Vehicle dual-fuel system operation control method and system

A fuel system and operation control technology, applied in the direction of charging system, engine control, combustion engine, etc., can solve the problems of low fuel temperature and difficult starting of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

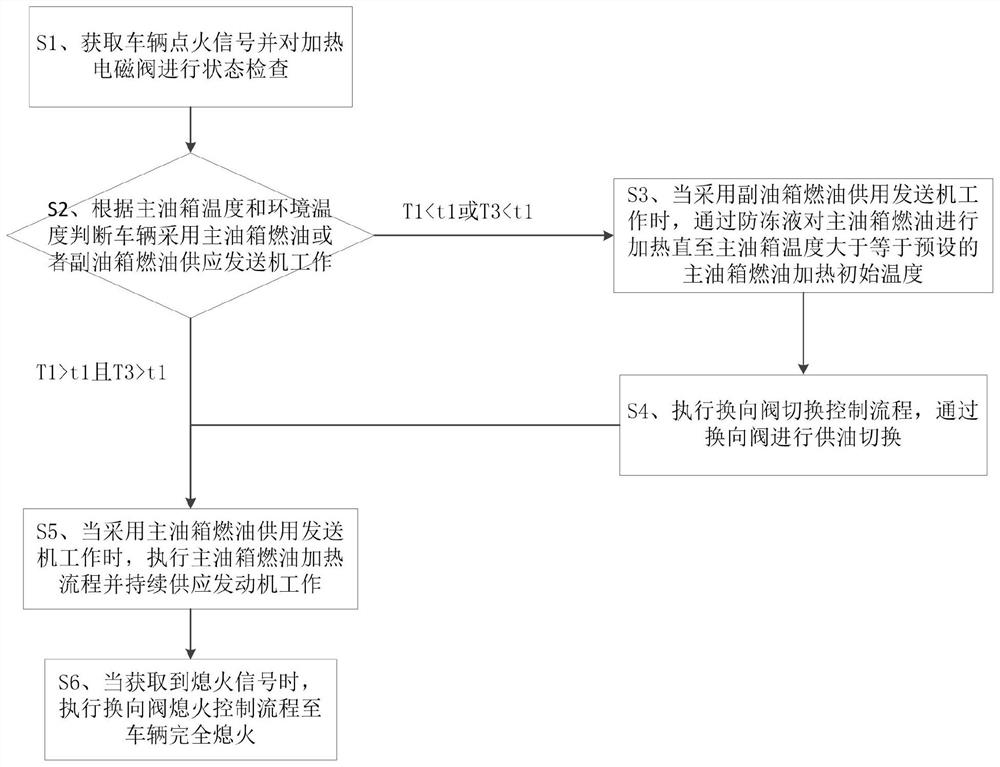

[0054] like figure 1 As shown, a method for controlling the operation of a vehicle dual-fuel system in the present invention comprises the steps of:

[0055] S1. Obtain the ignition signal of the vehicle and check the state of the heating solenoid valve;

[0056] S2. According to the temperature of the main fuel tank and the ambient temperature, it is judged that the vehicle uses the fuel from the main fuel tank or the fuel from the auxiliary fuel tank to supply the transmitter to work;

[0057] S3. When the auxiliary fuel tank is used to supply the transmitter, use antifreeze to heat the fuel in the main fuel tank until the temperature of the main fuel tank is greater than or equal to the preset initial temperature of the fuel in the main fuel tank;

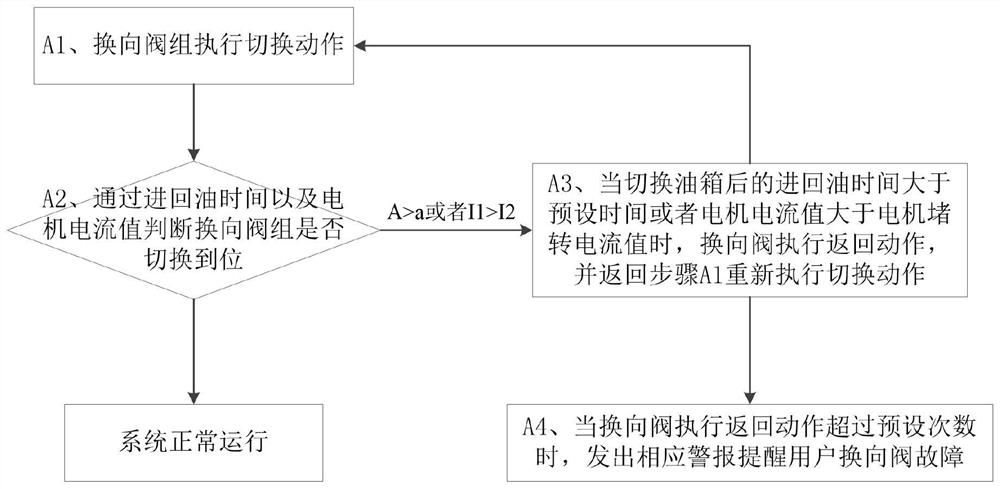

[0058] S4. Execute the switching control process of the reversing valve, and switch the oil supply through the reversing valve;

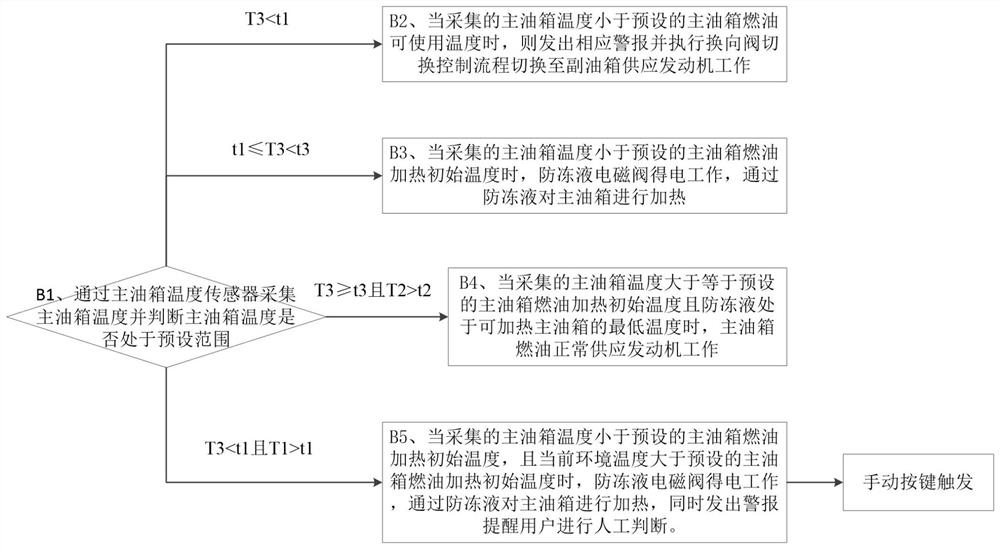

[0059] S5. When the main fuel tank fuel supply engine is used to work, execute the main fuel tank ...

Embodiment 2

[0085] like Figure 5 As shown, a vehicle dual fuel system operation control system of the present invention includes:

[0086] The start-up and status check module is used to obtain the vehicle ignition signal and check the status of the heating solenoid valve;

[0087] The fuel supply judging module is used to judge whether the vehicle uses the main fuel tank fuel or the auxiliary fuel tank fuel supply transmitter to work according to the temperature of the main fuel tank and the ambient temperature;

[0088] The main fuel tank fuel heating control module is used to heat the main fuel tank fuel through antifreeze until the main fuel tank temperature is greater than or equal to the preset When the auxiliary engine is working, perform the fuel heating process of the main fuel tank and continue to supply the engine;

[0089] The reversing control module is used to execute the switching control process of the reversing valve, and switch the oil supply through the reversing val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com