Rolling tea retaining device

A technology of tea utensils and baffle plates is applied in the fields of rolling tea stoppers and tea making tools, which can solve the problems of inability to change the rolling pressure, high manufacturing cost, low tea production efficiency, etc., and achieve the effect of good implementation effect and improved taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

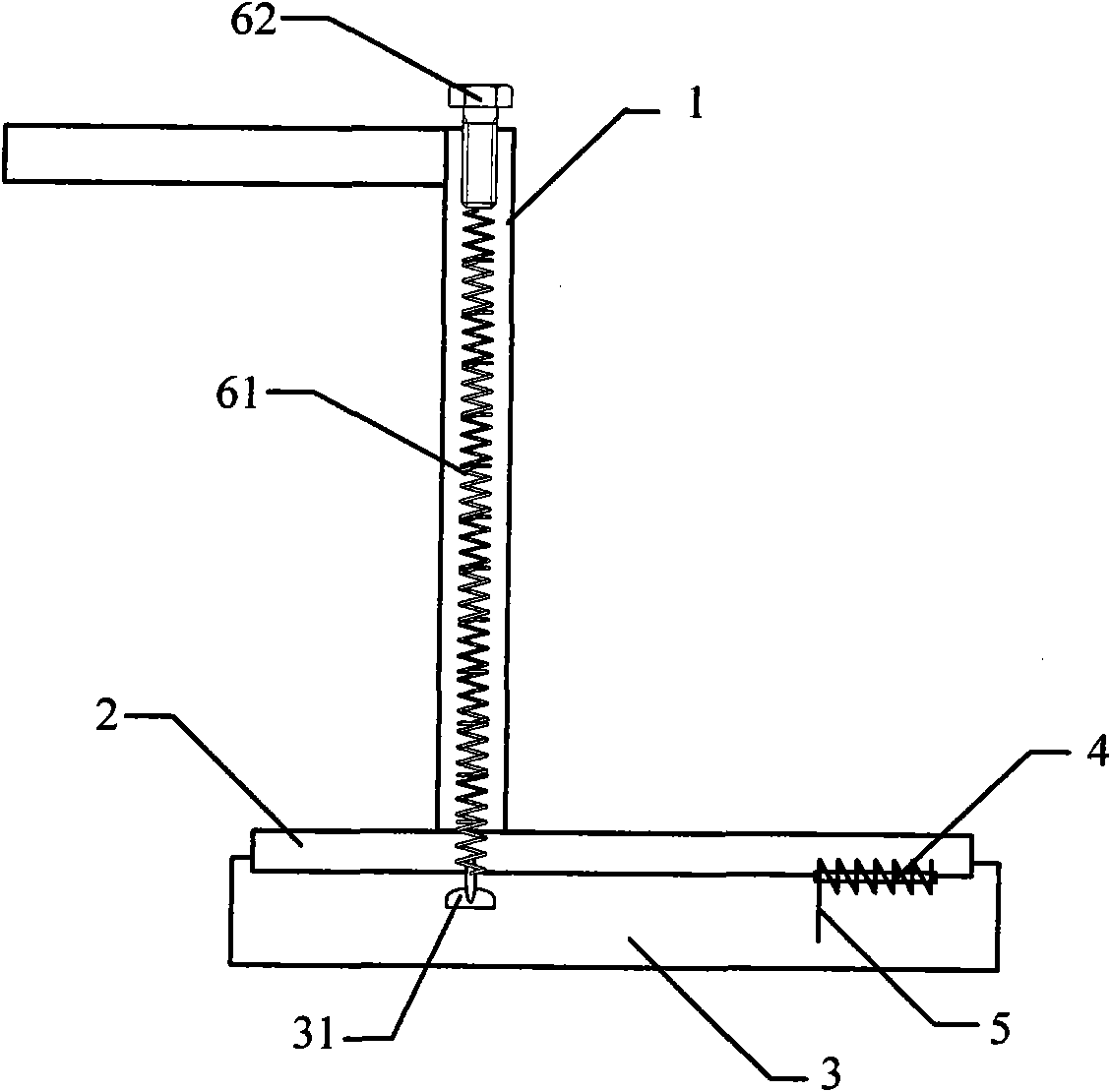

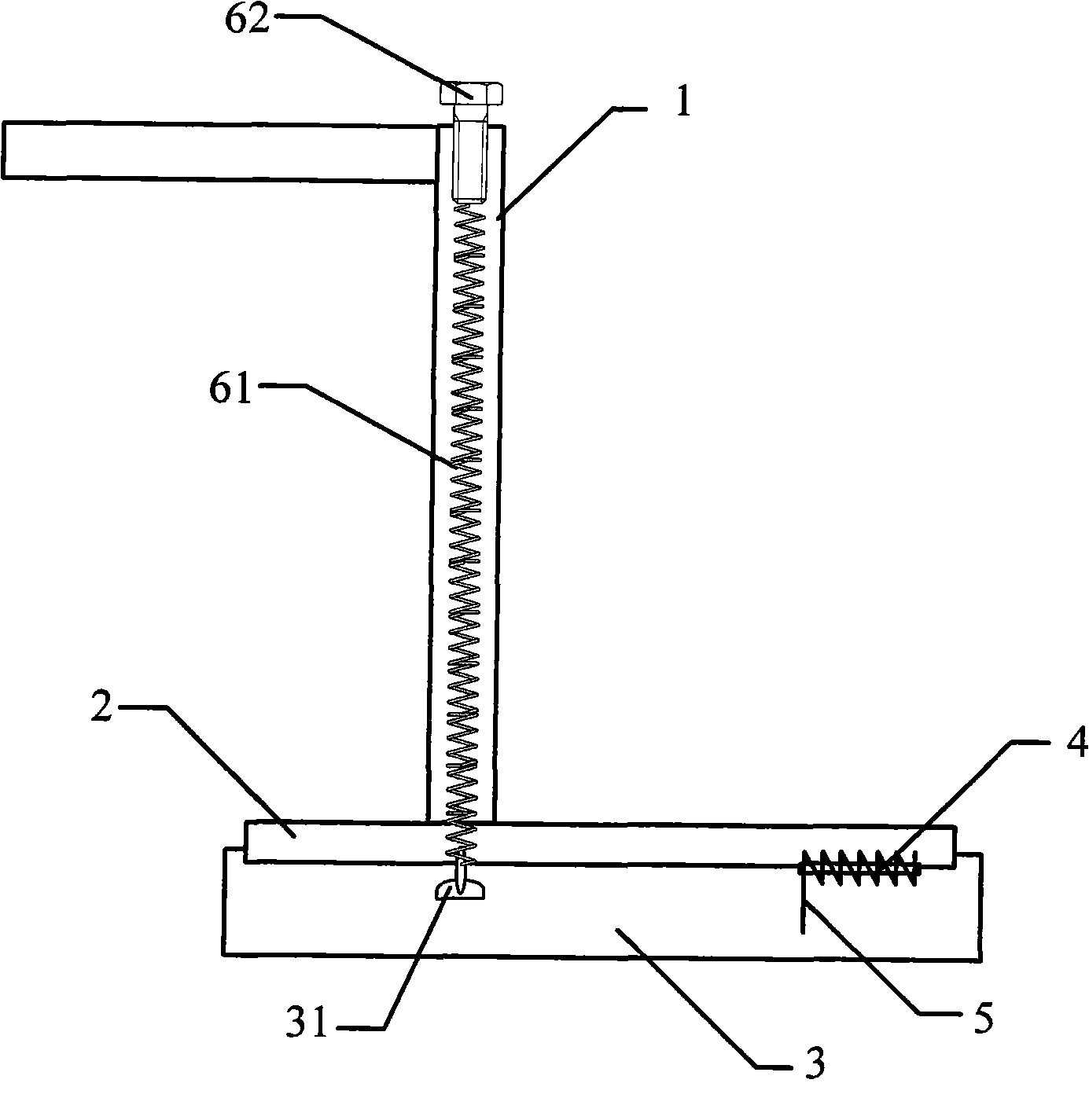

[0016] Such as figure 1 The rolling tea retainer shown, wherein: it includes a support rod 1, a baffle plate 2, a scraper 3, and an angle adjustment device. The baffle plate 2 is connected to the end of the support rod 1. An angle adjustment device is installed, and the scraper 3 is connected to the baffle plate 2 through the angle adjustment device. In this embodiment, the angle adjusting device is a torsion spring 4 , the two ends of the torsion spring 4 extend out from the stop bar 5 , and at least one stop bar 5 is connected to the scraper 3 . Utilizing the characteristics of the torsion spring 4, an angle can be presented between the scraper 3 and the baffle 2, and its range is 0° to 90°. Angle around 15°. In order to further adjust the rolling pressure during the operation of frying tea, the rolling tea retainer of the present invention especially improves the support rod: specifically, even if the support rod is designed as a hollow rigid pipe with a spring 61 inside,...

Embodiment 2

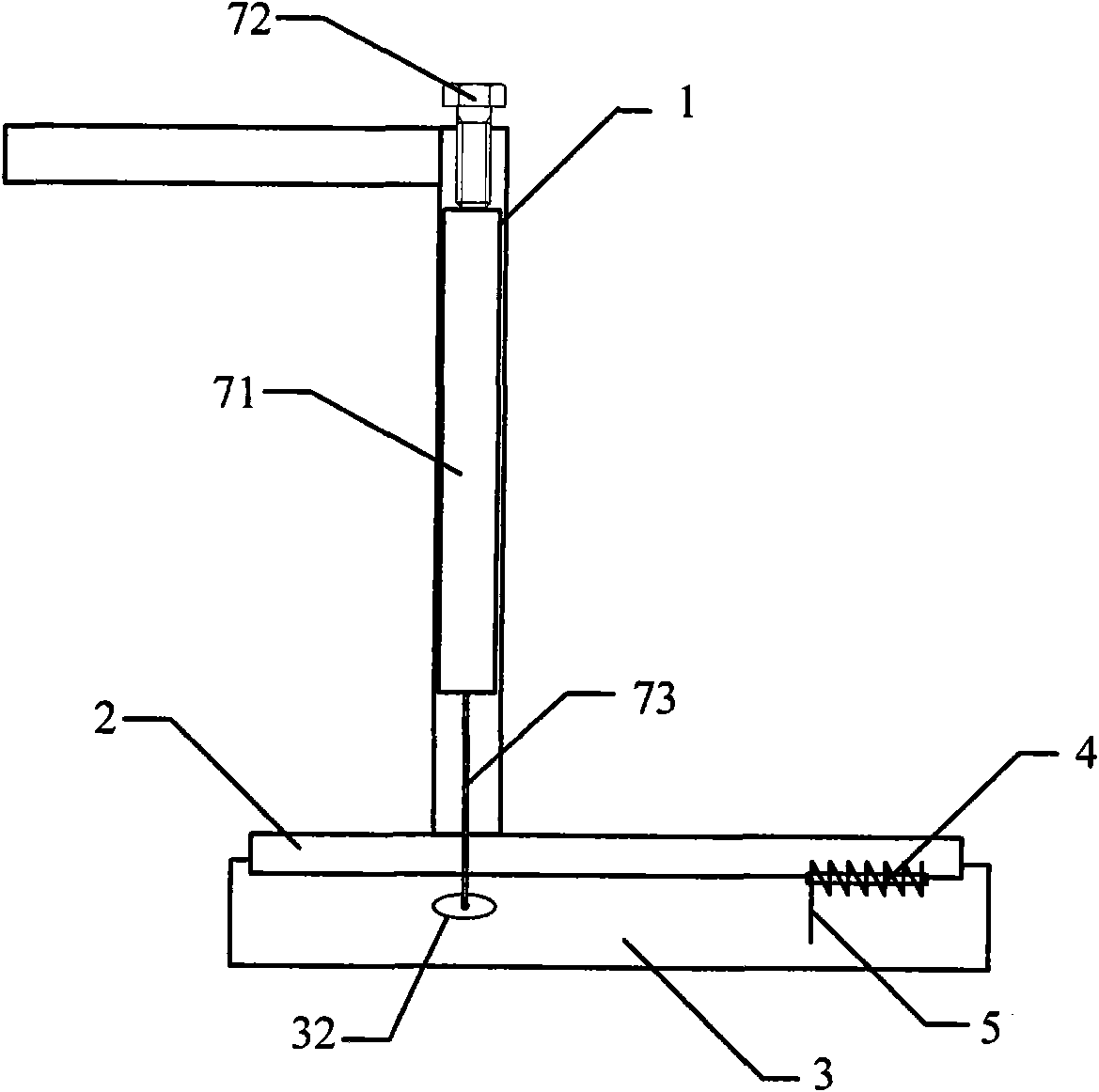

[0019] Such as figure 2 The basic structure of the twisting tea retainer shown is the same as that of the first embodiment, the difference is that in order to realize the adjustment of the rolling pressure during the operation of frying tea, the improvement of the support rod in this embodiment is as follows: the design of the support rod It is a rigid pipe body with a compressed air bag or a hydraulic cylinder 71 inside, and a threaded adjustment knob 72 is provided at one end away from the baffle to connect with the sealing baffle on one side of the compressed air bag or hydraulic cylinder, and the other end is a through nozzle. There is a thimble 73 with one end connected to the sealing baffle on the other side of the compressed air bag or the hydraulic cylinder. The thimble passes through the support rod 1 and abuts against the limit groove 32 provided at the corresponding position of the baffle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com