Recycling device for remained slurry of tubular pile

A technology of pipe pile residual slurry and recovery device, which is applied in the direction of clay preparation device, mixing operation control, mixing plant, etc., can solve the problems of inconvenient use, achieve the effect of improving work efficiency and preventing pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Several specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

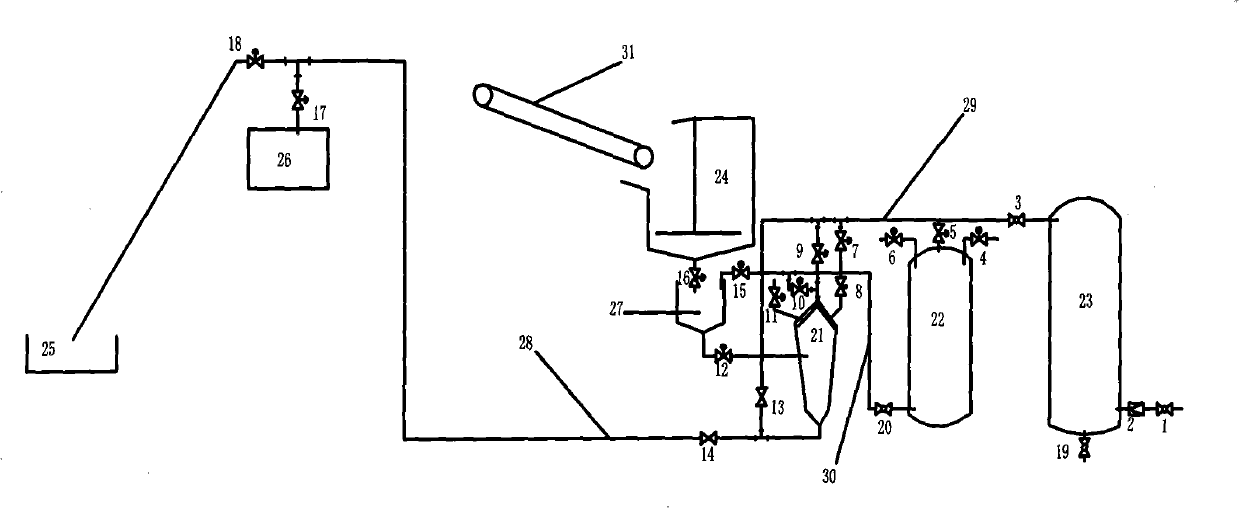

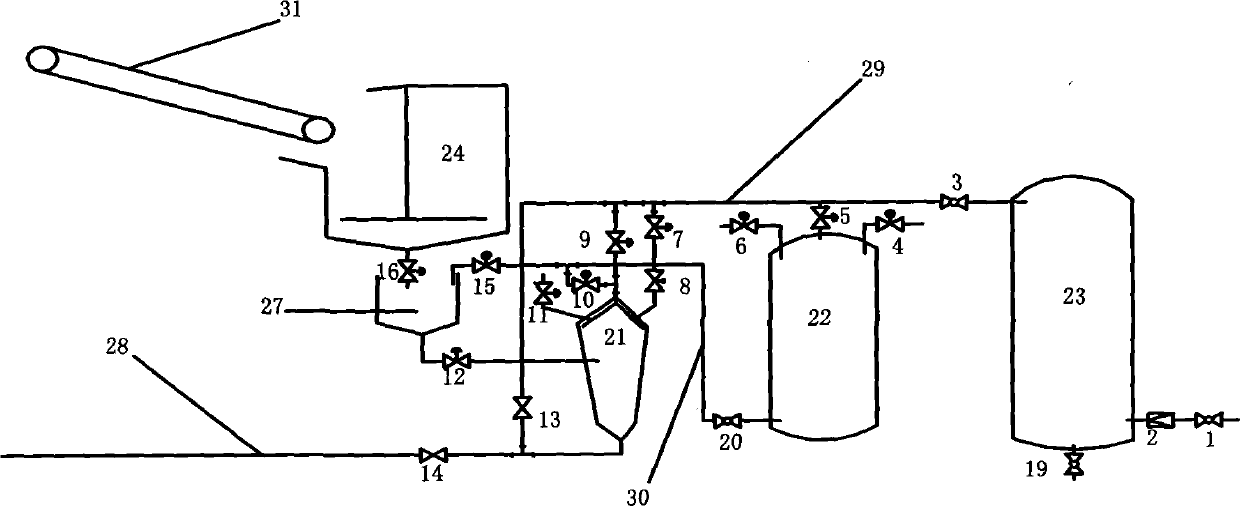

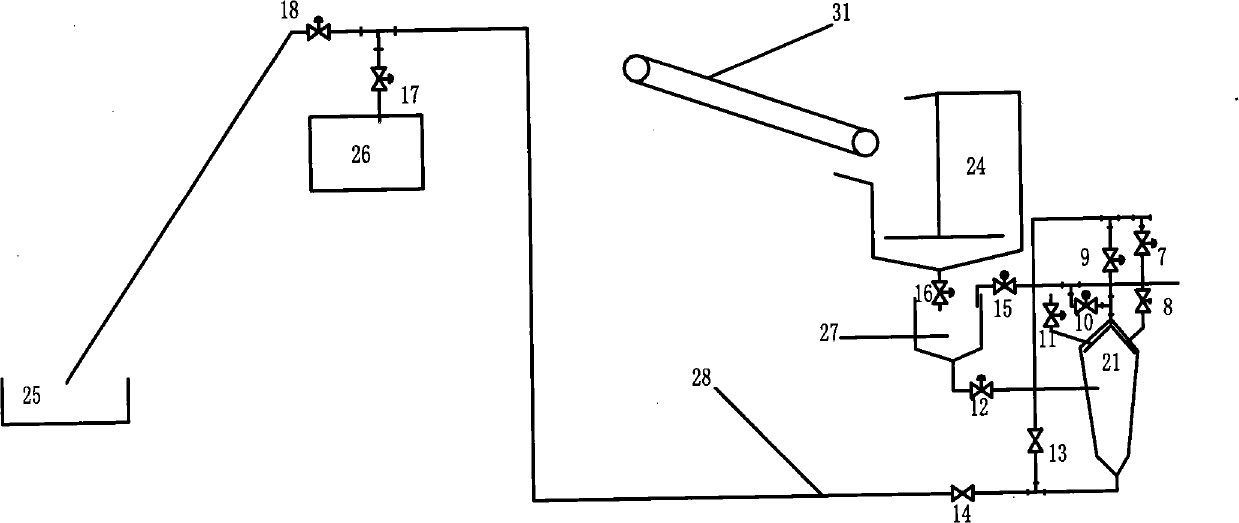

[0025] Such as Figure 1-Figure 3 As shown, the pipe pile residual slurry recovery device of the present invention includes a feeding tank 21, an air storage tank 23, a material receiving mixing tank 24 and a waste material pool 25, and the material receiving mixing tank 24 receives the concrete slurry input by the rubber hose 31, and continuously stirs the remaining slurry. slurry, receiving mixing tank 24 is connected to feeding tank 21 through discharge valve 12, and gas storage tank 23 is provided with inlet valve 1 and outlet valve 3, and inlet valve 1 imports external gas into the inside of gas storage tank 23, and gas storage tank There is a certain amount of gas stored in 23. When the pressure is constant, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com