New use of plotting-cutting machine for manufacturing sandwich glass

A technology of laminated glass and cutting machine, applied in the directions of lamination, layered products, lamination auxiliary operation, etc., can solve the problems of uneven force, cutting through, time-consuming and laborious, etc., and achieve the effect of semi-automatic operation and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

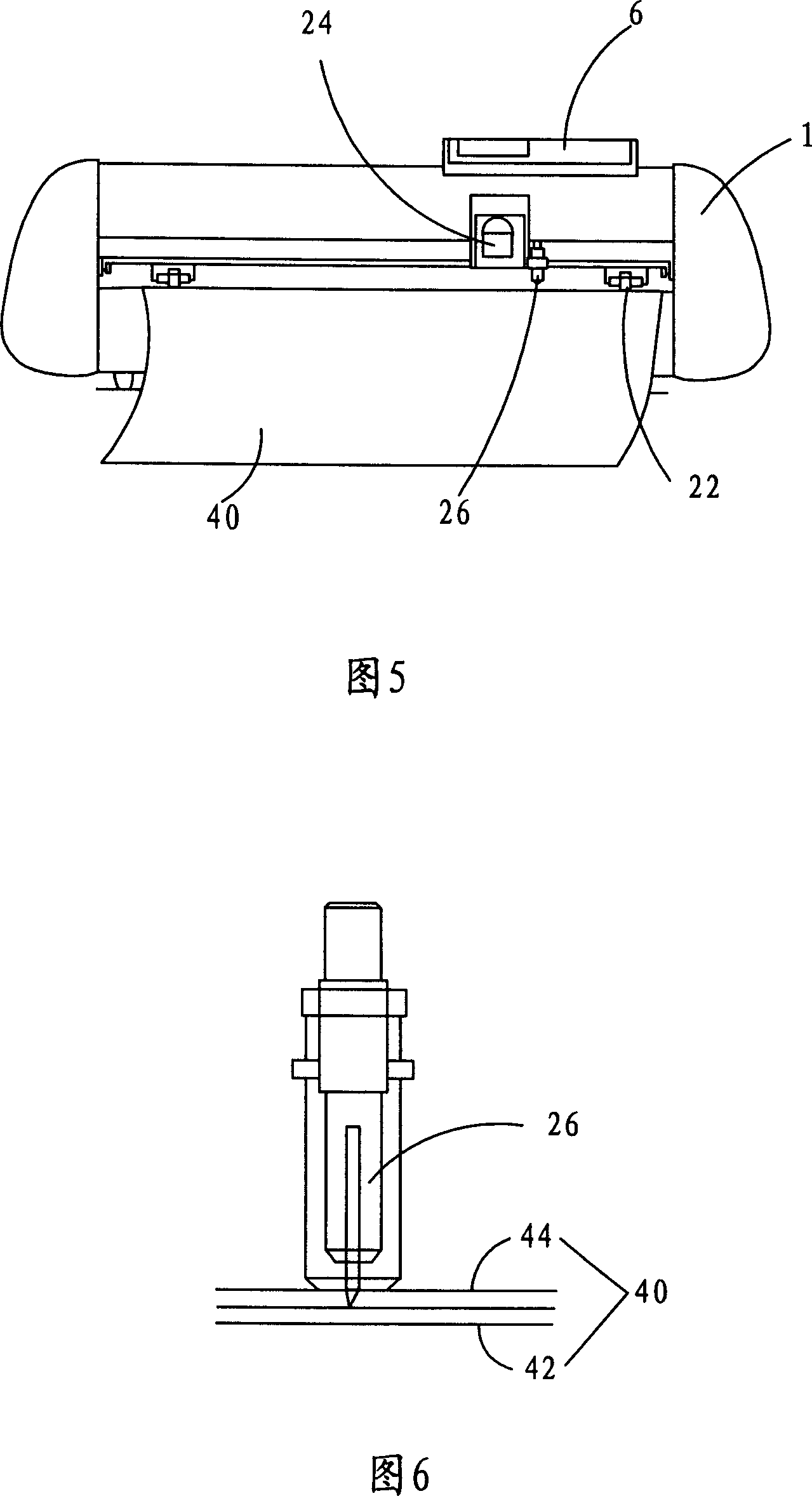

[0021] The new application of the plot cutting machine of the present invention in the manufacture of laminated glass, the plot cutting machine is used to cut the heat reflective film layer 44 in FIG. 7 .

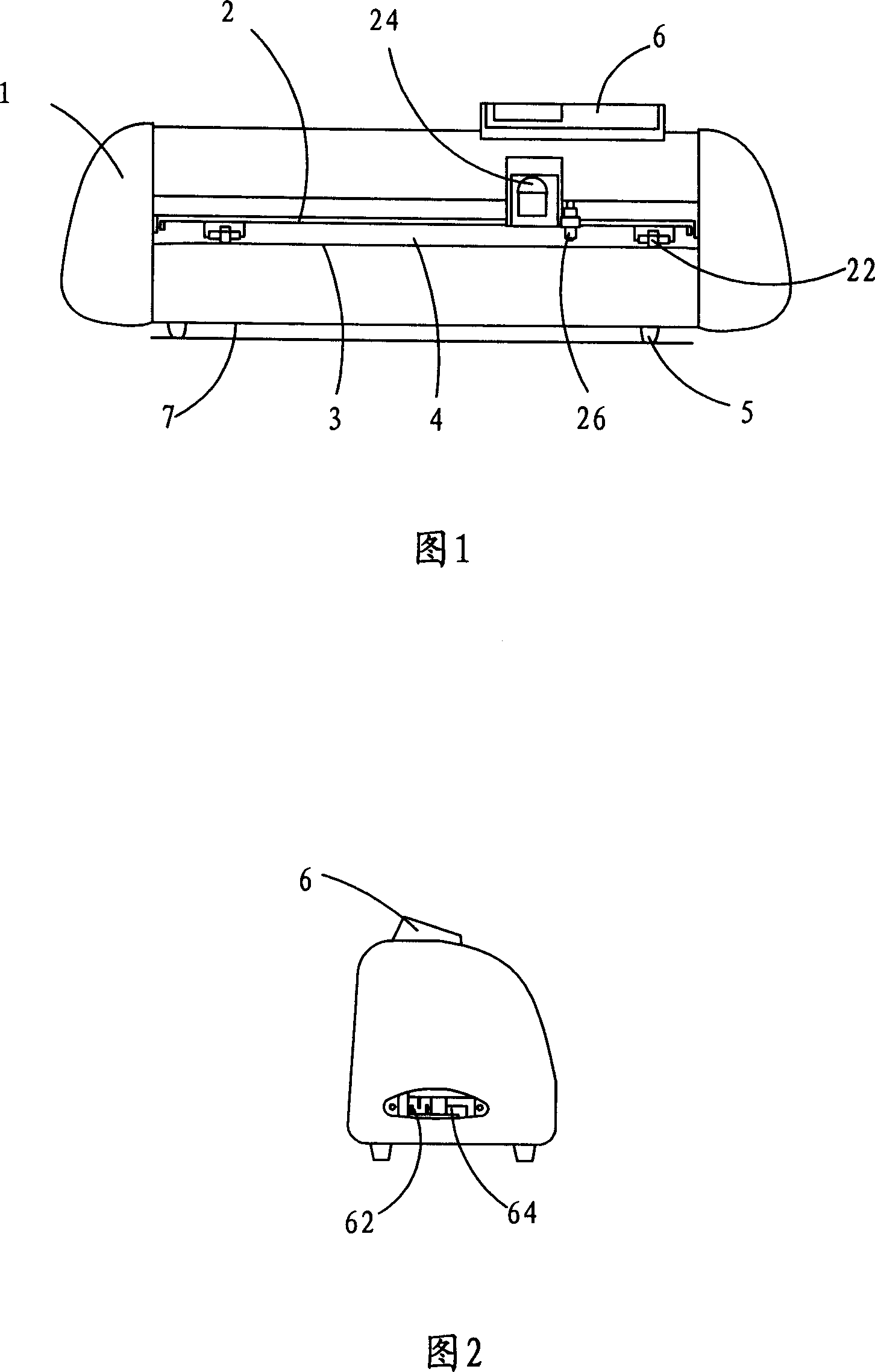

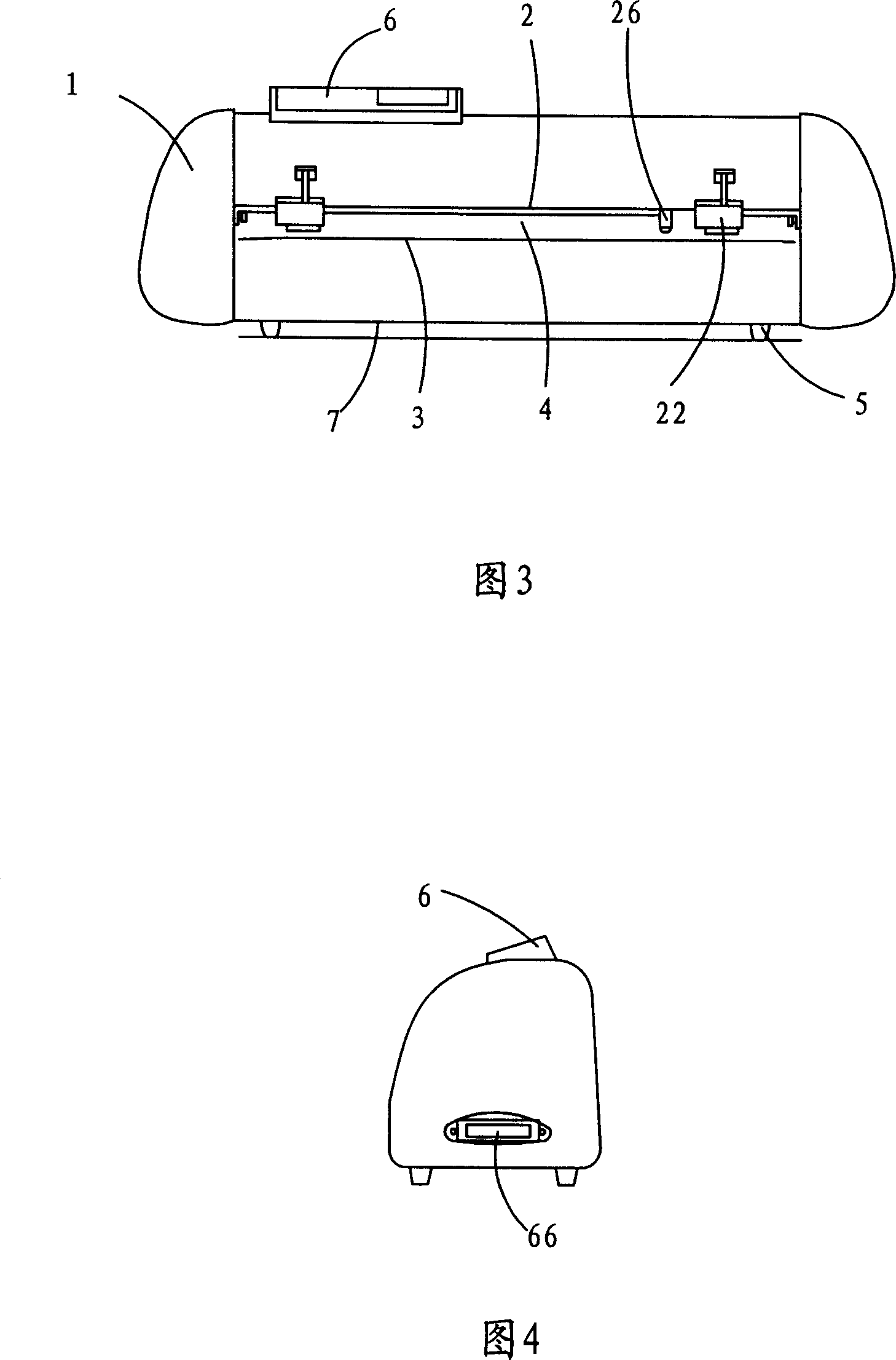

[0022] Please refer to Figure 1, the cutting machine includes a frame 1, a beam 2 fixed above the frame 1, a transmission spindle 3 fixed below the beam 2, a gap 4 in the middle of the frame, and a foot pad at the bottom of the cutting machine 5. The control panel 6 and the bottom plate 7 located at the top of the cutting machine.

[0023] A plurality of pressure rollers 22, a sports car 24 and a cutting knife 26 are fixed on the beam 2, the cutting knife 26 is fixedly connected to the sports car 24, and the sports car 24 drives the cutting knife 26 to move left and right under the control of the control panel 6. The pressing rollers 22 are used to press and fix the PVB functional film layer 40 , and the number of the pressing rollers 22 can be determined according to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com