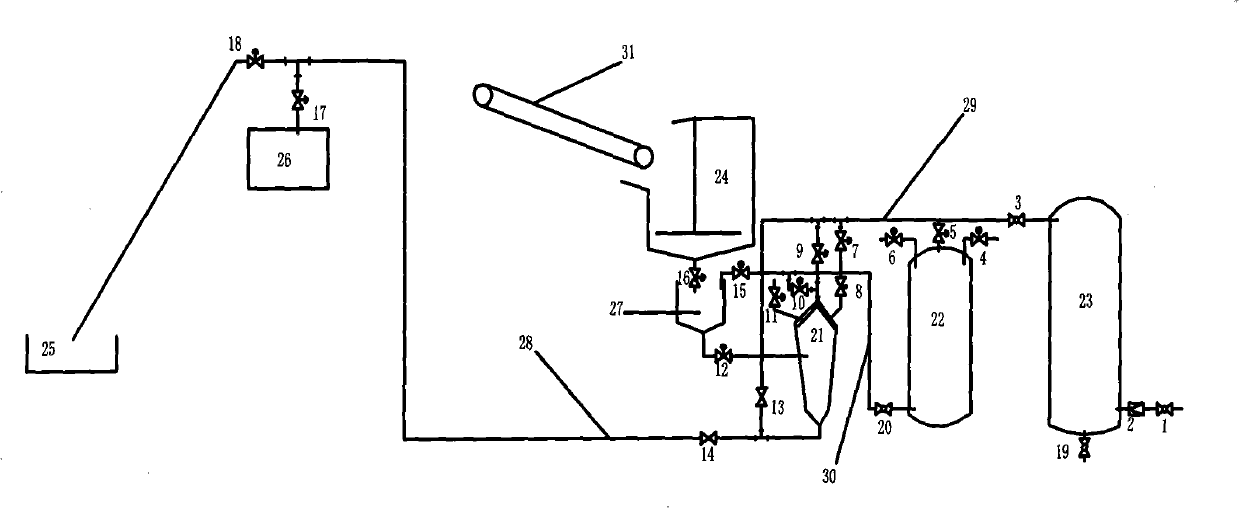

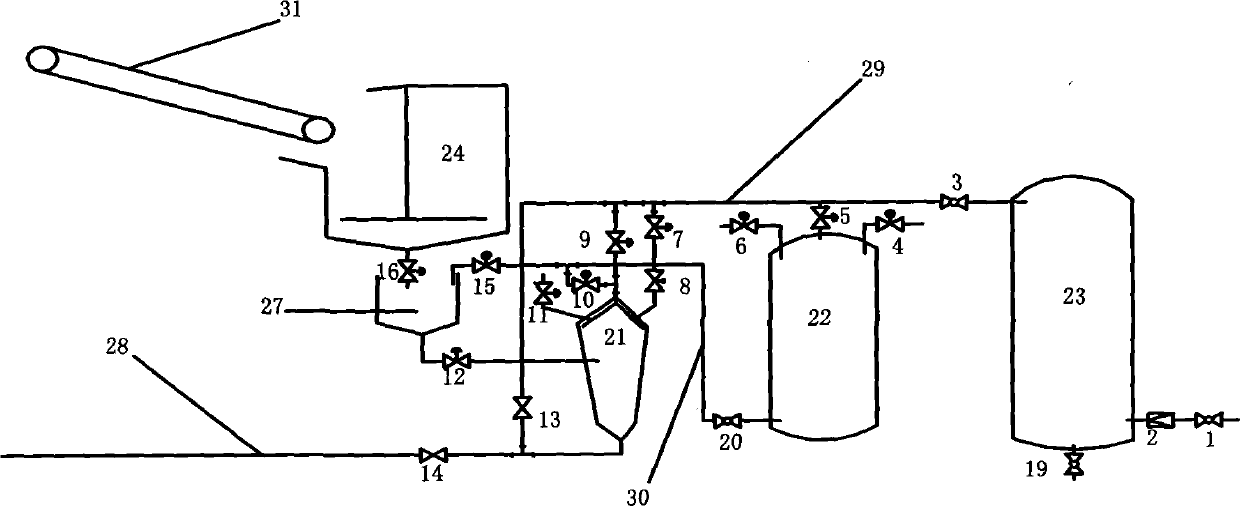

Recycling device for remained slurry of tubular pile

The invention discloses a recycling device for remained slurry of a tubular pile, in order to overcome the defect that the traditional remained slurry recycling device is not convenient to use. A material-receiving stirring tank of the recycling device is used for receiving and stirring the remained slurry of the tubular pile; the material-receiving stirring tank and a measuring tank are respectively used for putting the received remained slurry of the tubular pile into the measuring tank and a feeding tank according to design weight by a measuring valve and a discharging valve; an air storage tank is provided with an air outlet valve; a feeding valve is arranged at one end of the feeding tank; the feeding valve is connected to the air outlet valve of the air storage tank; the air pressure in the air storage tank is higher than the air pressure in the feeding tank; air in the air storage tank enters into the feeding tank through the feeding valve after flowing by the air outlet valve;the other end of the feeding tank is connected to a stirrer and a waste pool through a conveying pipe, a first discharging valve and a second discharging valve; and the remained slurry of the tubularpile in the feeding tank enters into the stirrer or the waste pool and is stored in the stirrer or the waste pool under the driving of the air in the air storage tank. The recycling device is characterized in that the measuring tank, the feeding tank and the conveying pipe are cleaned through the mixing of air and water, pipelines are efficiently prevented from being blocked, and automatic operation can be realized.

Owner:陈建文

Precise punching mechanism of building board

InactiveCN109648110AReasonable structural designSave labor and laborMachine tool componentsWork clamping meansEngineeringScale error

The invention discloses a precise punching mechanism of a building board. The precise punching mechanism comprises a bottom board, a rectangular opening is arranged in the middle of the bottom board,and an U-shaped mounting board is arranged between two sliding bases, two pressing air cylinders are arranged at the upper end of a cross board of the U-shaped mounting board, pressure heads are welded and fixed at the lower ends of pressing shafts, positioning air cylinders are fixedly arranged in a rectangular notch, and the lower ends of the output ends of the positioning air cylinders are fixedly connected with metal pressing pieces, a pushing air cylinder is fixedly arranged on one side of the upper end of a guide board, and a measuring board is fixed on the side, facing a side baffle, ofa rectangular frame board. According to the precise punching mechanism of the building board, pushing, positioning and pressing are achieved through the air cylinder, and semi-automatic operation isachieved, a lot of labor and manpower are saved in the construction site, punching and positioning are achieved through displacement of the mechanism and observation of the scale error, the error canbe reduced, the hole opening is more accurate, the hole opening speed can be increased, and the working efficiency can be improved.

Owner:盐城格圣机械有限公司

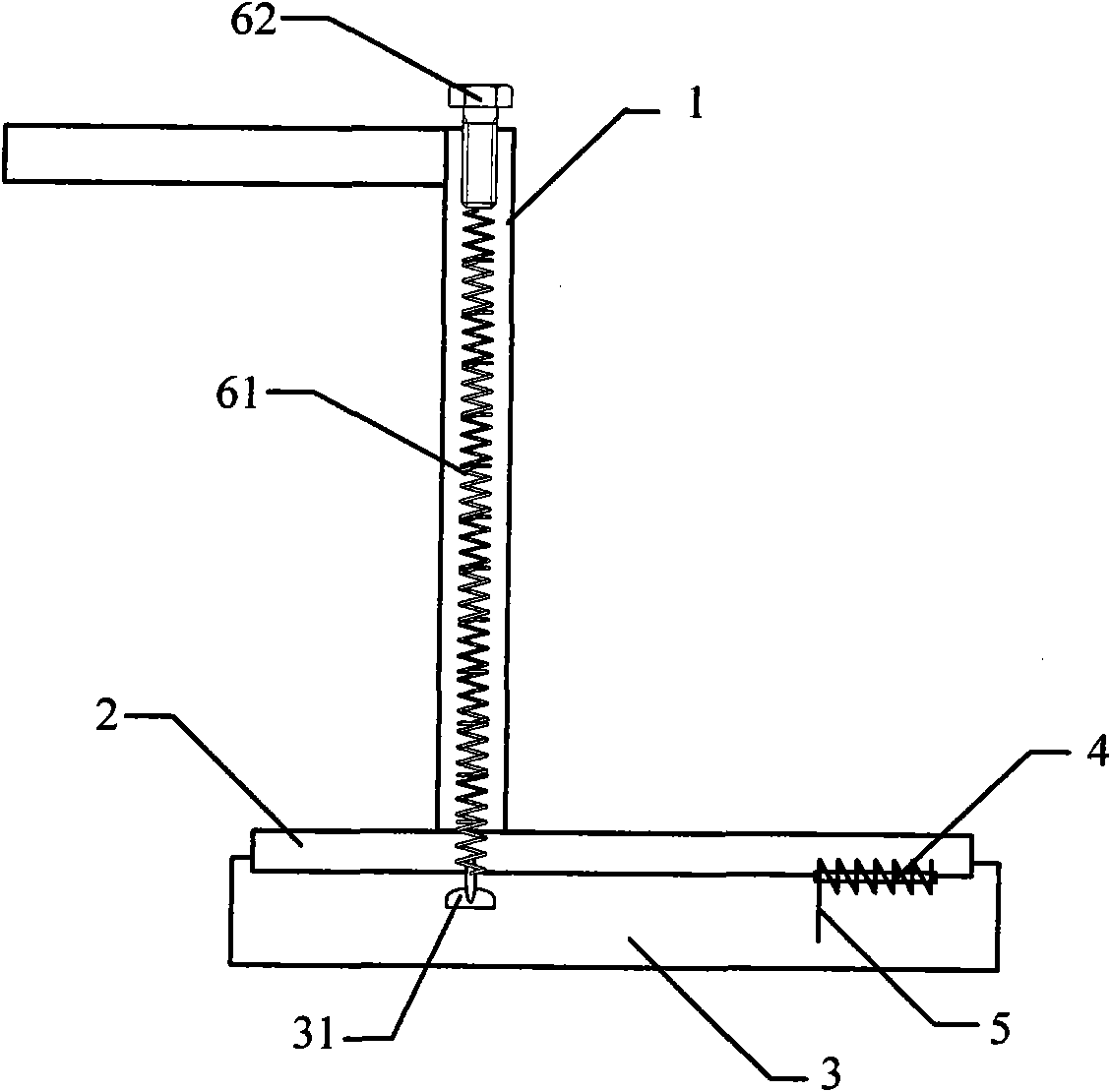

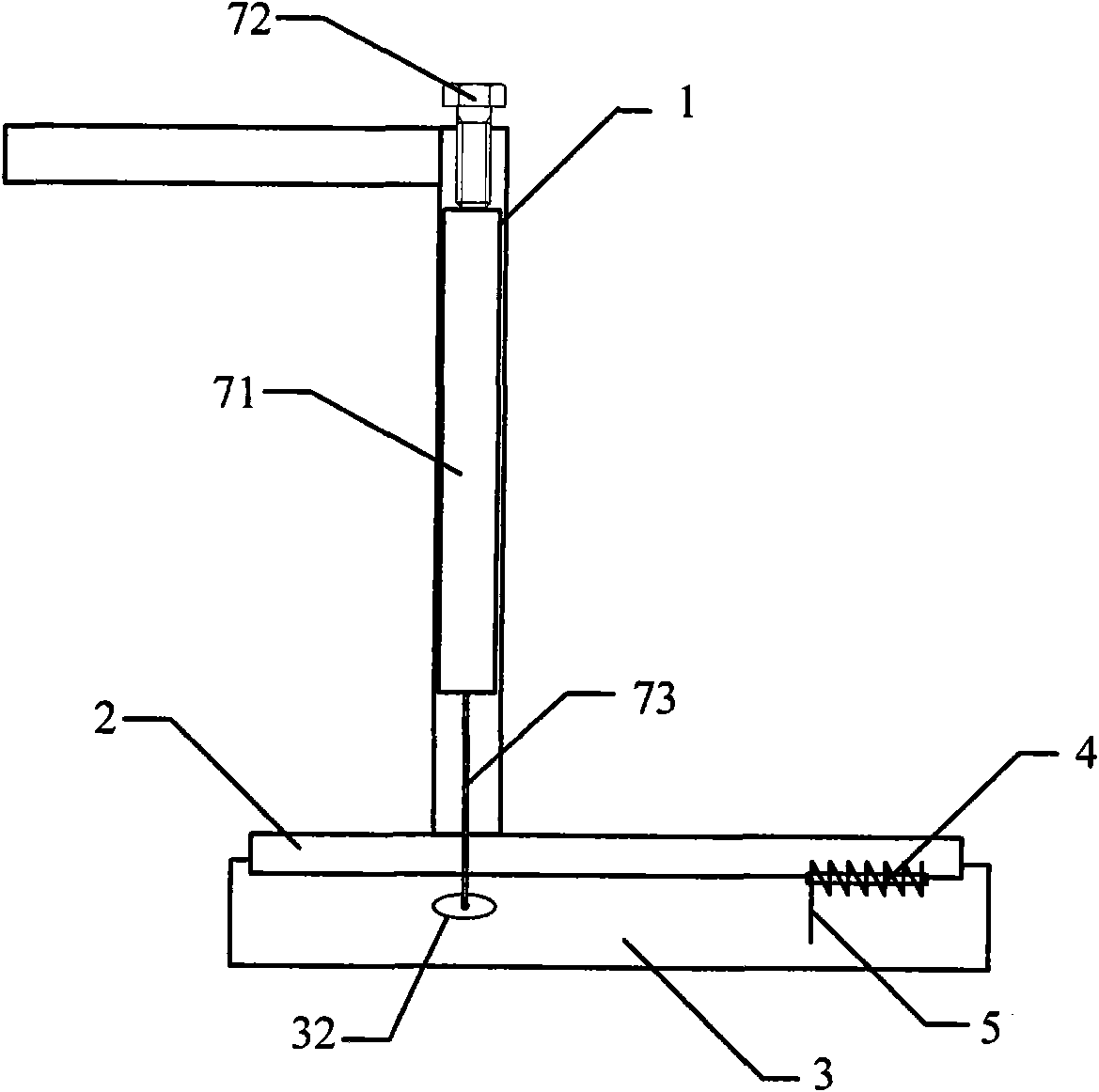

Clamping grinding device for steel sample and method

ActiveCN102401757ASimple structureReduce consumptionPreparing sample for investigationGrinding machinesEngineeringUltimate tensile strength

The invention provides a clamping grinding device for a steel sample and a method. According to the invention, a support plate is movably connected with a platform of a grinding machine through a rotating shaft, the upper end of the rotating shaft is provided with a stop with an inclined plane, and the lower end of an overturning rod equipped with a clamp is hinged onto the support plate; when the overturning rod upturns, the clamp on the overturning rod crashes with the stop, and a slide bar extends out and puts a steel sample to be ground into a groove of a chuck; when the overturning rod is loosened, under the action of a pressure spring, the slide bar allows the chuck to clamp the steel sample; when the overturning rod is turned down, a grinding surface of the steel sample abuts onto a sand paper, which enables the steel sample to be further locked; the steel sample is ground until the steel sample accords with the standard, the overturning rod is turned up, the chuck is loosened,and the steel sample is taken down and sent for inspection. The device provided in the invention has the advantages of a little investment, fast action and a simple structure, can be made by oneself and firmly clamp steel samples, and enables the clamping grinding speed of steel samples to be substantially accelerated, labor intensity of workers to be alleviated, operability to be improved, consumption of sand paper to be reduced, the problem of injury of people caused by falling off of steel samples to be eliminated and accuracy of component analysis of steel samples to be enhanced.

Owner:ANGANG STEEL CO LTD

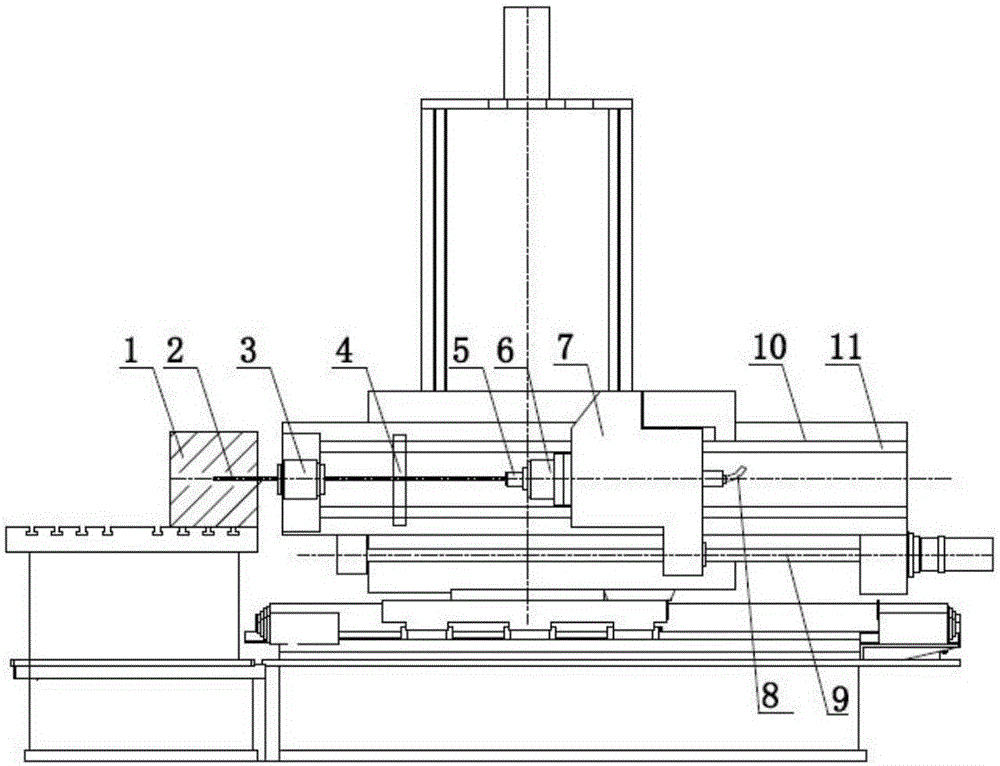

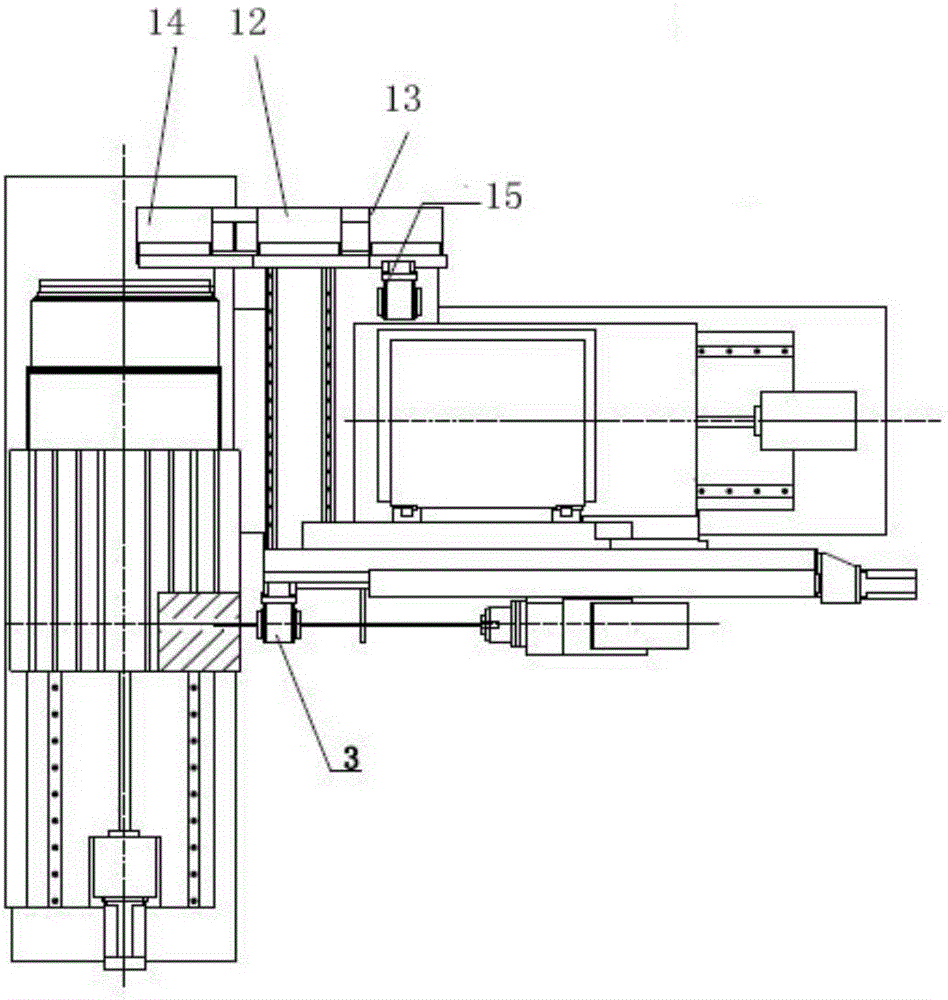

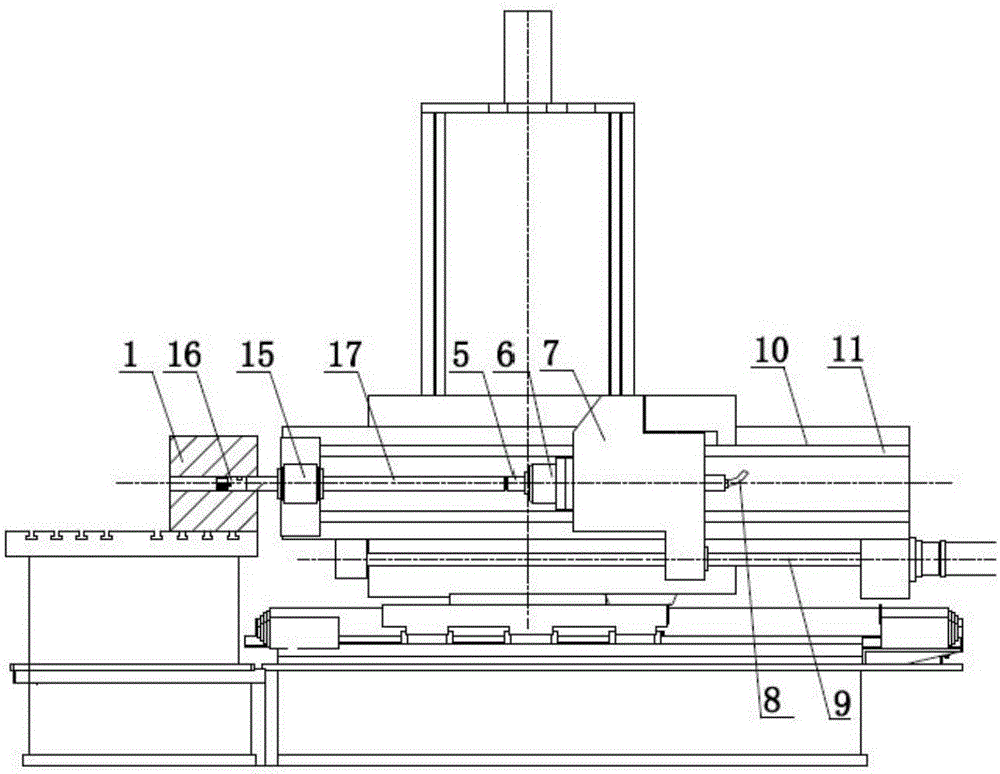

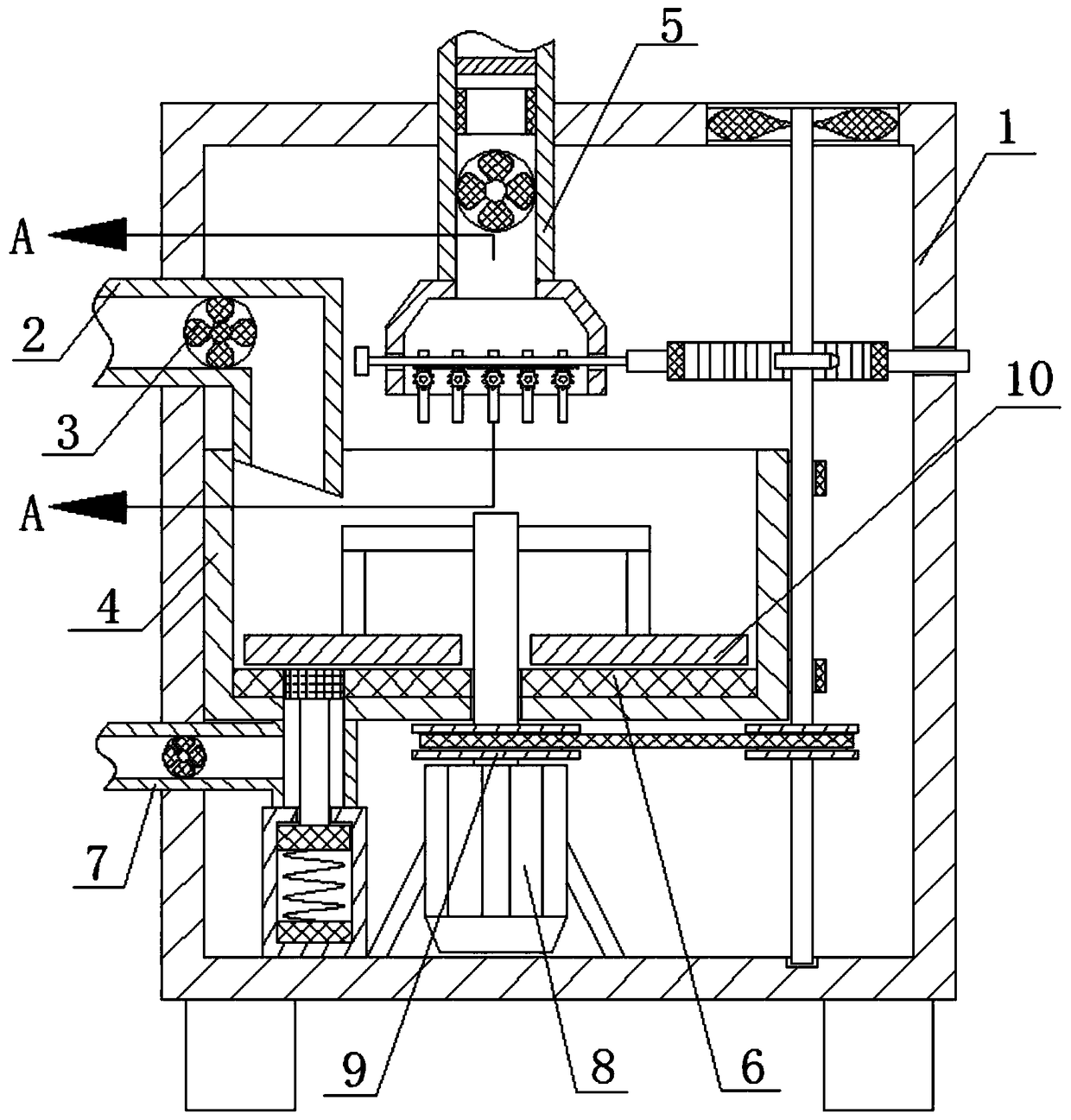

Mechanism for conveniently switching drilling, expanding, boring and milling functions on deep hole machine tool

ActiveCN106002314ARealize one machine with multiple functionsReduce processing costsLarge fixed membersBoring/drilling machinesEngineeringMachine tool

The invention discloses a mechanism for conveniently switching drilling, expanding, boring and milling functions on a deep hole machine tool. The mechanism comprises a drilling, expanding, boring and milling switching mechanism, tools (including a hole drilling tool, a hole expanding tool, a hole boring tool, a milling tool and a screw tap), special tool rods (including a hole drilling tool rod, a hole expanding tool rod, a hole boring tool rod and a screw tap rod), a front guide box, supporting frames (including a drill stem supporting frame, a hole expanding supporting frame and a hole boring supporting frame), a main shaft box, a main shaft, a main shaft chuck, a movable slide table capable of being precisely positioned, a slide table guide rail, a movable working table capable of being precisely positioned, and a machining cooling system. By means of the mechanism, the use range of the machine tool can be widened, the machining precision of the machine tool can be improved, the deep hole fine machining problem of a deep hole drilling machine can be thoroughly changed, and the deep hole machine tool can have the high-precision hole expanding and hole boring functions, and can truly become a deep hole machine tool with comprehensive machining functions.

Owner:太仓吉井机械有限公司

Carriage control device of instrument lathe

InactiveCN1651189AImprove machining accuracySlow and steady flowFluid-pressure actuatorsFeeding apparatusAir pumpEngineering

A control mechanism for the tool carriage of instrument lathe is composed of the first cylinder with piston and piston rod fixed to said tool carriage, the second cylinder, a speed regulating valve with an air inlet connected to air pump and two air outlets connected respectively to the upper connection tubes of both cylinders, and an oil tube connected between two lower connection tubes of both cylinders. Its advantages aresmooth advancing and high withdrawing speed.

Owner:王永德

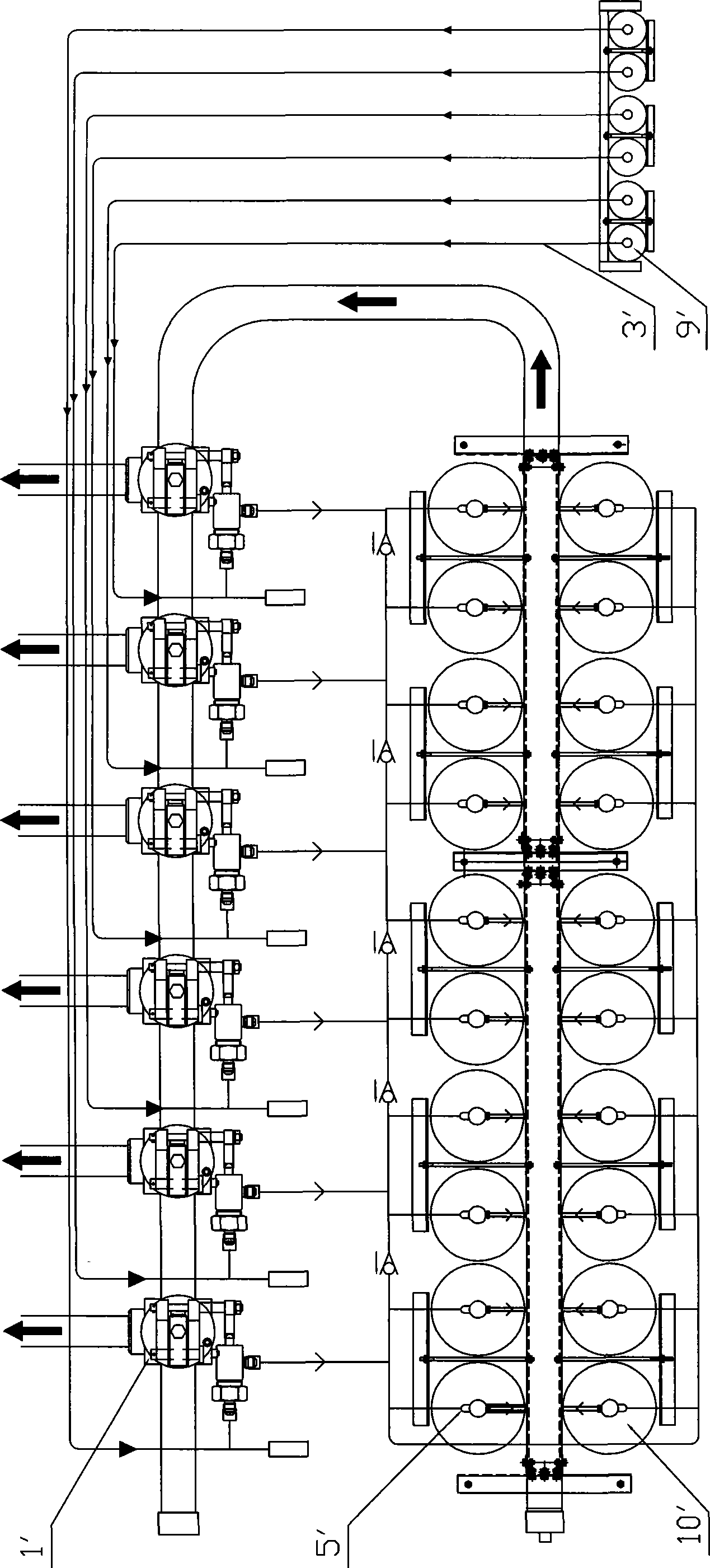

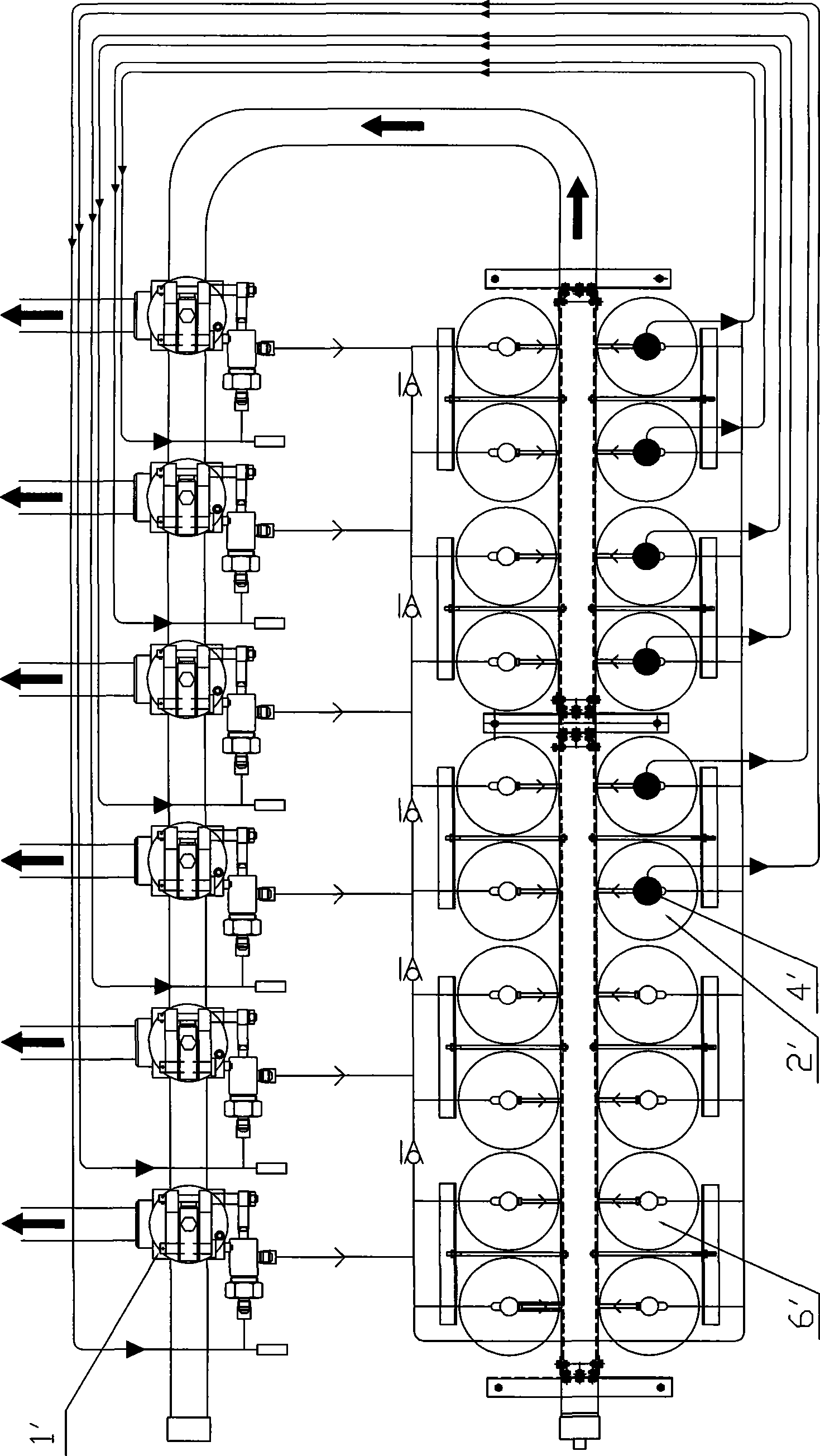

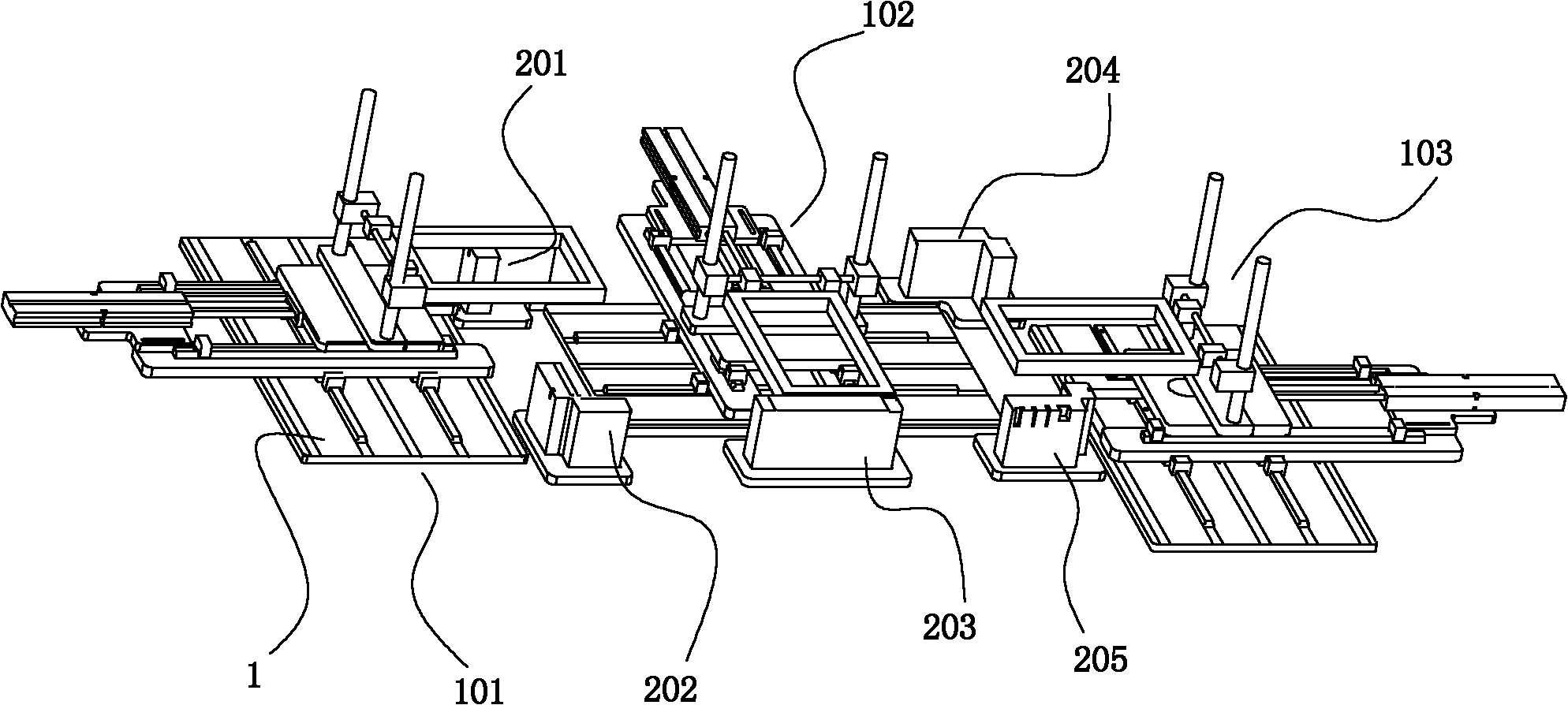

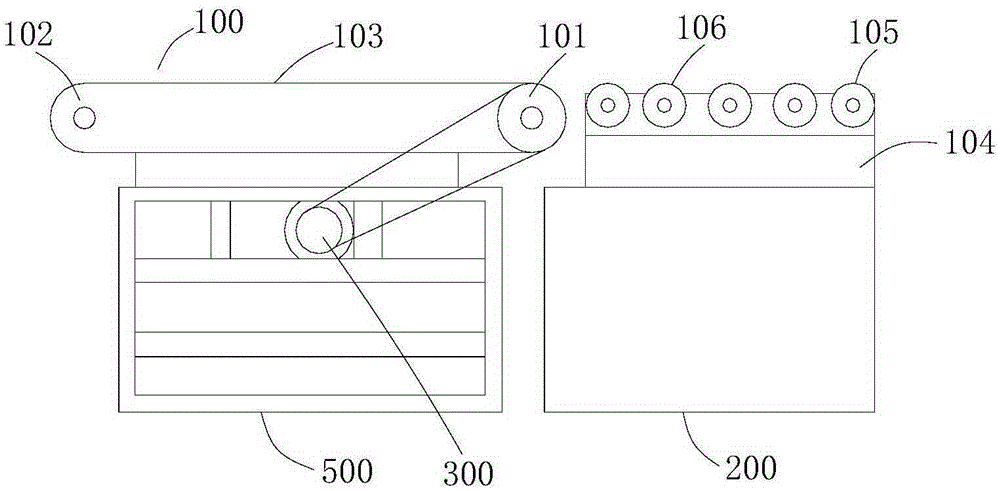

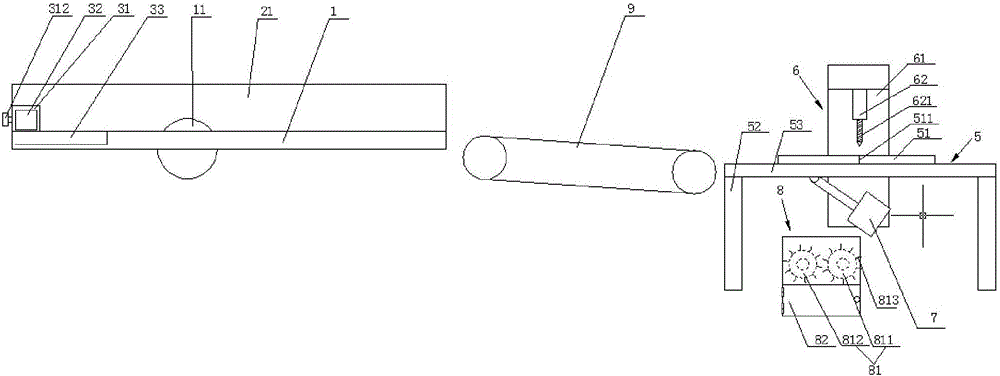

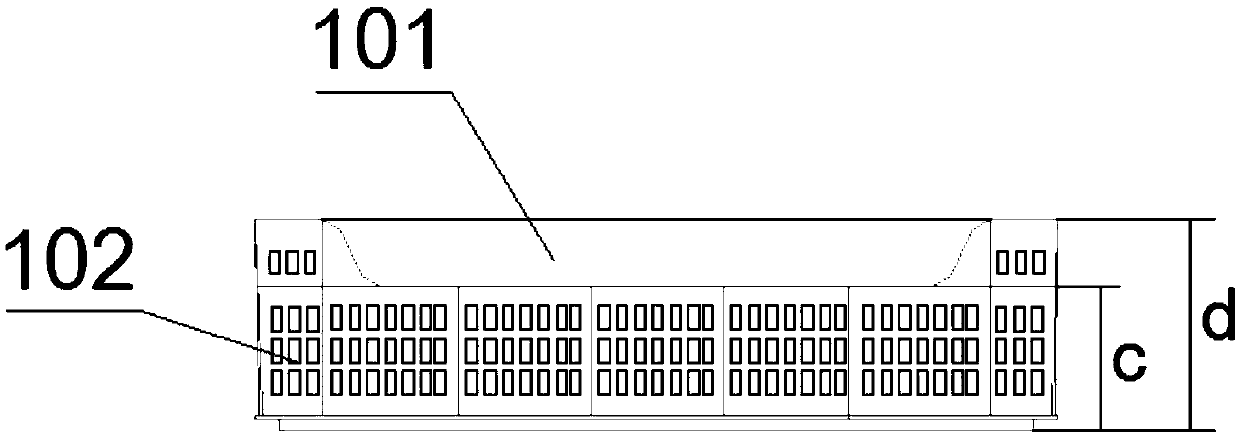

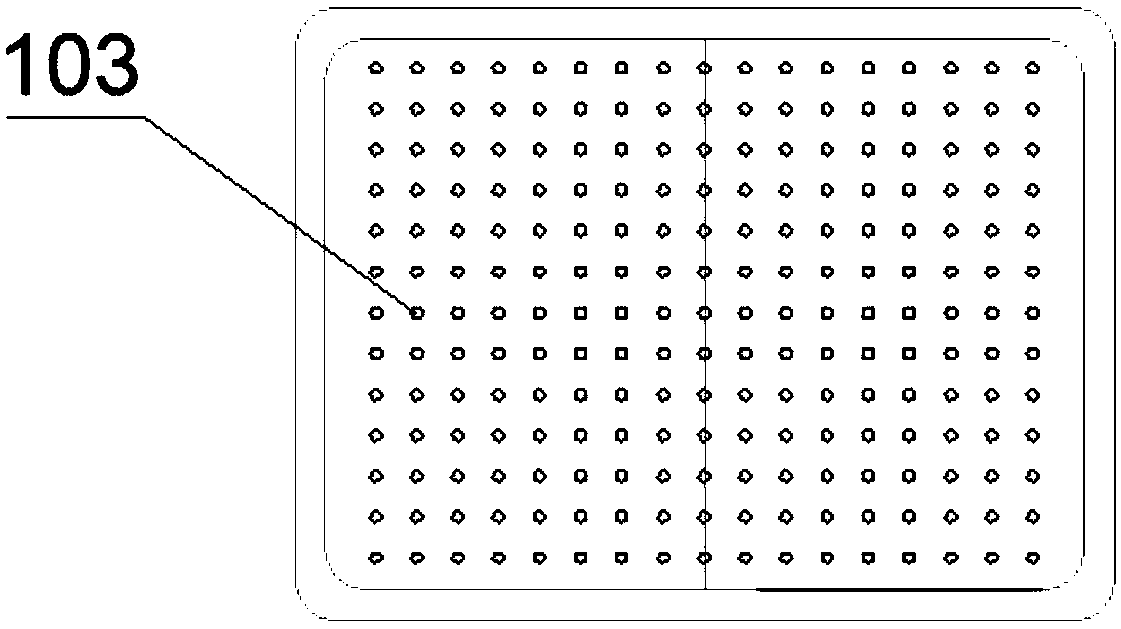

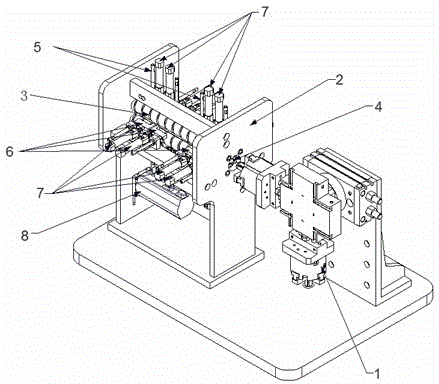

Screen printing device for television panel

ActiveCN102092178ARealize semi-automatic operationIncrease productivityScreen printersPrinting press partsScreen printingLiquid-crystal display

The invention relates to a printing device, in particular to a screen printing device for a panel of a liquid crystal display television. The invention aims at providing the screen printing device for the television panel, which can complete logo screen printing in multiple positions at one work station. The screen printing device for the television panel comprises a screen printing unit and a panel positioning component, wherein the screen printing unit comprises a first screen printing unit positioned on the left side for printing a left side frame of the panel, a second screen printing unit positioned at the middle part for printing a middle transverse side frame of the panel and a third screen printing unit positioned on the right side for printing a right side frame of the panel. The screen printing device comprises the first, the second and the third screen printing units, and can complete logo printing work in three different positions on the television panel at one work station, thereby greatly improving production efficiency, further reducing labor use and simultaneously reducing production cost.

Owner:PROACTION TECH CHANGZHOU

Novel grind-type smoothening equipment

ActiveCN105397598ASimple structureEasy to processBelt grinding machinesGrinding feedersDrive wheelSemi automatic

The invention provides novel grind-type smoothening equipment and belongs to the technical field of transportation equipment. The novel grind-type smoothening equipment comprises a grind-type smoothening unit, a conveying unit and a power unit, wherein the grind-type smoothening unit comprises a driving wheel, a driven wheel and a grind-type smoothening belt; the driving wheel is connected with the driven wheel by the grind-type smoothening belt; an output end of the power unit is connected with an input end of the driving wheel and is used for driving the driving wheel to rotate so as to drive the grind-type smoothening belt to rotate; the conveying unit is arranged at one end of the grind-type smoothening unit and is used for conveying a wooden plate material to the grind-type smoothening belt. The novel grind-type smoothening equipment has the advantages of realizing semi-automatic operation, saving both time and labor during grind-type smoothening and realizing high efficiency and high quality in grind-type smoothening of a wooden plate; the smoothened wooden plate is high in structural dimensional precision.

Owner:南通盟鼎新材料有限公司

Hydraulic clamping device for workpieces

ActiveCN105003492AAvoid scratchesRealize semi-automatic operationFluid-pressure actuator componentsClampsEngineering

The invention relates to a hydraulic clamping device for workpieces. The device comprises a platform, a backing plate, a slide bar and a hydraulic device, wherein a hinged support is arranged on the backing plate, and is rotatably connected with a supporting rod through a hinge shaft; a rolling wheel is mounted at the right end of the supporting rod; the left end of the supporting rod is connected with a steel wire rope through a pull ring; a hydraulic expansion rod is arranged at the upper end of the hydraulic device; a movable base is arranged at the right end of the hydraulic expansion rod, and is mounted on the slide bar; a fixed base is arranged below the movable base; a fixed rod penetrates into the center of the fixed base; the upper end of the fixed rod is fixedly connected with the movable base; a spring sleeves the lower end of the fixed rod; a baffle is mounted below the spring, and is connected with the steel wire rope through another pull ring. According to the invention, the supporting rod is pulled through the steel wire rope to complete the fastening of workpieces under the lever effect, and the hydraulic device is arranged to drive the movable base to effectively fix the workpieces; as the spring is additionally mounted on the fixed rod, during force unload of the hydraulic device, the movable base rebounds under the action of elastic force, and the release of the workpieces is completed; the structure is relatively simple, the practicability is relatively high, and the device is suitable for popularization and application.

Owner:CHANGZHOU LUOJUN MACHINE EQUIP

Transfer print device used for machining rubber tube opening circumference identification

InactiveCN104553274AGood consistencyReduce work intensityTransfer printingEngineeringMachining process

The invention discloses a transfer print device used for machining rubber tube opening circumference identification. The transfer print device is characterized in that a rotating support is arranged in the middle of one side of a base, the middle of the bottom of a lever is supported by the rotating support, a rubber tube positioning shaft is arranged at one end of the lever, the other end of the lever and one side of the upper portion of a device outer cover on the other side of the base are connected together through a cylinder, a driving wheel, a transfer print wheel and an ink wheel are arranged in the device outer cover, synchronous wheels are arranged on the other side of the driving wheel, the other side of the transfer print wheel and the other side of the ink wheel respectively, the synchronous wheels on the driving wheel, the transfer print wheel and the ink wheel are connected together through a synchronous belt, and an ink box is arranged below the ink wheel. By means of the arrangement, the rubber tube opening circumference identification machining process is automatically completed, the labor intensity of workers is lowered, the project quality is improved, the production efficiency is improved, the semiautomatic operation is achieved, and the transfer print device is safe, reliable, stable in action and long in service life.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

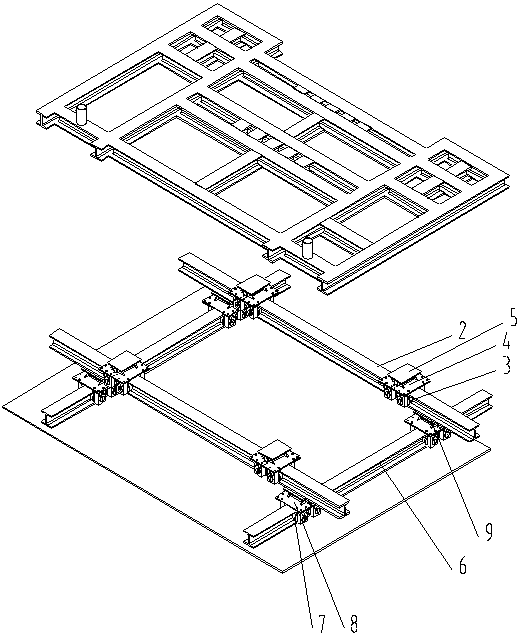

Machining unit suitable for panels of different widths

InactiveCN105773378ASimple structureAchieve fixationGrinding carriagesStationary drilling machinesEngineeringMechanical engineering

The invention provides a machining unit suitable for panels of different widths. The machining unit comprises a cutting machine and a drilling machine which are connected through a second conveying part. The cutting machine comprises a supporting mechanism and a limiting mechanism capable of moving. The supporting mechanism comprises a base and a supporting rod which are fixed through a locking part. The length of the supporting rod of the supporting mechanism can be adjusted according to the widths of the panels so that it can be ensured that the suspended ends of the panels are supported, and saw clamping or fracture of the panels in the cutting process is avoided. Meanwhile, the movement of a limiting plate is achieved through the limiting mechanism via a clamp, the distance between the limiting plate and an abrasive-disk cutter is adjusted so as to cut the panels of different sizes, and adaptability of the cutting machine is improved. The panels cut through the cutting machine are conveyed to the drilling machine through the second conveying part, the process is smooth, too much manpower does not need to be input, and the work efficiency is high. The unit is simple in overall structure, operation is convenient and can be finished by common workers, and manpower is reduced by at least one half.

Owner:SUZHOU TIANYUAN FURNITURE CO LTD

Fuel drying device for rural biomass gasification power generation

ActiveCN109028818AEfficient dryingReduce labor intensityGranular material dryingDrying gas arrangementsAir cycleSemi automatic

The invention provides a fuel drying device for rural biomass gasification power generation. The fuel drying device comprises an outer box, a feeding pipe and a first material pump. The lower end of the outer box is fixedly connected with four supporting feet, and the feeding pipe is inserted into the upper end of the side wall of one side of the outer box in a communicating mode. The first material pump is mounted on the feeding pipe. A drying box is fixedly connected to the inner side wall of one side of the outer box, and a hot air circulating device is arranged above the drying box. An electric heating plate is fixedly connected to the inner bottom wall of the drying box, and a plurality of laying stirring plates abut against the upper end of the electric heating plate. According to the fuel drying device, the defects of the prior art are overcome, the design is reasonable, the structure is compact, semi-automatic operation is achieved, waste particles do not need to be laid and sub-packaged, burden of workers is reduced greatly, the drying efficiency is improved, and large-scale assembly line drying production is facilitated.

Owner:安徽省建辉生物质能发展有限公司

Pile holding device for wind power installation platform

PendingCN109469061AEasy to moveAccurate realizationBulkheads/pilesWind energy generationElectricityEngineering

The invention relates to a pile holding device for a wind power installation platform. The device comprises a chassis and at least one clamping arm assembly arranged on the chassis, the chassis is driven by a transverse moving mechanism to achieve transverse moving in the horizontal direction, a longitudinal moving mechanism drives the chassis to achieve longitudinal moving in the horizontal direction, the clamping arm assembly comprises a pair of box type left arm and a box type right arm which are matched, the box type left arm and the box type right arm are arranged on the chassis through stand columns, the box type left arm and the box type right arm are hinged to the corresponding stand columns, and the box type left arm and the box type right arm are driven by a swing mechanism to hold tightly or be separated from piles. The device has the advantages that through the transverse moving mechanism and the longitudinal moving mechanism, moving of the chassis in the transverse direction and the longitudinal direction is achieved, through joint operation of the swing mechanism, deviation rectifying in the any direction is achieved, and the deviation rectifying range is greatly widened.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

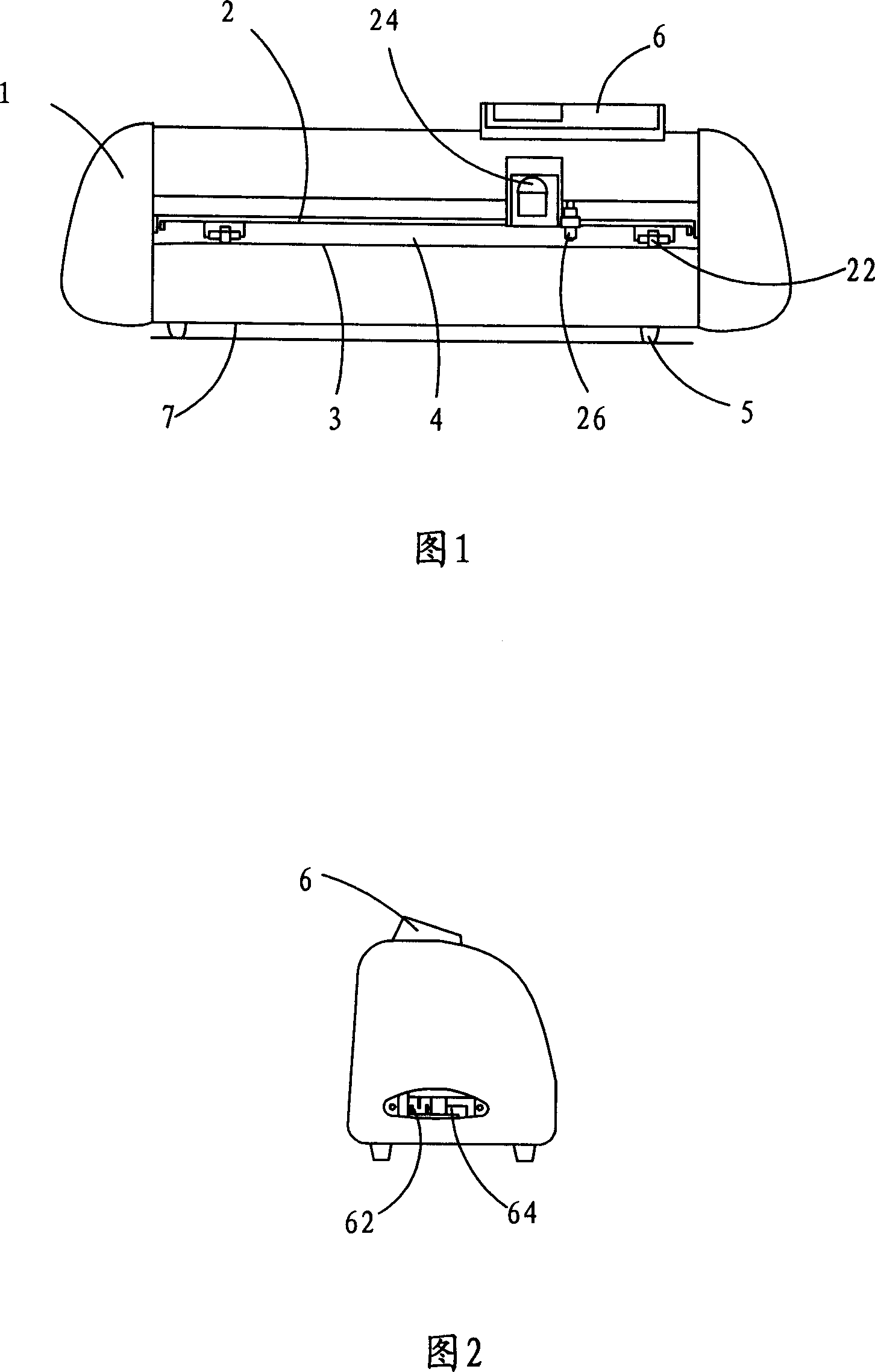

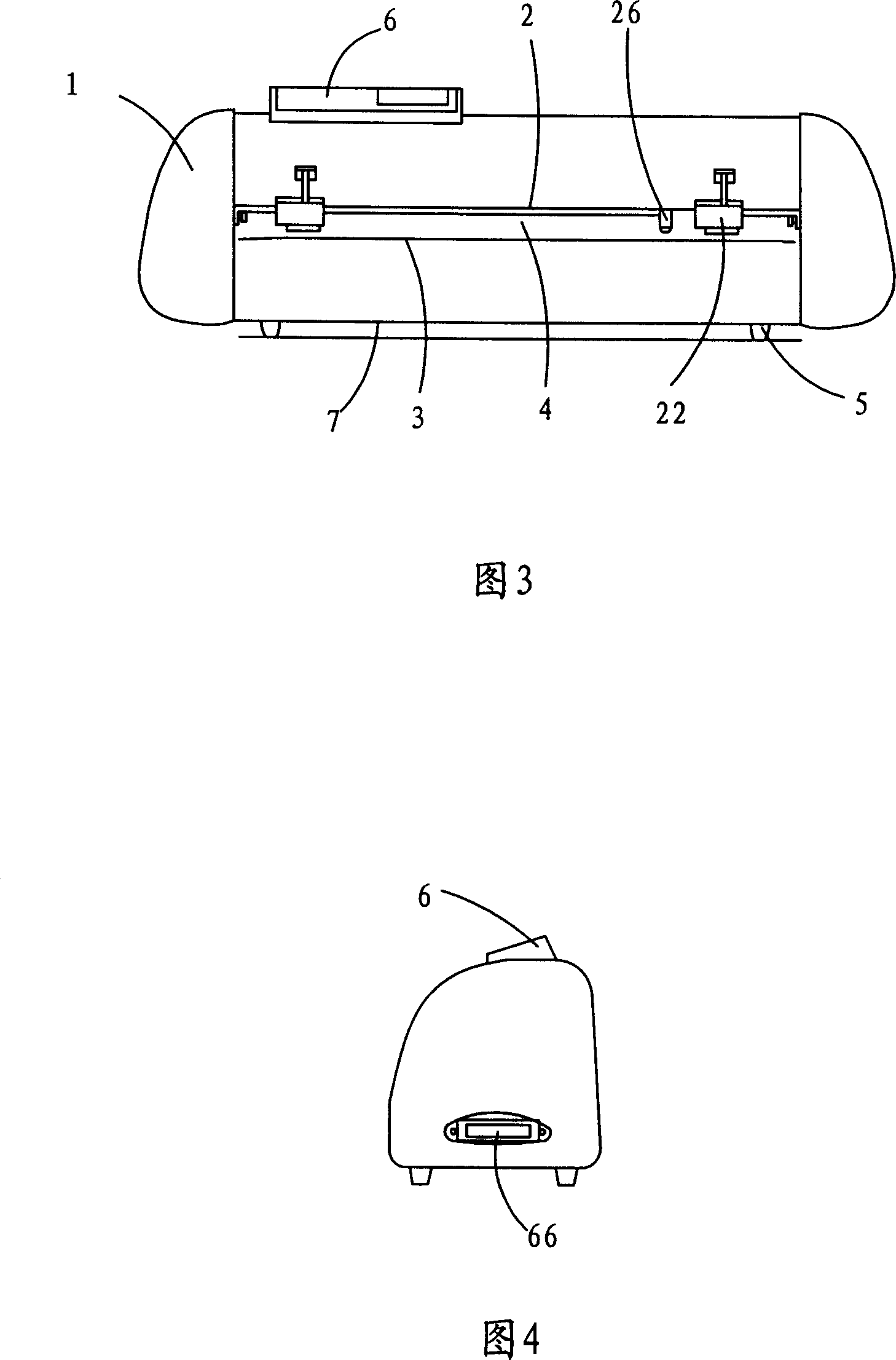

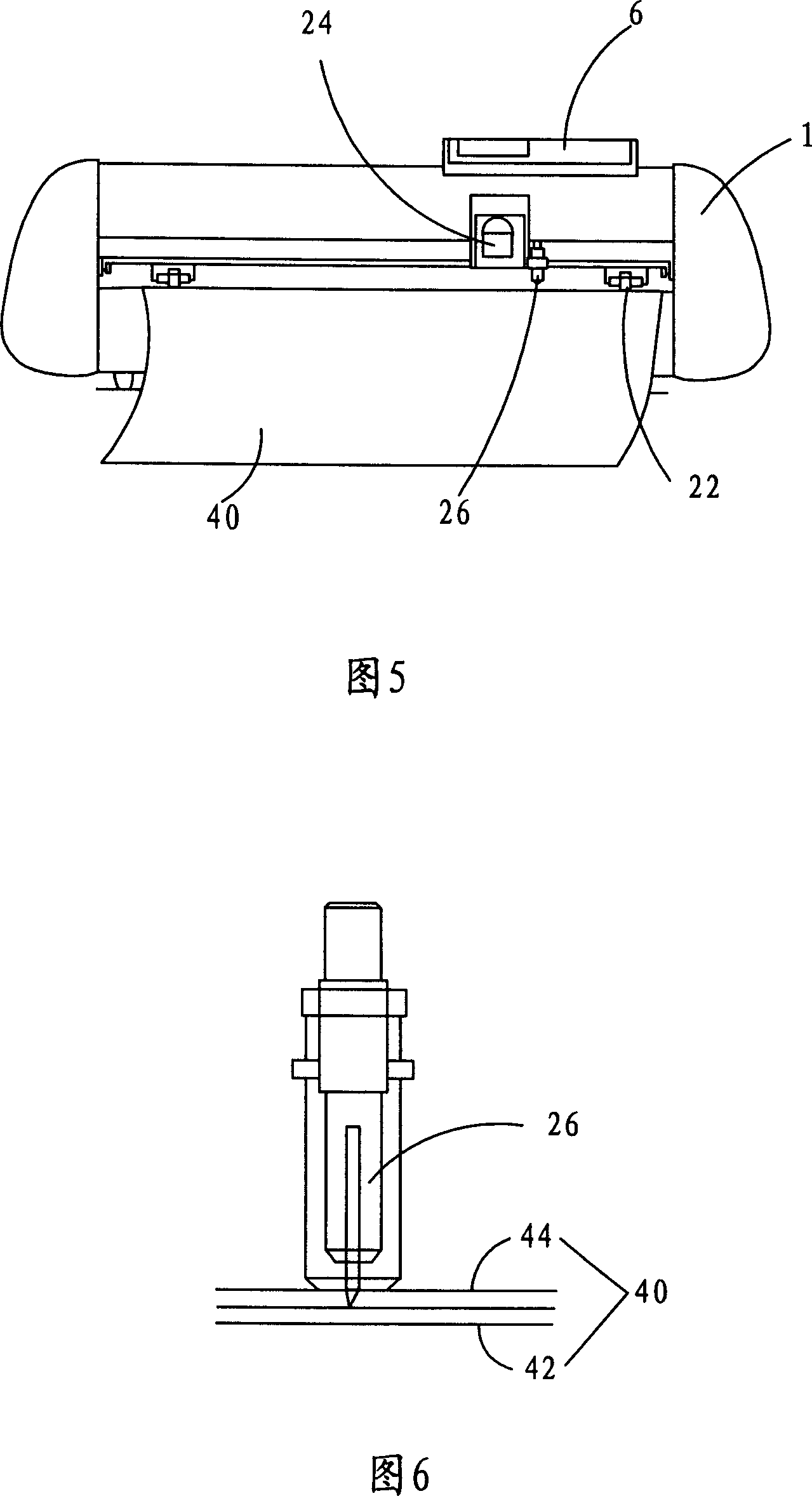

New use of plotting-cutting machine for manufacturing sandwich glass

InactiveCN1935472AUniform forceRealize semi-automatic operationLamination ancillary operationsLaminationSemi automaticEngineering

The present invention relates to a new application of plotting cutter in production of laminated glass. It is characterized by that in the production process of laminated glass said plotting cutter can be used for cutting and separating the thermal reflection membrane layer of PVB (polyvinyl butyral) functional membrane layer from PVB film layer. The use of said plotting cutter can accurately define cutting parameter of cutter so as to implement semi-automatic operation.

Owner:FUYAO GLASS IND GROUP CO LTD

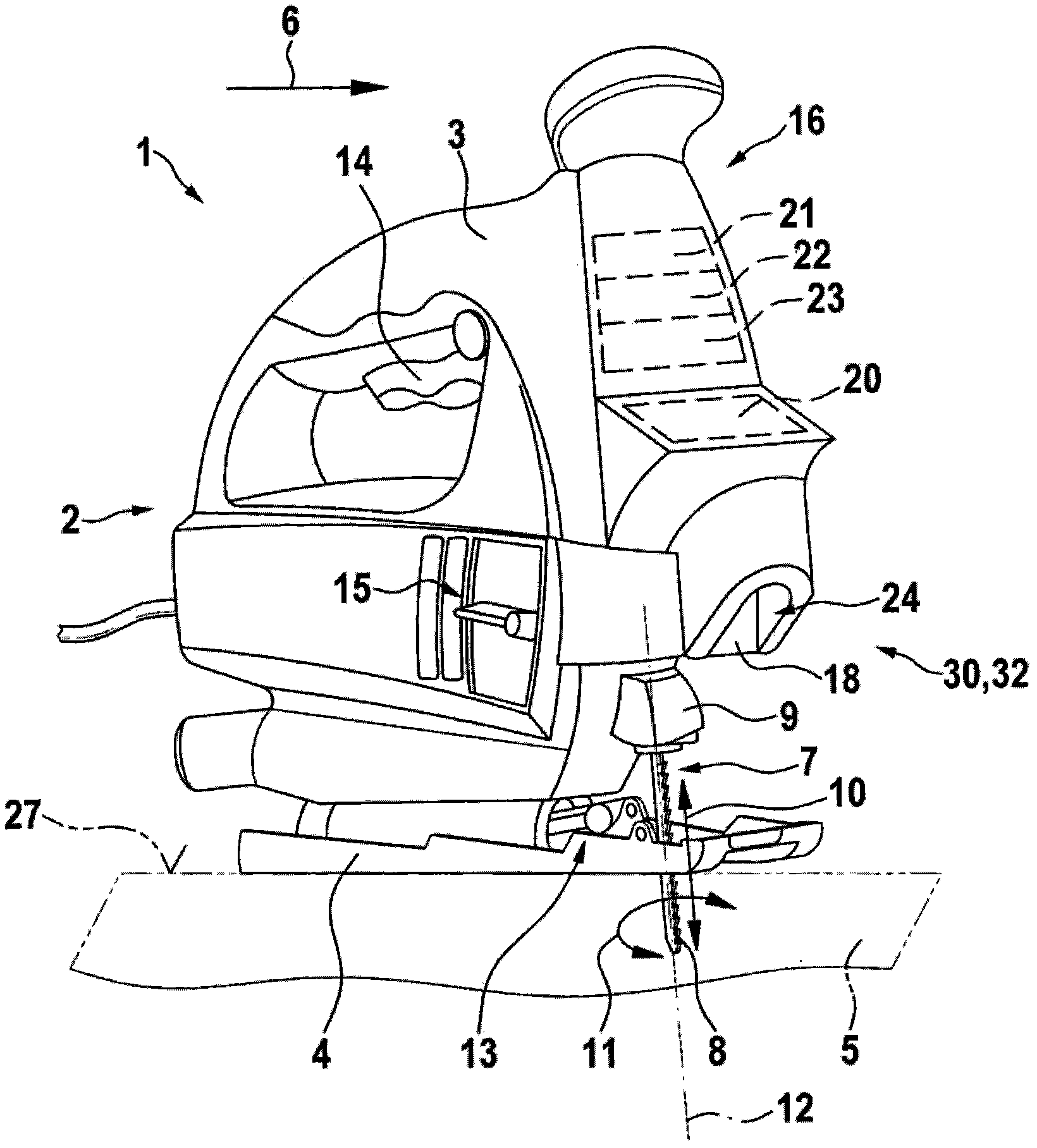

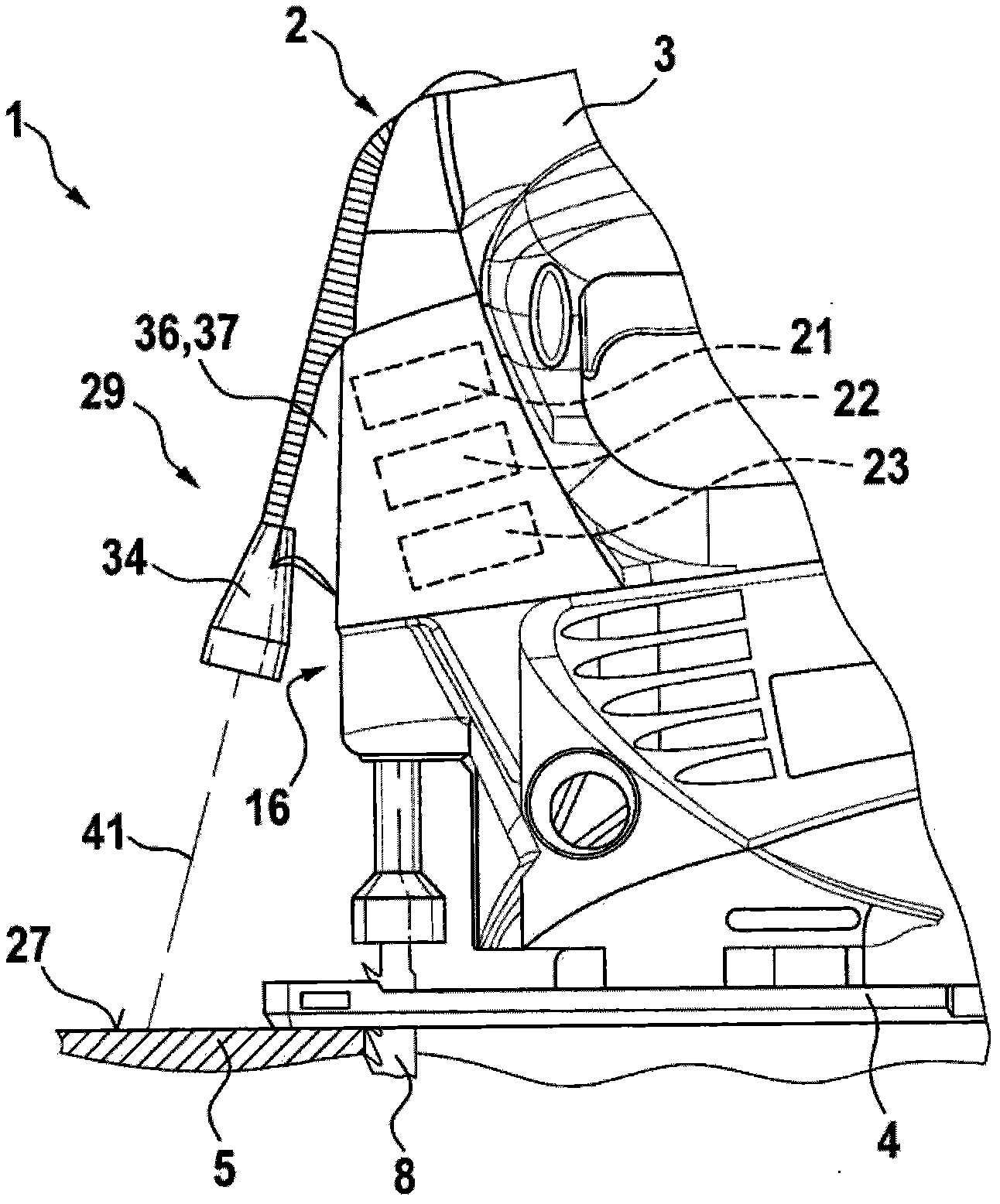

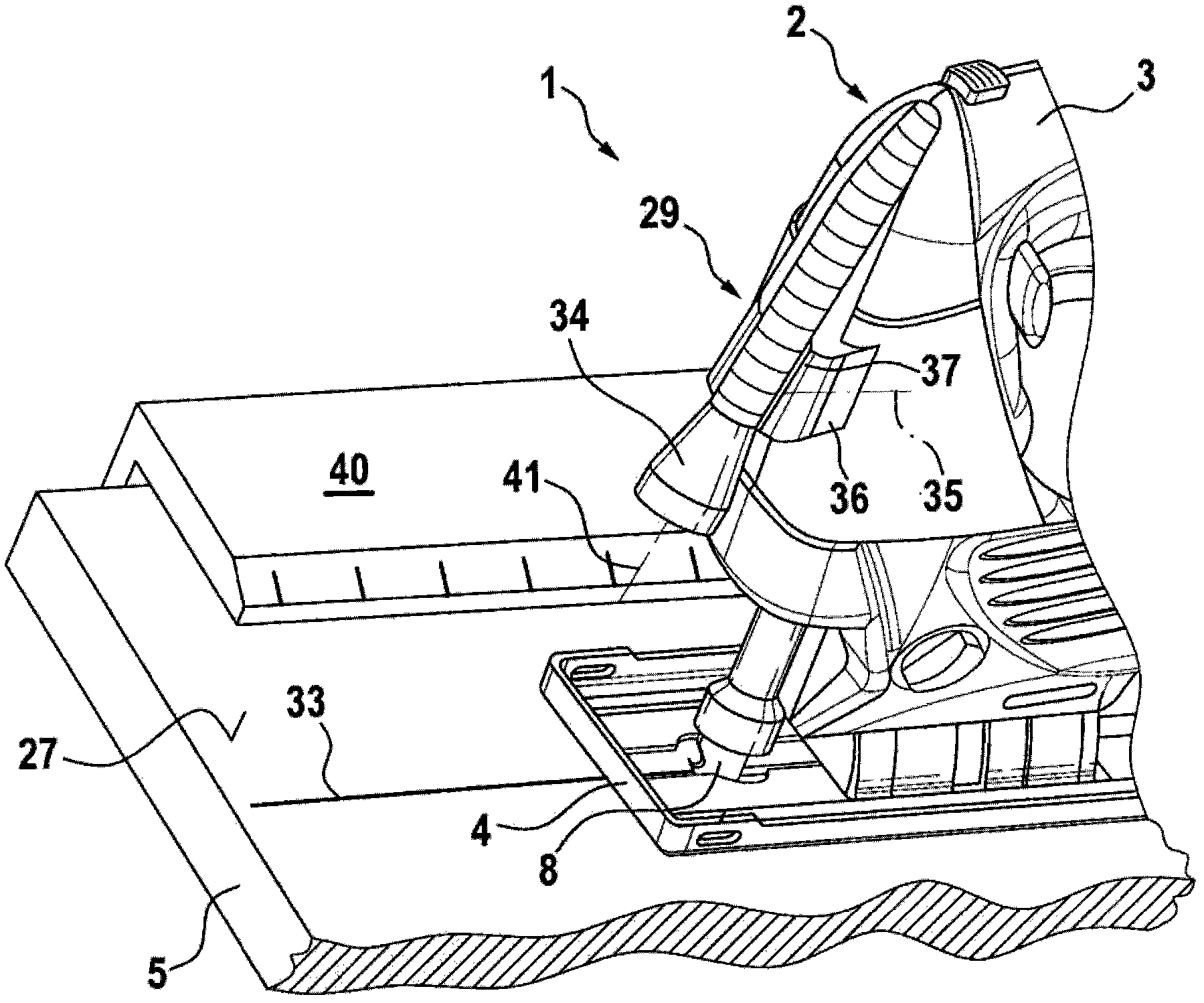

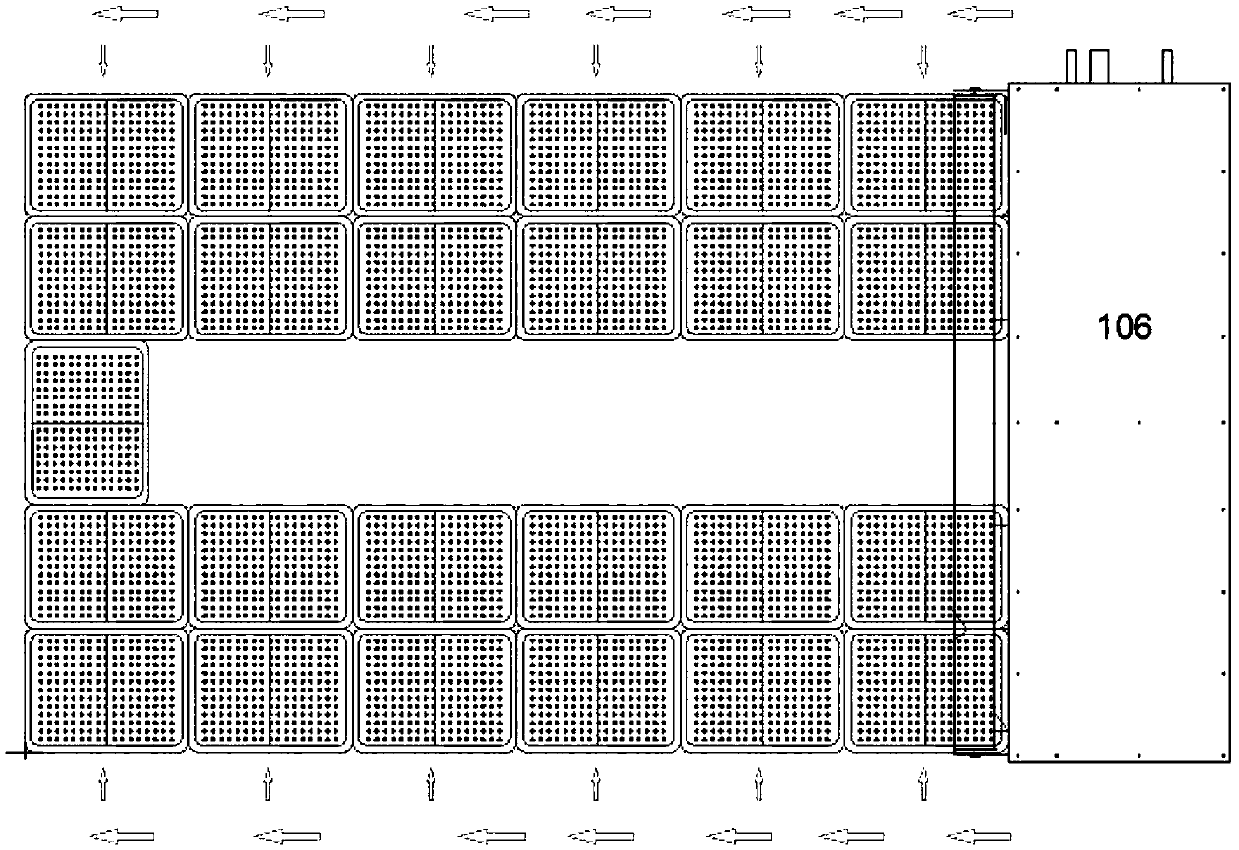

Machine tool, especially hand-held machine tool

InactiveCN102741016ARealize semi-automatic operationAchieve lightingMetal sawing devicesMetal sawing accessoriesHand heldMachine tool

Owner:ROBERT BOSCH GMBH

Picking, pre-cooling and storing integrated basket, application thereof, and method for pre-cooling small-fruit-diameter perishable fruits

ActiveCN109645105AAchieve standardizationRealize semi-automatic operationFood processingPackaging fruits/vegetablesCold chainProcess engineering

The invention provides a picking, pre-cooling and storing integrated basket, application thereof, and a method for pre-cooling small-fruit-diameter perishable fruits, and belongs to the technical field of fruit and vegetable picking after-treatment. Based on the design of the picking, pre-cooling and storing integrated basket, the modes of standard picking, pre-cooling, storing boxes and trays areadopted, the method for pre-cooling small-fruit-diameter perishable fruits is successfully provided, standardization of a cold chain process is easily realized, semi-automatic operation in the process is realized, and labor and time are saved. Meanwhile, a critical freeze injury temperature method is adopted for delivering air, in this way, pre-cooling time can be effectively shortened, pre-cooling energy consumption can be effectively lowered, meanwhile, a quench effect can be realized in fruit and vegetable pre-cooling treatment, and the storing circulating deadline of follow-up steps is delayed; an alternate-air-delivery variable-air direction method is adopted, in this way, the uniformity of the pre-cooling process is improved, and the phenomenon of dead zones during pre-cooling heattransfer is prevented; a time-period-division variable-air speed air delivery mode is adopted, so that while the pre-cooling time is guaranteed, the pre-cooling energy consumption is lowered.

Owner:SHANDONG UNIV

Rolling tea retaining device

InactiveCN101828608AGreat tasteRealize semi-automatic operationPre-extraction tea treatmentEngineeringRigid structure

The invention discloses a rolling tea retaining device, which comprises a fulcrum bar, a baffle, a scraper blade and an angle adjusting device, wherein the baffle is connected to the tail end of the fulcrum bar; the baffle and the fulcrum bar are vertical to each other and are connected at a right angle; the baffle is provided with the angle adjusting device; and the scraper blade is connected to the baffle through the angle adjusting device. The rolling tea retaining device is characterized in that: the fulcrum bar is a hollow rigid tube in which an elastic or telescopic structure is arranged; one end of the fulcrum bar far from the baffle is provided with a thread adjusting knob, while the other end is a through orifice; and a rigid structure arranged in the fulcrum bar penetrates the fulcrum bar and supports against a corresponding position of the baffle. The thread adjusting knob controls the elastic or telescopic structure in the fulcrum bar to change a position so as to control a gap between the tail end of the scraper blade and an inner pan of a tea frying device or the flexibility of adjusting an angle between the scraper blade and the baffle; and the rolling tea retaining device meets various requirements in the tea frying process, furthers improve the taste of the prepared tea leaves, is suitable for large-scale production while saving labor, and has good implementation effect.

Owner:周勤君

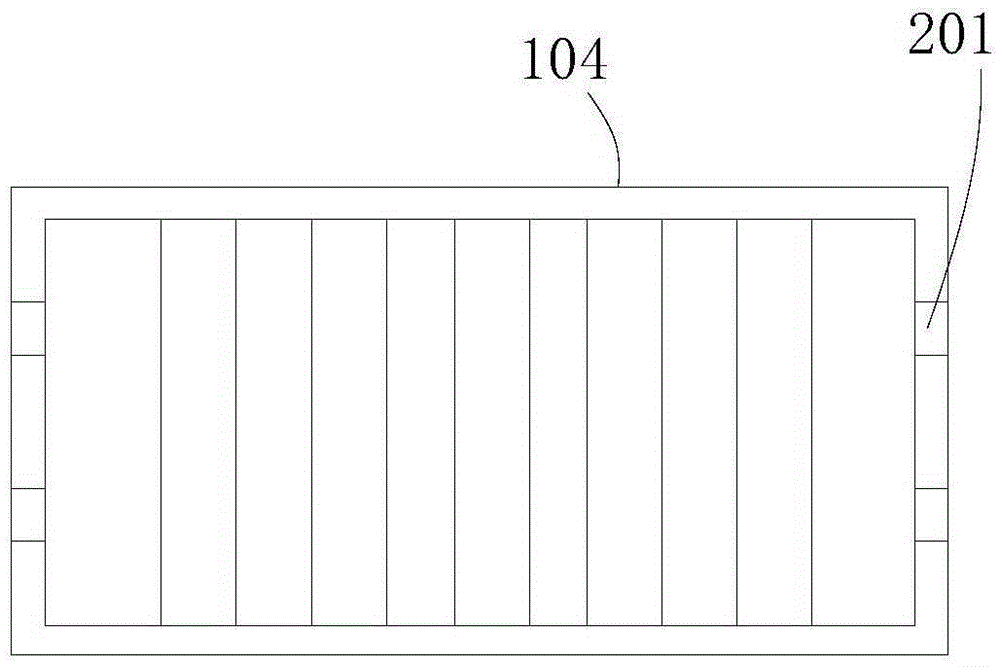

Deep hole O-shaped sealing ring sleeving mounting machine

ActiveCN104647020AImprove work efficiencyImprove accuracyMetal working apparatusEngineeringDeep hole

The invention relates to a deep hole O-shaped sealing ring sleeving mounting machine. The machine comprises a lifting rotating four-claw supporting and picking mechanism. The machine is characterized in that a mounting device rack is arranged at one side of the lifting rotating four-claw supporting and picking mechanism; four lead screws are arranged in parallel to the rack and are distributed in four corners of a horizontal rectangle; a sleeve is arranged at the inner side of each four lead screw and is tangent to each of the four lead screws; two groups of supporting mechanisms opposite to the sleeves are arranged at the front and back of the rack; the sleeves can be alternatively clamped and positioned through the supporting mechanisms. The machine has the advantages that original operation of manually sleeving an O-shaped ring is replaced, and thus the working efficiency and accuracy are qualitatively increased; in addition, the automation is achieved, so that the labor intensity of workers is reduced; the machine has a good market prospect under the large automatic production background in the current product; the machine is free of a complex structure, and the function can be performed only after the processing precision and the corresponding strength are ensured.

Owner:QUANSTAR PRECISION MACHINERY SHANGHAI

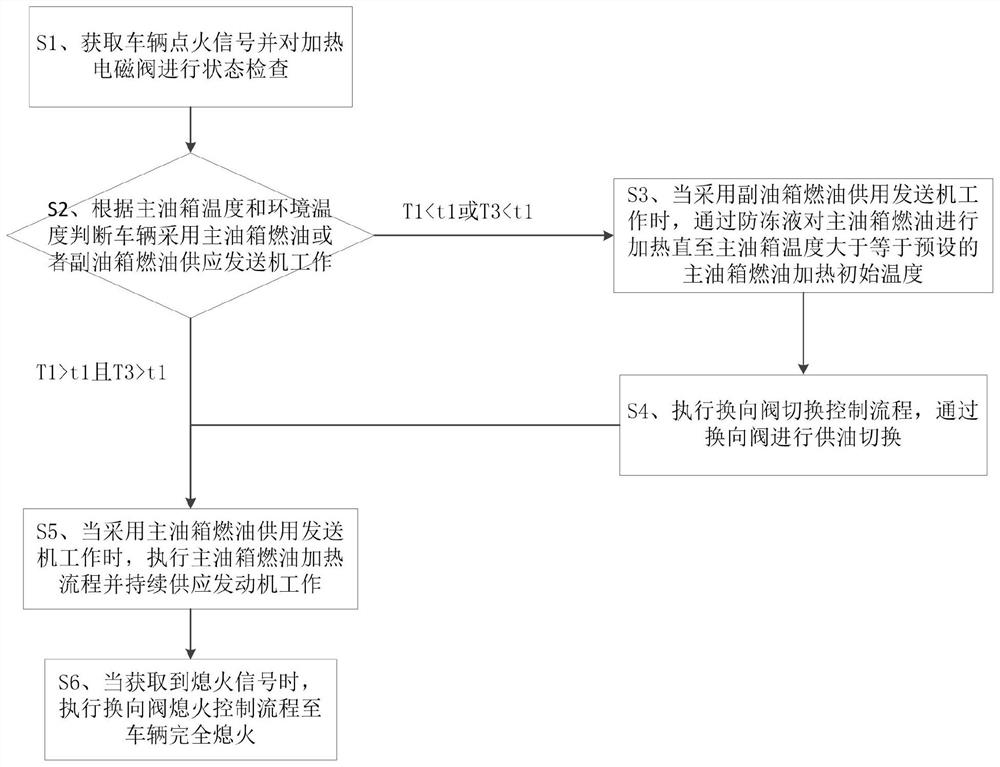

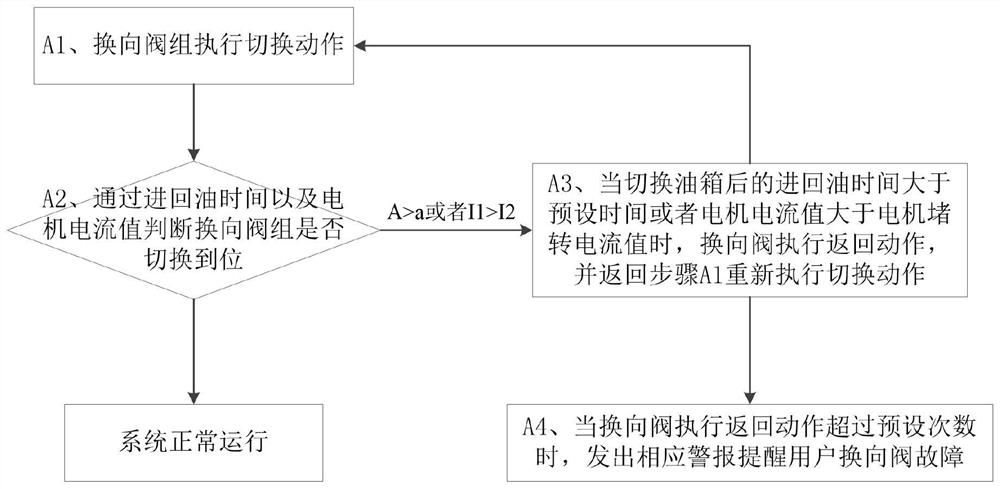

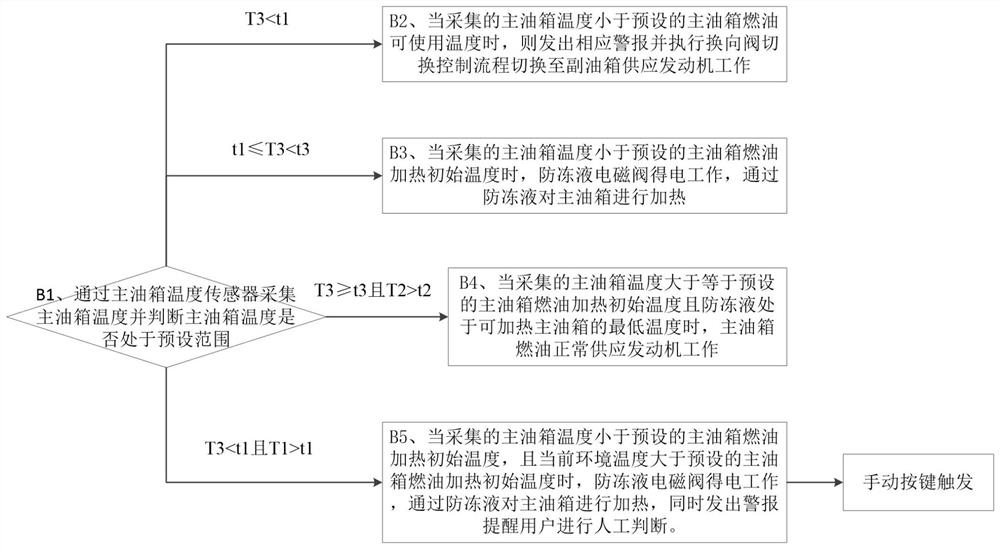

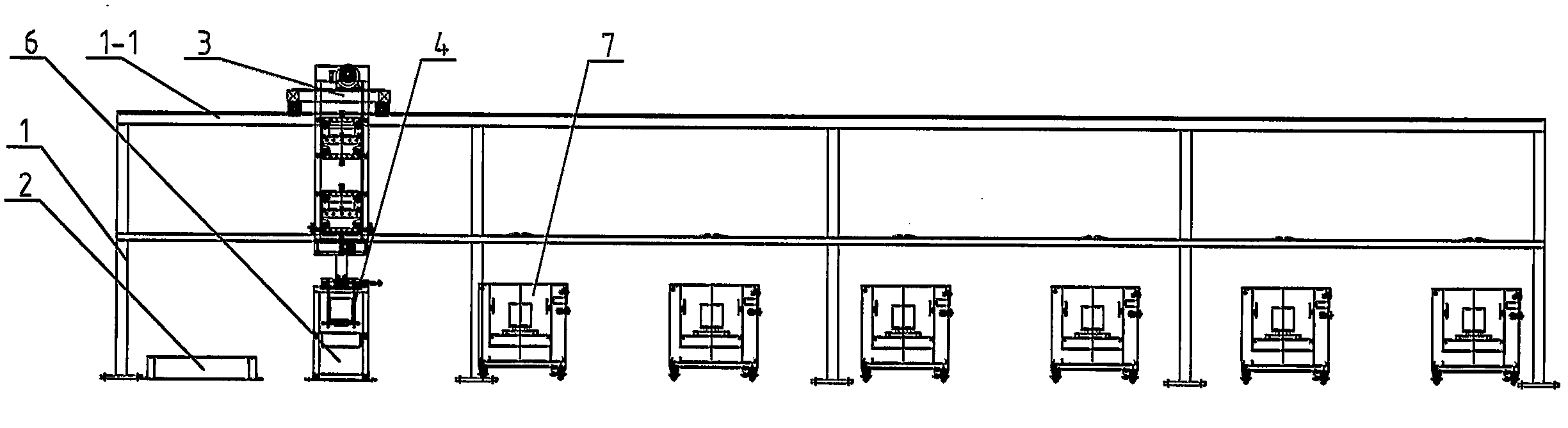

Vehicle dual-fuel system operation control method and system

PendingCN113279863ARealize semi-automatic operationInternal combustion piston enginesEngine controllersControl systemFuel tank

The invention belongs to the technical field of vehicle fuel supply control, and provides a vehicle dual-fuel system operation control method. The vehicle dual-fuel system operation control method comprises the following steps that a vehicle ignition signal is acquired, and the state of a heating electromagnetic valve is checked; according to the main oil tank temperature and the environment temperature, whether the vehicle adopts main oil tank fuel oil or auxiliary oil tank fuel oil to supply an engine to work is judged; a reversing valve switching control process is executed, and oil supply switching is conducted through a reversing valve; when the main oil tank fuel oil is used for the engine to work, the main oil tank fuel oil heating process is executed, and the engine is continuously supplied for work; and when the flameout signal is obtained, a reversing valve flameout control flow is executed until the vehicle is completely flameout. The invention further provides a vehicle dual-fuel system operation control system which has the advantages that the fuel temperature of the main fuel tank is detected in real time, the control process is switched through the reversing valve to switch fuel supply of the main fuel tank and the auxiliary fuel tank, and corresponding alarm is given through a panel to remind a user when a fault occurs.

Owner:宁波华工热控科技有限公司

Turnover degumming all-in-one machine

The invention discloses a turnover degumming all-in-one machine which comprises a machine frame, a loading guiding frame, a mechanical arm, a lifting workpiece holder, a wafer box, a turnover mechanism and a plurality of heating degumming groove bodies. The turnover mechanism is used for turning over a connecting plate, wherein wafers are stuck to the front face and the back face of the connecting plate. The loading guiding frame, the turnover mechanism and the heating degumming groove bodies are sequentially arranged in parallel. A mechanical arm track device is arranged at the upper portion of the machine frame. The mechanical arm is installed on the mechanical arm track device in a slidable mode and located above the loading guiding frame, the turnover mechanism and the heating degumming groove bodies. The lifting workpiece holder is installed on the mechanical arm. According to the turnover degumming all-in-one machine, manual degumming can be achieved, the quality of the wafers is improved, the wafer burning phenomenon and injury accidents are avoided, and the semi-automatization operation in the washing and degumming processes is achieved.

Owner:江苏有则创投集团有限公司

Repairing device for metal roof lap joint

InactiveCN110259181ARealize semi-automatic operationReduce manual workBuilding repairsRoof toolsSemi automaticLap joint

The invention relates to a repairing device for a metal roof lap joint. The repairing device comprises a vehicle body, the vehicle body comprises a vehicle box body with universal wheels and a handle, and a cleaning mechanism, a painting mechanism and a spreading mechanism are additionally arranged from the end, away from the handle, of the bottom of the vehicle box body to the end, close to the handle, of the bottom of the vehicle box body in sequence; the cleaning mechanism comprises a cleaning bracket and a cleaning brush additionally arranged on the cleaning bracket; the painting mechanism comprises a paint box additionally arranged in the vehicle box body, a paint support additionally arranged on the vehicle box body and a paint brush additionally arranged on the paint support, and a discharge port is formed in the bottom end of the paint box; a sealing cover is hinged to the discharge port; and the spreading mechanism includes a spreading bracket additionally arranged on the vehicle box body, a roller rotatably connected with the spreading bracket and a coil sleeving the roller. The repairing device has the effects of realizing semi-automatic operation, reducing manual work, accelerating repair efficiency and reducing construction cost.

Owner:北京世纪海森防水材料有限公司

Recycling device for remained slurry of tubular pile

The invention discloses a recycling device for remained slurry of a tubular pile, in order to overcome the defect that the traditional remained slurry recycling device is not convenient to use. A material-receiving stirring tank of the recycling device is used for receiving and stirring the remained slurry of the tubular pile; the material-receiving stirring tank and a measuring tank are respectively used for putting the received remained slurry of the tubular pile into the measuring tank and a feeding tank according to design weight by a measuring valve and a discharging valve; an air storage tank is provided with an air outlet valve; a feeding valve is arranged at one end of the feeding tank; the feeding valve is connected to the air outlet valve of the air storage tank; the air pressure in the air storage tank is higher than the air pressure in the feeding tank; air in the air storage tank enters into the feeding tank through the feeding valve after flowing by the air outlet valve;the other end of the feeding tank is connected to a stirrer and a waste pool through a conveying pipe, a first discharging valve and a second discharging valve; and the remained slurry of the tubularpile in the feeding tank enters into the stirrer or the waste pool and is stored in the stirrer or the waste pool under the driving of the air in the air storage tank. The recycling device is characterized in that the measuring tank, the feeding tank and the conveying pipe are cleaned through the mixing of air and water, pipelines are efficiently prevented from being blocked, and automatic operation can be realized.

Owner:陈建文

An orchard ditching device and method for fertilizing target holes

ActiveCN105144918BImprove the efficiency of fertilization operationsIncrease profitPlantingFertiliser distributersFruit treeAgricultural science

The invention provides a device and method for strip-type ditching toward-target hole fertilization in an orchard. The device comprises ditching equipment, hole fertilizer feeding equipment, detecting equipment and a controller for fertilization amount adjustment, wherein the hole fertilizer feeding equipment comprises a fertilizer box and hole fertilizer feeders, and is used for realizing precise control of the fertilizer feeding amount and a fertilizer feeding position; the detecting equipment comprises a machine traveling speed detecting unit and a fruit tree target detecting unit, and is used for acquiring machine traveling speed information and fruit tree position information; the controller takes a single chip microcomputer as a core, is used for setting fertilizer feeding information of each tree and crown width information, processing the fruit tree position information and the machine traveling speed information, and controlling the hole fertilizer feeder to perform quantitative hole fertilizer feeding. According to the device and the method, a center position of each fruit tree can be calculated according to fruit tree target information and the traveling speed of the fertilizer distributor; aiming at center control of fruit trees on the two sides, the fertilizer feeders are correspondingly controlled to realize toward-target precision fertilization to improve the orchard fertilization operation efficiency, so that an approach for solving the orchard fertilization labor shortage problem in some regions in China.

Owner:NORTHWEST A & F UNIV

Automobile blade fuse pull-out tester

InactiveCN104155184BRealize semi-automatic operationEffectively fixedMaterial strength using tensile/compressive forcesEngineeringMechanical engineering

The invention relates to a pull-out tester for an automobile insert fuse, comprising a beam and a bracket, the beam is fixed on the bracket, and a driving assembly is arranged above the beam, and the driving assembly includes a motor, a support, a slider and a lead screw, the motor and a support They are respectively arranged on both sides above the beam, one end of the screw is fixed on the support, the other end of the screw is connected to the motor transmission, the screw passes through the slider and the screw is connected to the slider, and there are mutually symmetrical first The clamping arm and the second clamping arm, the first clamping arm is fixed on the beam, the top of the second clamping arm is fixedly connected with the slider, the second clamping arm is slidingly connected with the beam, the first clamping arm and the second clamping arm The clamping arm is provided with a clamping assembly capable of clamping the automobile blade fuse. Through the cooperation of the motor and the lead screw, the automobile blade fuse pullout tester realizes the semi-automatic operation of clamping the automobile blade fuse, and effectively fixes the automobile blade fuse through the clamping component, which improves the testing efficiency Accuracy, improve work efficiency.

Owner:常州常利来电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com