Turnover degumming all-in-one machine

An all-in-one machine and turning mechanism technology, which can be used in work accessories, stone processing equipment, manufacturing tools, etc., and can solve problems such as the cumbersomeness of the one-piece connecting plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

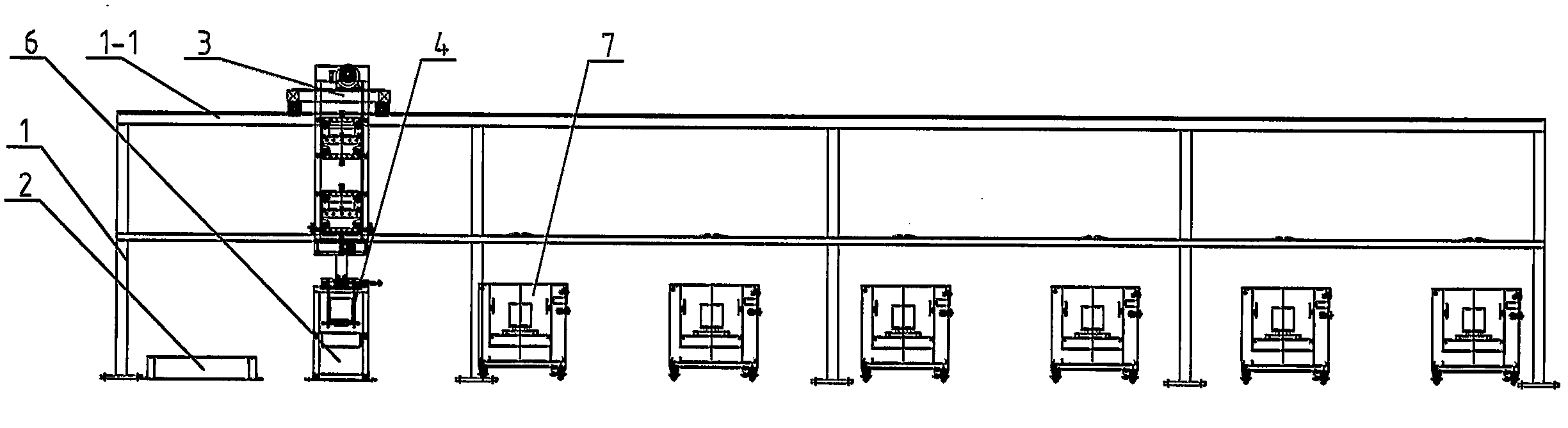

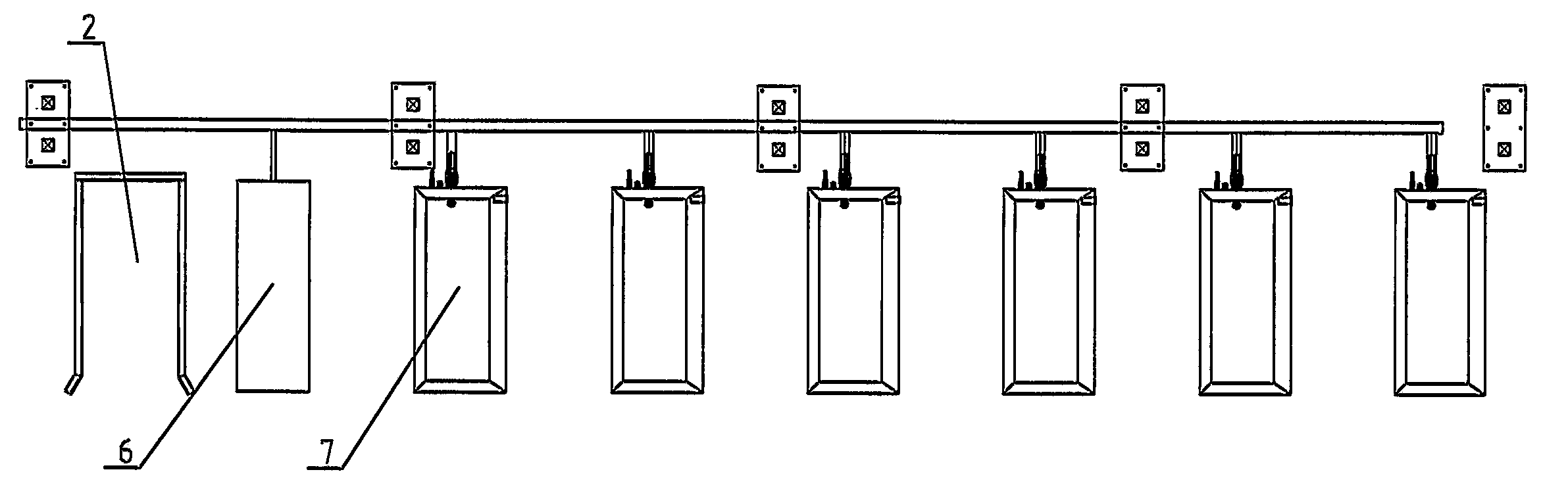

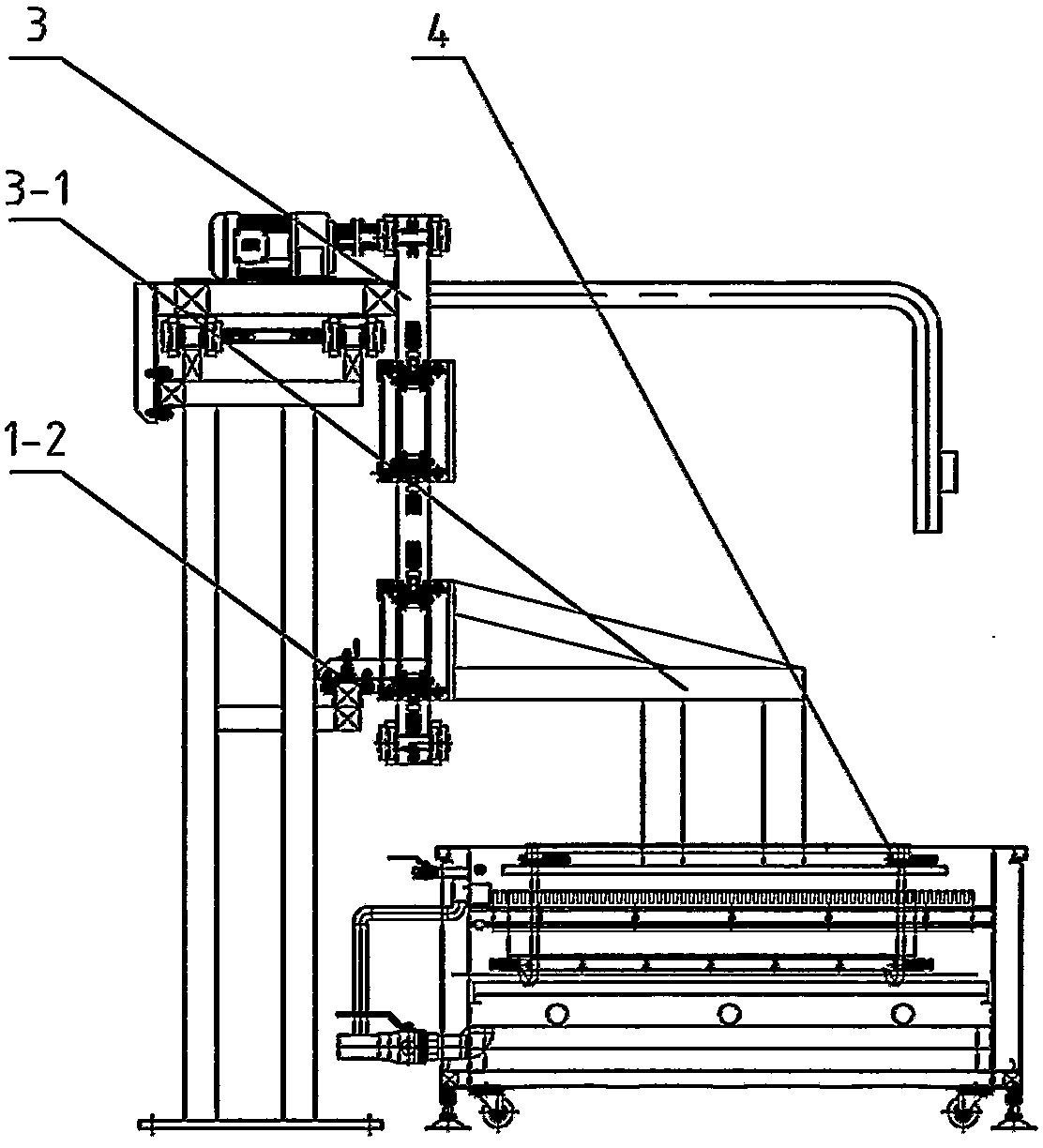

[0022] like Figure 1~11 As shown, a turning and degumming all-in-one machine includes a frame 1, a feeding guide frame 2, a manipulator 3, a lifting workpiece fixture 4, a silicon wafer box, and a turning machine for turning over the connecting plate 5 with silicon wafers stuck on the front and back sides. Mechanism 6 and multiple heating and degumming tanks 7, feeding guide frame 2, turning mechanism 6 and multiple heating and degumming tanks 7 are arranged side by side in sequence, and the upper part of frame 1 is provided with manipulator rail device 1-1, and manipulator 3 can slide It is installed on the manipulator rail device 1-1, and is located above the feeding guide frame 2, the turning mechanism 6 and a plurality of heating degummin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com