Repairing device for metal roof lap joint

A metal roofing and lap joint technology, applied in roofing, roof engineering tools, building maintenance, etc., can solve problems such as low efficiency, reduce manual work, and speed up repair efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

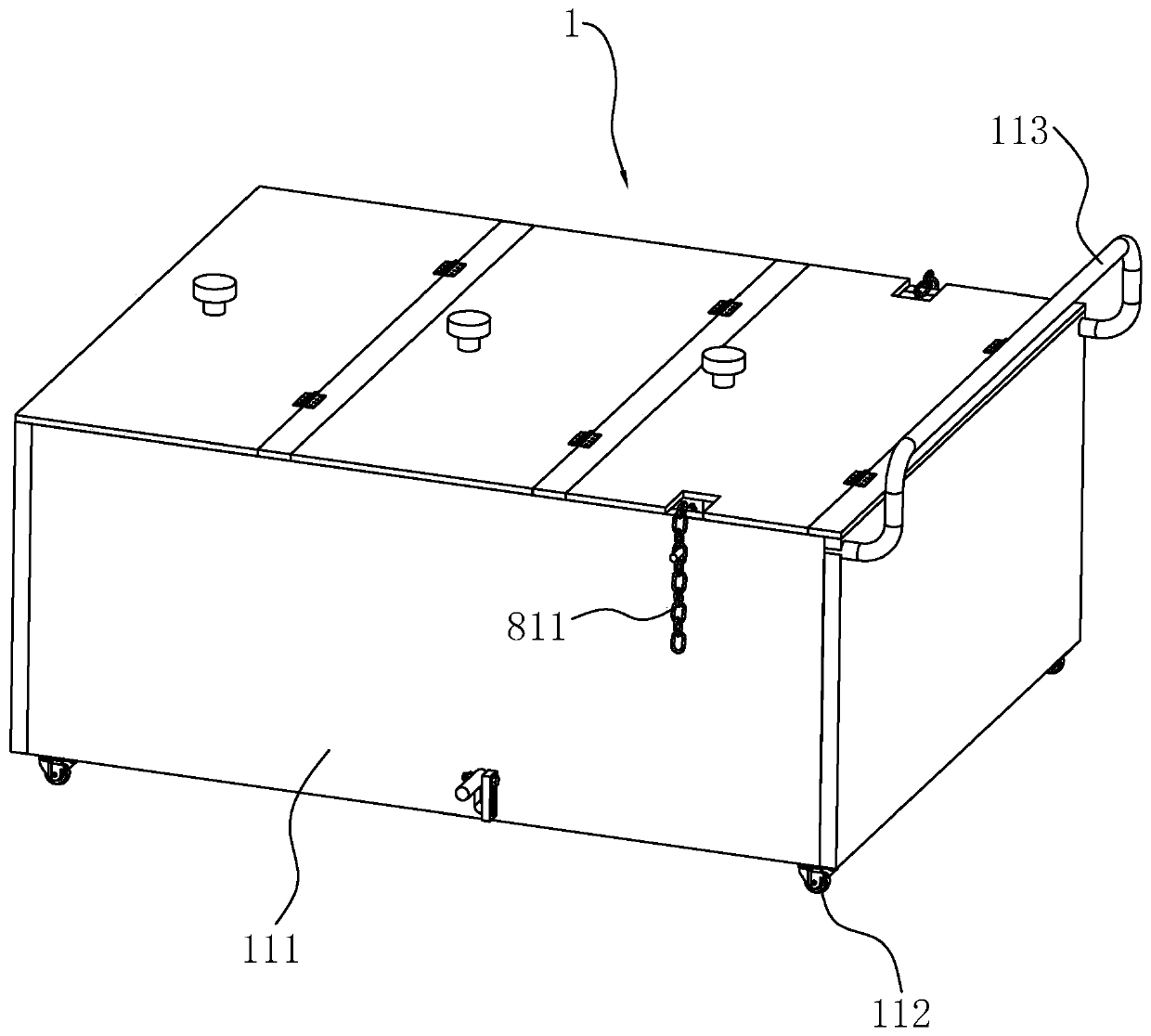

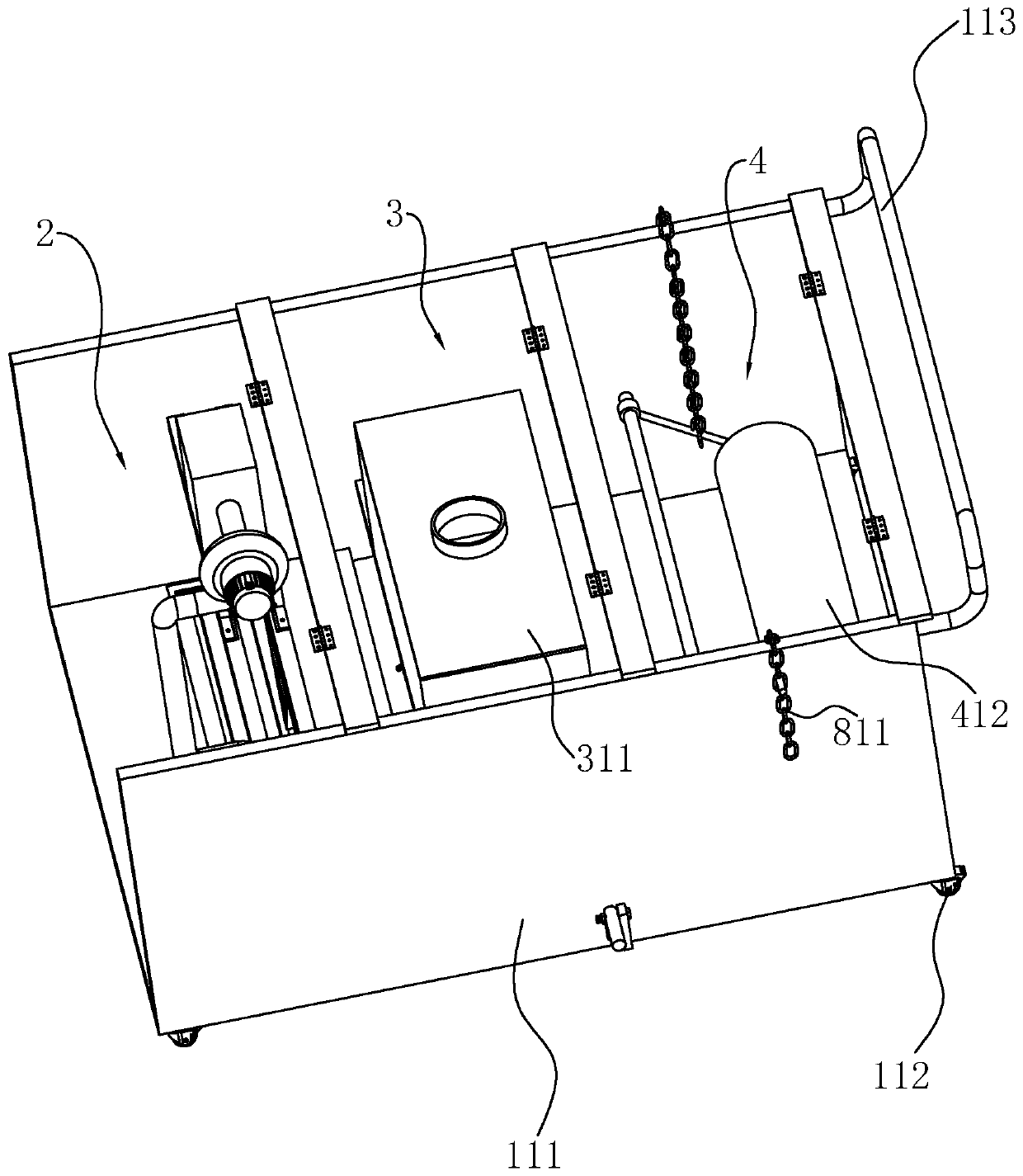

[0035] Example: such as figure 1 Shown here is a repairing device for metal roof lap joints disclosed in the present invention. It includes a car body 1. The car body 1 includes a car body 111 without a cover. The four corners of the lower end of the car body 111 are Four universal wheels 112 are fixedly connected, and a handle 113 is fixedly connected to the side end surface of the vehicle box body 111.

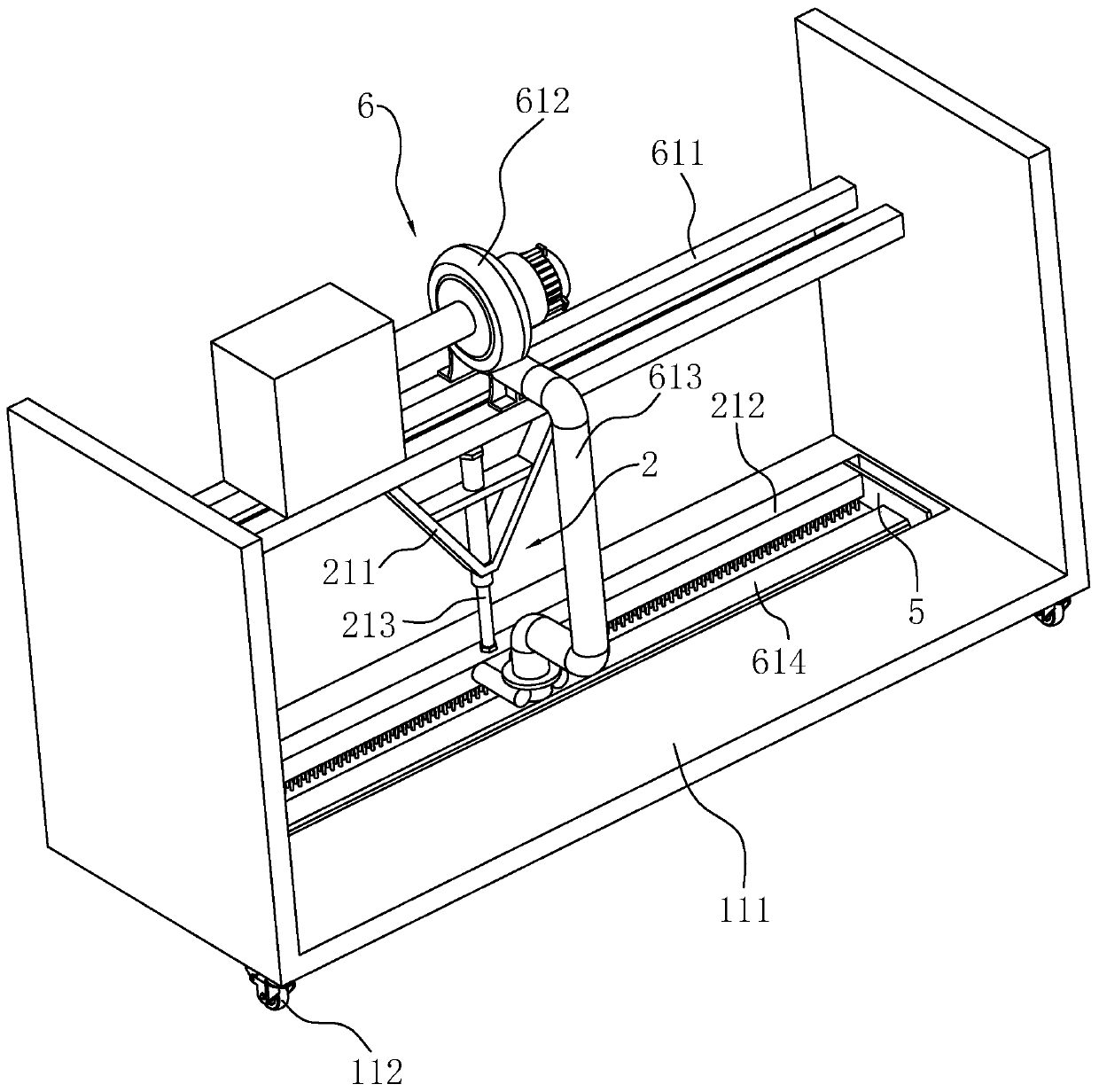

[0036] Such as figure 2 with image 3 As shown, a cleaning mechanism 2 is added to the end of the vehicle box 111 away from the handle 113. The cleaning mechanism 2 includes a cleaning bracket 211 and a cleaning brush 212. The lower end of the vehicle box 111 is provided at a position facing the cleaning brush 212 for cleaning. The strip-shaped slot through which the brush 212 passes, the cleaning bracket 211 is fixed to the inside of the car body 111, and the cleaning bracket 211 is fixed with an air cylinder 213, and the piston rod of the air cylinder 213 is threadedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com