Clamping grinding device for steel sample and method

A chuck and fixture technology, which is applied in the field of inspection and testing equipment, can solve problems affecting the accuracy of analysis results, steel samples falling off and splashing and hurting people, easy to fall off and splashing and hurting people, etc., so as to reduce sandpaper consumption, improve operation efficiency, and eliminate safety hazards. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the present invention will be further described in conjunction with the accompanying drawings.

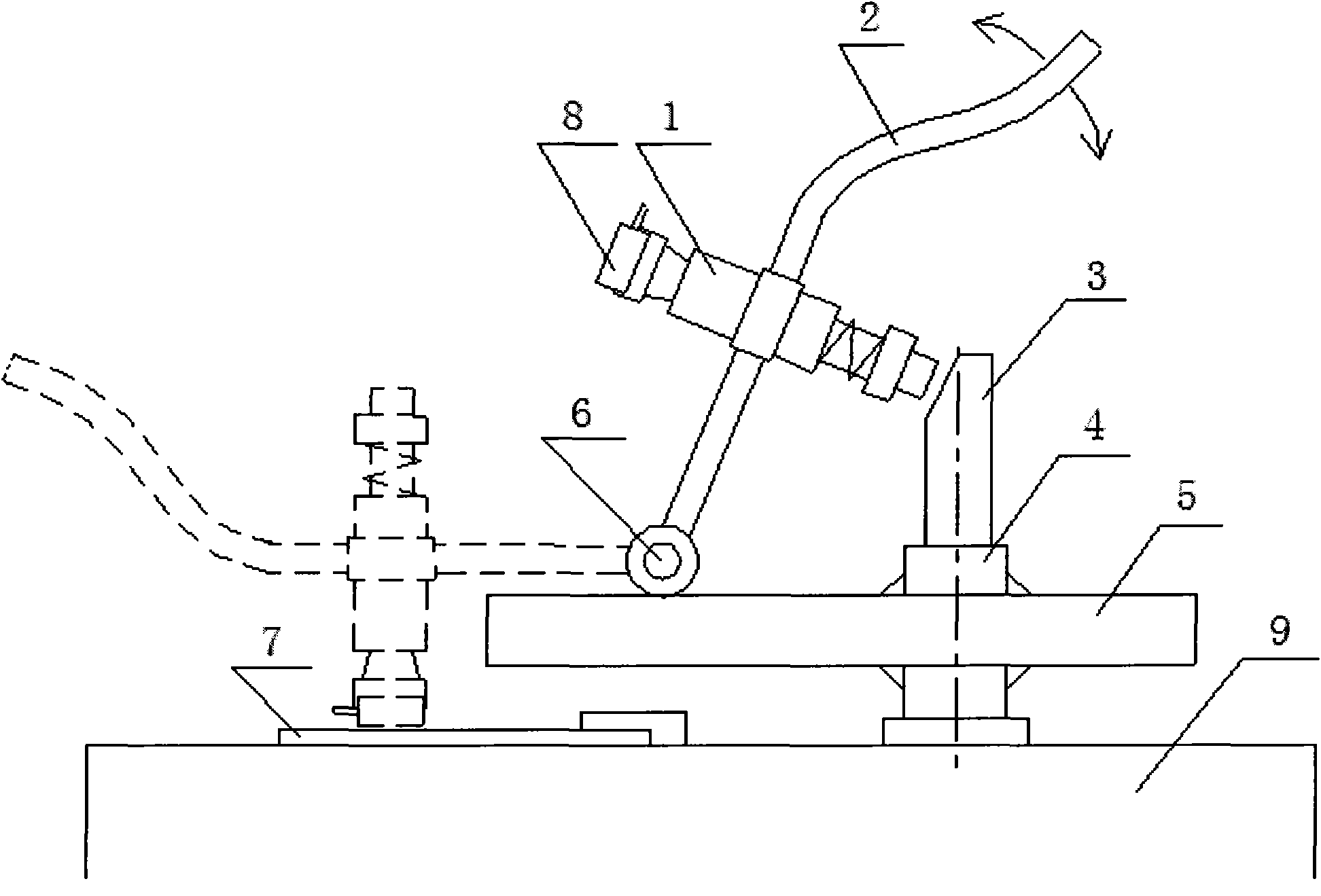

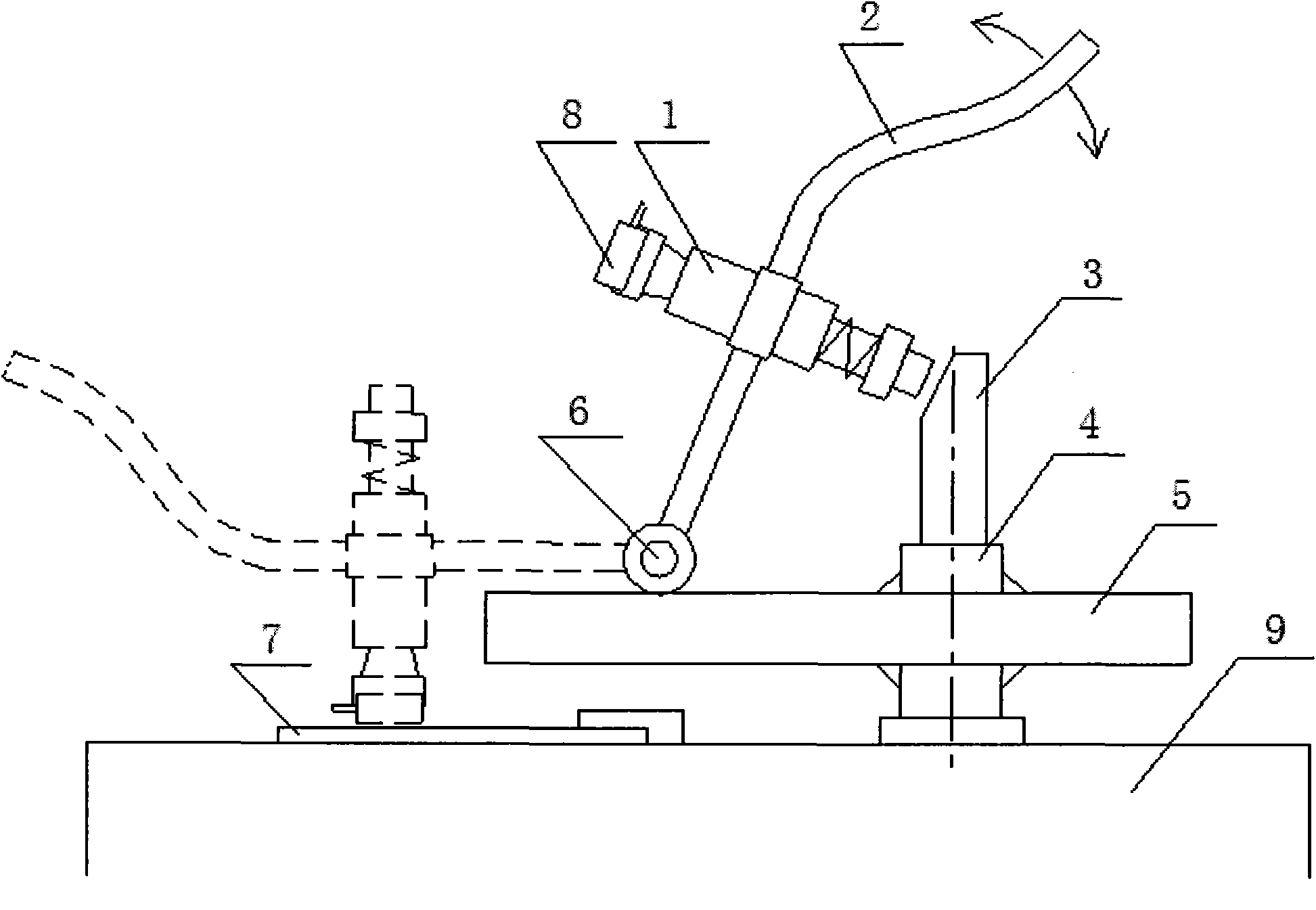

[0031] Depend on figure 1 It can be seen that the steel sample clamping and grinding device of the present invention is mainly composed of a clamp 1, a turning lever 2, a meeting head 3, a rotating shaft 4, a support plate 5, a hinge shaft 6 and a sample grinding machine platform 9. The support plate 5 is movably connected to the right side of the upper surface of the sample mill platform 9 through the rotating shaft 4, and the supporting plate 5 can rotate horizontally with the rotating shaft 4 as an axis. A meeting head 3 is arranged on the upper end of the rotating shaft 4, and the top of one side of the meeting head 3 has an inclined surface; a clamp 1 is fixed on the straight bar section in the middle of the curved turning bar 2, and the lower end of the turning bar 2 is hinged on the support plate 5 through the hinge shaft 6 On the left side of the upper surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com