Patents

Literature

83 results about "Scale error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In developmental psychology, a scale error is a serious attempt made by a child to perform a task that is patently impossible because of the extreme differences in the size of the objects involved. An example of this would be a child attempting to slide down a toy slide or attempting to enter and drive a miniature toy car.

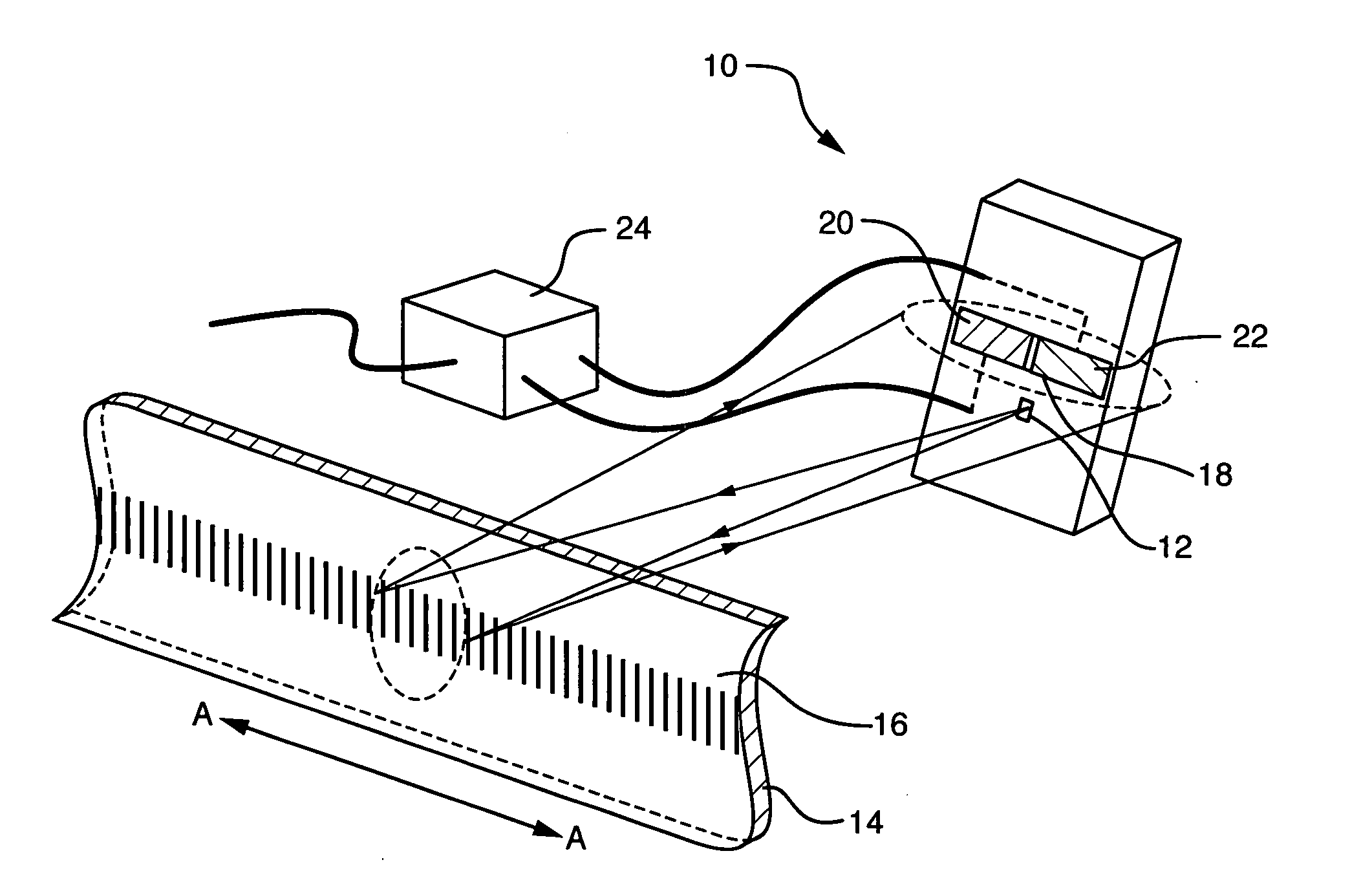

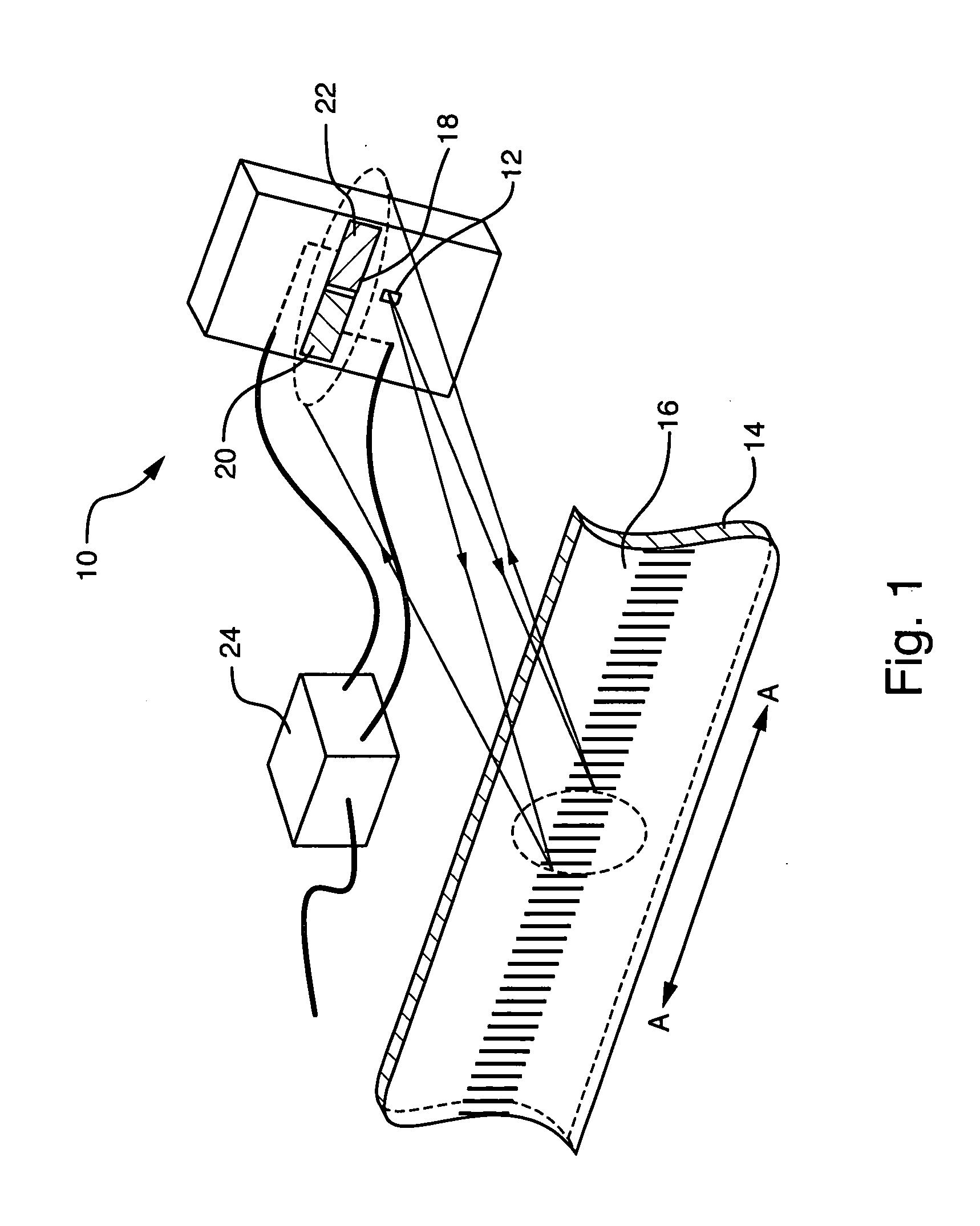

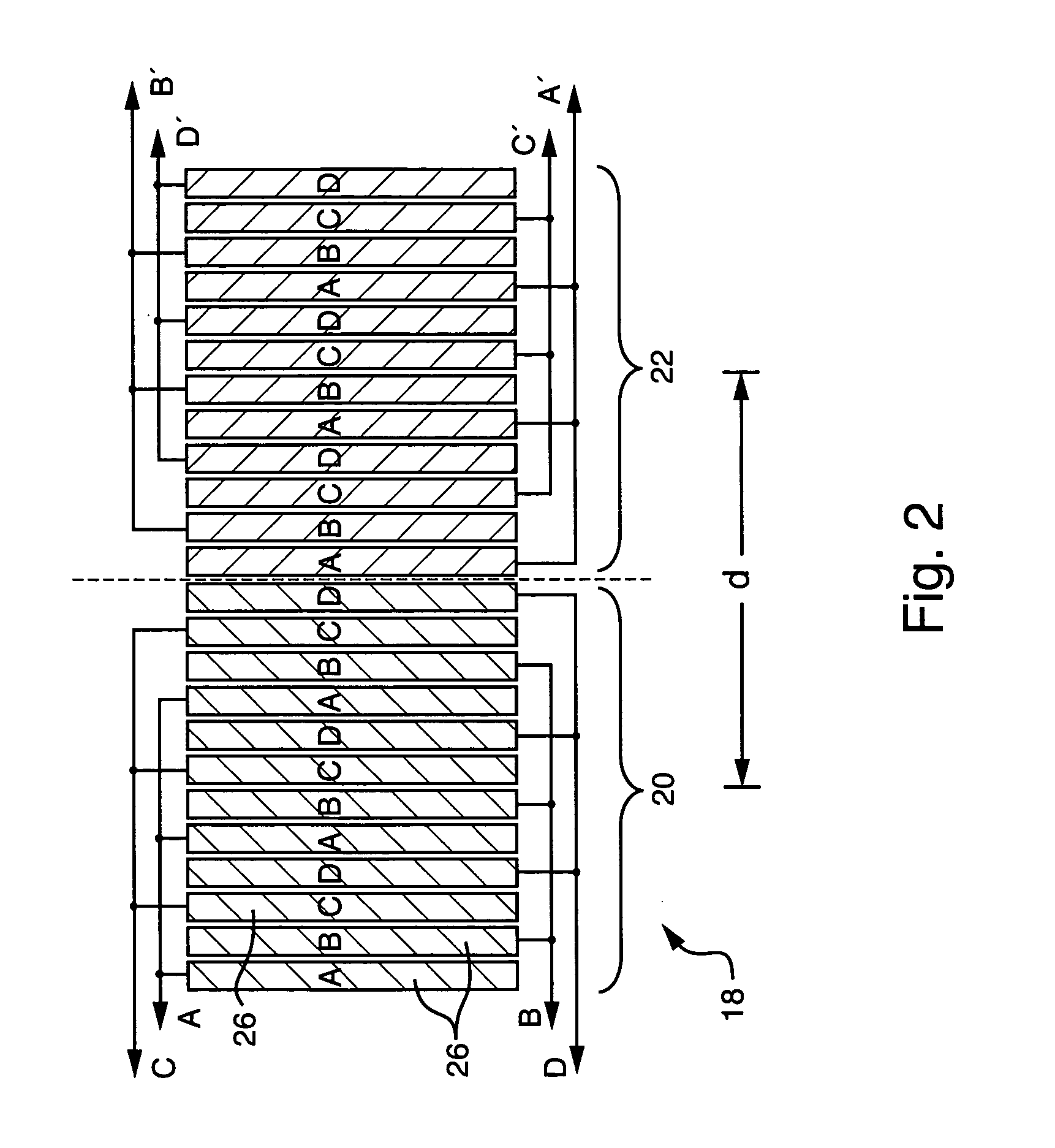

Encoder scale error compensation employing comparison among multiple detectors

InactiveUS20050274878A1High resolutionLow costMaterial analysis by optical meansUsing optical meansPhase differenceIn situ calibration

An encoder calculates position error values and applies compensation values to encoder position measurements in-situ. The encoder includes a scale and a multi-section detector for detecting a spatially periodic pattern, such as an optical interference pattern, produced by the scale. The detector includes spatially separated first and second sections. A signal processor estimates respective phase values from detector sections and calculates a phase difference reflecting a spatial position error in the scale. A compensation value is calculated from the phase difference and included in the estimate of the scale position to compensate for this spatial position error. The compensation values may be calculated and used on the fly, or calculated and saved during an in-situ calibration operation and then utilized during normal operation to compensate uncorrected measurements.

Owner:THE GSI GRP LLC

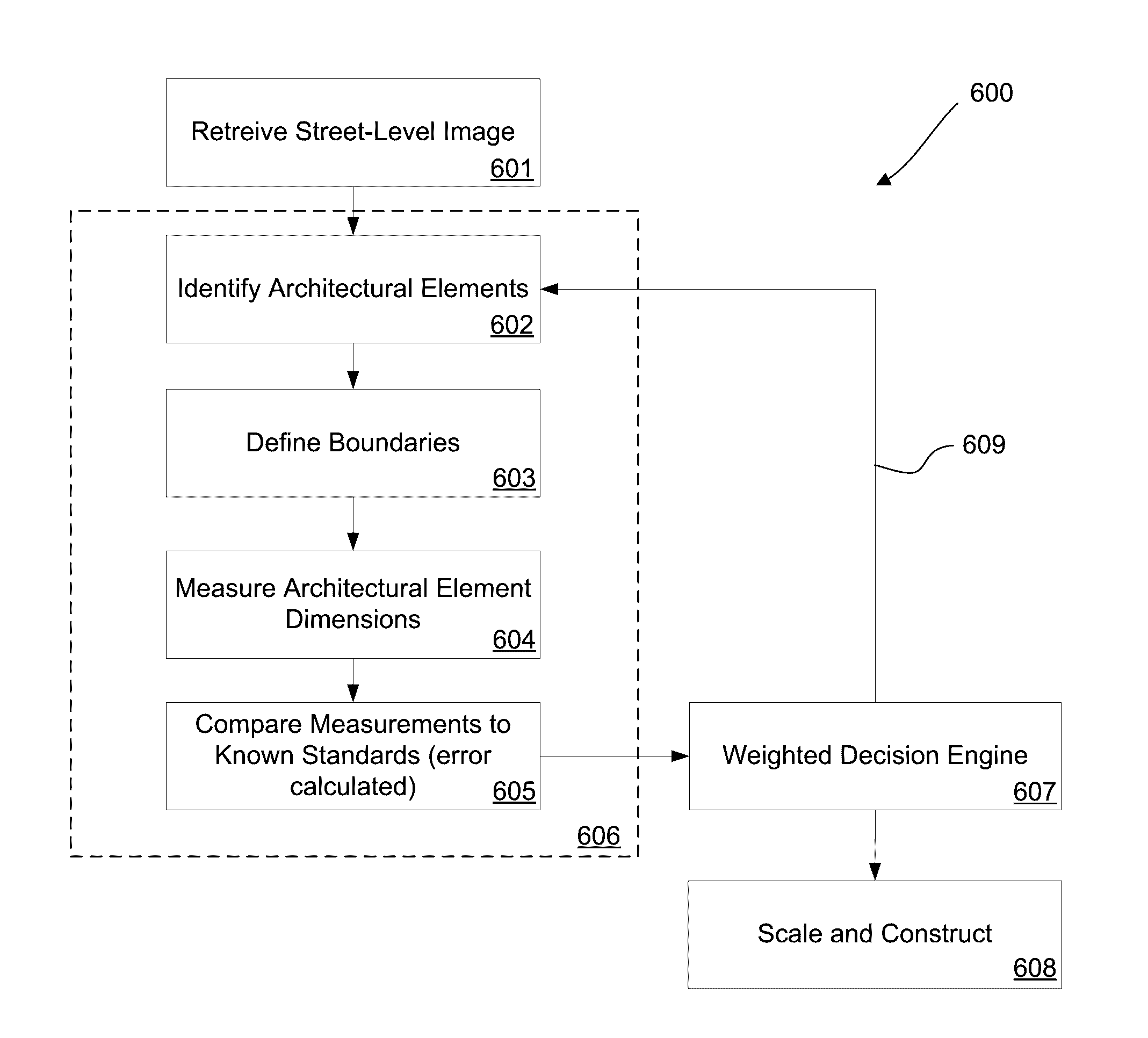

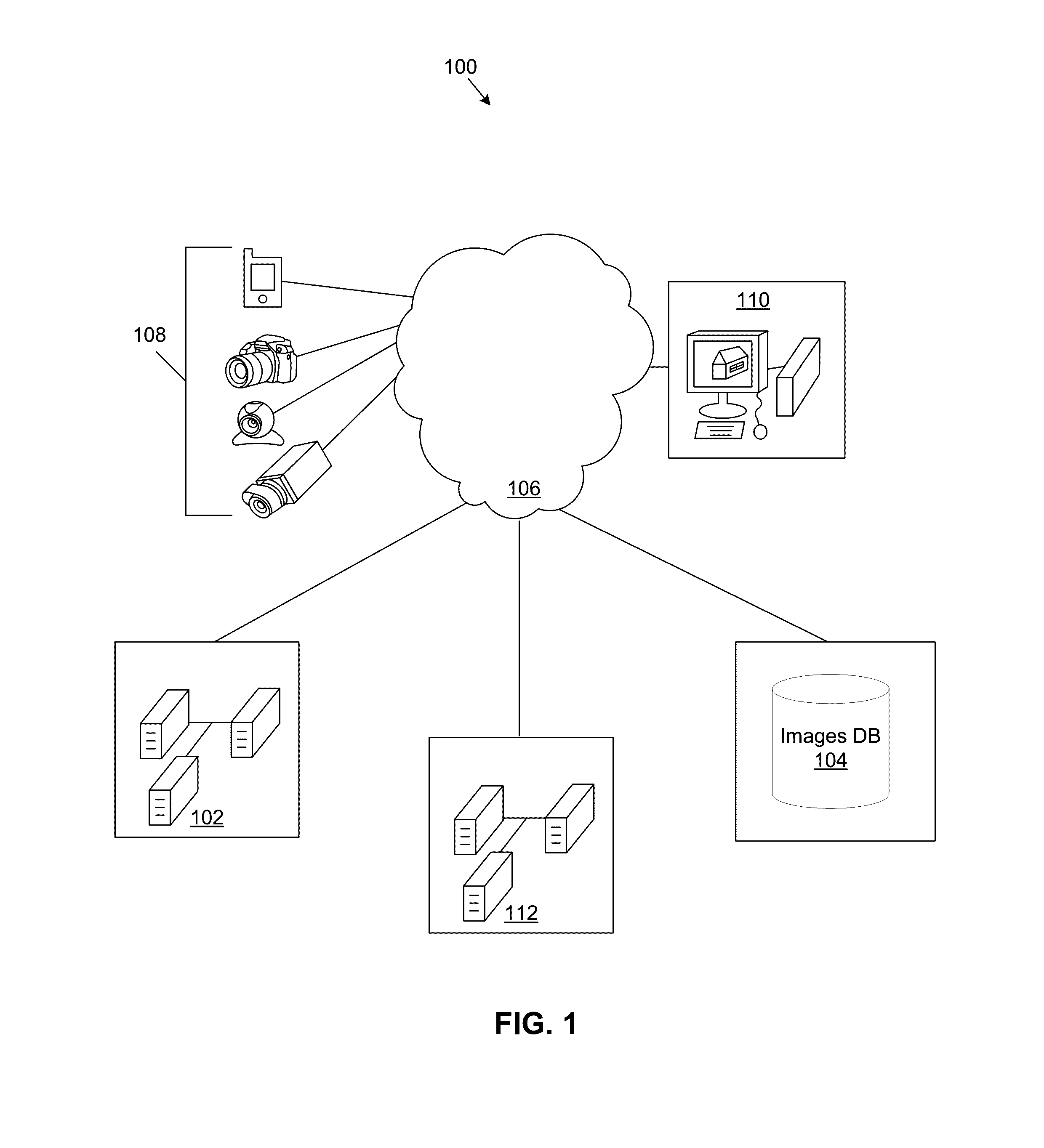

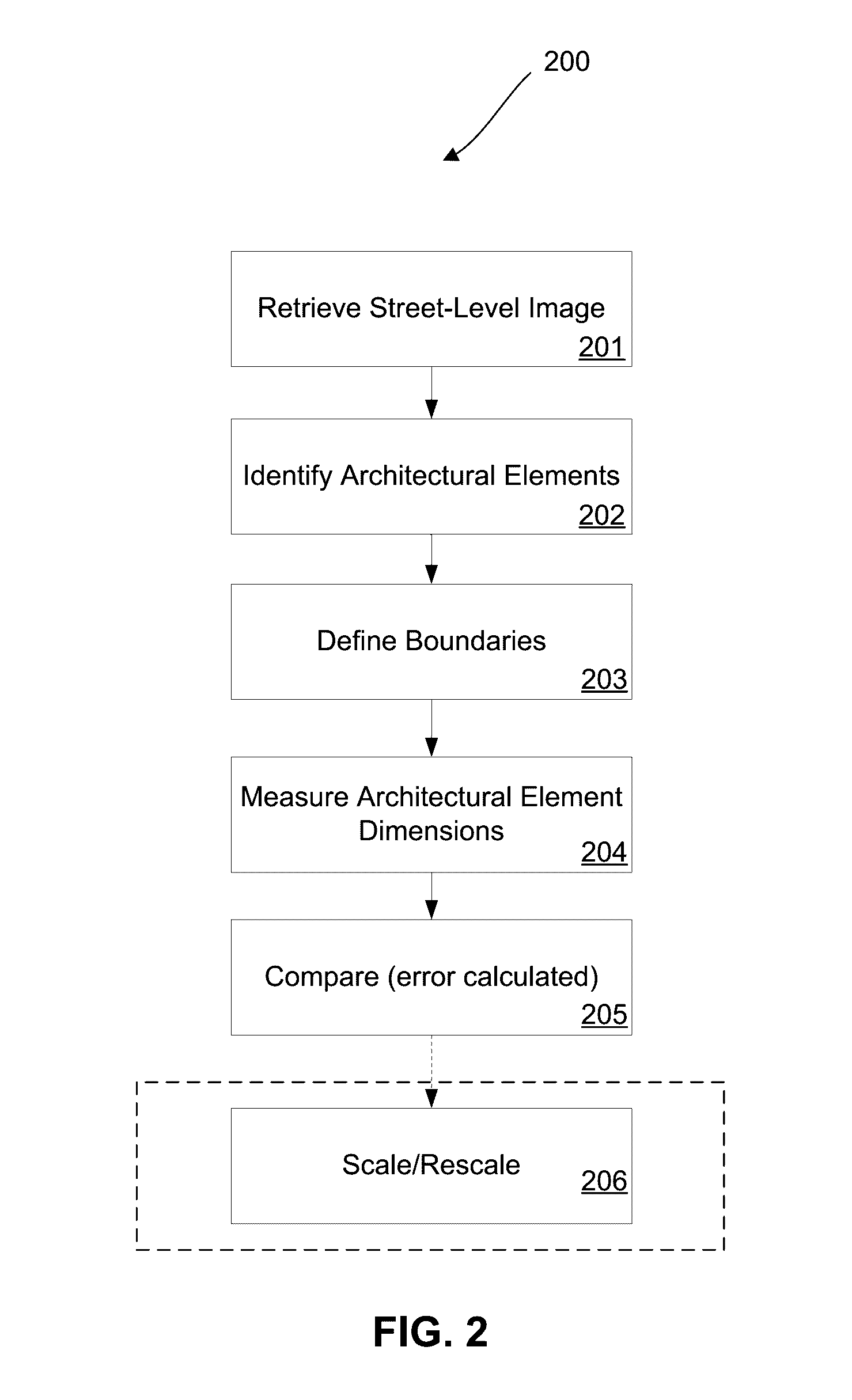

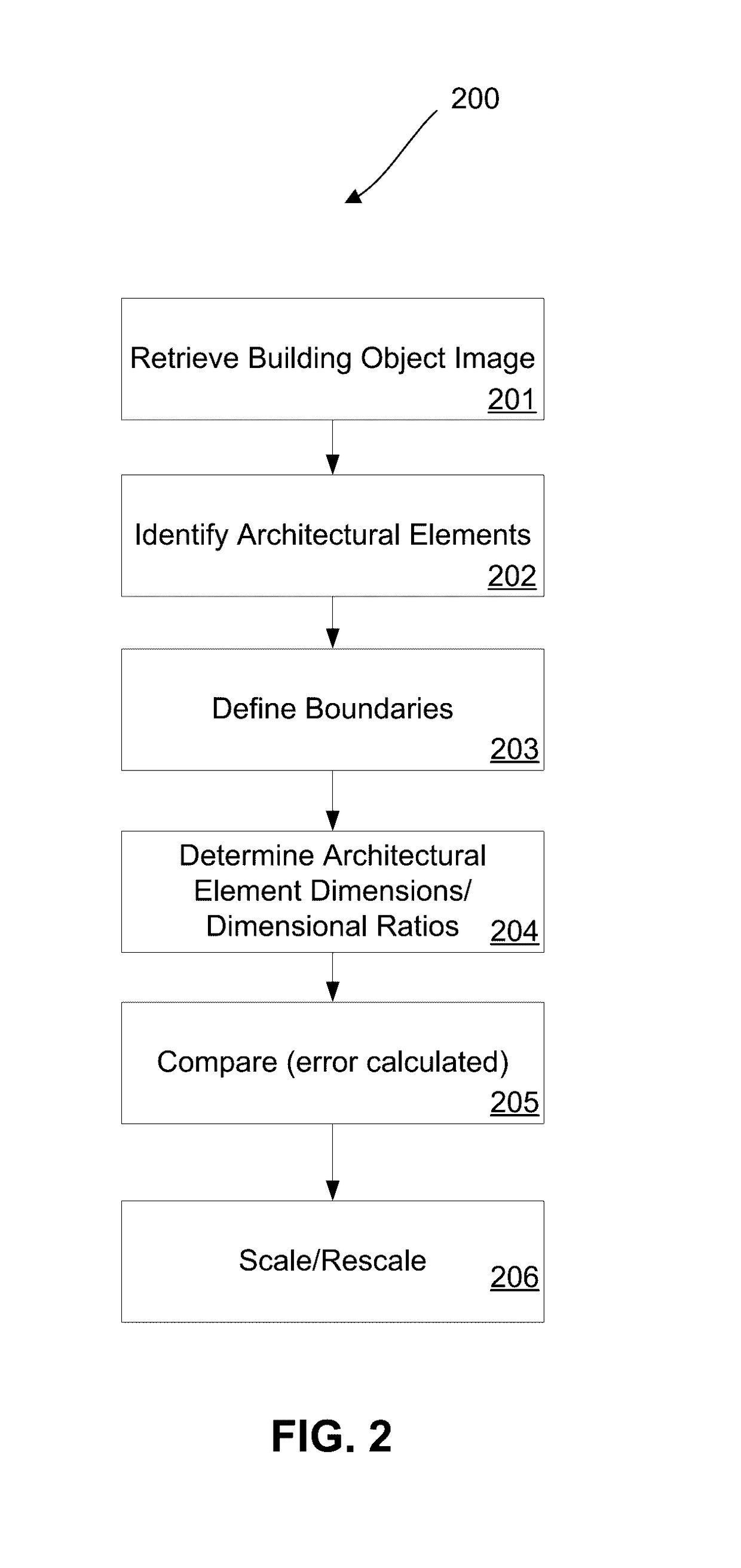

Scale error correction in a multi-dimensional model

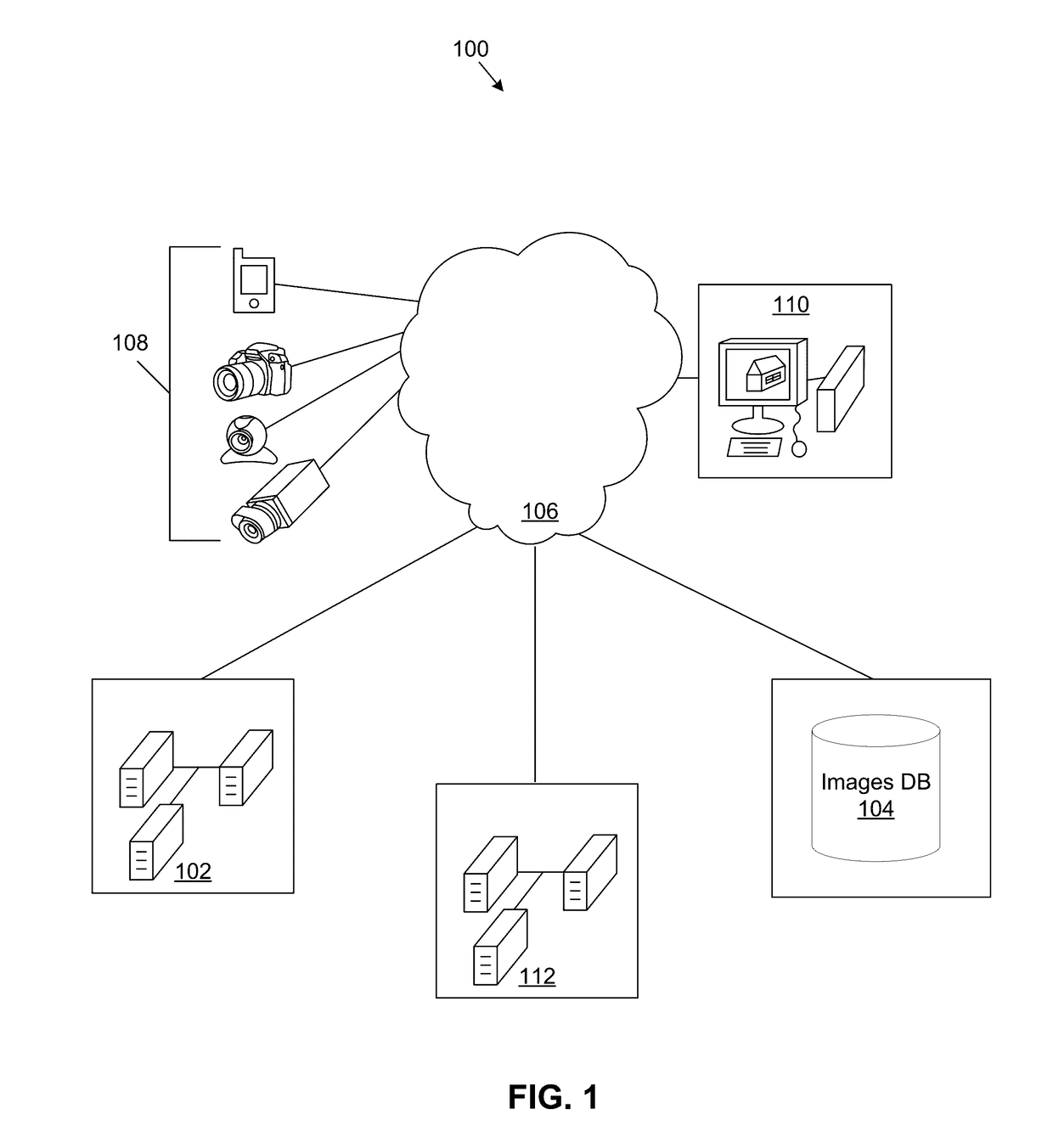

A system and method is provided for identifying error and rescaling and constructing or reconstructing a multi-dimensional (e.g., 3D) building model using street-level imagery. Street-level imagery is used to identify architectural elements that have known architectural standard dimensions. Dimensional measurements of architectural elements in the multi-dimensional building model (poorly scaled) are compared with known architectural standard dimensions to rescale and construct / reconstruct an accurate multi-dimensional building model.

Owner:HOVER

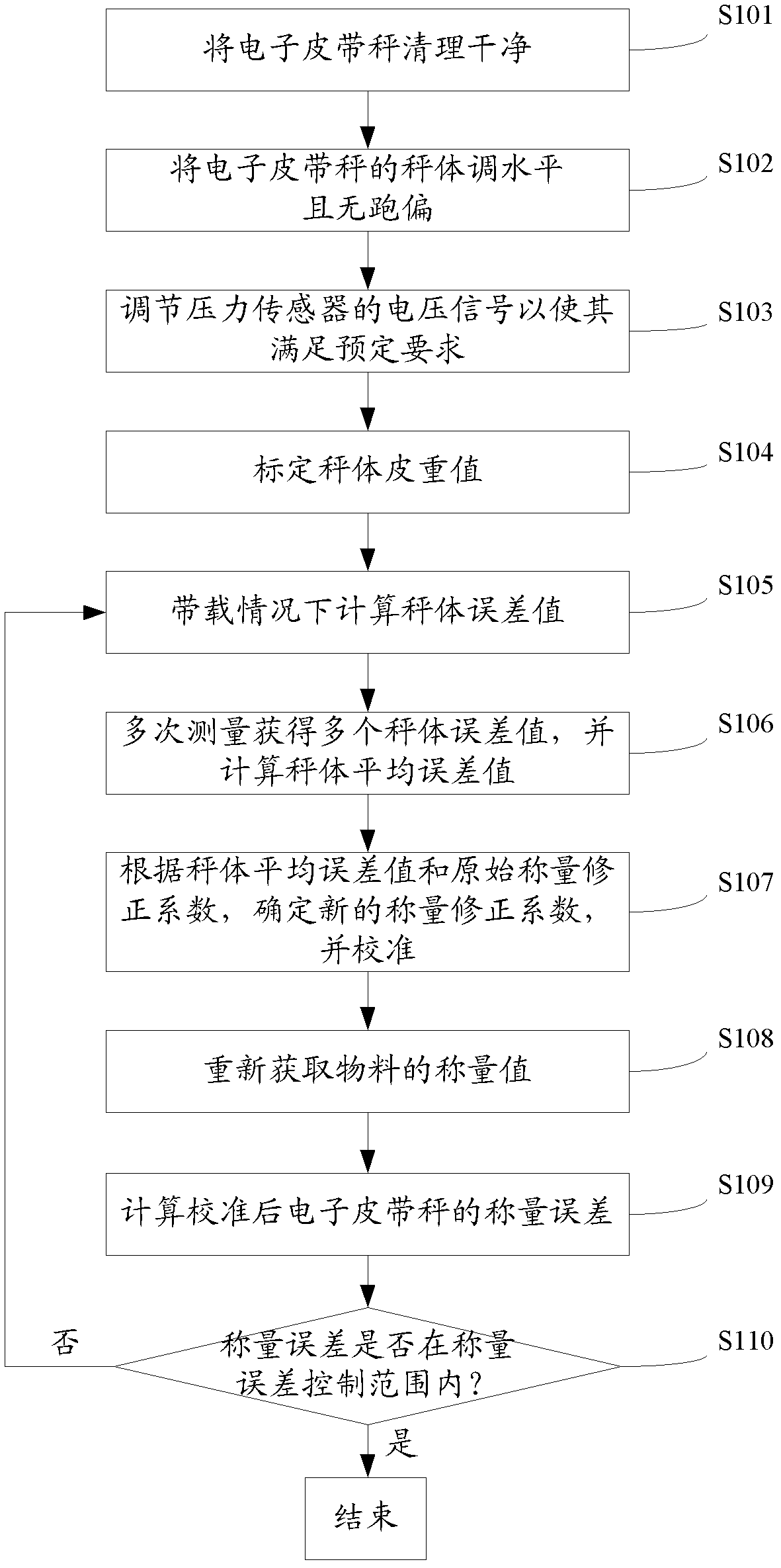

Method for calibrating electronic belt scale

InactiveCN102494753AHigh precisionEasy to operateWeighing apparatus testing/calibrationEngineeringScale error

The invention provides a method for calibrating an electronic belt scale. The method comprises the following steps of: making preparation for calibration, namely cleaning and adjusting the electronic belt scale, adjusting a pressure sensor and calibrating a tare value; on the condition that the electronic belt scale operates normally, obtaining the weighed value of a material of which the actual weight is known, and determining a scale error valve according to the actual weight and the weighed valve of the material; repeating the above measuring step so as to obtain multiple scale error values and determining an average scale error value according to the multiple scale error values; and determining a new weighed value correction factor according to the average scale error valve and an original weighed value correction factor and calibrating the electronic belt scale. The method is simple and has an obvious effect; and the calibrated electronic belt scale has high measurement accuracy and can be used for weighing large granular materials.

Owner:YUNNAN JIANSHUI MANGANESE

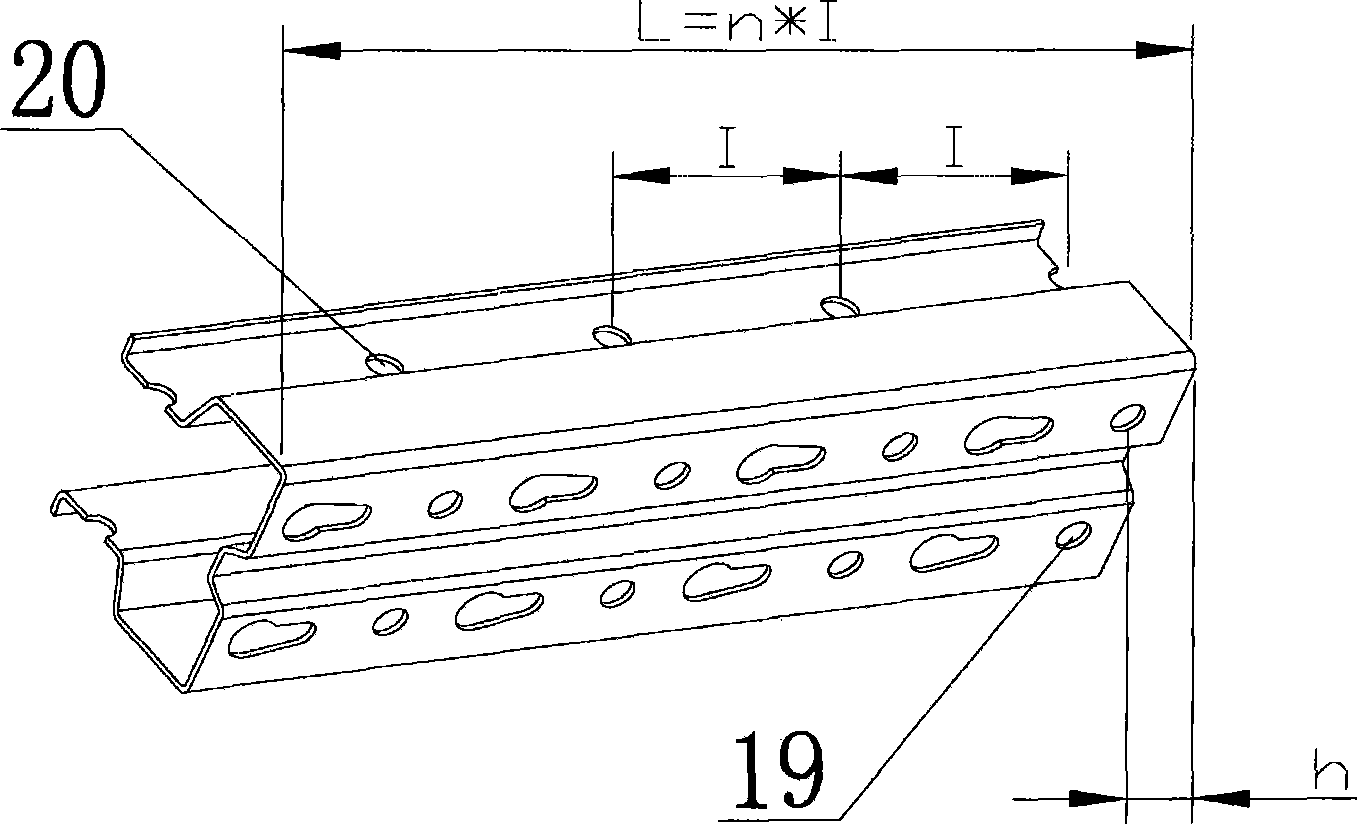

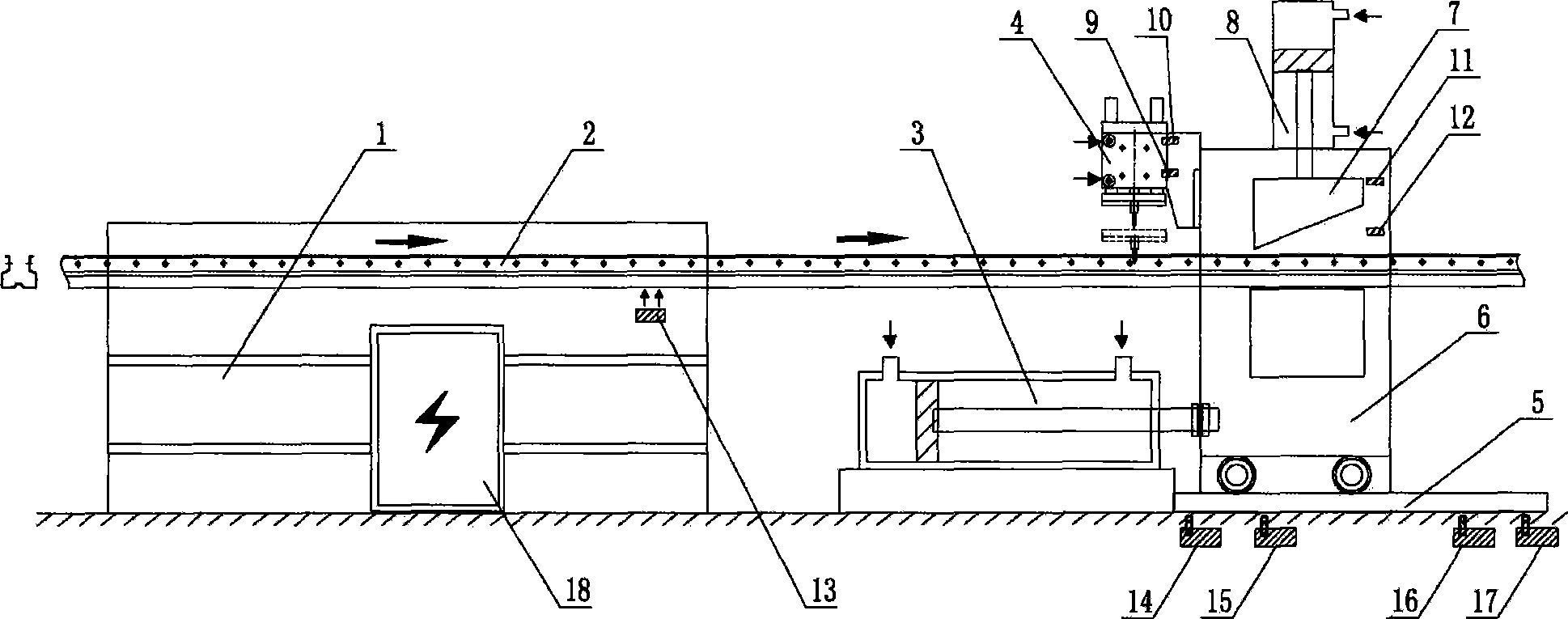

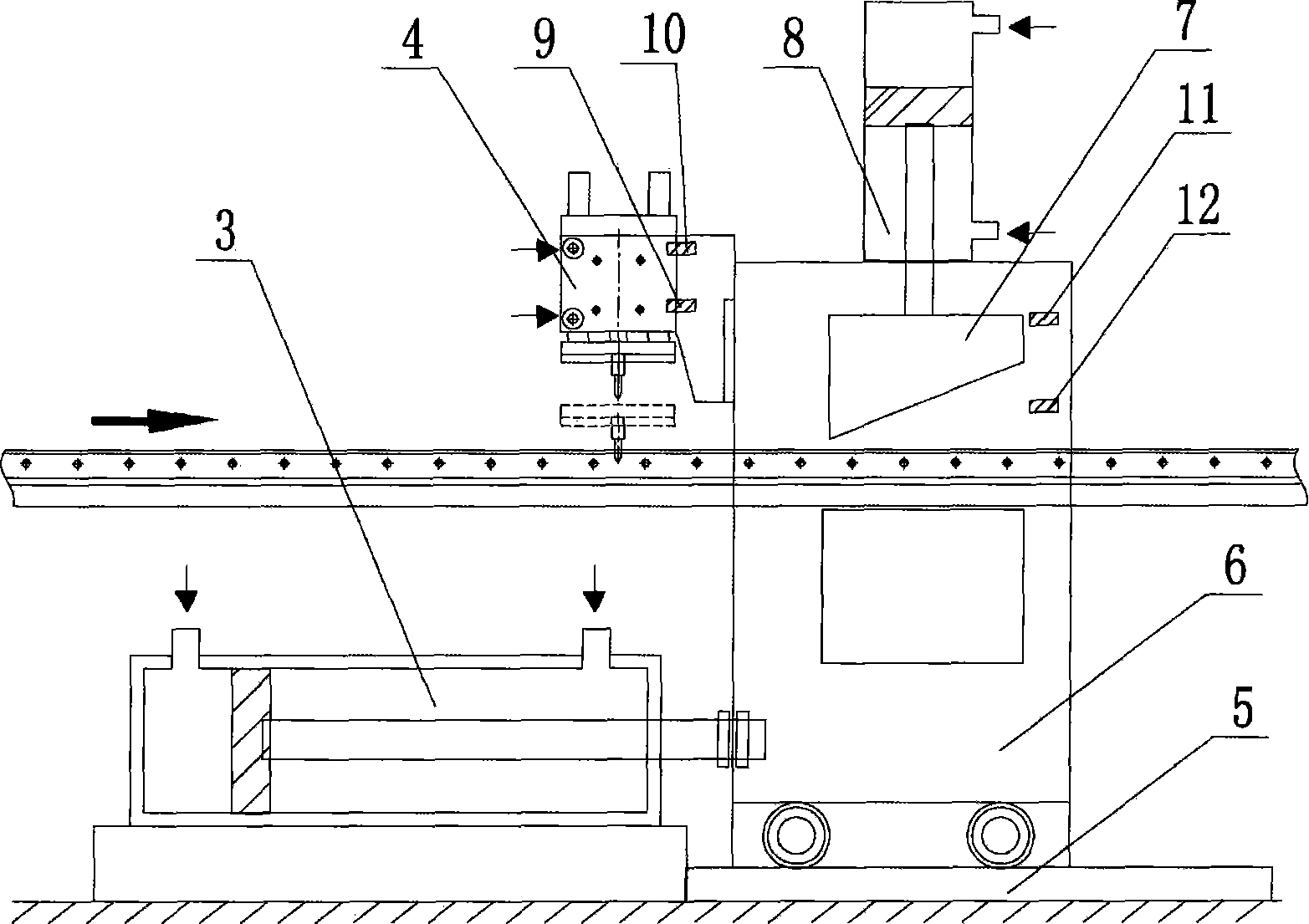

Fixed-hole fixed-length continuous shearing method of basic bore system section steel

ActiveCN101417353AGuaranteed accuracyHigh precisionShearing machinesMetal rolling arrangementsLength measurementMechanical engineering

The invention relates to a continuous shearing method of a basic hole system section with fixed hole and fixed length, which is characterized in that length measurement is carried out by counting the number of basic hole system section fabrication holes, the relative position of the section and a cutting device is locked by inserting plug pins into the fabrication holes after the length measurement so as to realize the static synchronous following of the flying shearing process; the static synchronous following is adopted to replace the dynamic synchronous following in servo flying shearing, which improves the precision of scale flying shearing; and a screw rod adjusting device is adopted to adjust the spacing between the plug pins and a cutting die, which can adapt to batch products with different benchmark sizes. The method has the advantages of precise shearing, stability and reliability, convenient installation, simple and compact structure, convenient operation, and is economical and practical. The method leads the system to run reliably and have high synchronization precision and small scale error, is applicable to shearing the basic hole system sections of various specifications, and has wide generalization and application values.

Owner:上海精星仓储设备工程有限公司

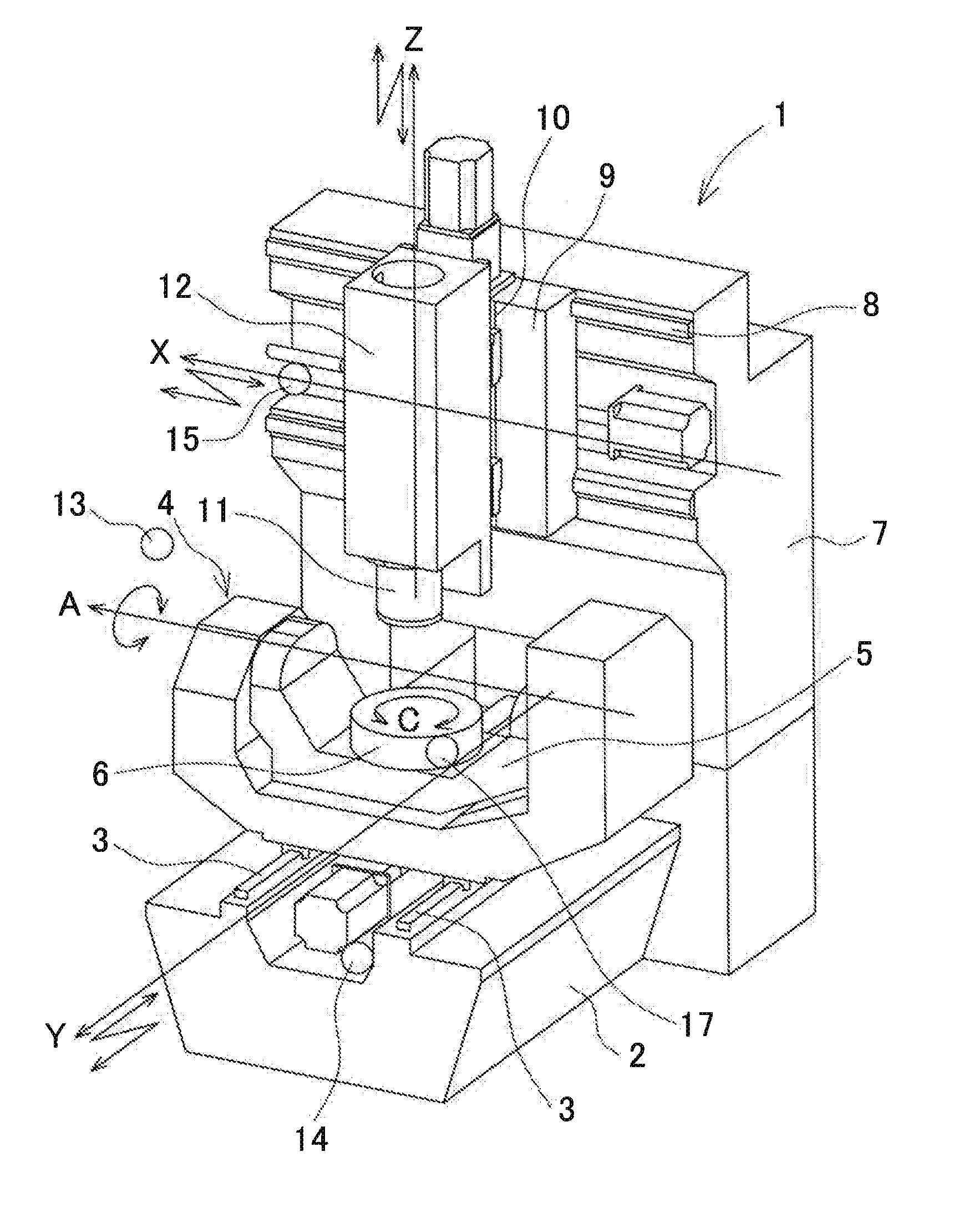

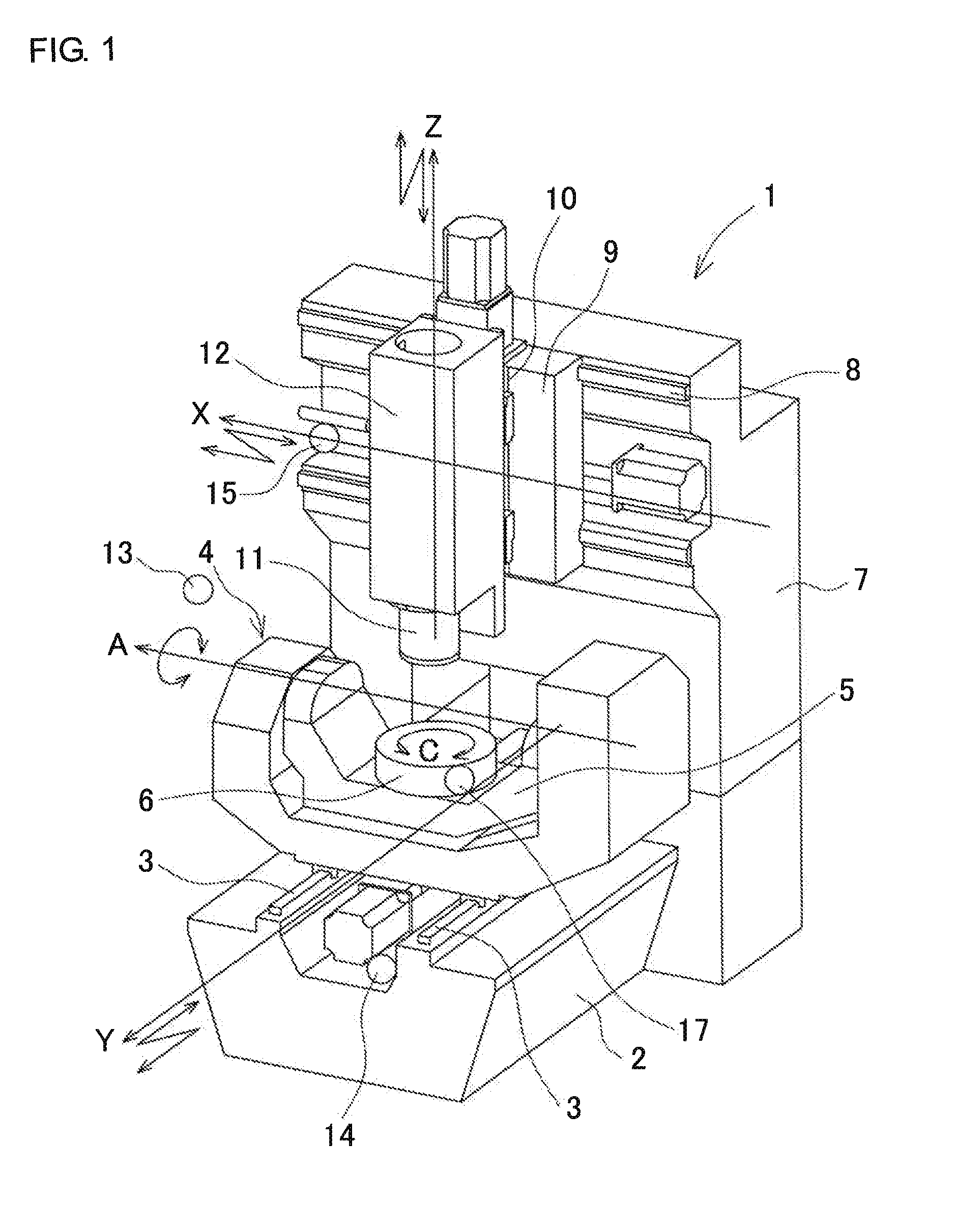

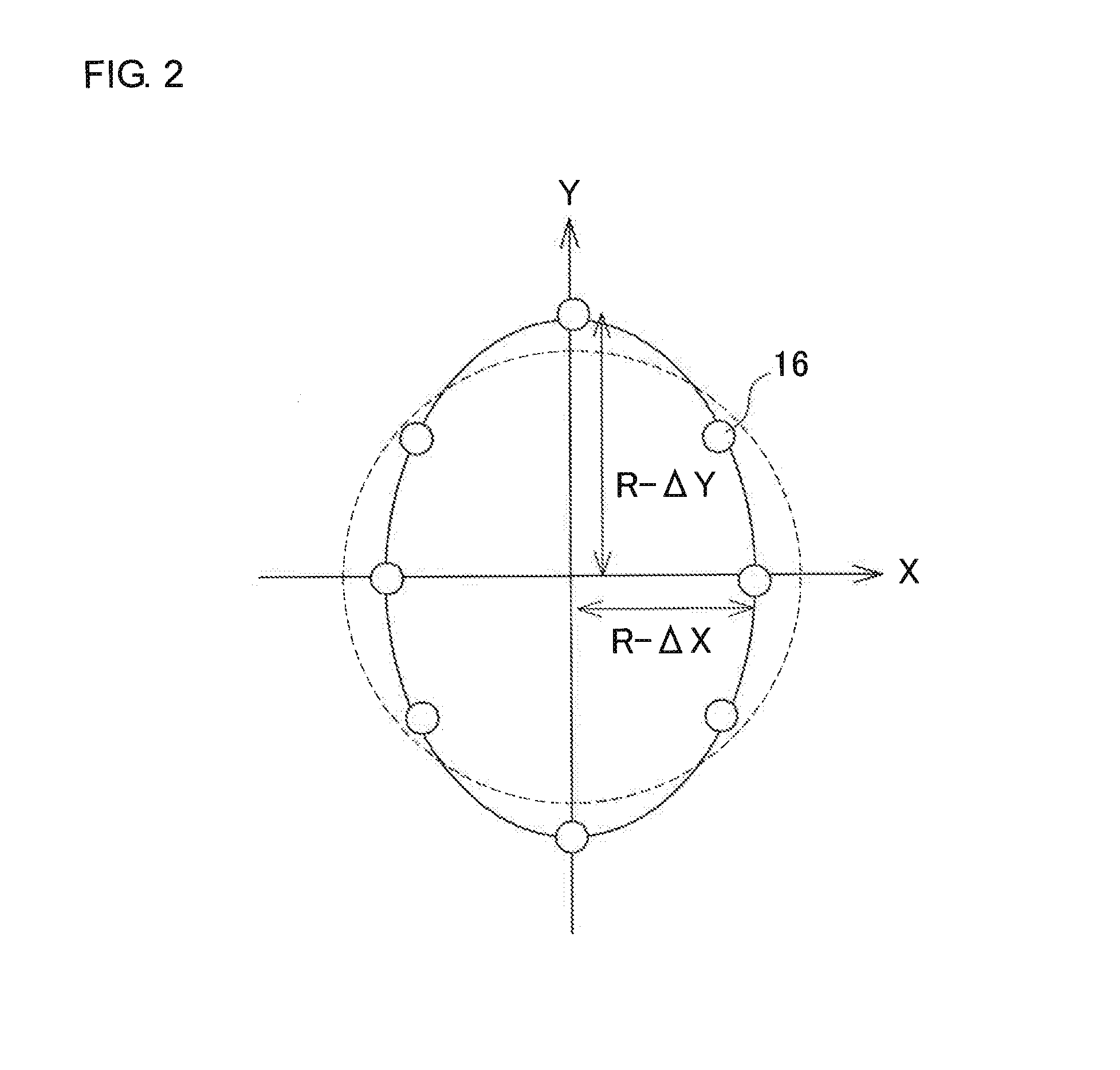

Geometric error identification method of multi-axis machine tool and multi-axis machine tool

ActiveUS20150160049A1High precision machiningHigh precisionProgramme controlMechanical counters/curvatures measurementsGeometric errorEllipse

A geometric error identification method of multi-axis machine tool includes a measuring step of indexing a position of a target ball mounted on one of a main spindle and a table into a plurality of angles around an rotation axis, and measuring the position of the target ball at respective indexed positions by using a touch probe mounted on the other one of the main spindle and the table, a geometric error calculation step of calculating a geometric error from the measured position of the target ball, an ellipse-expression calculation step of calculating an ellipse approximate expression by an arc trajectory measured by operating the rotation axis, and an error correcting step of calculating and correcting a scaling error of translation axes from the calculated ellipse approximate expression.

Owner:OKUMA CORP

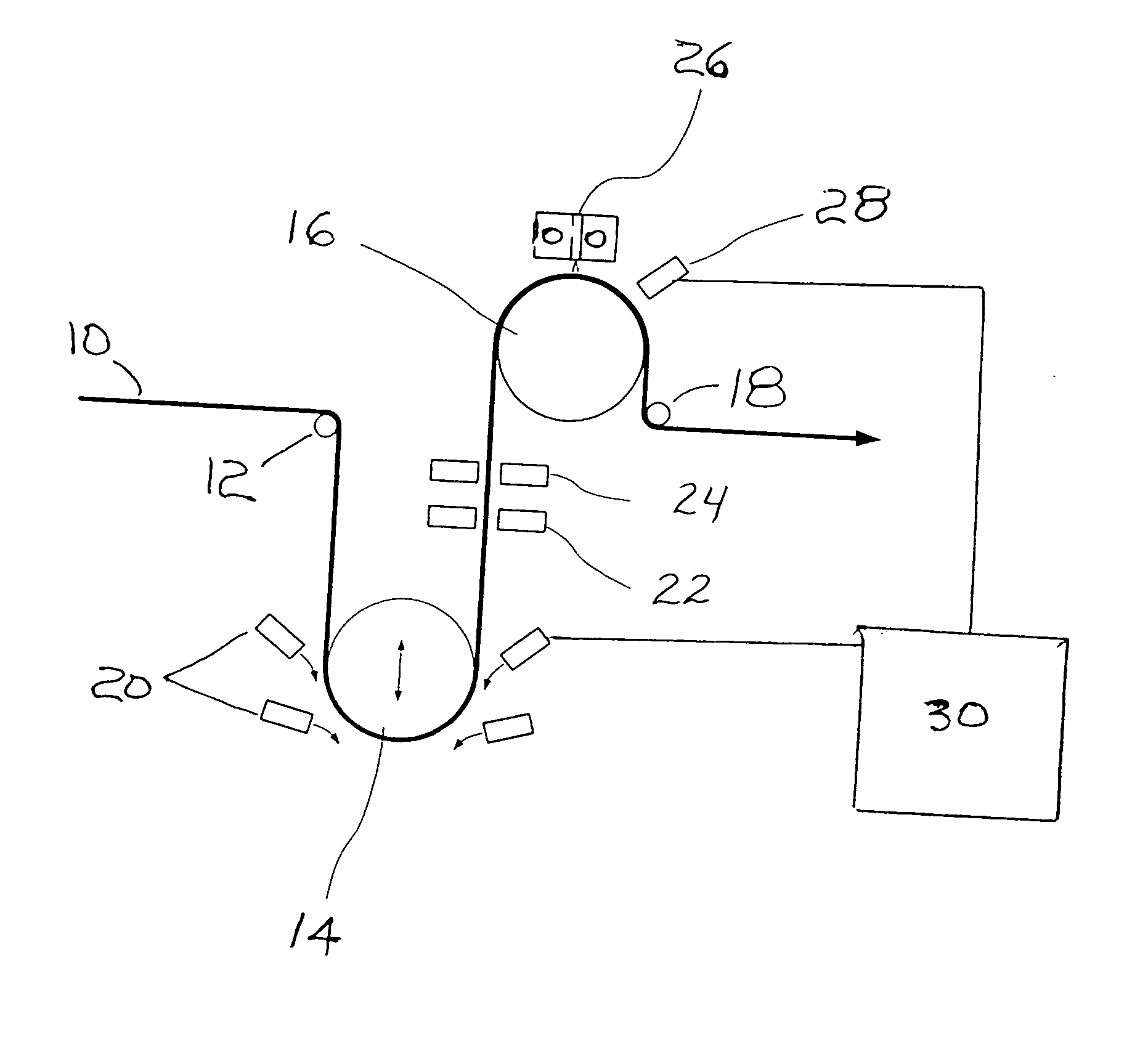

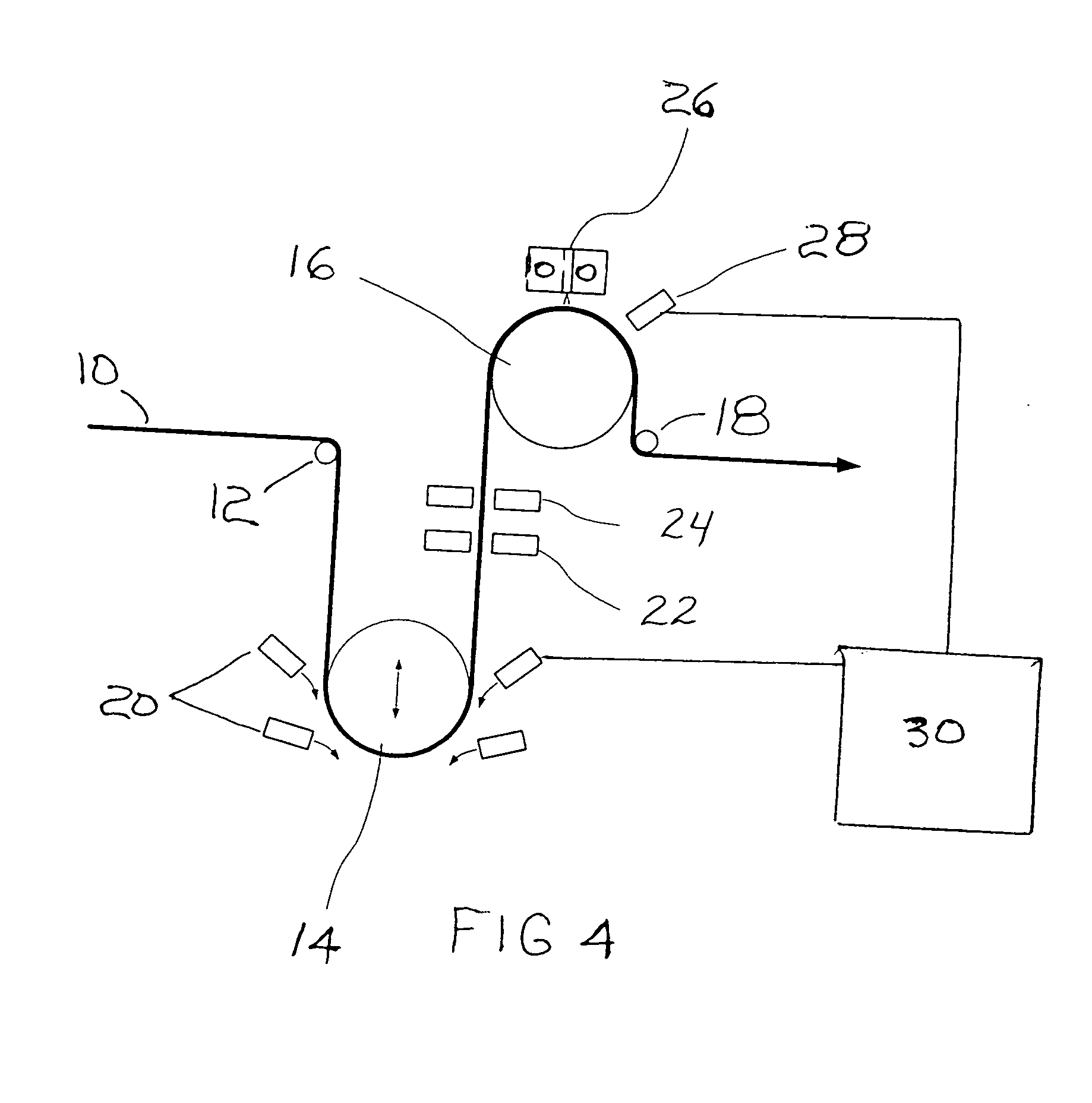

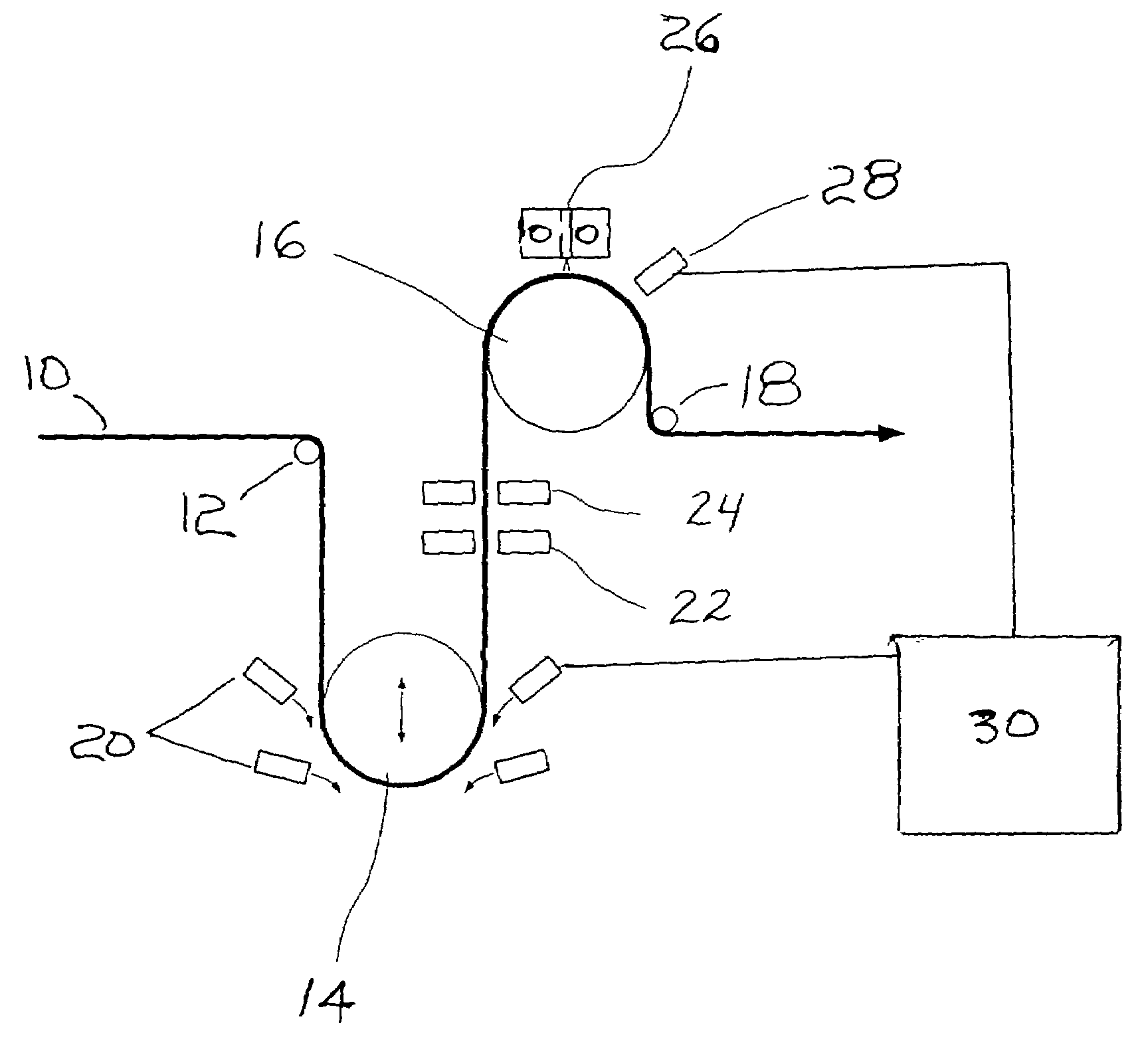

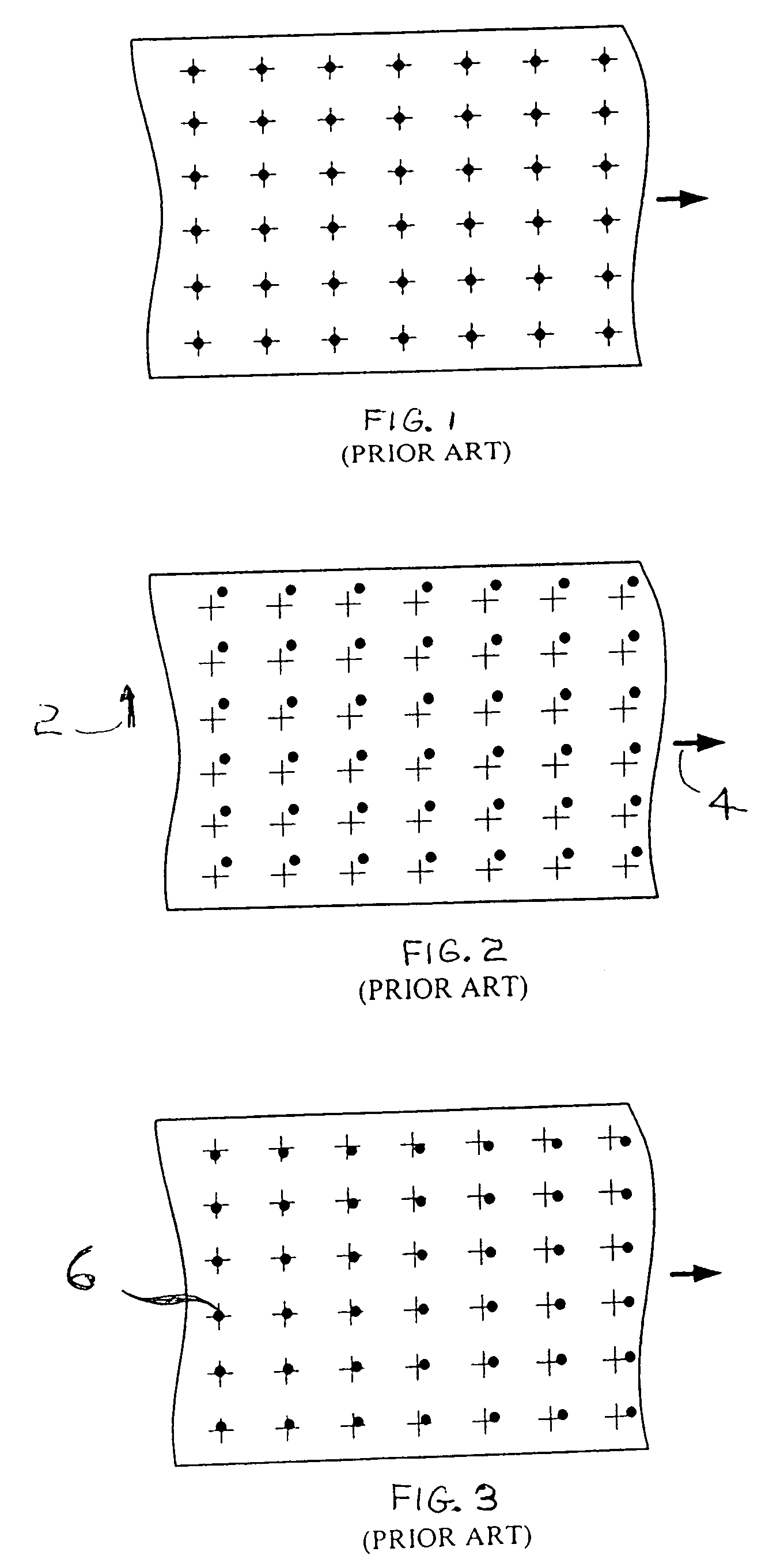

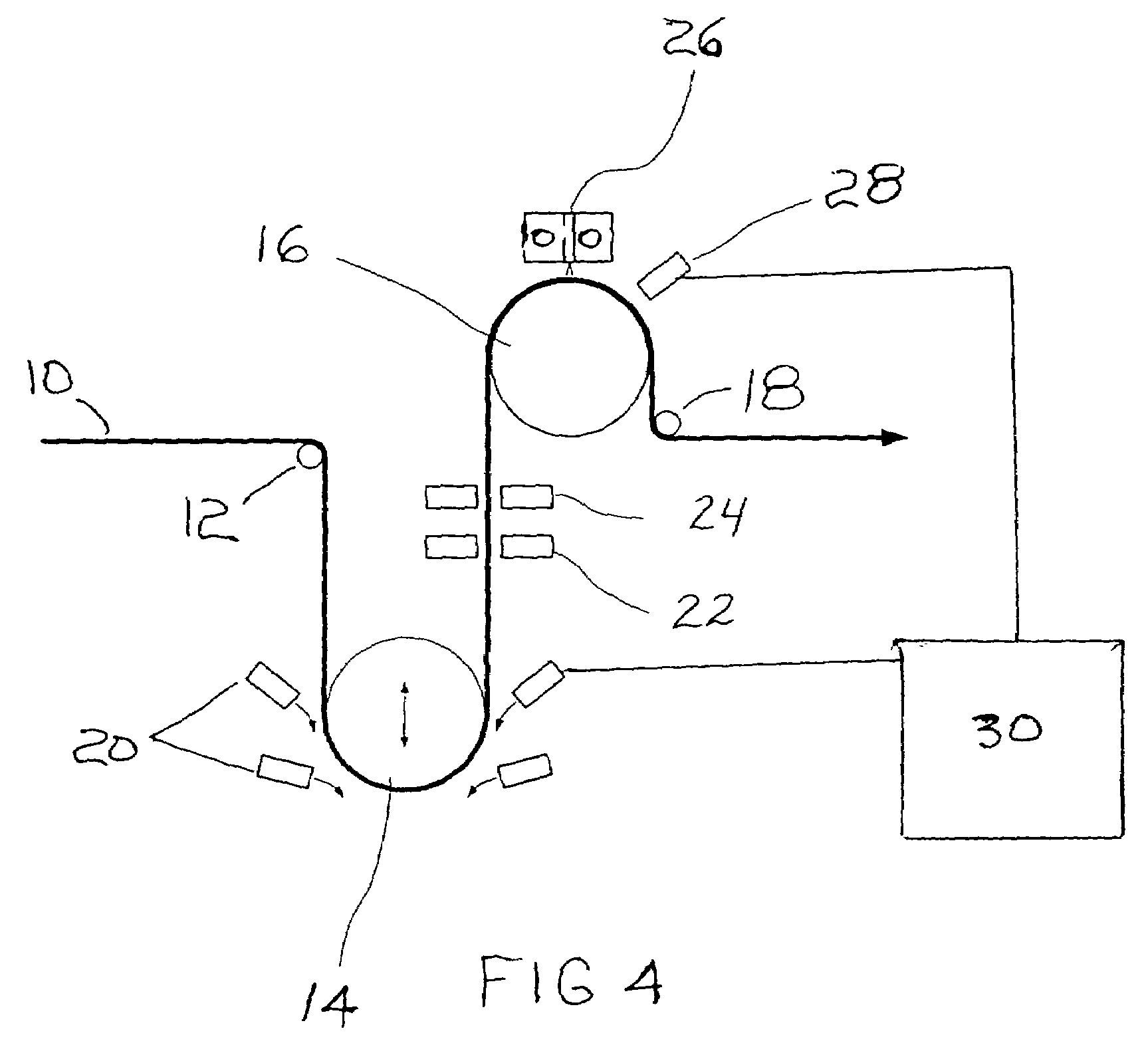

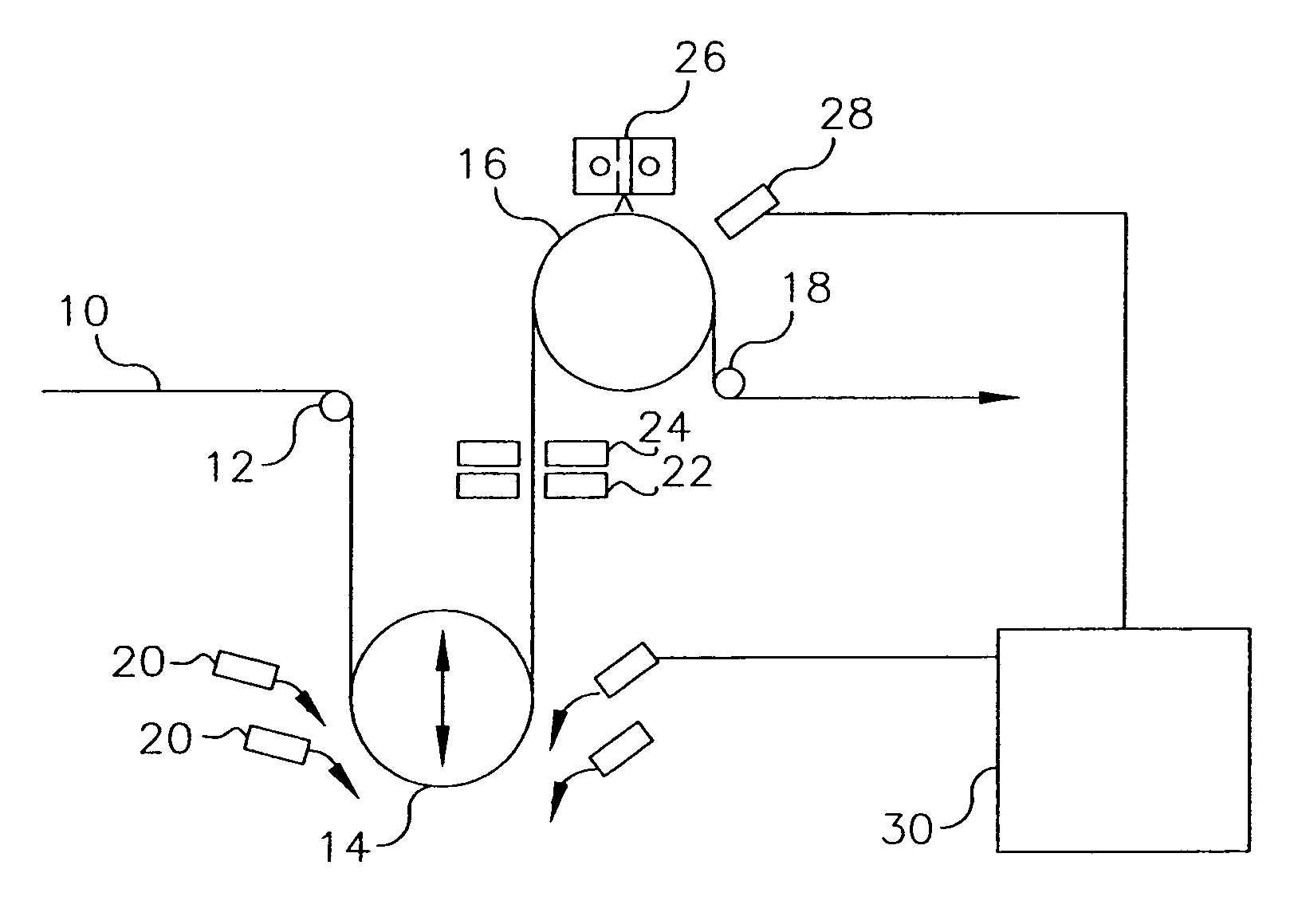

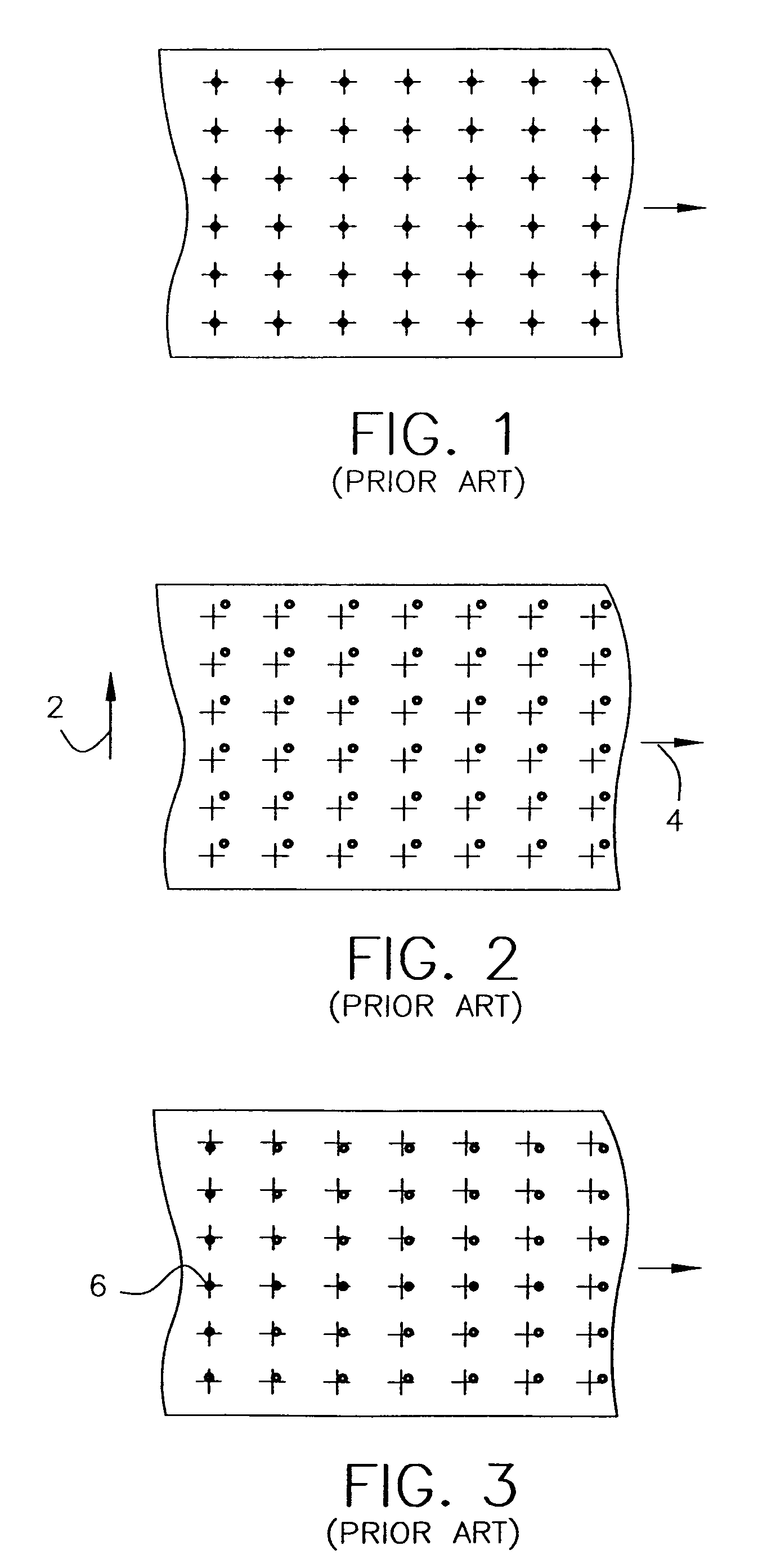

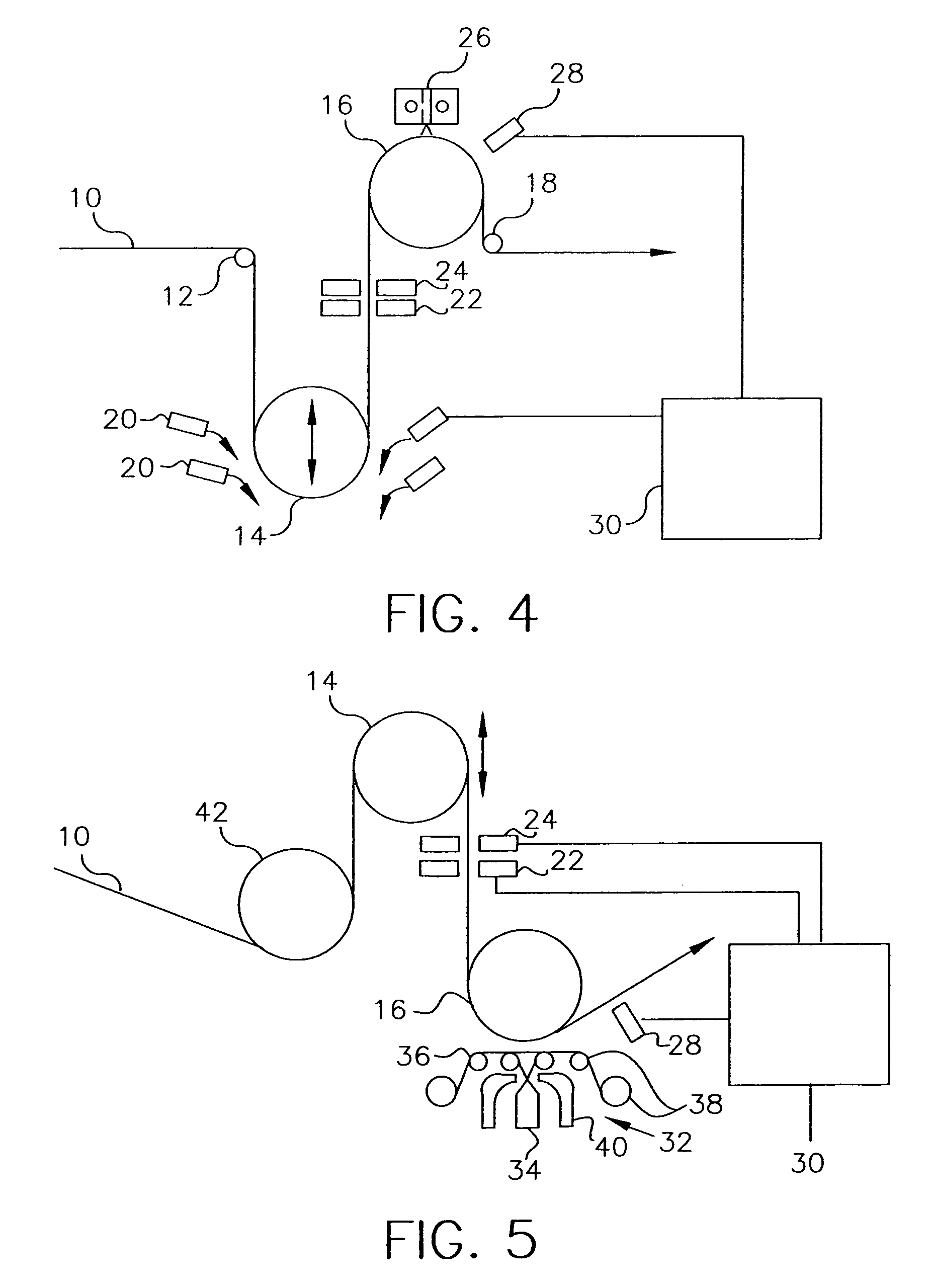

Method for registering patterns on a web

ActiveUS20060174792A1Avoid nonlinear distortionAddressographsPlaten pressesNonlinear distortionProportional control

A method for registering patterns on a web to provide independent scale control in both the lateral and longitudinal directions is provided. The method comprises routing the web over a first roller; routing the web over a second roller and stabilizing the web; applying a pattern to the web using process hardware; measuring registration of the pattern and providing an error signal; controlling lateral position error using the error signal; controlling longitudinal position error using the error signal; controlling lateral scale error using the error signal; and controlling longitudinal scale error using the error signal. The method provides independent scale control in both the lateral and longitudinal directions. Independent scale control avoids non-linear distortions otherwise imposed by attempting to accomplish both corrections by stretching the web in both directions.

Owner:EASTMAN KODAK CO

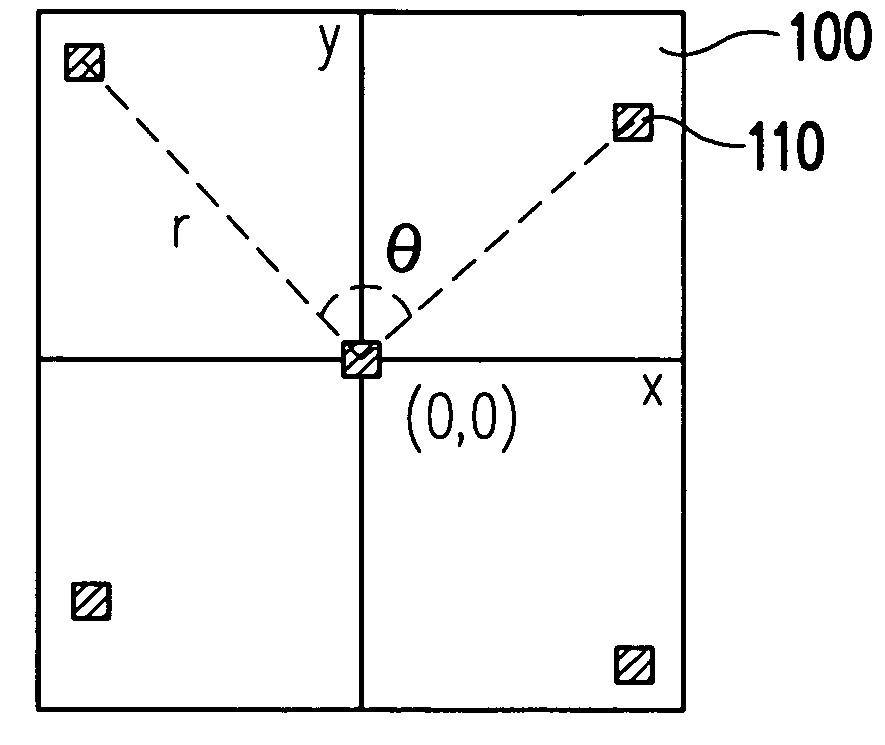

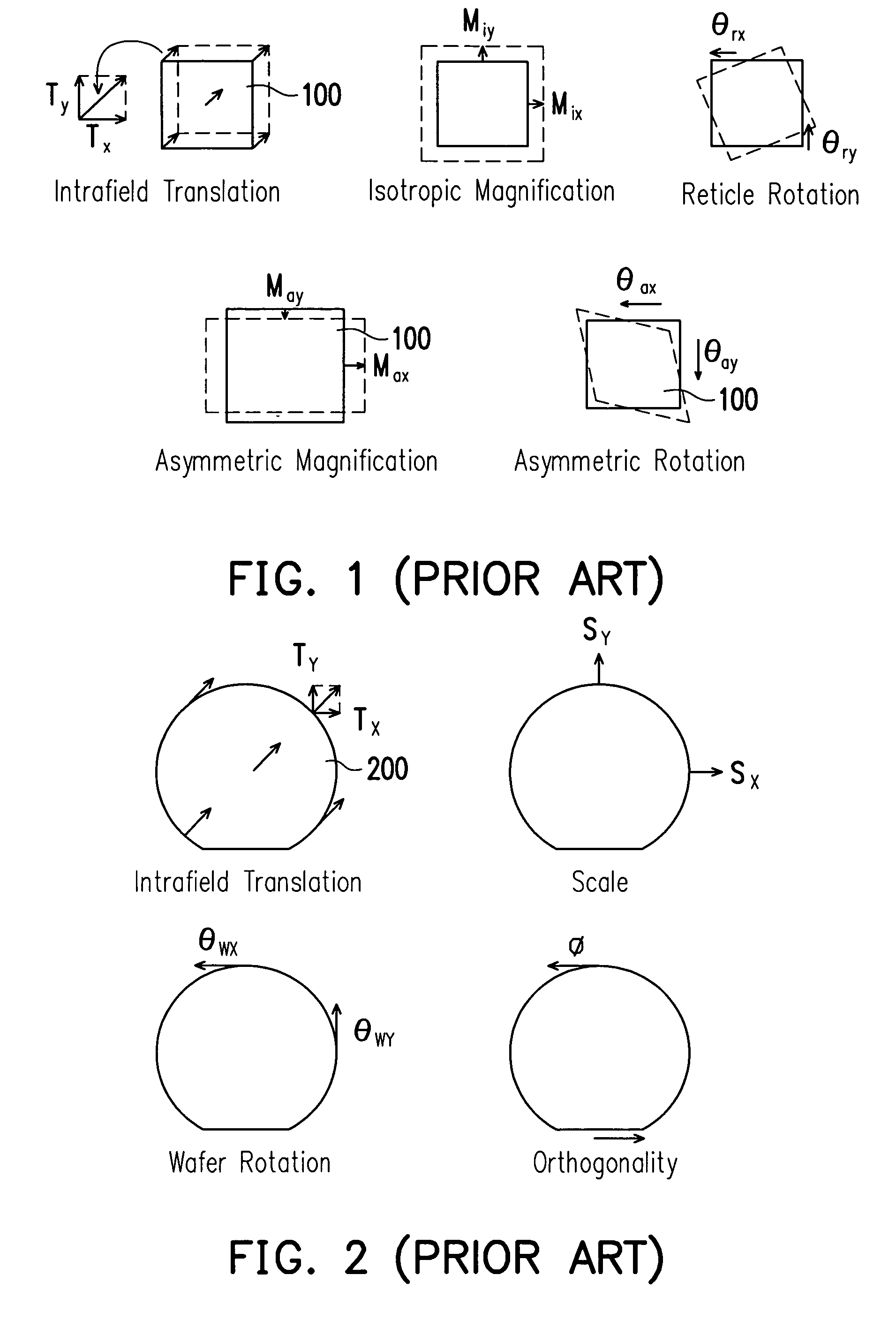

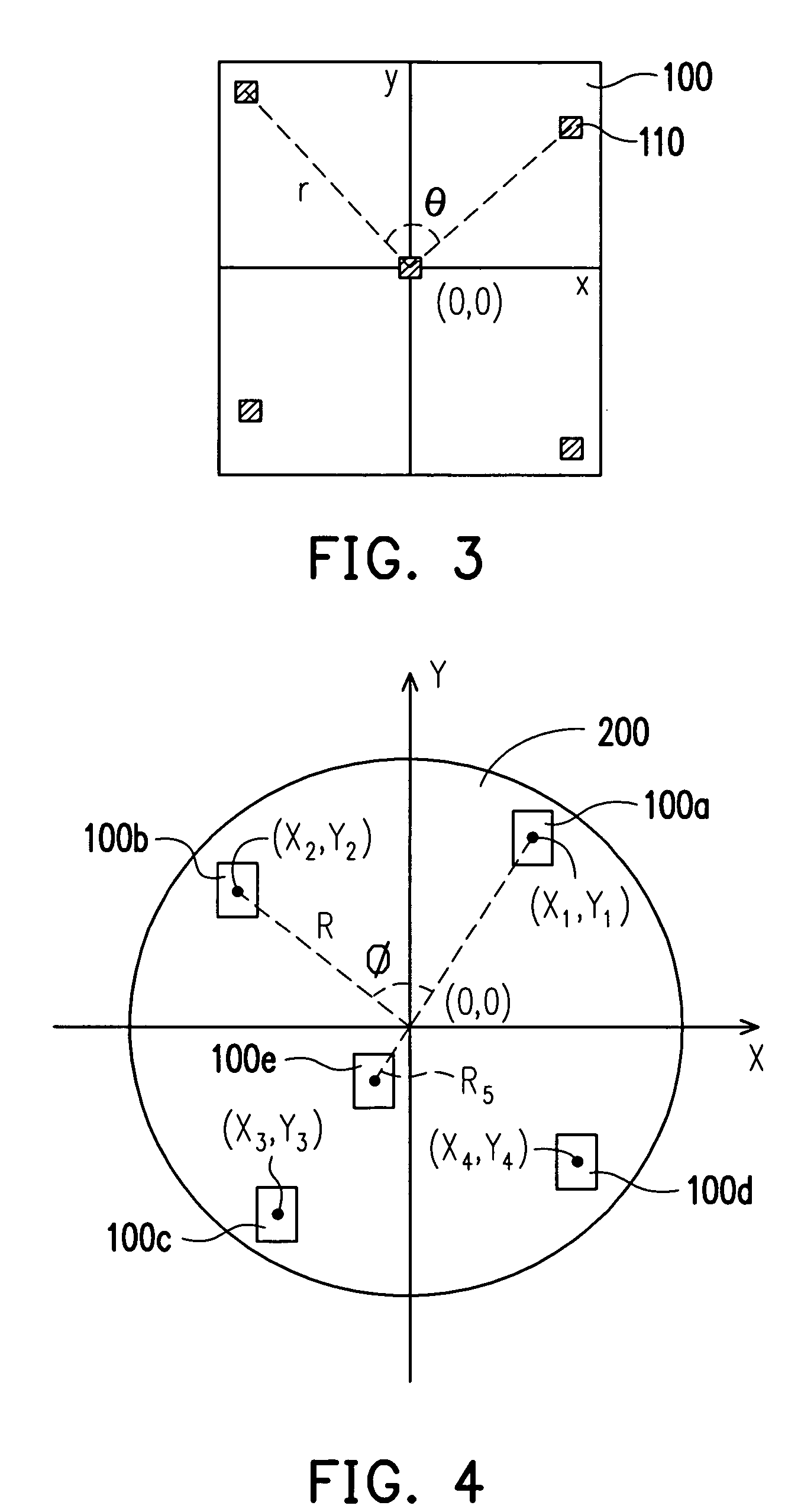

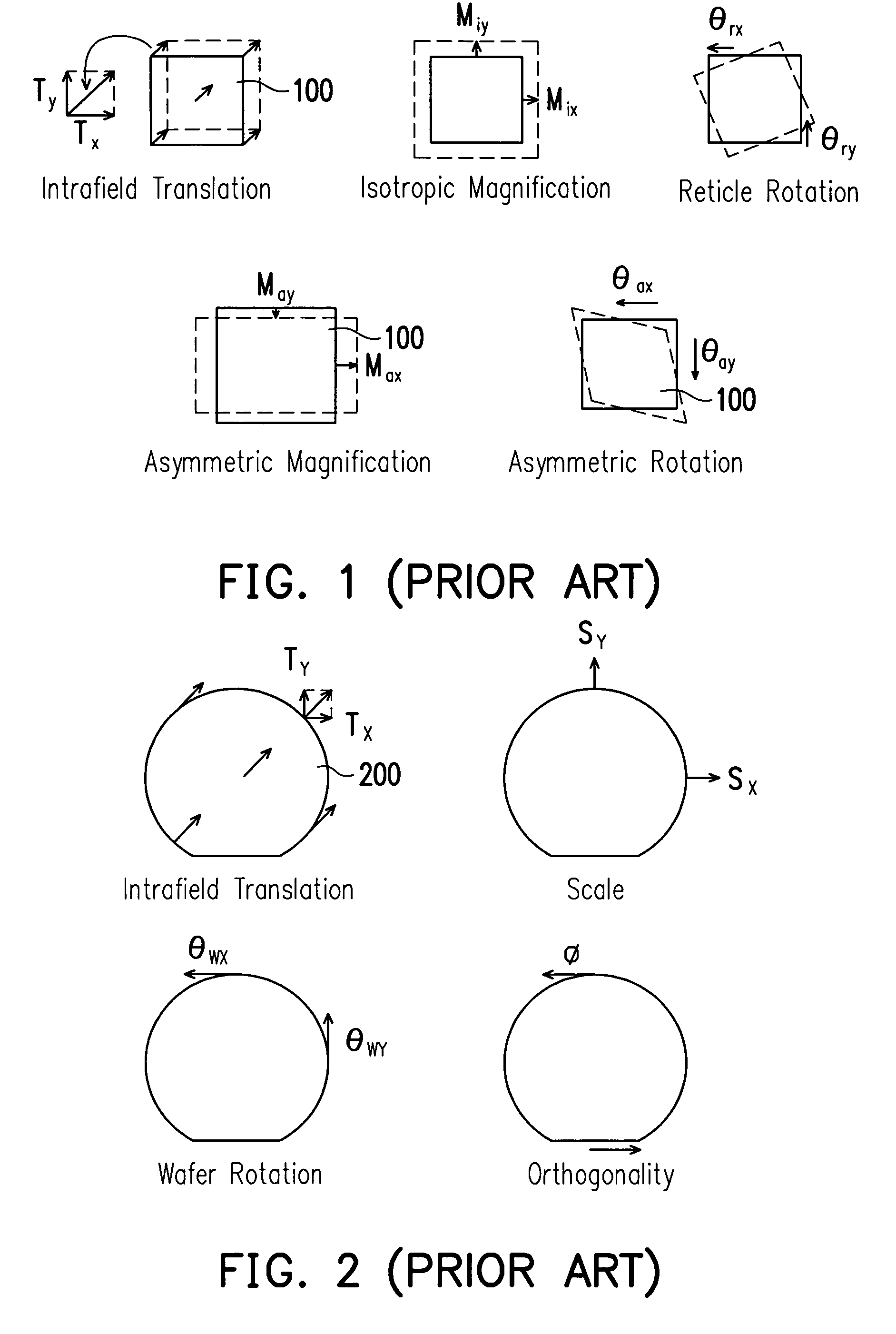

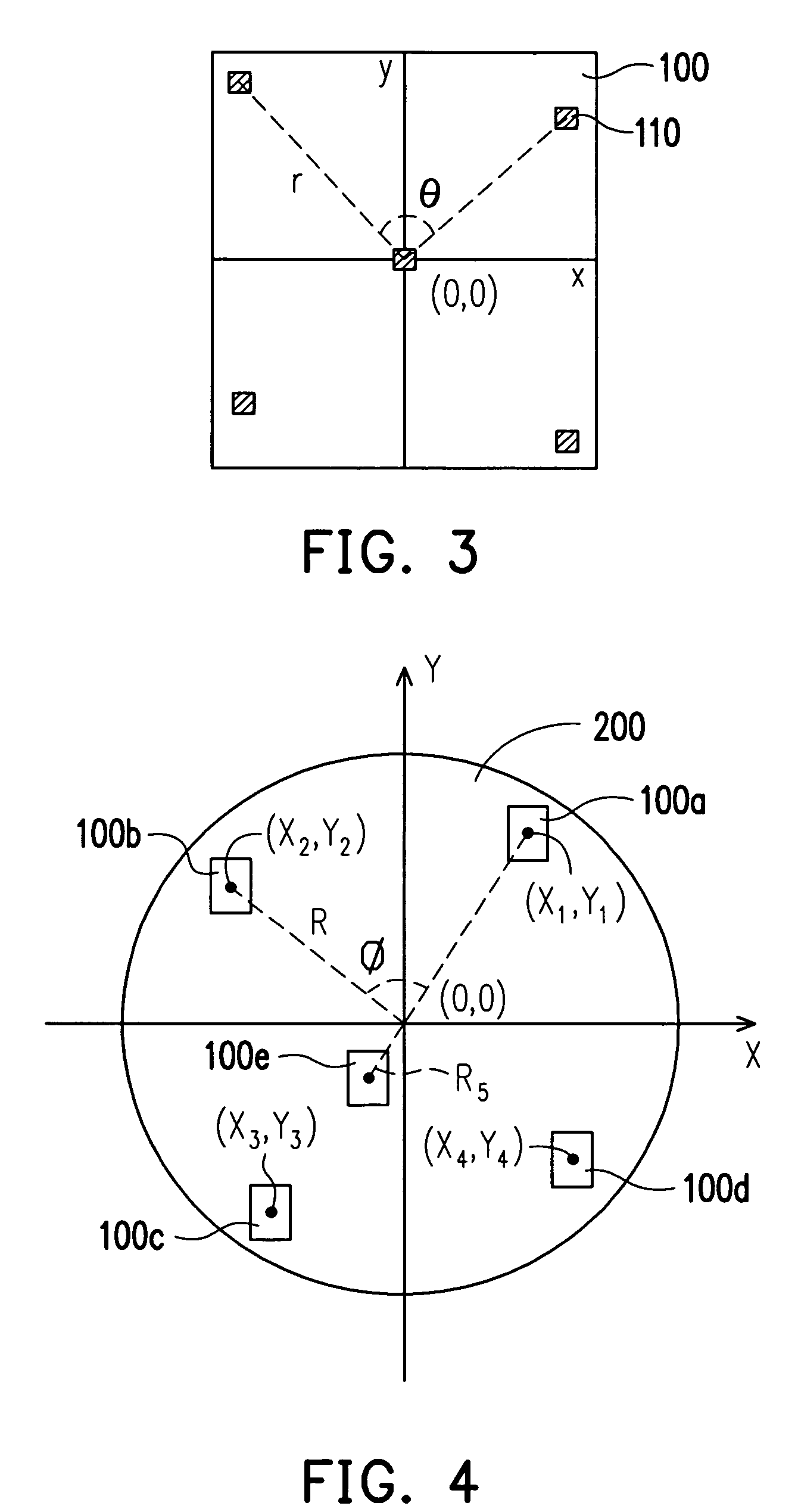

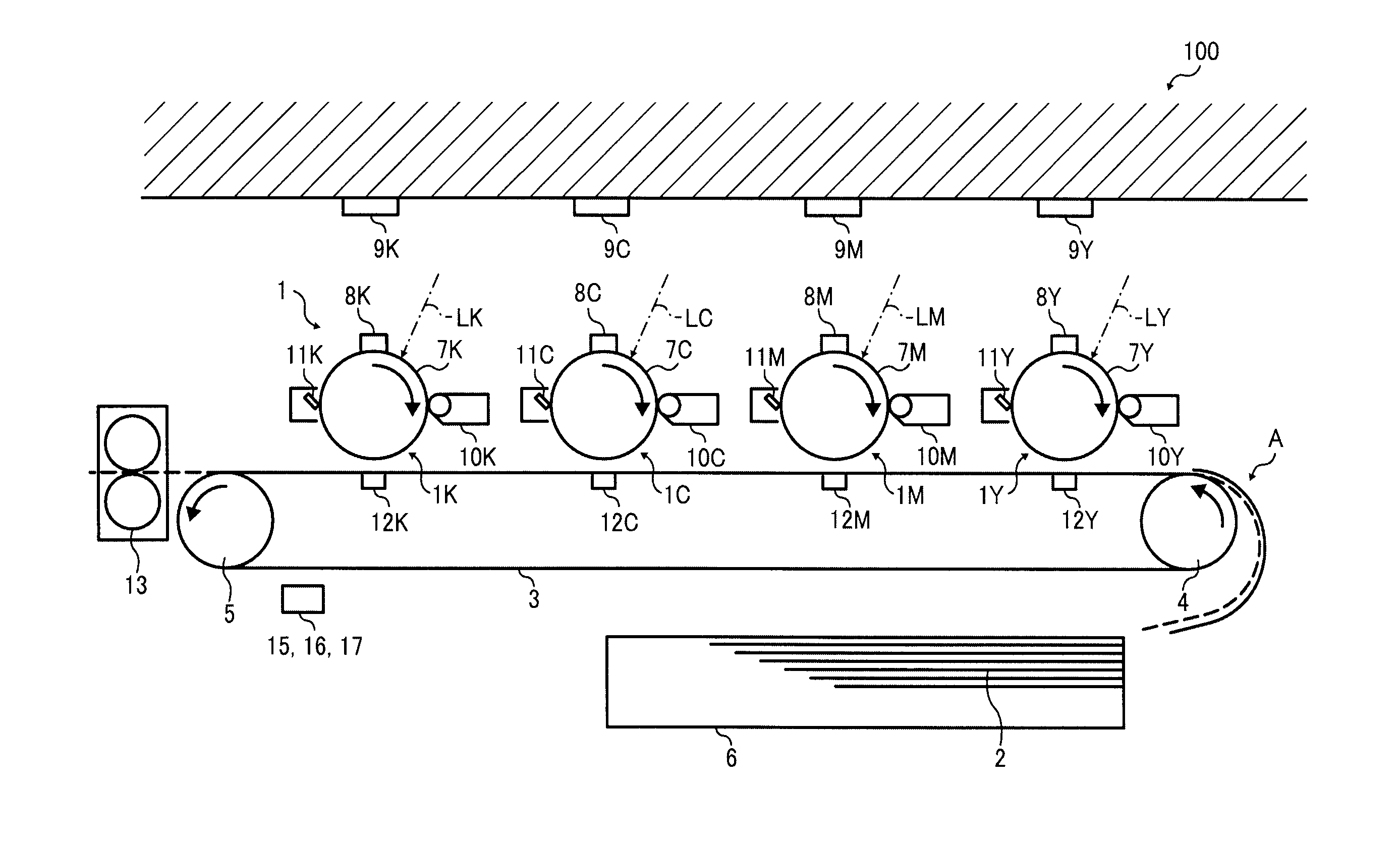

Method for analyzing overlay errors

InactiveUS20060238761A1Improve performanceImprove accuracyPhotomechanical apparatusUsing optical meansLithographic artistMagnification

A method for analyzing overlay errors in lithography is described. Interfield sampling and intrafield sampling are first conducted to sample multiple positions on each of the wafers, and then the overlay error value at each of the positions is measured. An overlay error model including coefficients of intrafield and interfield overlay errors of different types is used to fit the measured overlay error values with respect to the sampled positions. In the overlay error model, the intrafield overlay errors include intrafield translation, isotropic magnification, reticle rotation, asymmetric magnification and asymmetric rotation, and the interfield overlay errors include interfield translation, scale error, wafer rotation and orthogonality error.

Owner:MACRONIX INT CO LTD

Method for registering patterns on a web

ActiveUS7100510B2Avoid nonlinear distortionAddressographsPlaten pressesNonlinear distortionProportional control

Owner:EASTMAN KODAK CO

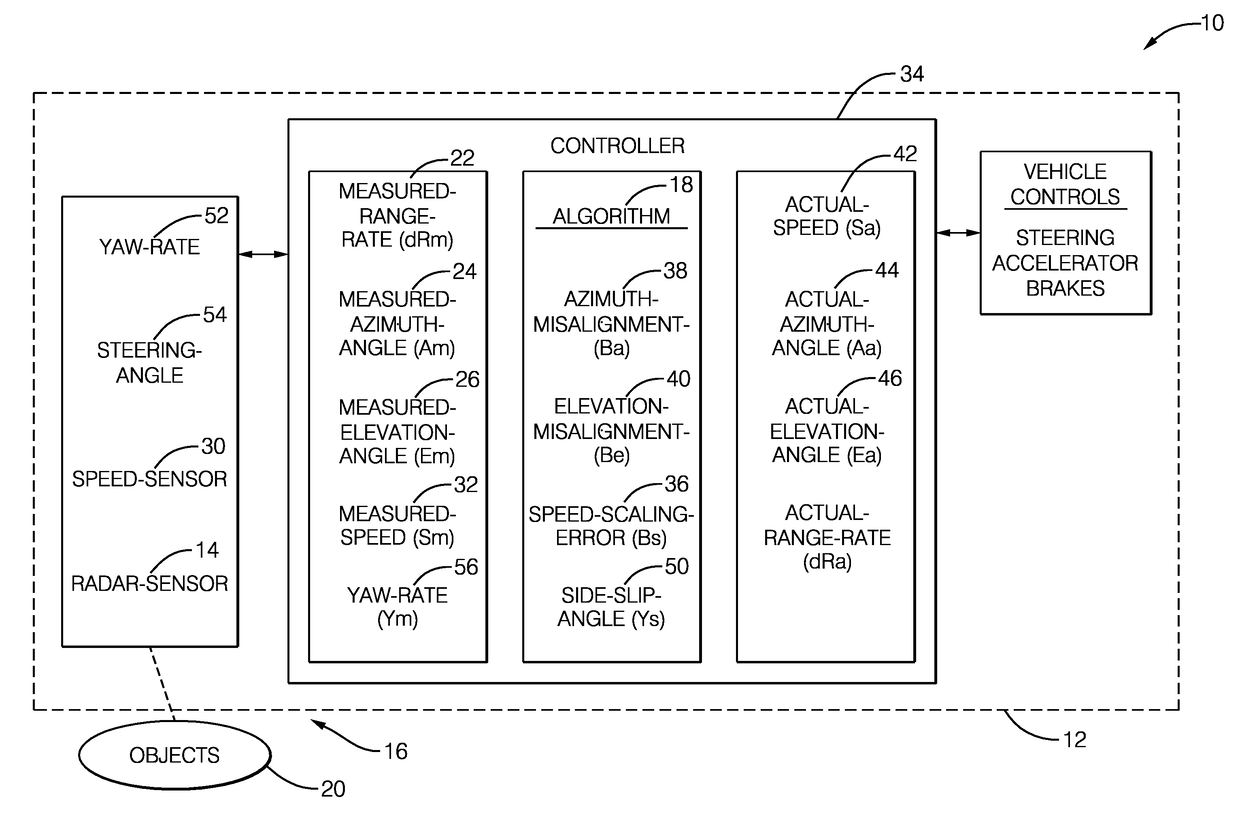

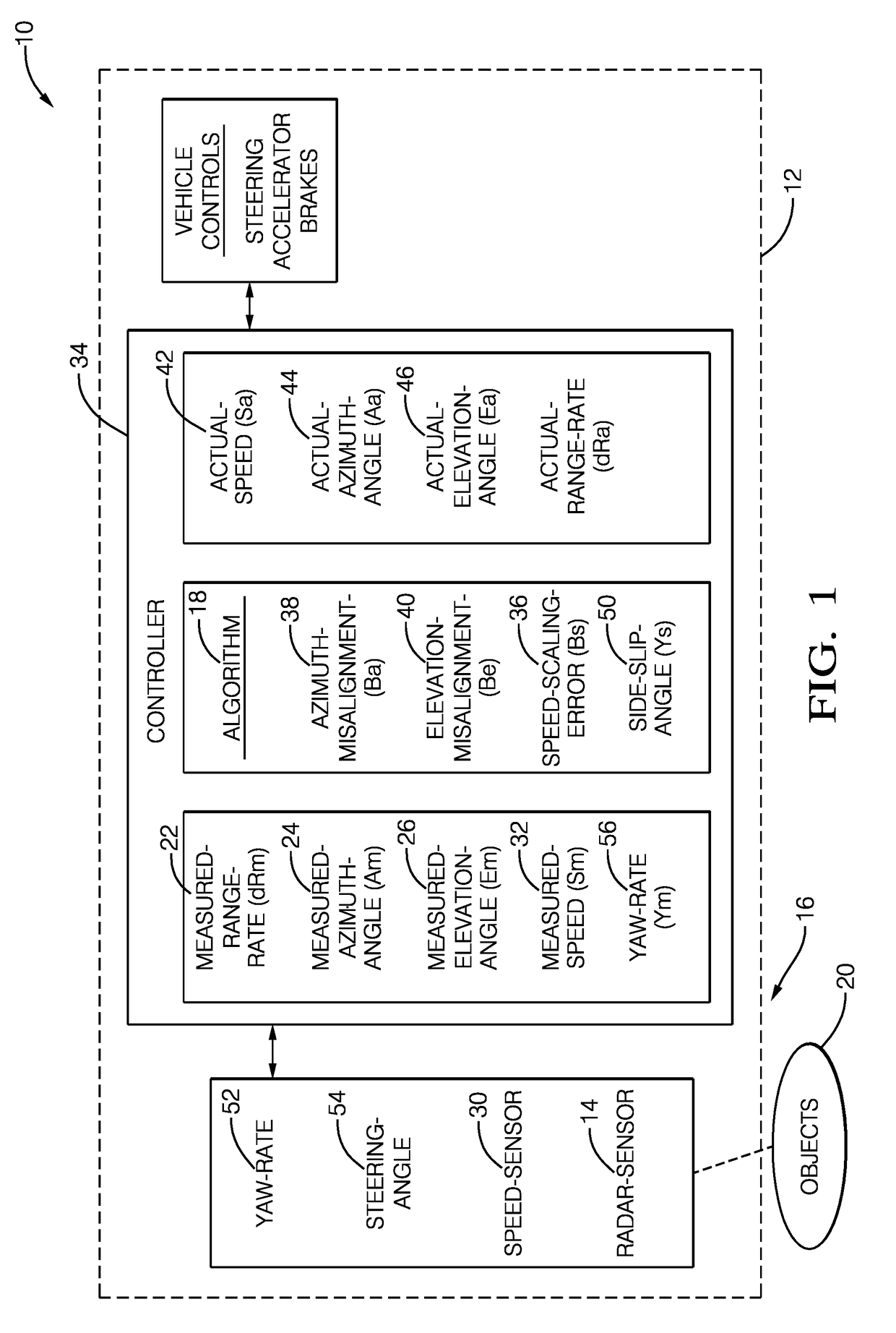

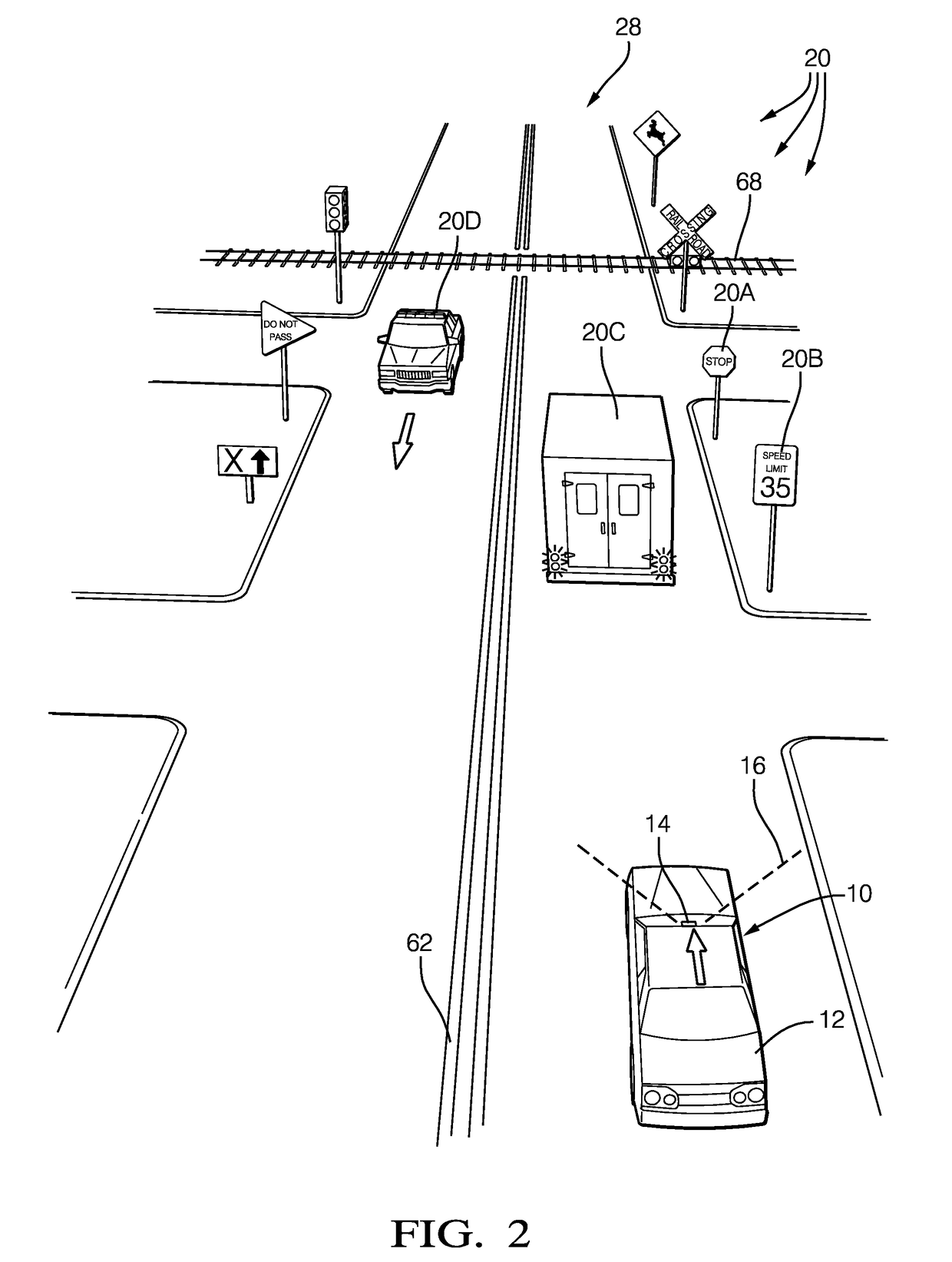

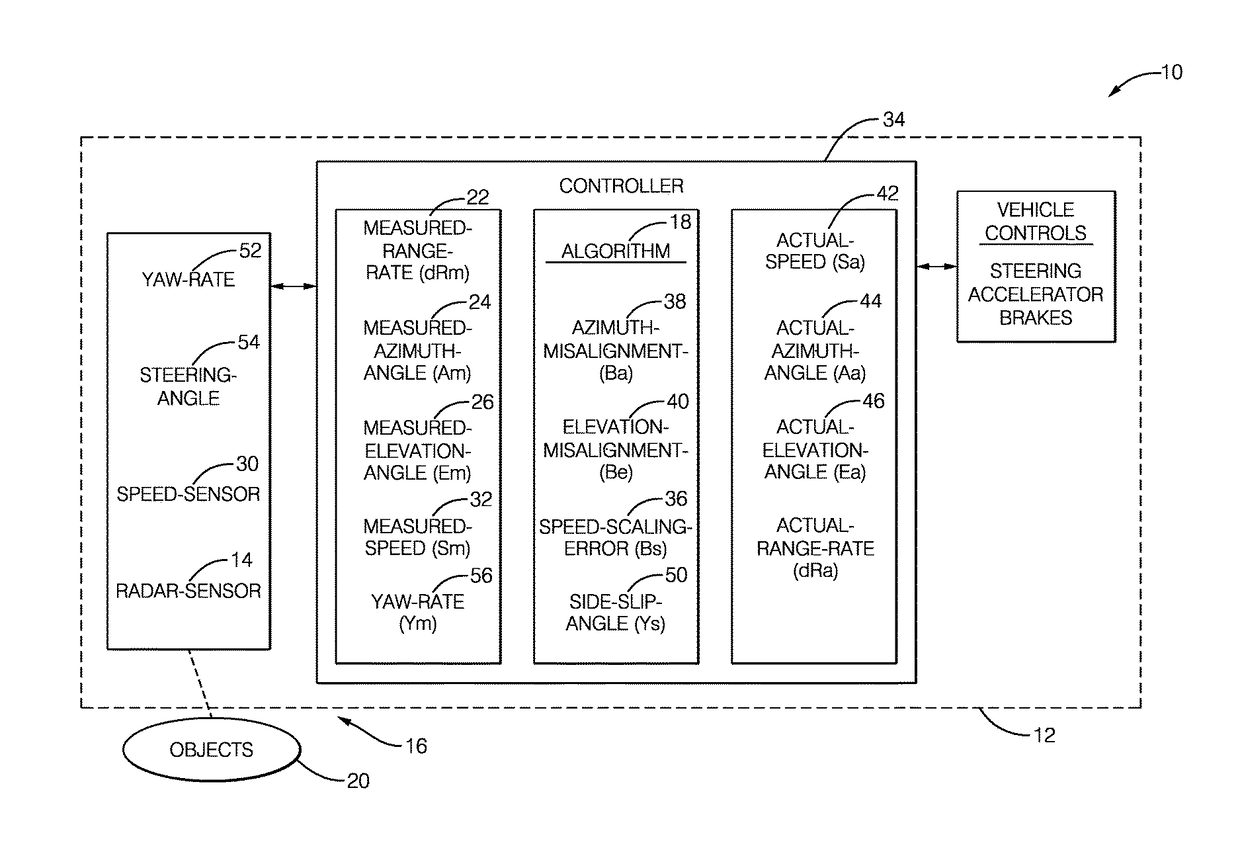

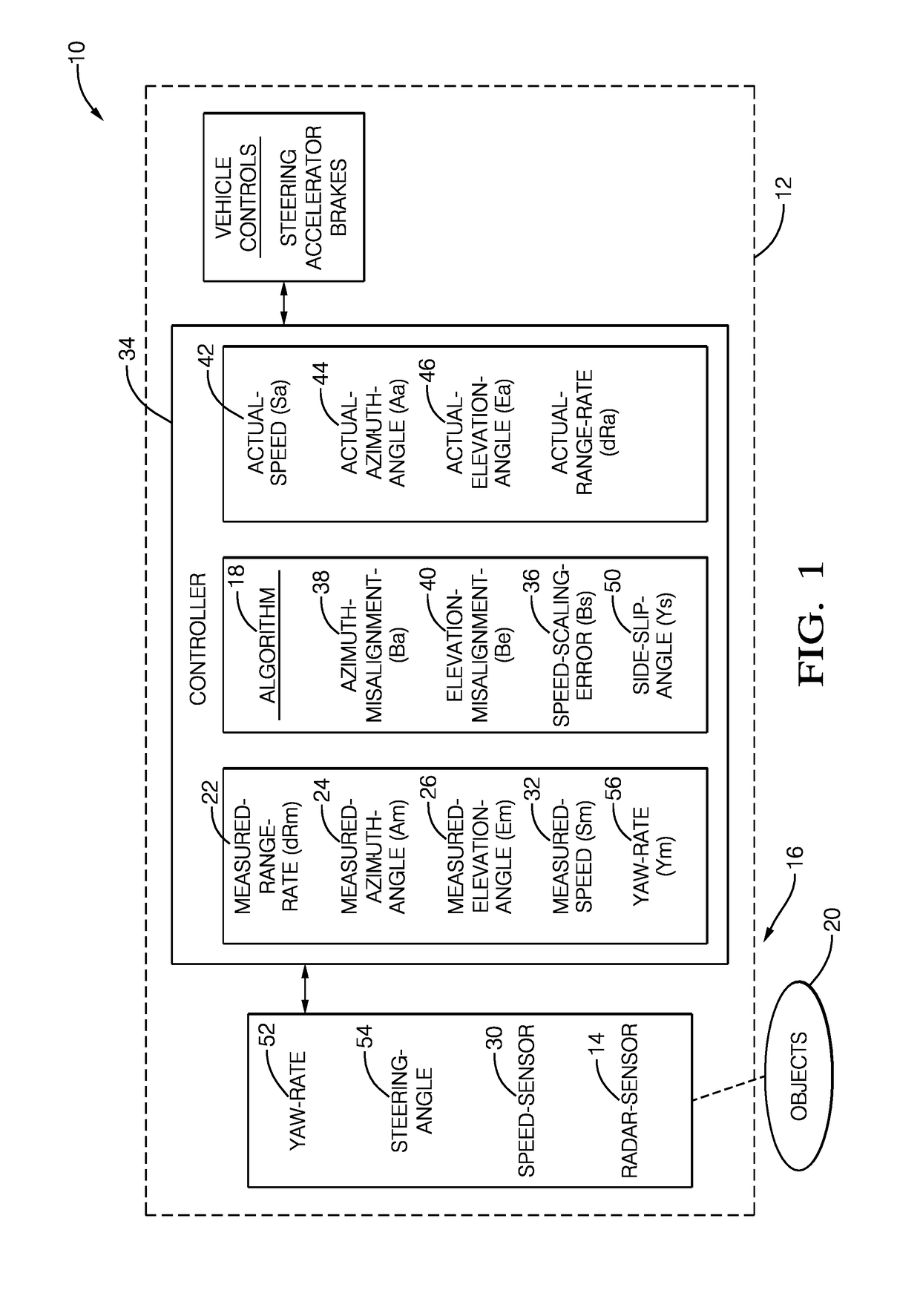

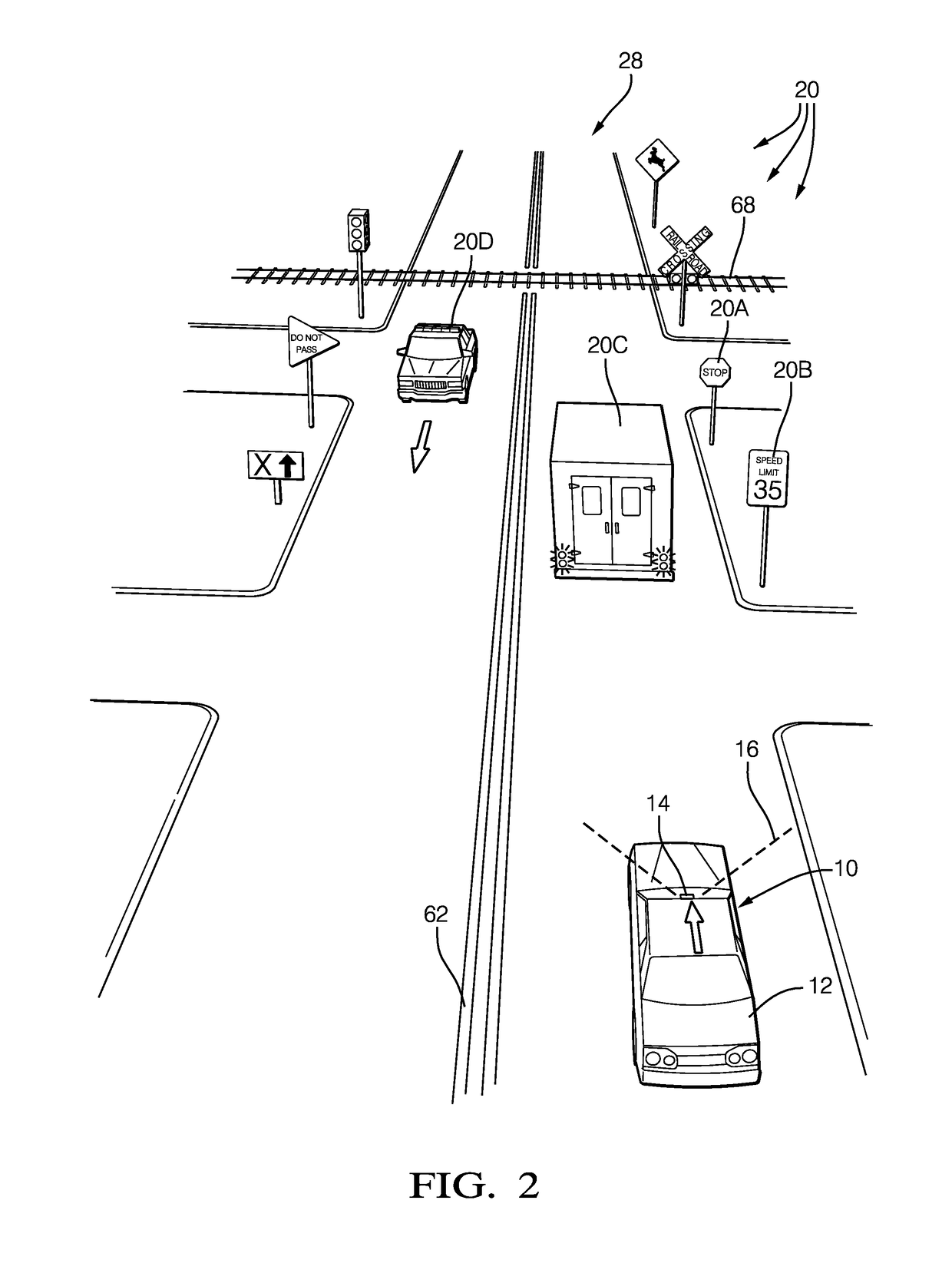

Automated vehicle radar system with auto-alignment for azimuth, elevation, and vehicle speed-scaling-error

In accordance with one embodiment, a radar system with auto-alignment suitable for use in an automated vehicle is provided. The system includes a radar-sensor, a speed-sensor, and a controller. The radar-sensor is used to detect objects present in a field-of-view proximate to a host-vehicle on which the radar-sensor is mounted. The radar-sensor is operable to determine a measured-range-rate (dRm), a measured-azimuth-angle (Am), and a measured-elevation-angle (Em) to each of at least three objects present in the field-of-view. The speed-sensor is used to determine a measured-speed (Sm) of the host-vehicle. The controller is in communication with the radar-sensor and the speed-sensor. The controller is configured to simultaneously determine a speed-scaling-error (Bs) of the measured-speed, an azimuth-misalignment (Ba) of the radar-sensor, and an elevation-misalignment (Be) of the radar-sensor based on the measured-range-rate, the measured-azimuth-angle, and the measured-elevation-angle to each of the at least three objects, while the host-vehicle is moving.

Owner:APTIV TECH LTD

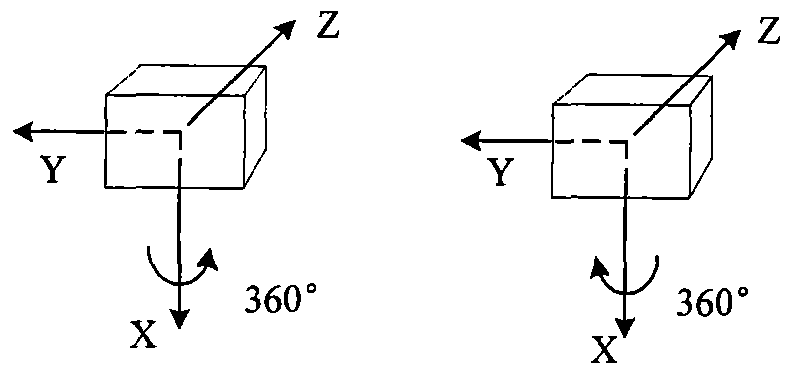

Non-oriented multi-position and high-precision calibrating method for inertial measuring unit

InactiveCN101029902AImprove the accuracy of useImprove calibration efficiencyTesting/calibration of speed/acceleration/shock measurement devicesAcceleration measurement using gyroscopesGyroscopeAccelerometer

An astatic multi-position high-accuracy calibrating method of inertia measurement unit can accurately calibrate out 33 error coefficients in 7 types such as gyroscope scale factor gyroscope erection error, accelerometer scale error, etc by making IMU rotate at six position with 12 times of rotation under condition that accurate rotary platform is not pointed at north.

Owner:BEIHANG UNIV

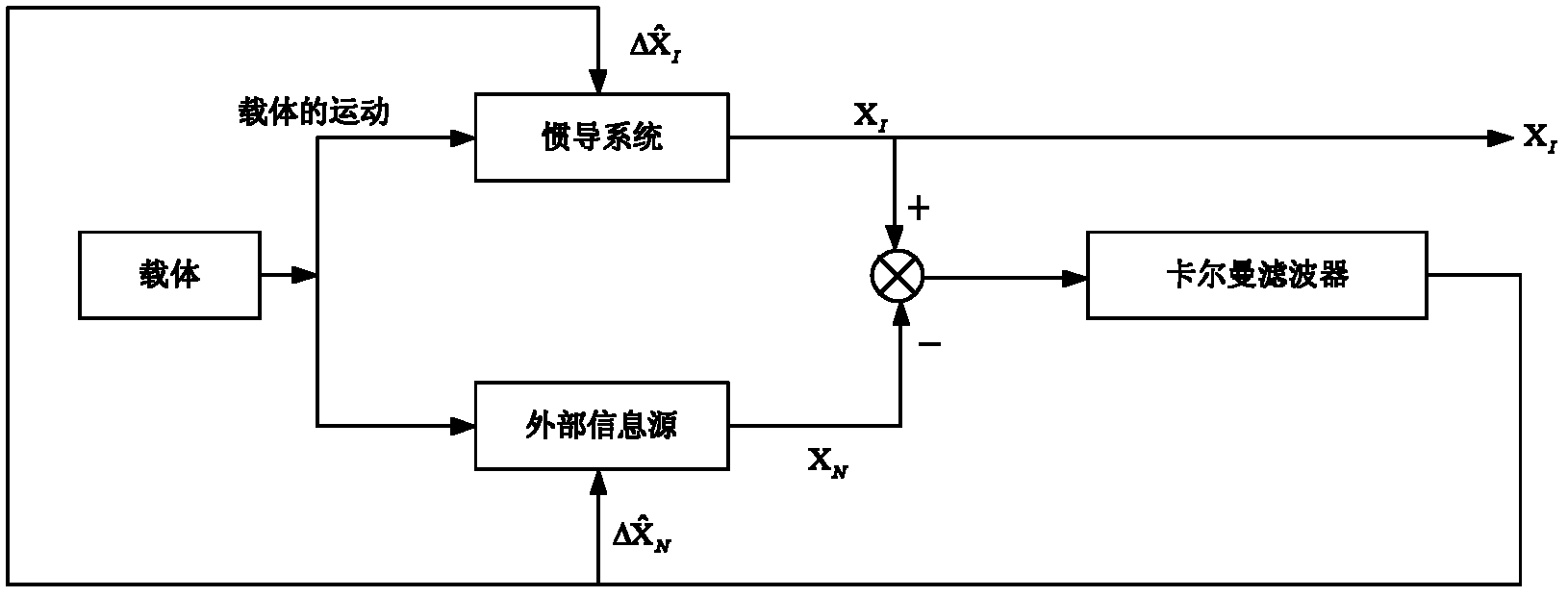

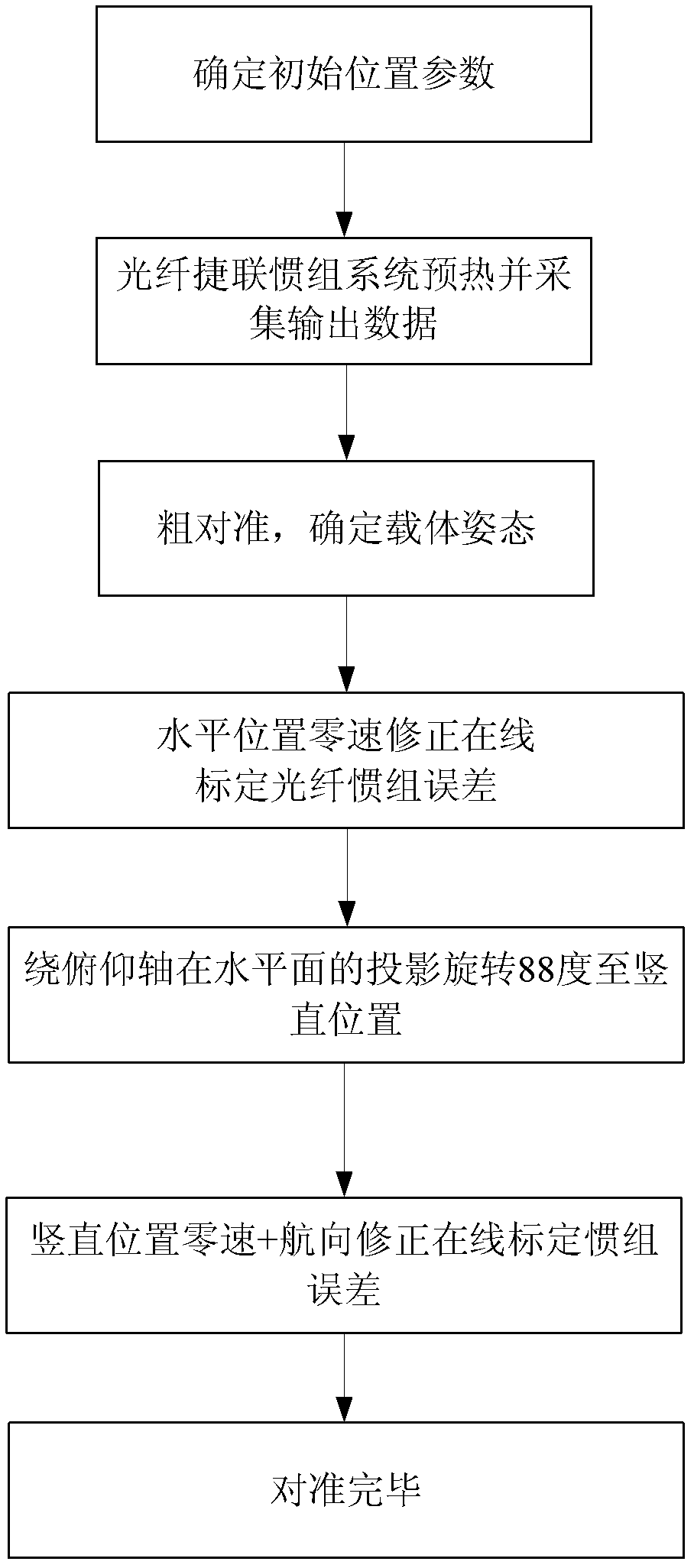

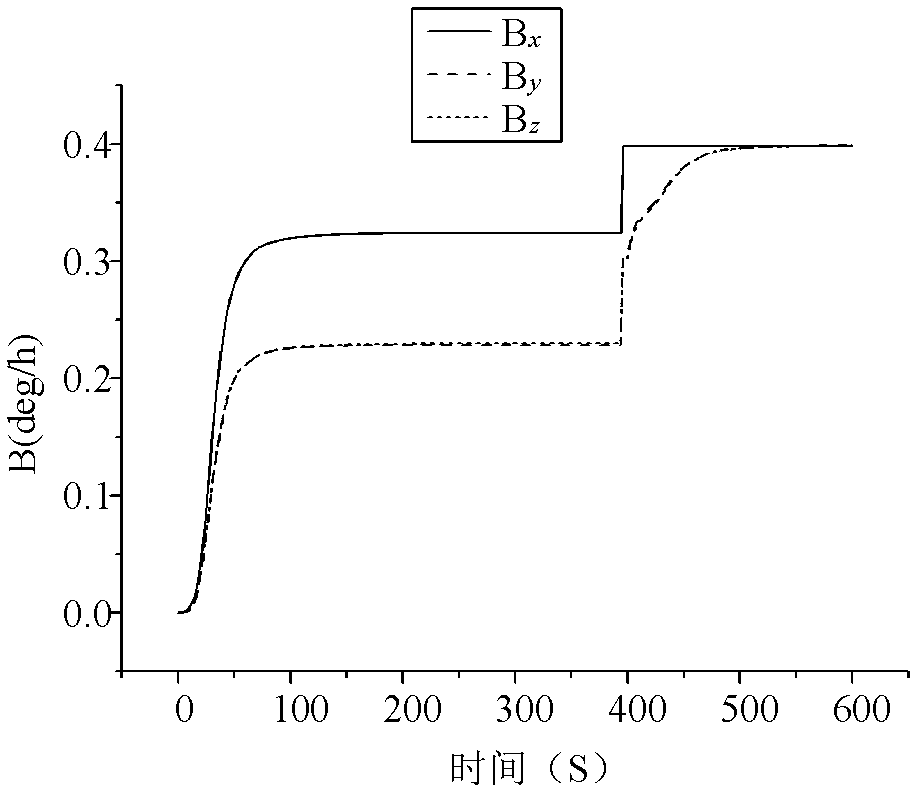

Zero-velocity/course correction application online calibrating method for optical fiber strapdown inertial measuring unit

InactiveCN102680000AImprove navigation performanceImprove parameter identification accuracyNavigation by speed/acceleration measurementsAccelerometerComputer science

The invention discloses a zero-velocity / course correction application online calibrating method for optical fiber strapdown inertial measuring unit, and belongs to the field of inertial technology. A carrier erection two-position aligning process is utilized sufficiently, main error sources including drift errors, scale errors, mounting errors and the like of the optical fiber inertial measuring unit are calibrated by a filtering method on the basis of zero-velocity correction and heading correction, and the actual use precision of the optical fiber inertial measuring unit is improved. Output data of an optical fiber gyro and output data of a quartz accelerometer are acquired by determining parameters of the initial position of a carrier; the gesture of the carrier is determined by means of coarse alignment; and online calibration is realized by precise alignment for a horizontal position and a vertical position. The method is used for calibrating main error items of the optical fiber inertial measuring unit, so that the parameter identification precision of a system and an actual navigation performance of the optical fiber strapdown inertial measuring unit are improved.

Owner:BEIHANG UNIV

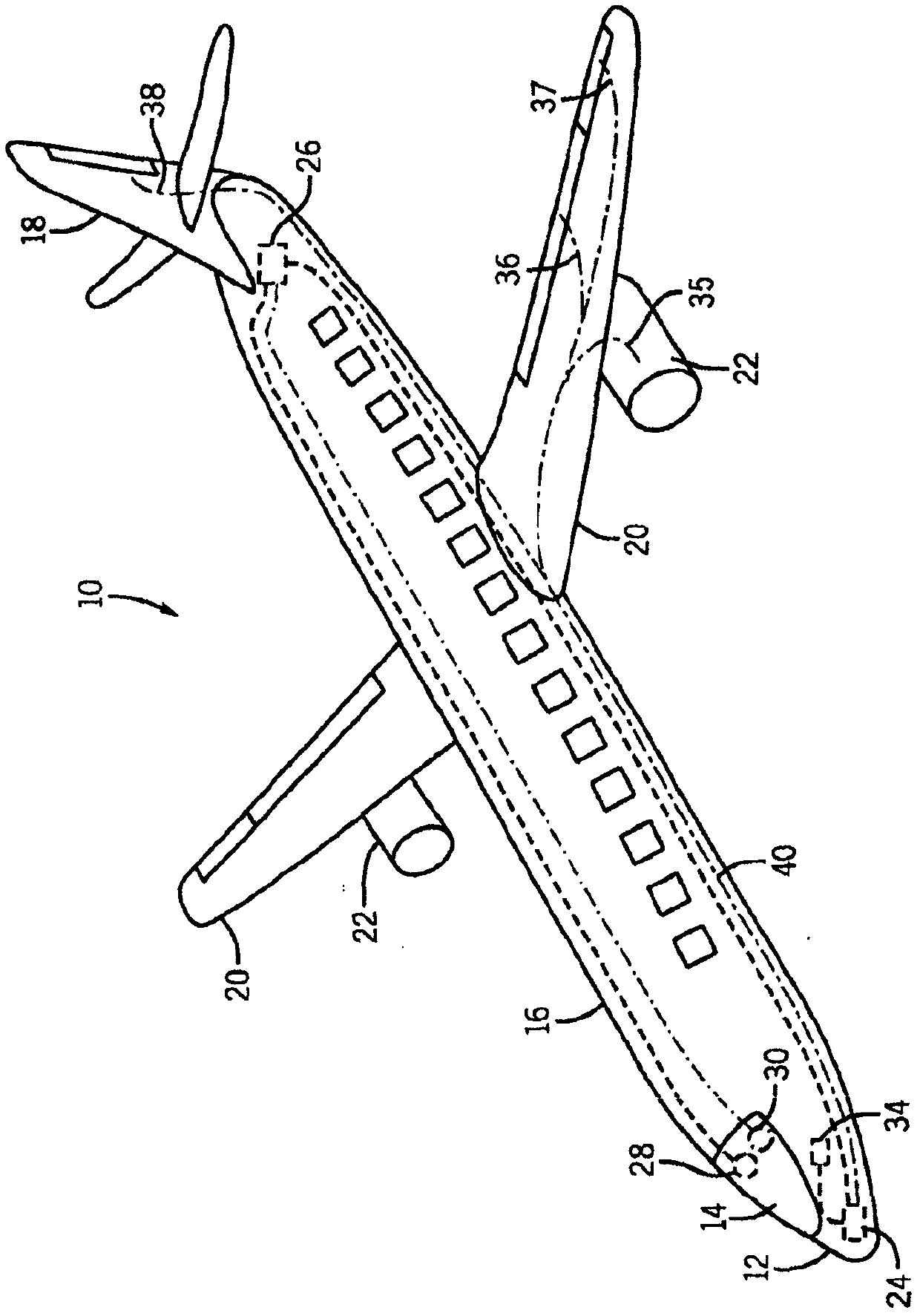

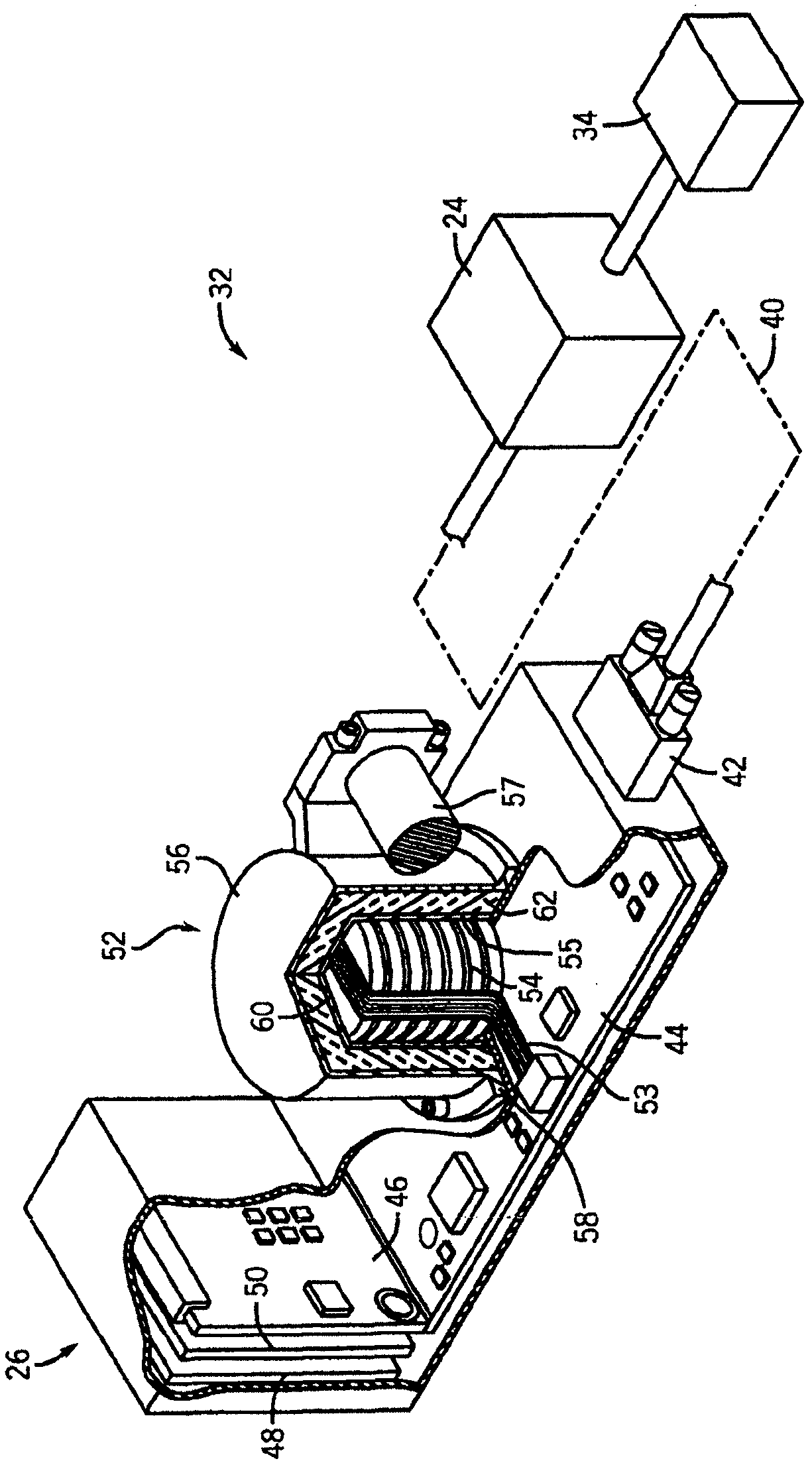

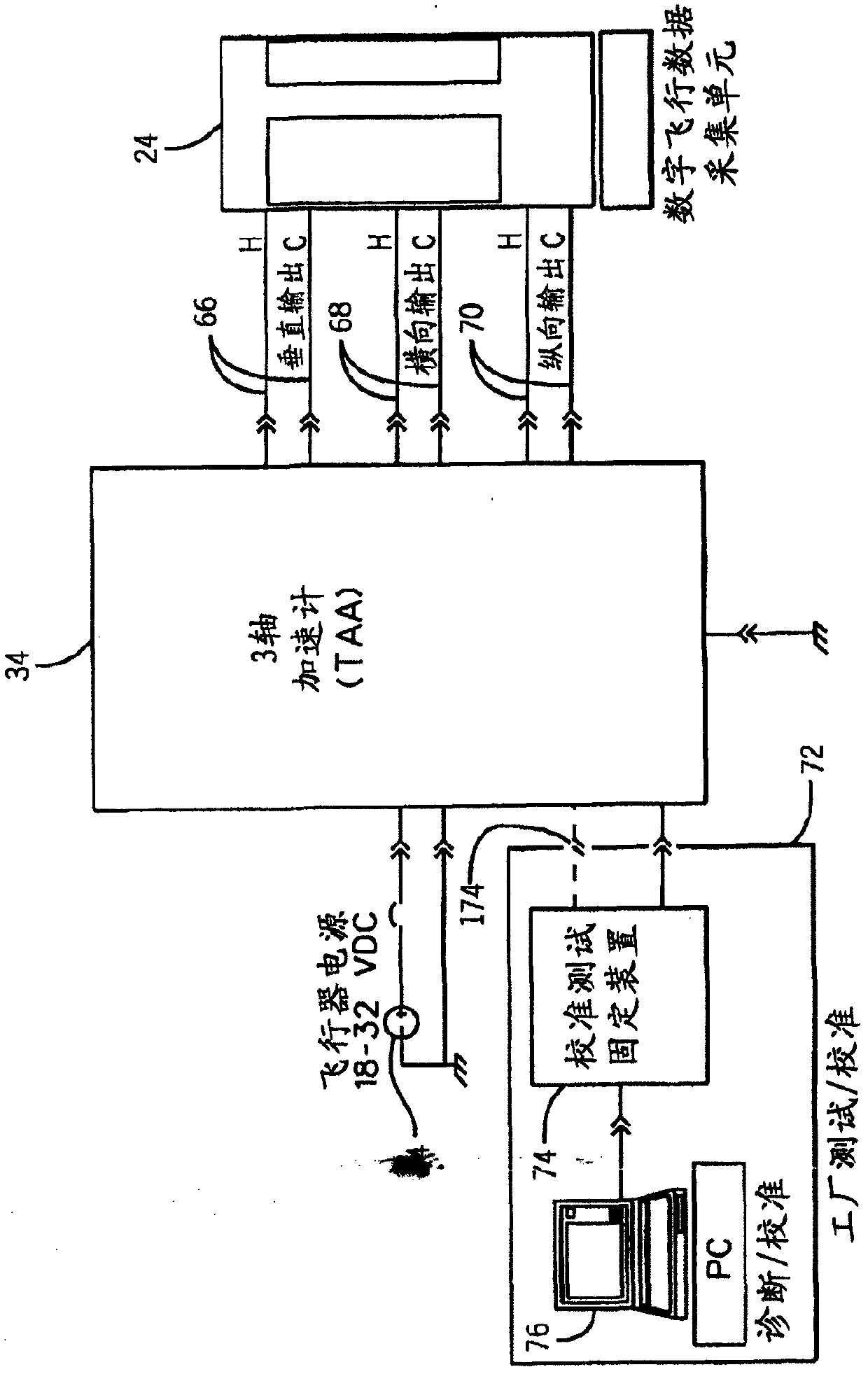

Accelerometer and method for error compensation

ActiveCN102016605AAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsAccelerometerTransducer

Owner:L 3 COMM CORP

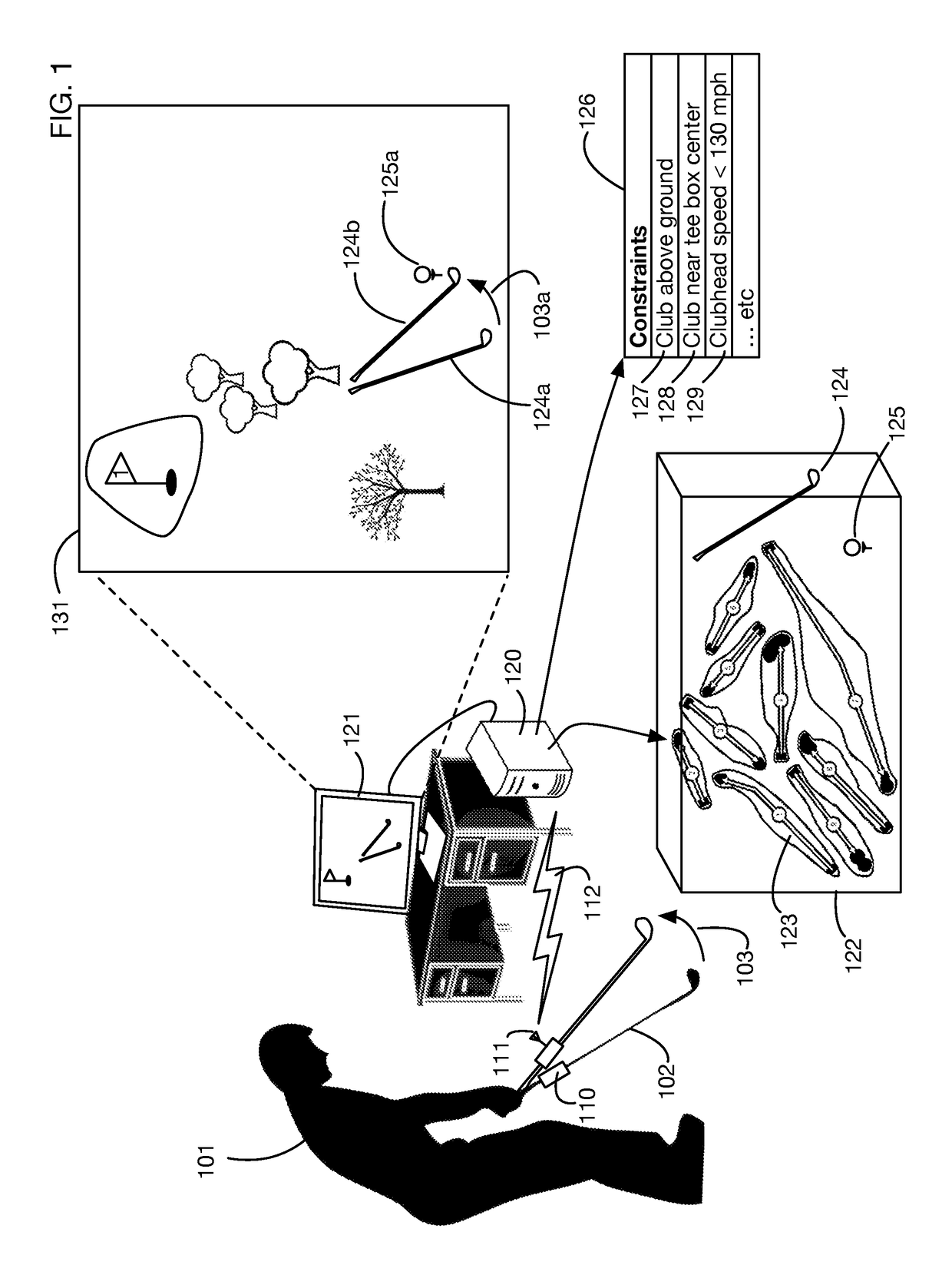

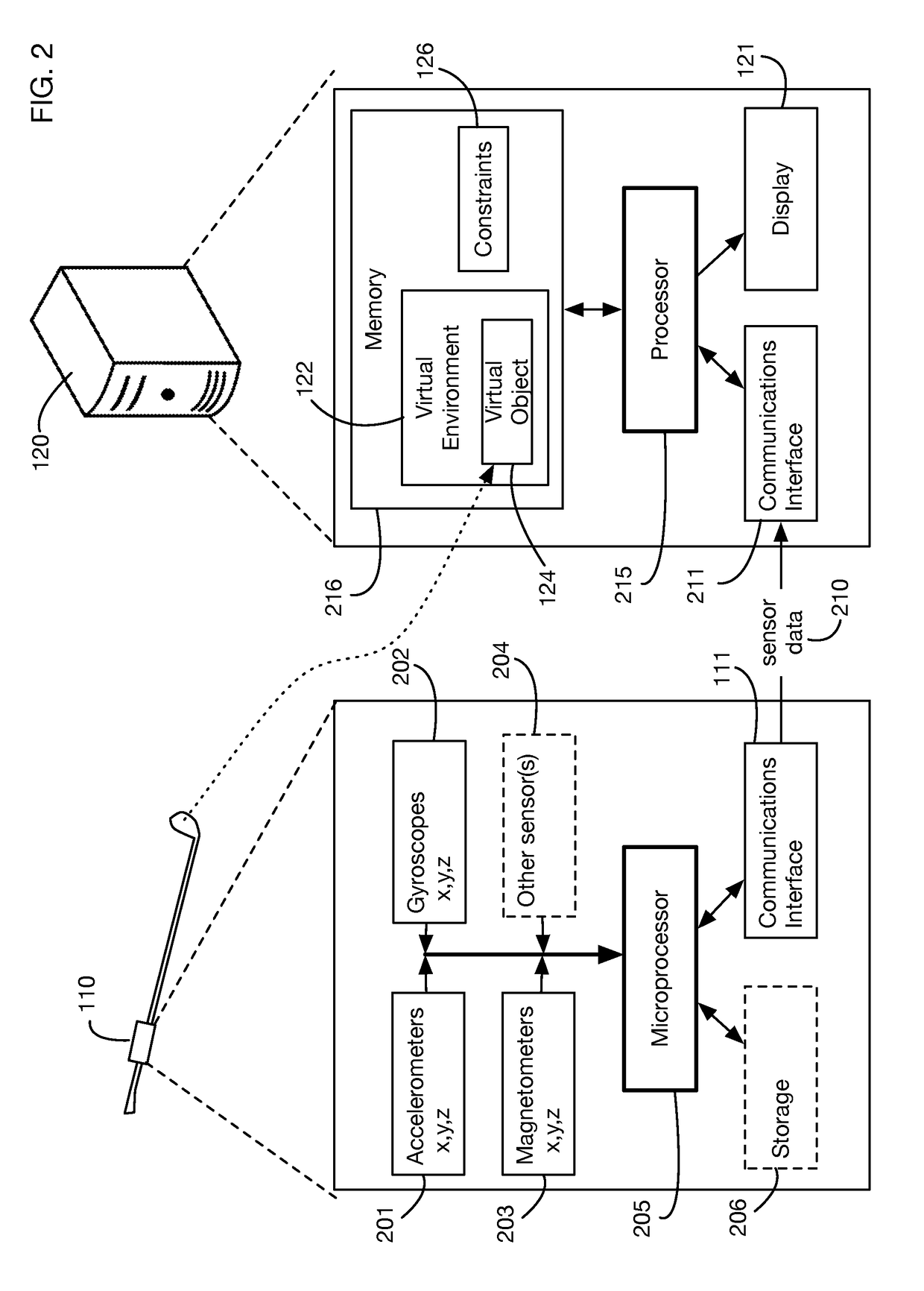

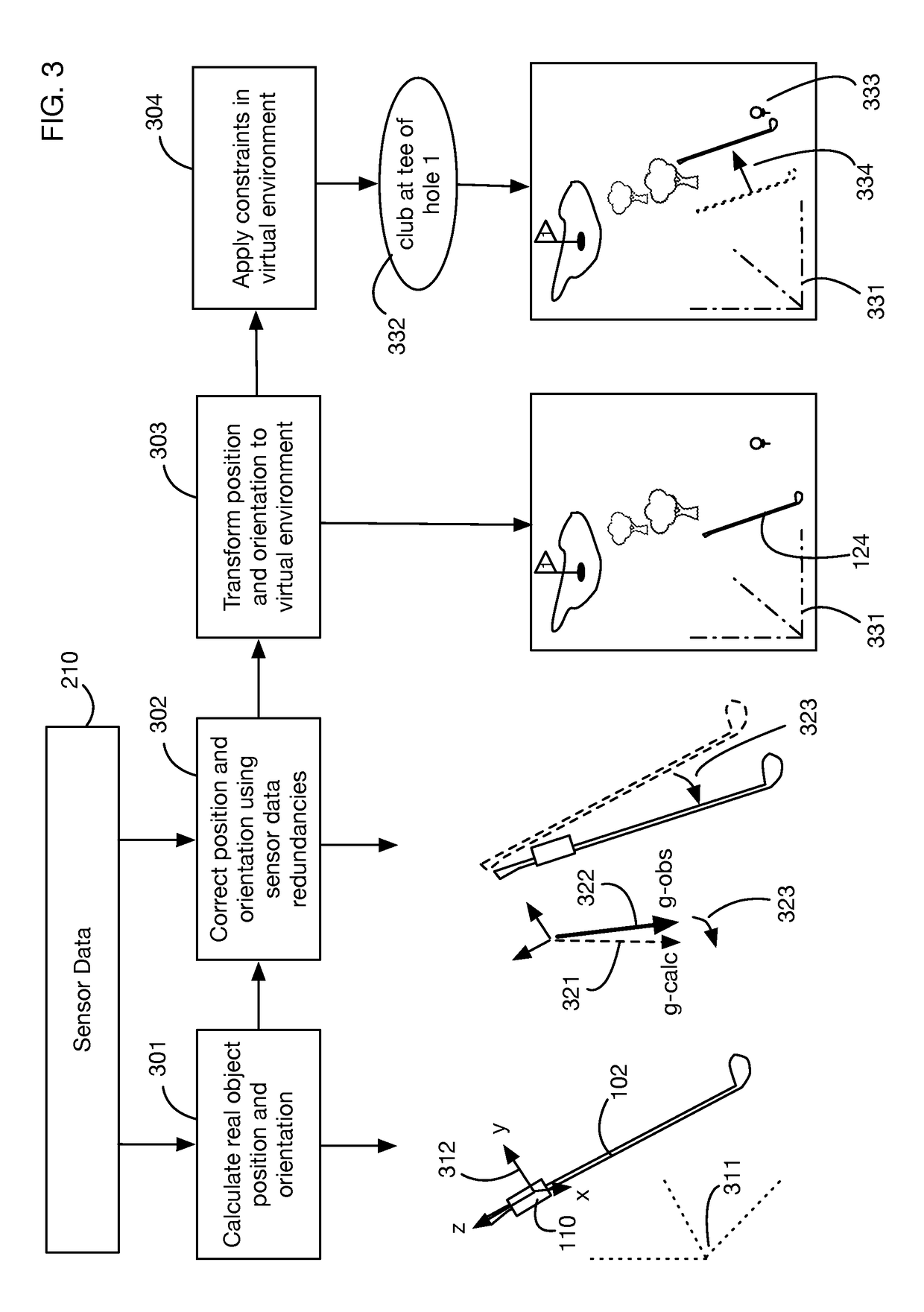

Motion mirroring system that incorporates virtual environment constraints

A system that mirrors motion of a physical object by displaying a virtual object moving in a virtual environment. The mirroring display may be used for example for feedback, coaching, or for playing virtual games. Motion of the physical object is measured by motion sensors that may for example include an accelerometer, a gyroscope, and a magnetometer. Sensor data is transmitted to a computer that calculates the position and orientation of the physical object and generates a corresponding position and orientation of the virtual object. The computer may correct or adjust the calculations using sensor data redundancies. The virtual environment may include constraints on the position, orientation, or motion of the virtual object. These constraints may be used to compensate for accumulating errors in position and orientation. The system may for example use proportional error feedback to adjust position and orientation based on sensor redundancies and virtual environment constraints.

Owner:NEWLIGHT CAPITAL LLC

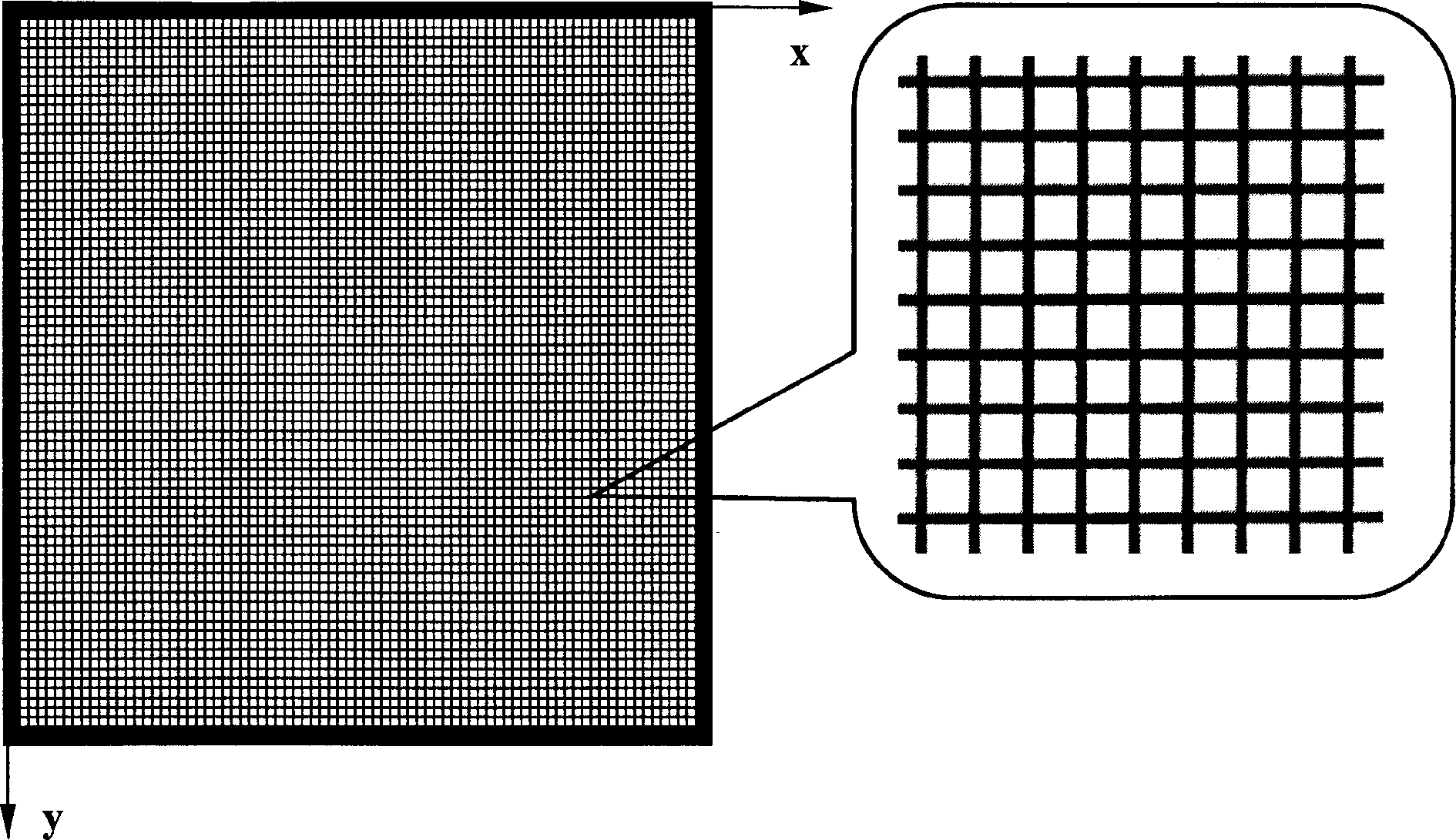

Method for exactly calibrating and modifying scanner by using normal scanner in precision measurement

InactiveCN1484190AHigh precisionCharacter and pattern recognitionHigh frequency vibrationComputer science

The method in the invention includes: a. arranges the image and the mark around the image on the platform of the scanner through precise orthogonal grid and precise linear grid, and defines the scanner line CCD direction is X direction, step motor is Y direction; b. carries on whole scan to the image and the mark through precise orthogonal grid and precise linear grid; c. marks and amends one or more sub-items error to the scanned image, the sub-items are X-X error, X-Y error, Y-Y error, Y-X error, lines proportion error, row proportion error, vertical and horizontal proportion error, scanning error and high frequency vibration error.

Owner:NAT UNIV OF DEFENSE TECH

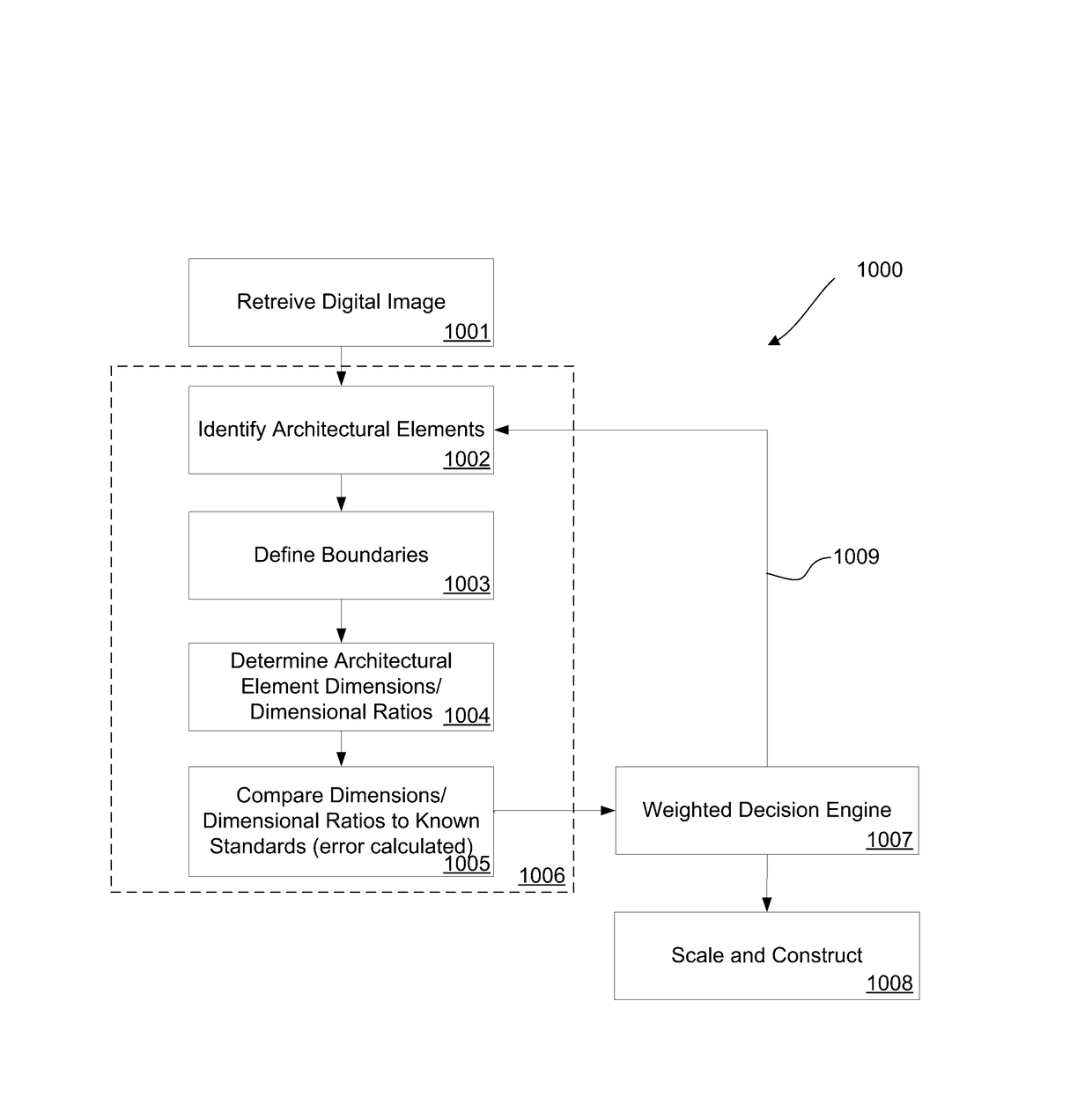

Multi-dimensional model dimensioning and scale error correction

A system and method is provided for identifying scale, scale error, or improper positioning during construction or reconstruction of a multi-dimensional (e.g., 3D) building model using known architectural dimensions. The system identifies architectural elements that have known architectural standard dimensions. Dimensional measurements (or dimensional ratios) of architectural elements in the multi-dimensional model (poorly scaled) are compared with known architectural standard dimensions, with or without scale error, to properly scale, rescale or position one or more planes within the multi-dimensional building model.

Owner:HOVER

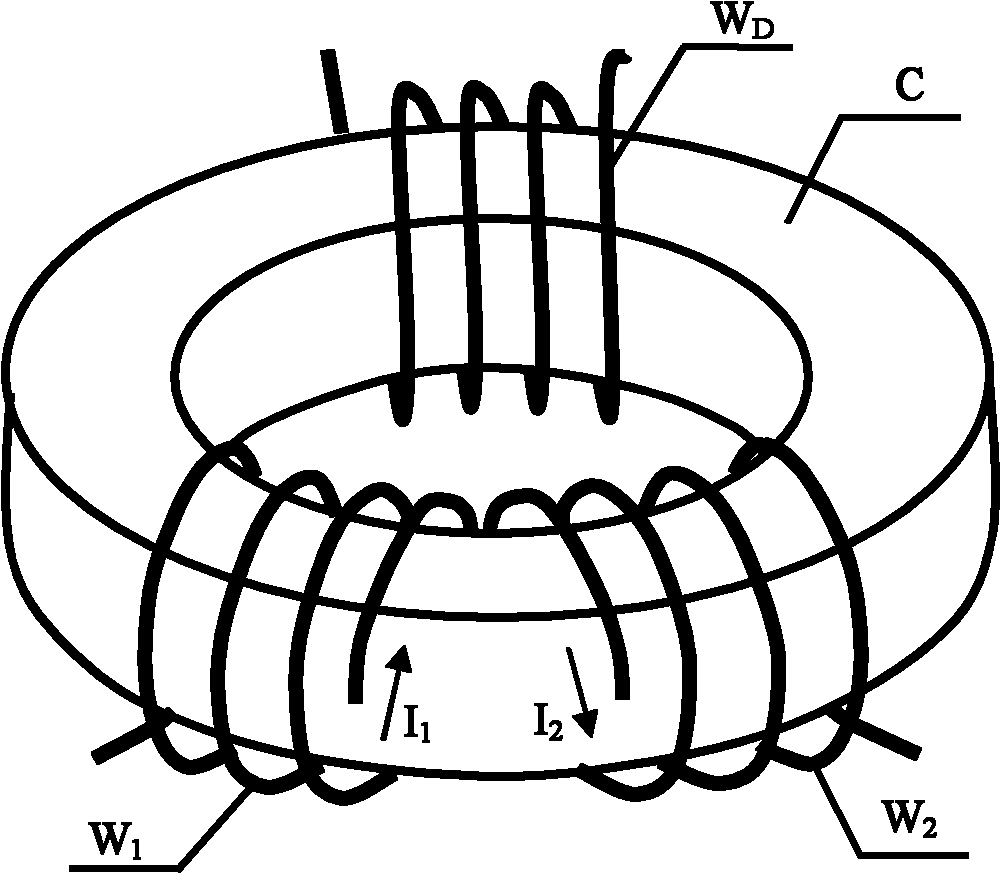

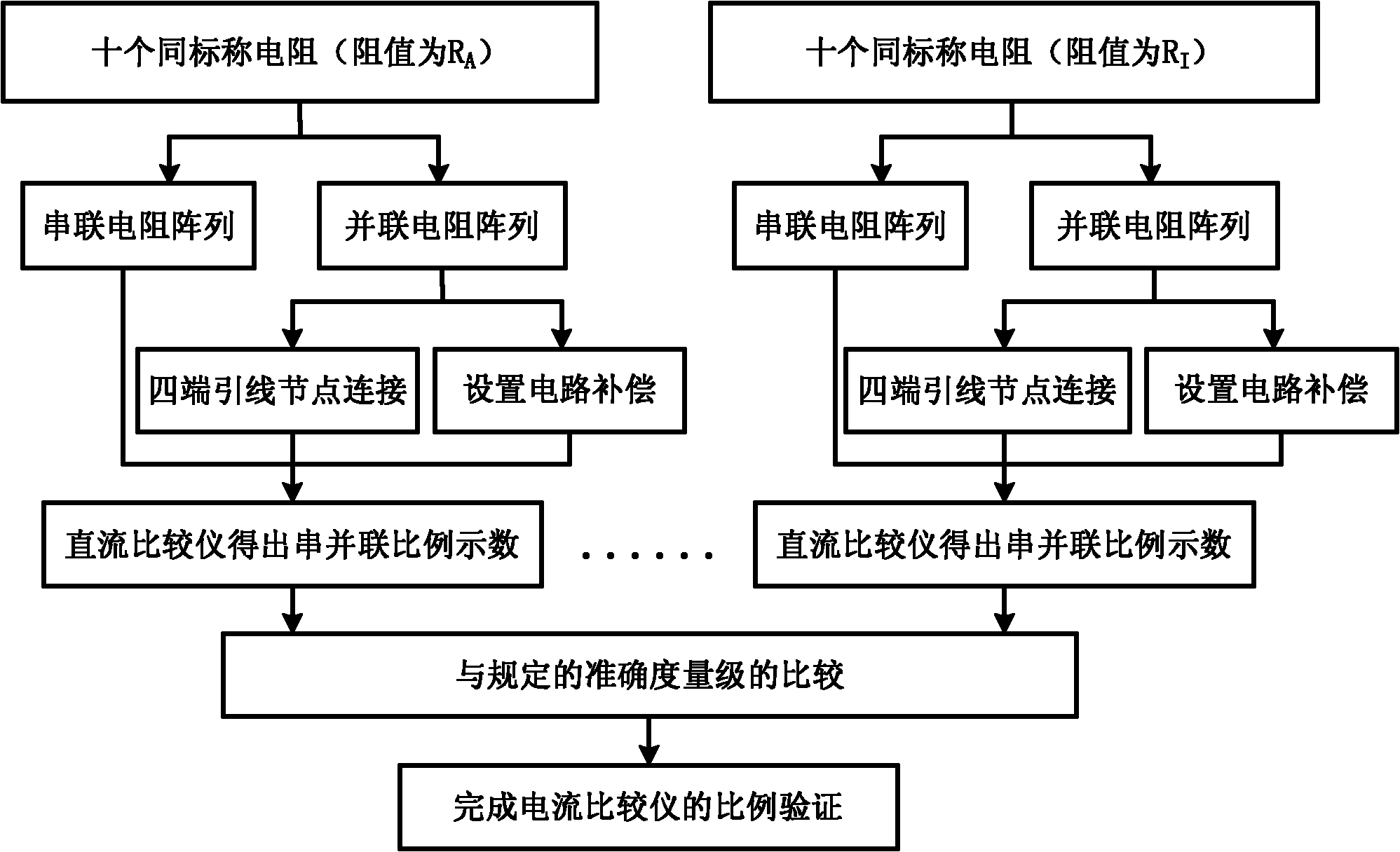

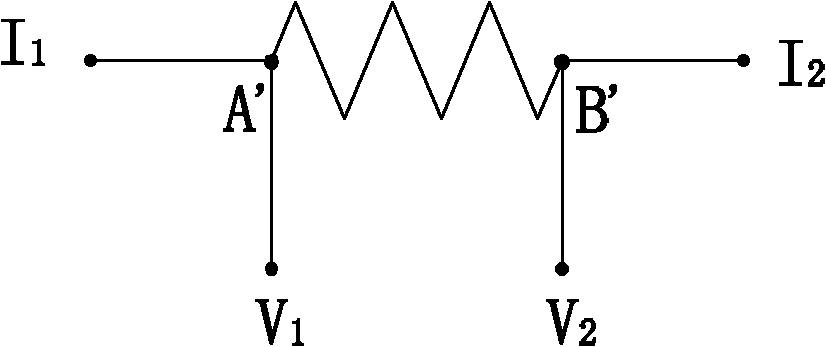

Method and device for verifying high-accuracy direct-current comparator

ActiveCN102096058AAvoid interferenceError Elimination and ReductionElectrical measurementsElectrical resistance and conductanceDc current

The invention provides a method and device for verifying a high-accuracy direct-current comparator for resistance measurement. The method comprises the following steps: firstly connecting two or more than two same nominal resistors in serial and in parallel so as to respectively form serial resistor arrays and parallel resistor arrays; connecting the parallel resistor arrays with nodes at the two ends of all parallel resistors by virtue of a four-end lead node structure, and setting short-circuit compensation for externally-connected short-circuit sheets when the resistor arrays are connected in parallel; then carrying out proportion measurement by virtue of measured direct-current comparators, and obtaining serial-parallel proportion readings by the direct-current comparators; connecting three groups or more than three groups of nominal resistors in series and in parallel, and then carrying out the proportion measurement by virtue of the measured direct-current comparators; and comparing with the specified accuracy level according to the production of the serial-parallel proportion readings of all the groups of serial and parallel resistor arrays, so as to realize the proportion verification of the direct-current comparators. By utilizing the method provided by the invention, accurate verification of proportional errors of the high-accuracy (the accuracy reaches 10-7-10-8 levels) direct-current comparator used for resistance measurement can be realized.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

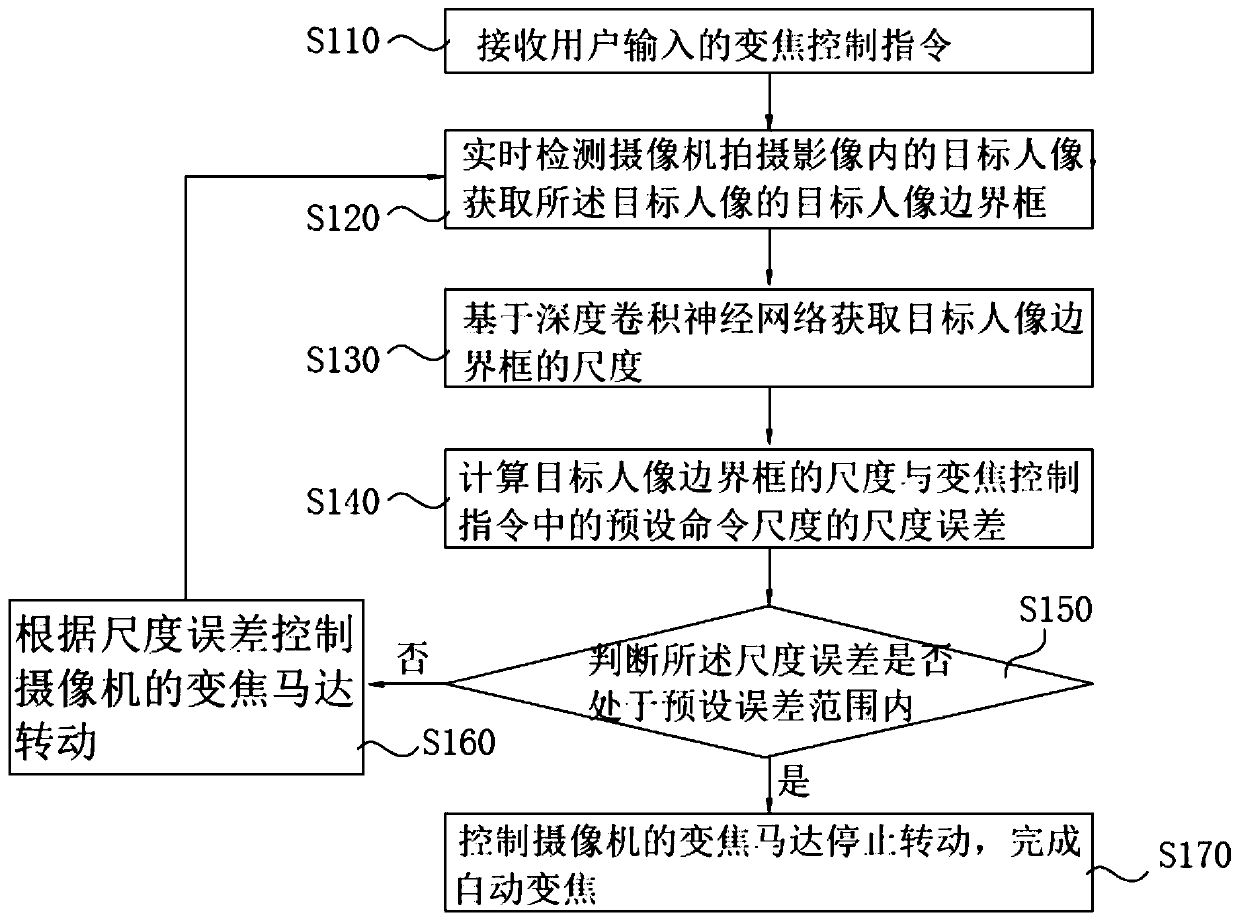

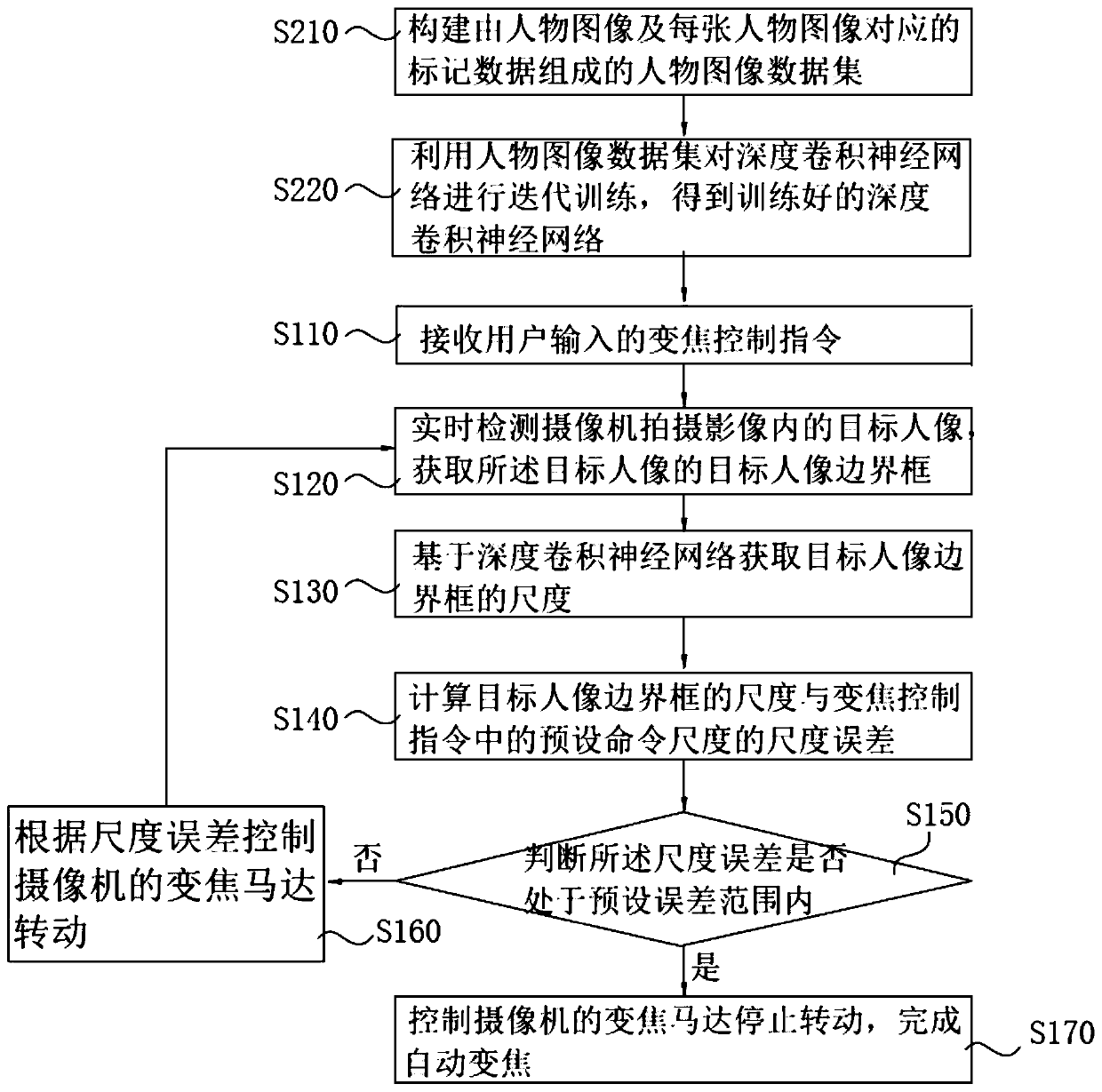

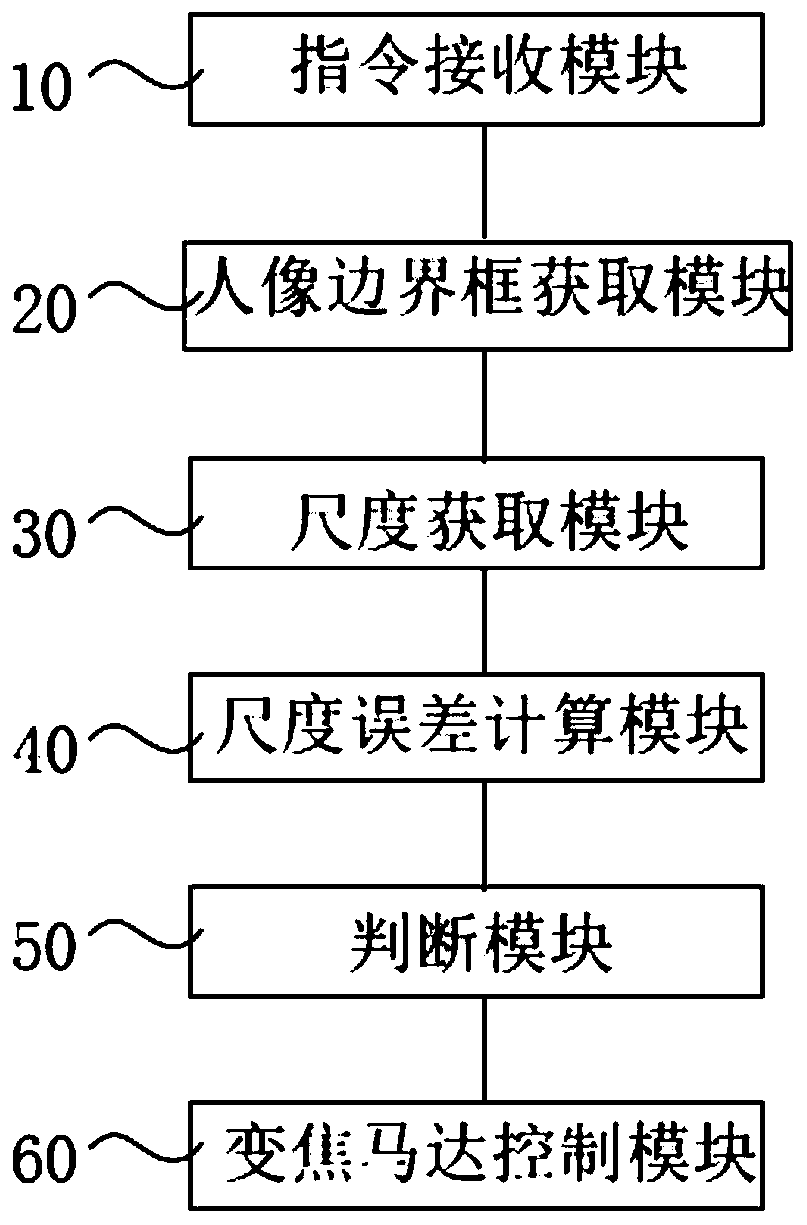

Unmanned shooting automatic zooming method and system, unmanned camera and storage medium

ActiveCN109803090AMeet individual needsImprove the shooting effectTelevision system detailsColor television detailsFrame basedUser input

The invention discloses an unmanned shooting automatic zooming method and system, an unmanned camera and a storage medium. The unmanned shooting automatic zooming method comprises the following steps:receiving a zooming control instruction input by a user; Detecting a target portrait in the image shot by the camera in real time, and obtaining a target portrait boundary frame of the target portrait; obtaining the scale of a target portrait boundary frame based on the deep convolutional neural network; calculating a scale error between the scale of the target portrait boundary frame and a preset command scale in the zoom control instruction; Judging whether the scale error is within a preset error range, and if not, controlling a zoom motor of the camera to rotate according to the scale error; and if yes, controlling a zoom motor of the camera to stop rotating, and finishing automatic zoom. The zoom motor of the camera is controlled to rotate by acquiring the scale of the target portrait boundary frame and cooperating with different preset command scales, automatic zoom shooting of the shot target can be completed without directly operating the camera manually, the shooting effect is improved, and the user requirement is met.

Owner:REMO TECH CO LTD

Automated vehicle radar system with auto-alignment for azimuth, elevation, and vehicle speed-scaling-error

Owner:APTIV TECH LTD

Method for registering patterns on a web

ActiveUS7650839B2Avoid nonlinear distortionAddressographsPlaten pressesNonlinear distortionPosition error

Owner:EASTMAN KODAK CO

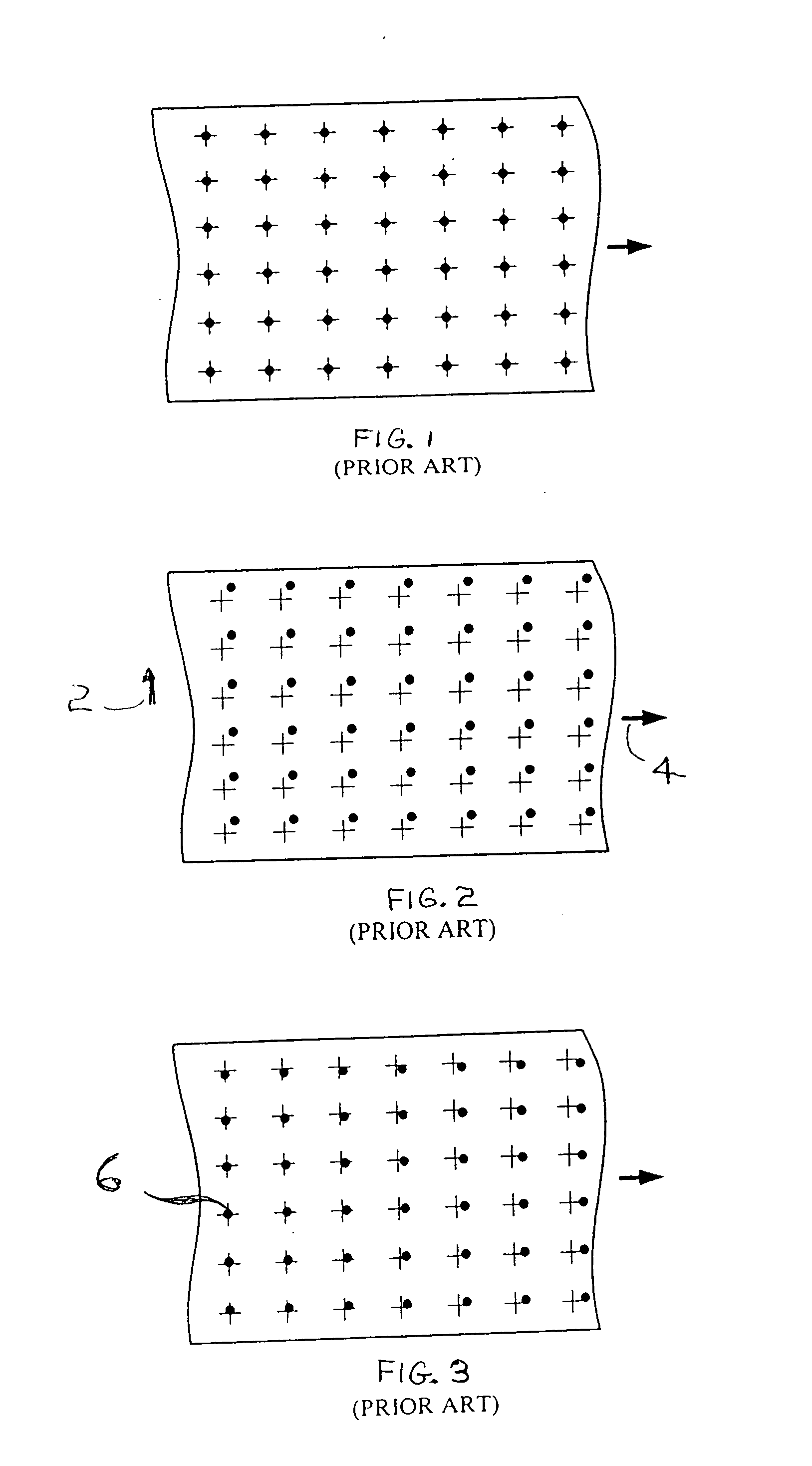

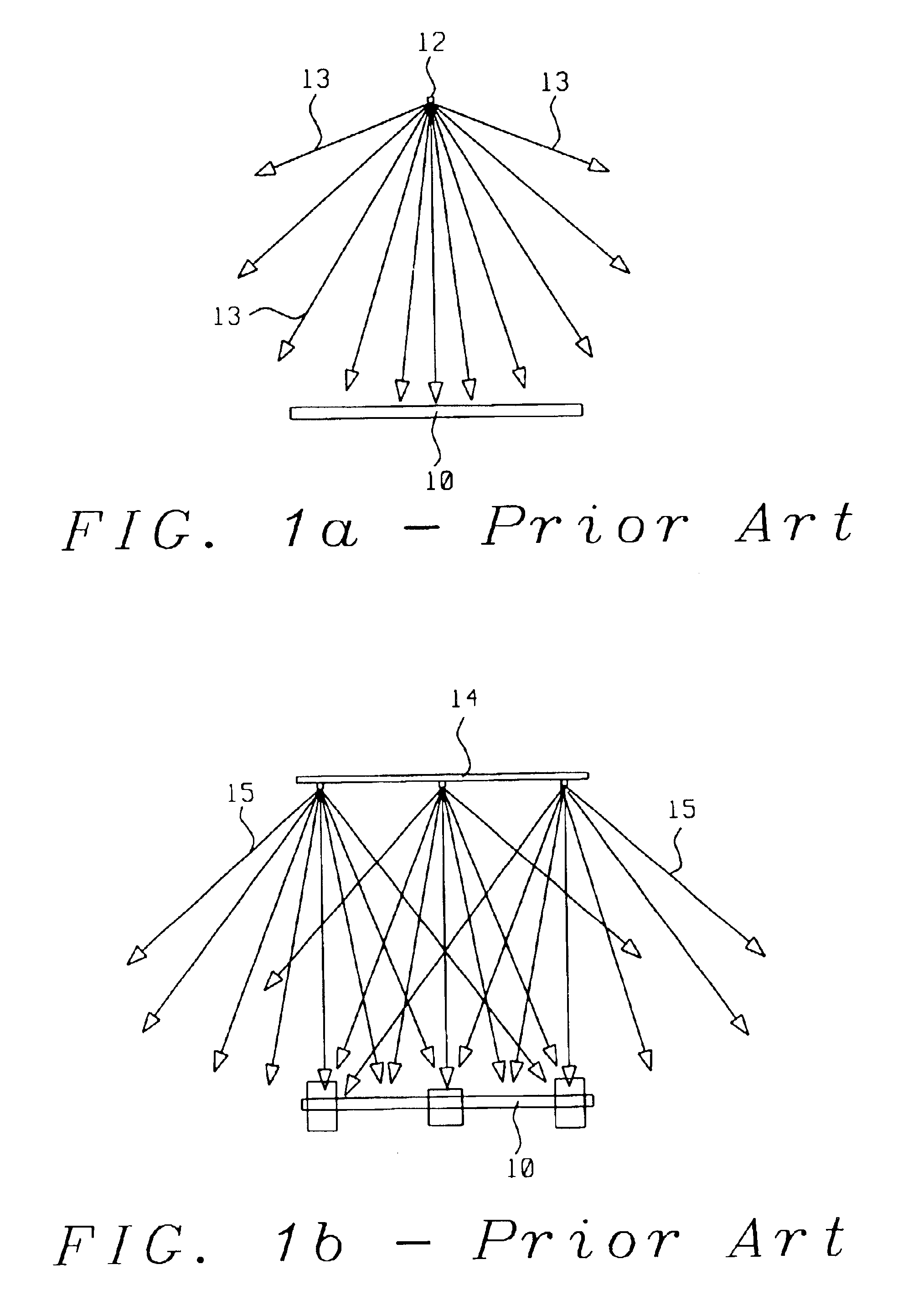

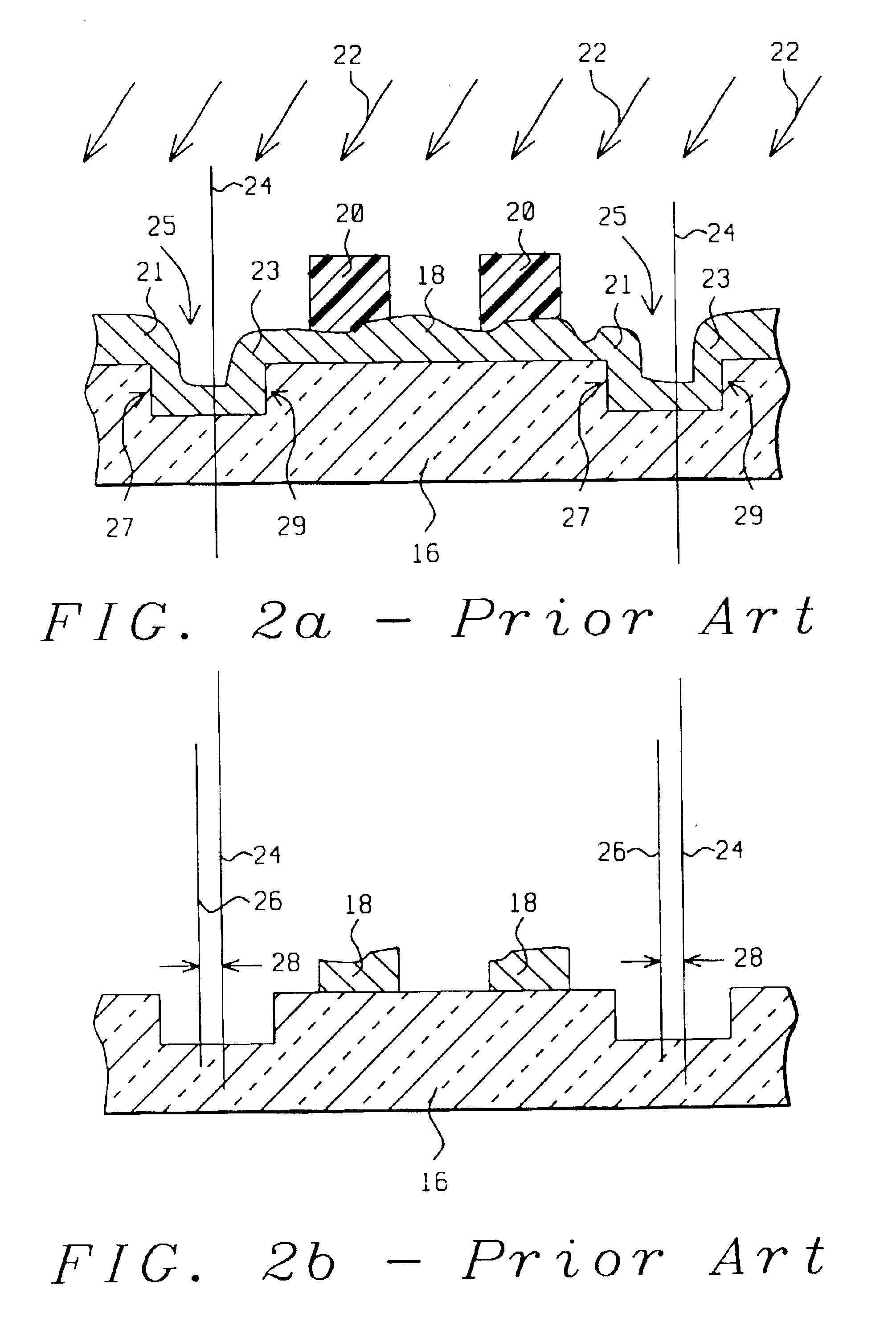

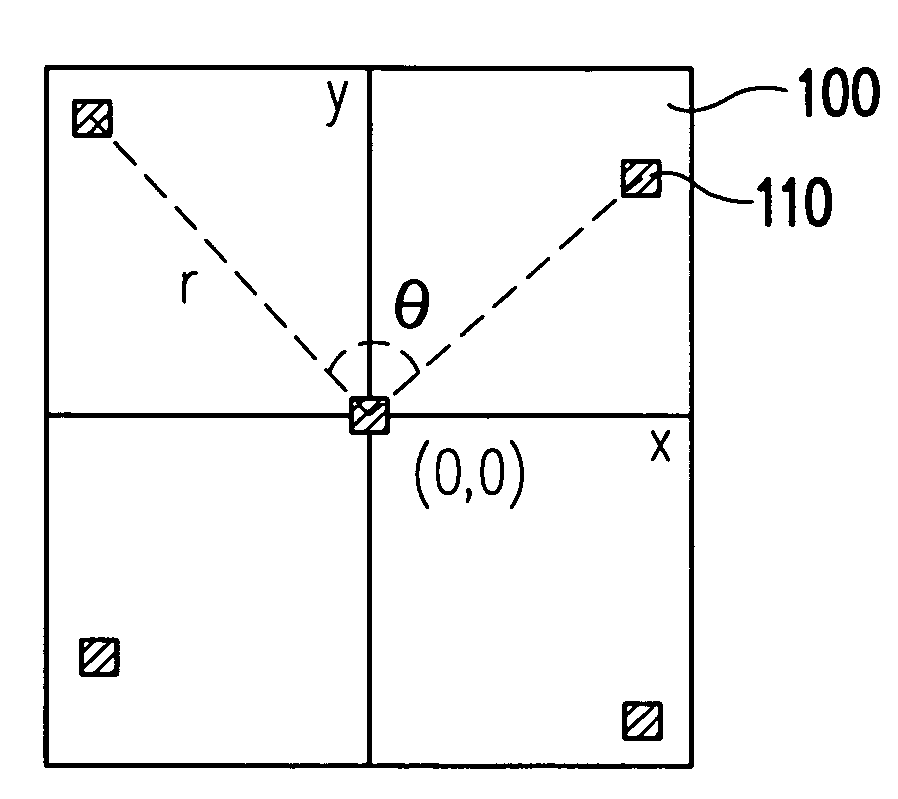

Define overlay dummy pattern in mark shielding region to reduce wafer scale error caused by metal deposition

InactiveUS6838217B1Reduction in wafer scaling errorPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringScale error

A new method is provided for the creation of a dummy pattern. A typical wafer exposure mask contains a Clear Out Window (CLWD) pattern, this CLWD pattern is of no value during the process of shielding the area on the surface of the wafer where the alignment mark must be placed. This CLWD can therefore be used to create a dummy overlay pattern, resulting in a reduction in the wafer scaling error that typically occurs as a result of metal deposition. For the same reasons, a dummy overlay pattern can also be created in the scribe lines of the wafer surface.

Owner:TAIWAN SEMICON MFG CO LTD

Method for analyzing overlay errors

InactiveUS7586609B2Improve performanceImprove accuracyPhotomechanical apparatusUsing optical meansLithographic artistMagnification

A method for analyzing overlay errors in lithography is described. Interfield sampling and intrafield sampling are first conducted to sample multiple positions on each of the wafers, and then the overlay error value at each of the positions is measured. An overlay error model including coefficients of intrafield and interfield overlay errors of different types is used to fit the measured overlay error values with respect to the sampled positions. In the overlay error model, the intrafield overlay errors include intrafield translation, isotropic magnification, reticle rotation, asymmetric magnification and asymmetric rotation, and the interfield overlay errors include interfield translation, scale error, wafer rotation and orthogonality error.

Owner:MACRONIX INT CO LTD

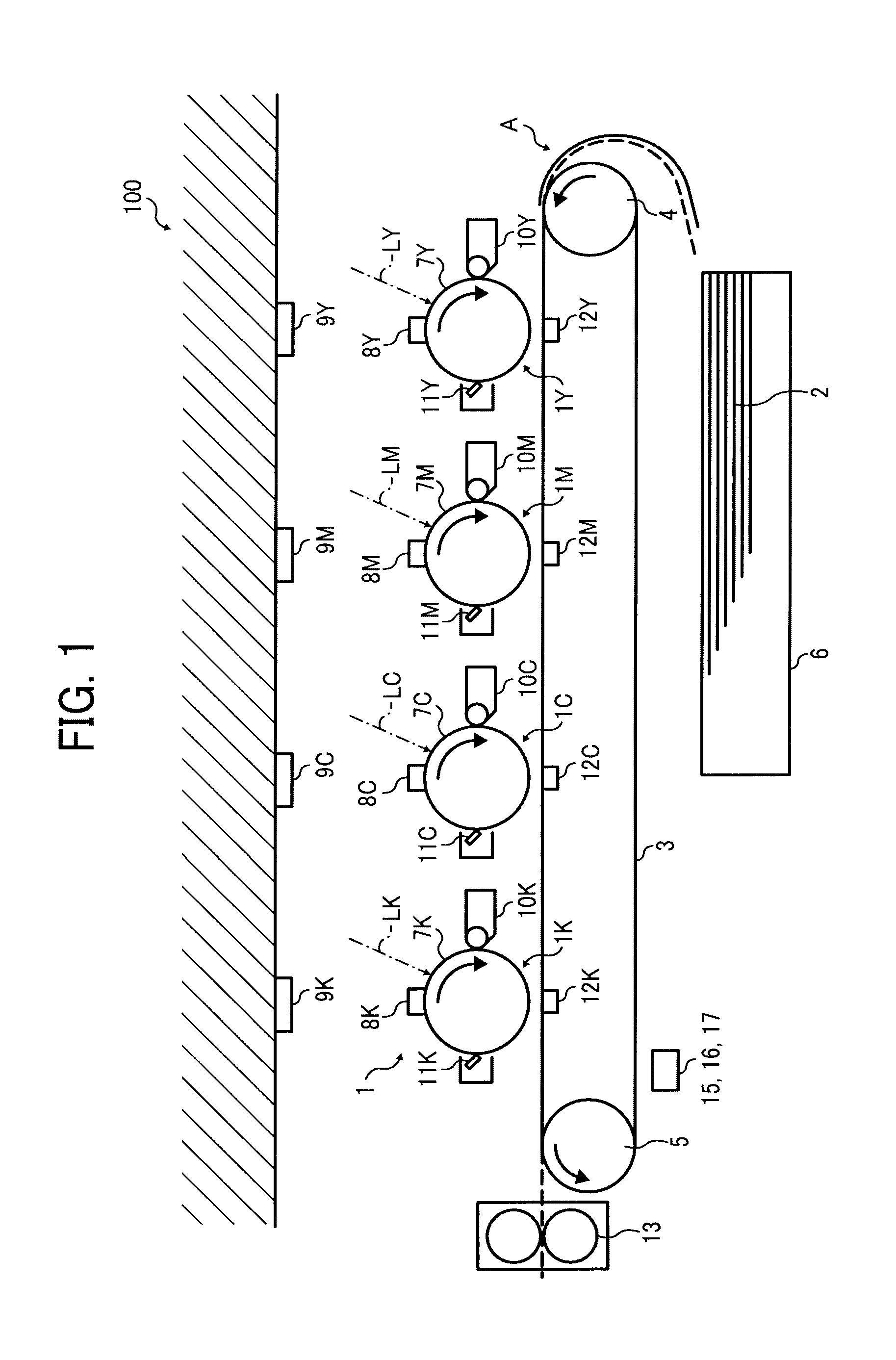

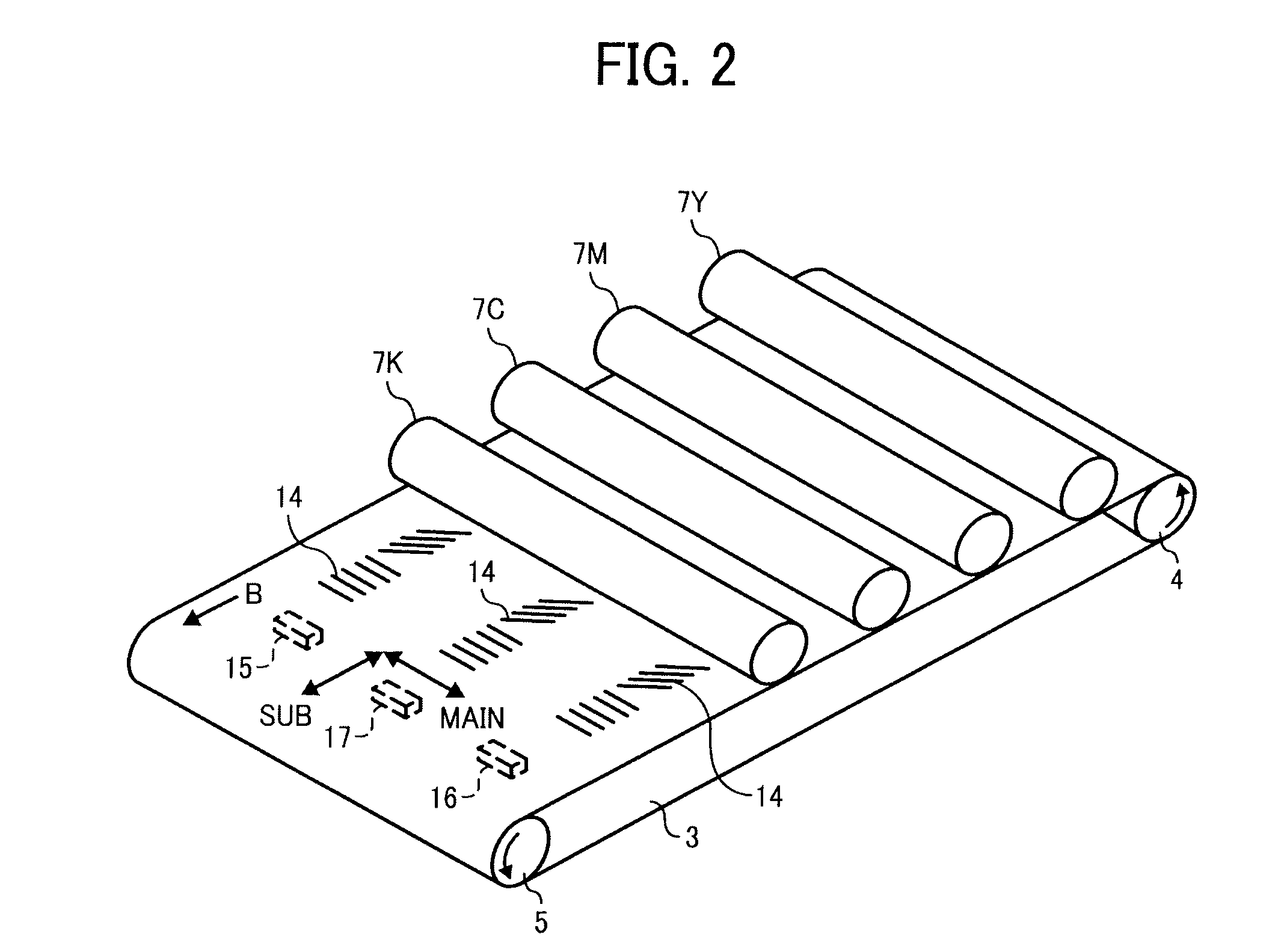

Image forming apparatus

InactiveUS20130107286A1Precise positioningEffectively performing positional error correctionDigitally marking record carriersDigital computer detailsImage formationLight beam

An image forming apparatus includes: Photoreceptors; an image carrier; a plurality of light emitting element arrays each configured to emit a light beam to a corresponding one of the photoreceptors independently; an angle adjustment unit to adjust a mounting angle of the light emitting element arrays to a frame of the image forming apparatus; a pattern forming unit to form a positional error correction pattern of each color on the image carrier; a optical detector to detect the correction pattern formed on the image carrier; a positional error calculation unit to calculate a printing skew error and a main scanning scaling error of the light emitting element arrays based on the correction pattern detected by the optical detector; a skew correction unit to correct the printing skew error detected by the positional error calculation unit; and further a main scanning scaling error correction unit.

Owner:RICOH KK

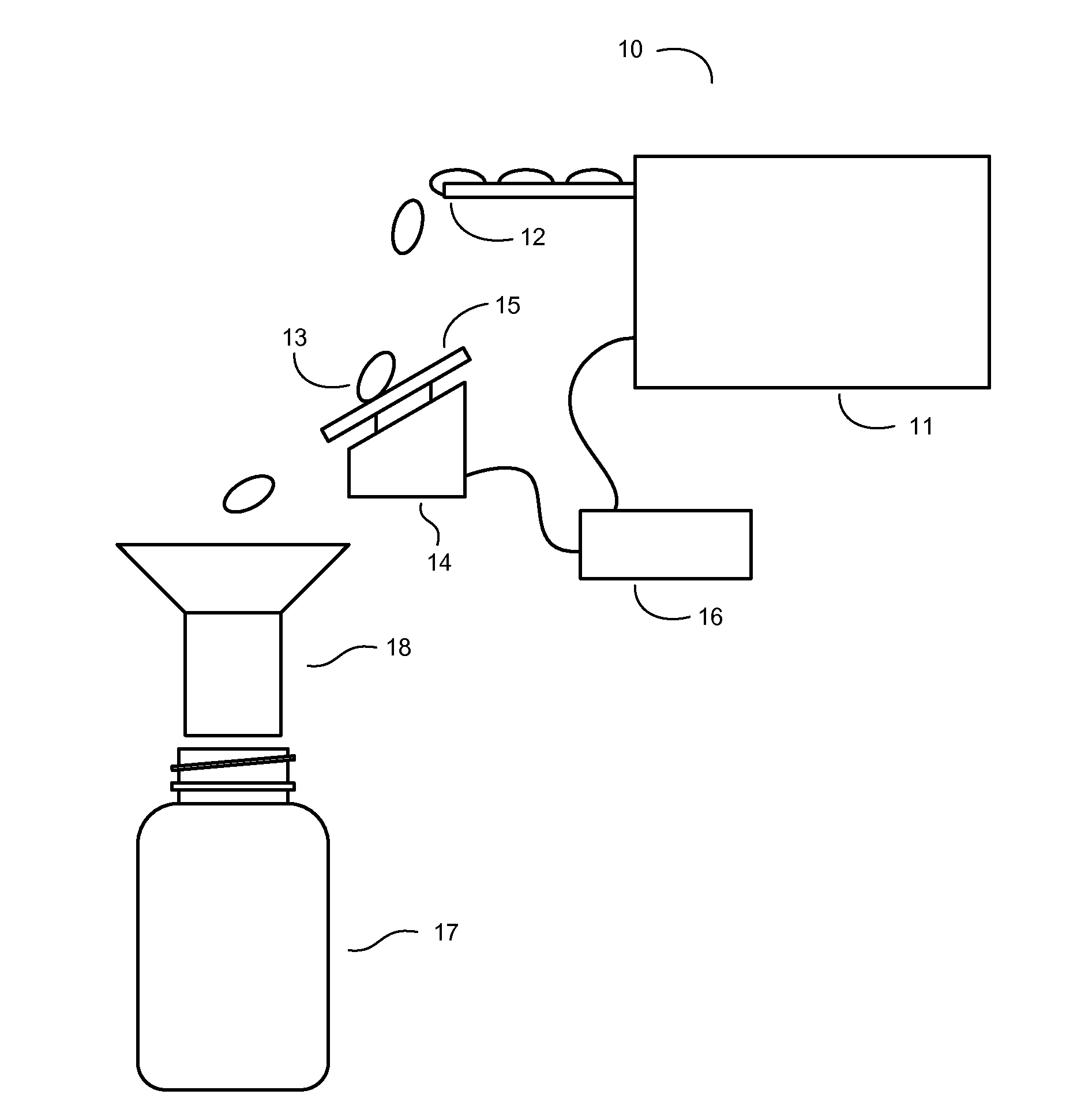

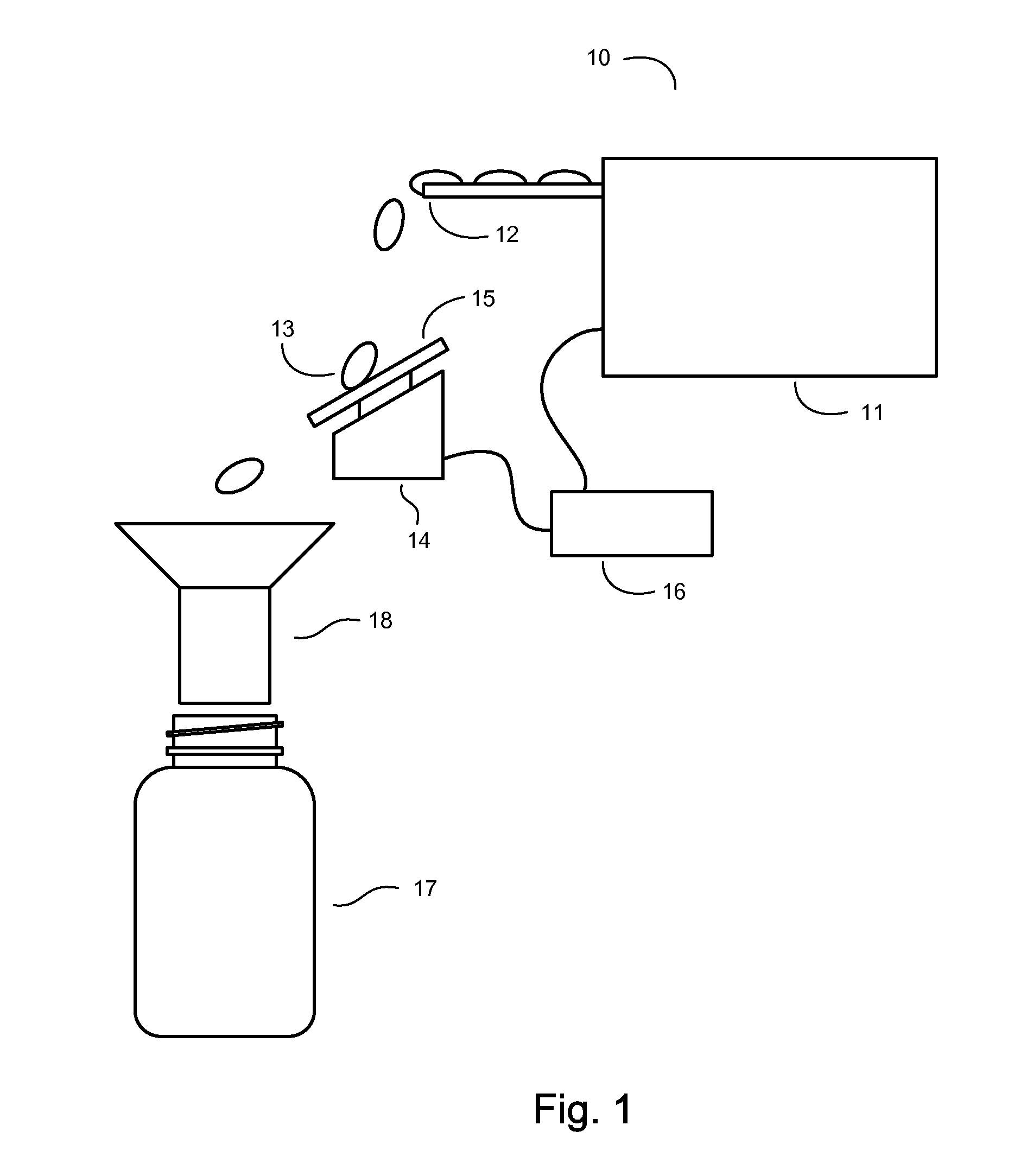

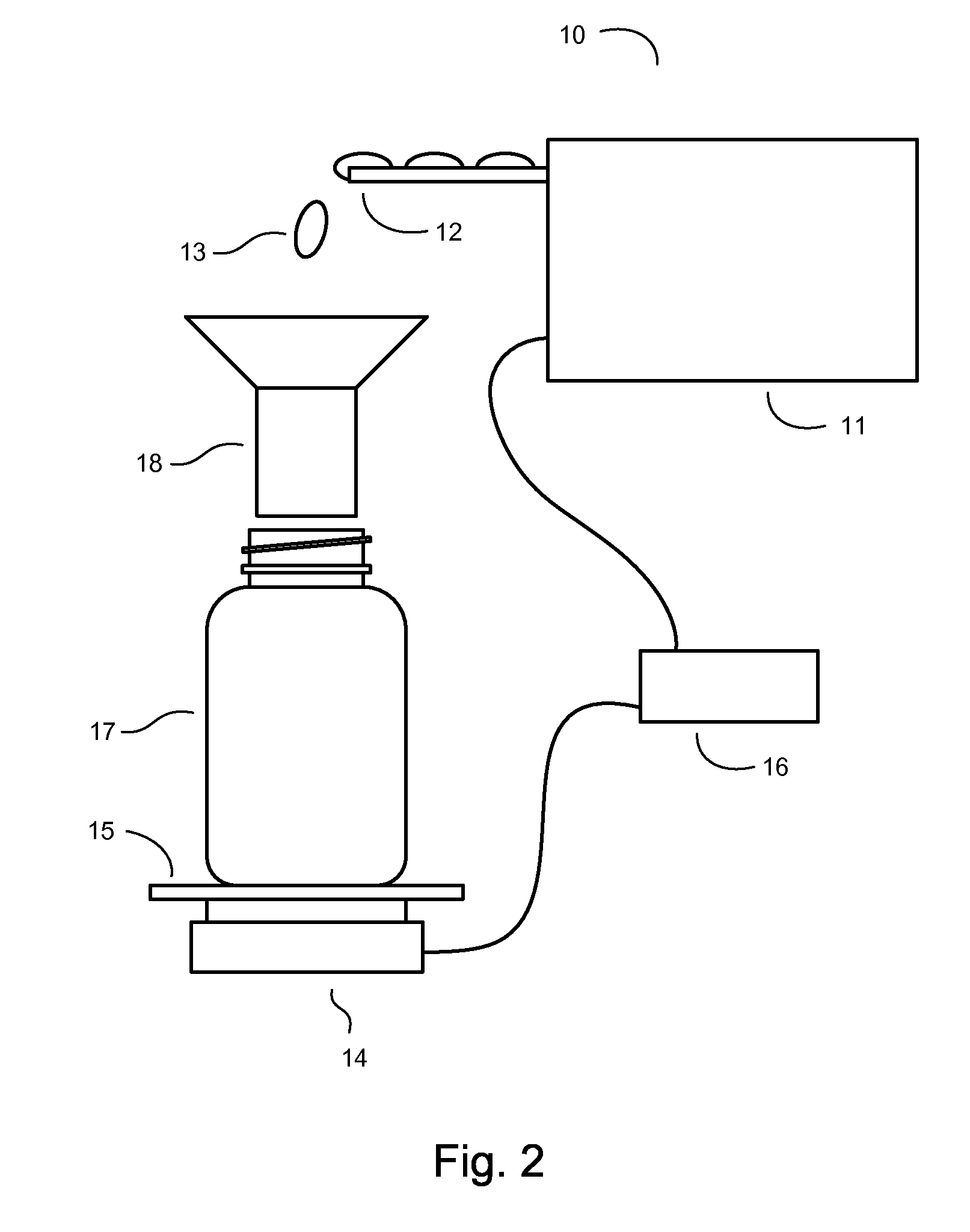

Pill counter

InactiveUS20110036644A1More accurateWeighing apparatus for materials with special property/formSpecial purpose weighing apparatusTotal countPill count

The pill counter of the present invention, counts pills by measuring the weight of individual or a small number of pills as they gradually drop onto a weight scale. During the time between each pill drop, the count is obtained by comparing the weight of latest pills dropped to the expected weight ranges of one or more pills. The expected weight range includes pill weight variation and weight scale error. When the measured weight is between two expected ranges, there is at least one broken pill in addition to the whole pill count of the lower expected range. The counter adds the count of each pill drop to obtain the total count of the pills. In different approach, whenever there is a change in the reading of weight scale more than the error of the weight scale or a predetermined value, the count of pills is increased by one.

Owner:UNITEDHEALTH GROUP

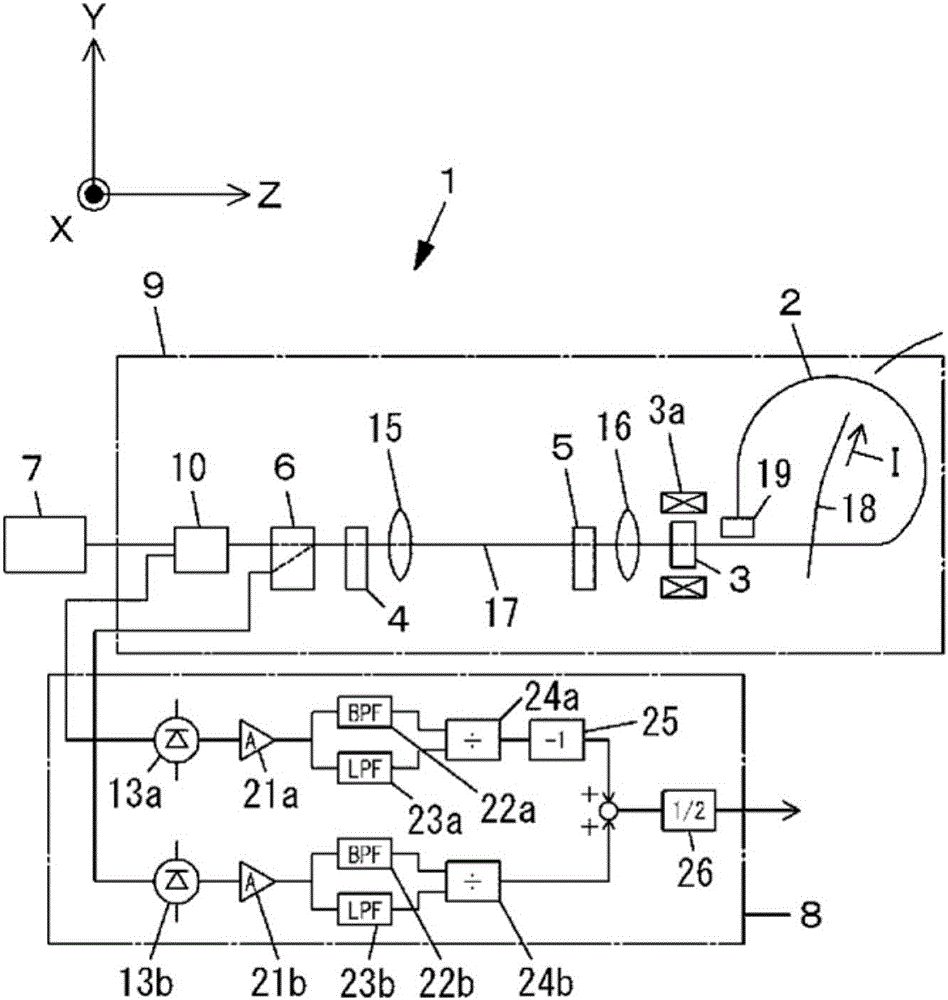

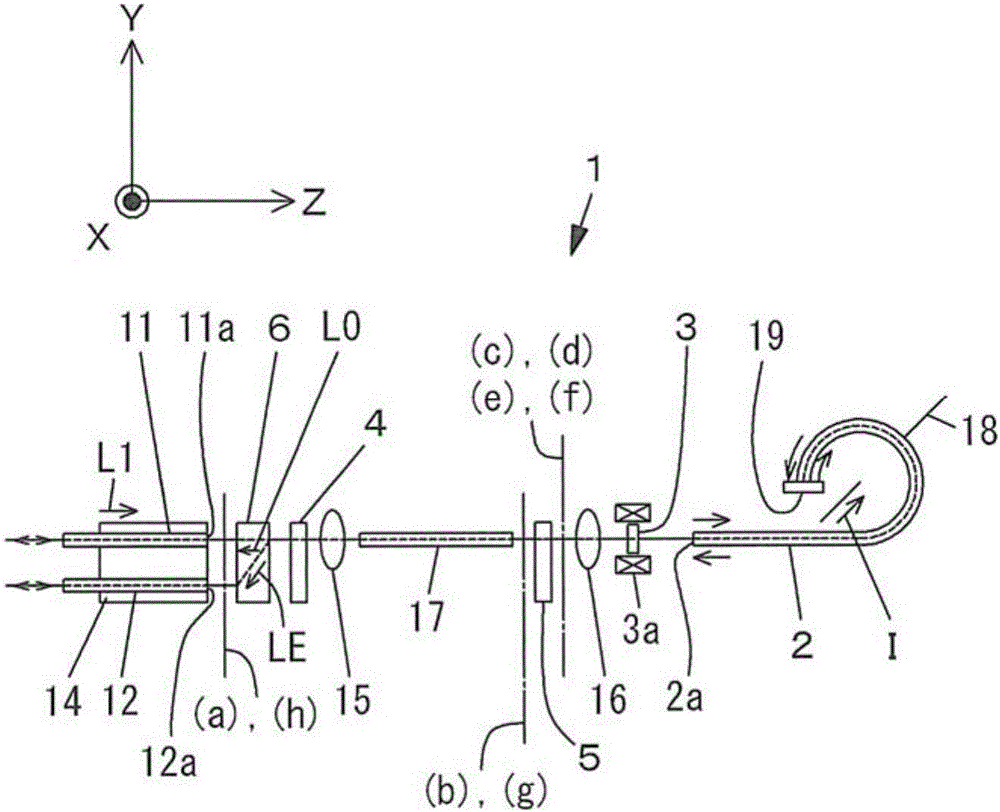

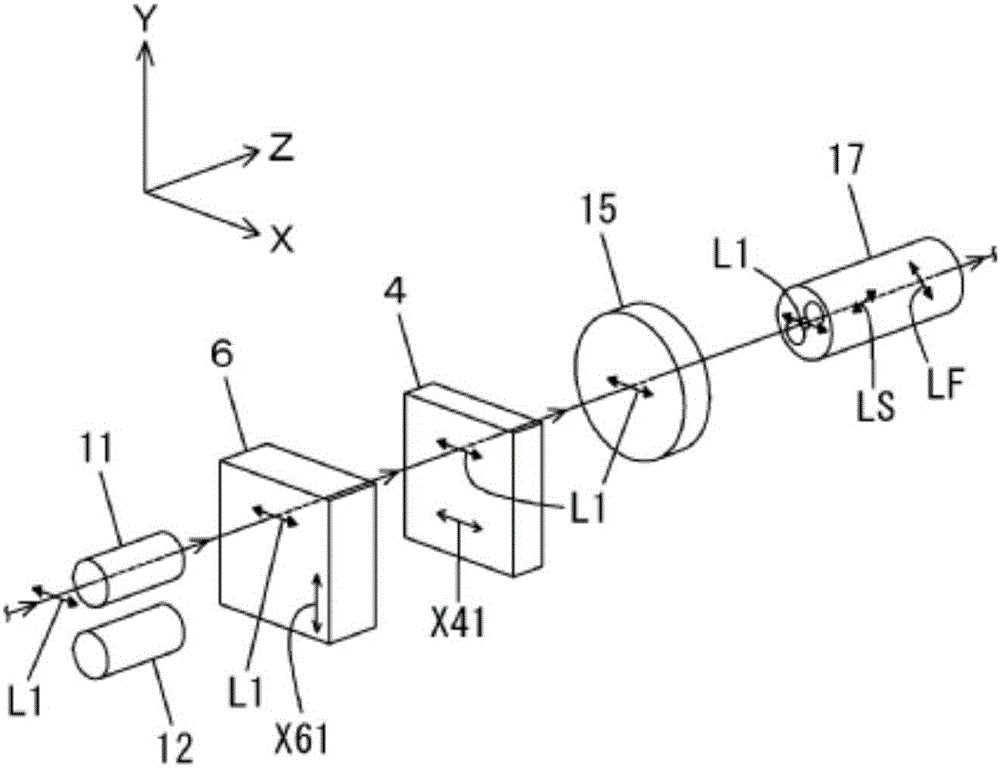

Current measuring device

ActiveCN105026937ALittle changeProportional Error Accurate LimitCurrent measurements onlyVoltage/current isolationSignal processing circuitsPhase difference

Provided is a current measuring device such that it is possible to reliably keep the fluctuation range for the ratio error in output to within a range of ±0.5% and such that assembly thereof can be simplified. The current measuring device is configured to include at least a light entrance and exit, an optical fiber for a sensor, a Faraday rotator, a first 1 / 4 wavelength plate, a second 1 / 4 wavelength plate, a polarization separator, a light source, and a signal processing circuit comprising a photoelectric conversion element. The optical fiber for a sensor has birefringence and comprises one end into which two circularly polarized light beams having different directions of rotation enter and another end that reflects the circularly polarized light beams that have entered. In addition, the phase difference of two linearly polarized light beams in the round-trip light path between the two 1 / 4 wavelength plates is compensated, and the Faraday rotational angle when the Faraday rotator is magnetically saturated is set to 22.5°+α° so that the fluctuation range for the ratio error in the measured value of the current to be measured is set to be in the range of ±0.5%. In addition, the crystal axes on the optical faces of the two 1 / 4 wavelength plates are set to be perpendicular or are set to be in the same direction.

Owner:NAMIKI PRECISION JEWEL CO LTD

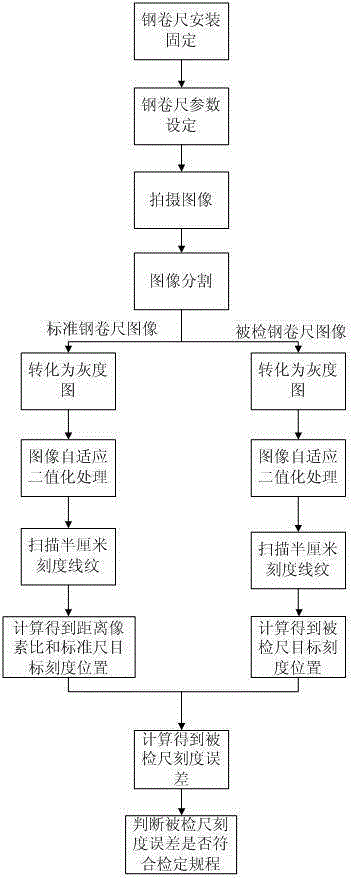

Steel band tape scale error measuring method

InactiveCN105180732ARealize automatic measurementReduce manual labor intensityMeasuring tapesMachine visionMeasurement point

The invention discloses a steel band tape scale error measuring method, which comprises the steps of: step 1, arranging and fixing a verified tape and a standard tape on a verification platform horizontally; step 2, adopting a camera for photographing at a measuring point to obtain a steel band tape image; step 3, processing the steel band tape image to obtain a distance-to-pixel ratio of the standard tape; step 4, acquiring a standard tape target scale position W1 and a verified tape target scale position W2; step 5, and calculating scale error of the verified tape by utilizing the acquired standard tape target scale position W1, the verified tape target scale position W2 and the distance-to-pixel ratio, and judging whether scale error of the measuring point of the verified tape meets the requirement. The steel band tape scale error measuring method is simple in process, convenient to implement and low in cost, measures steel band tape scale error based on machine vision, realizes automatic measurement of steel band tape scale error, can increase measurement accuracy, and can improve the detection efficiency.

Owner:成都市计量检定测试院

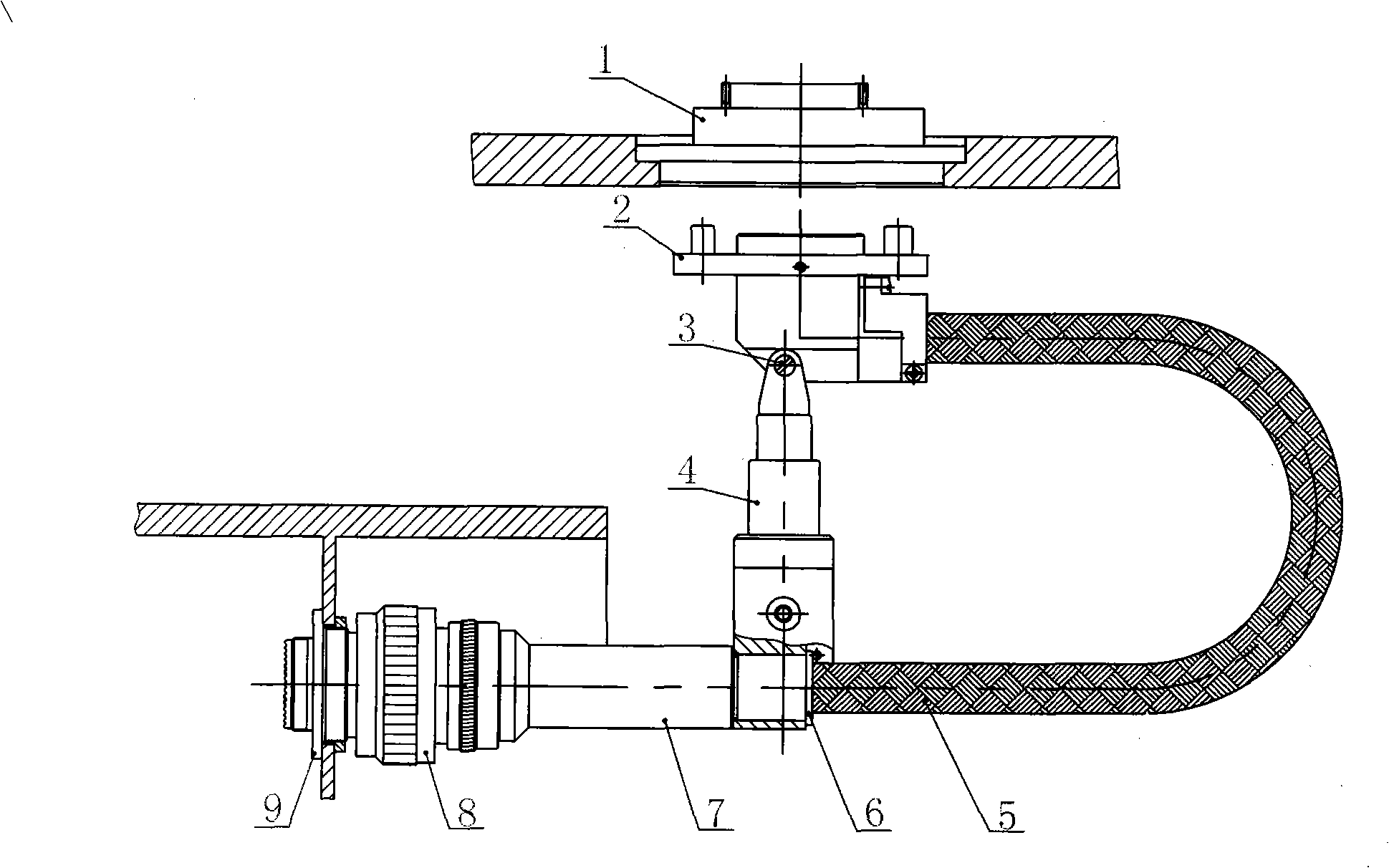

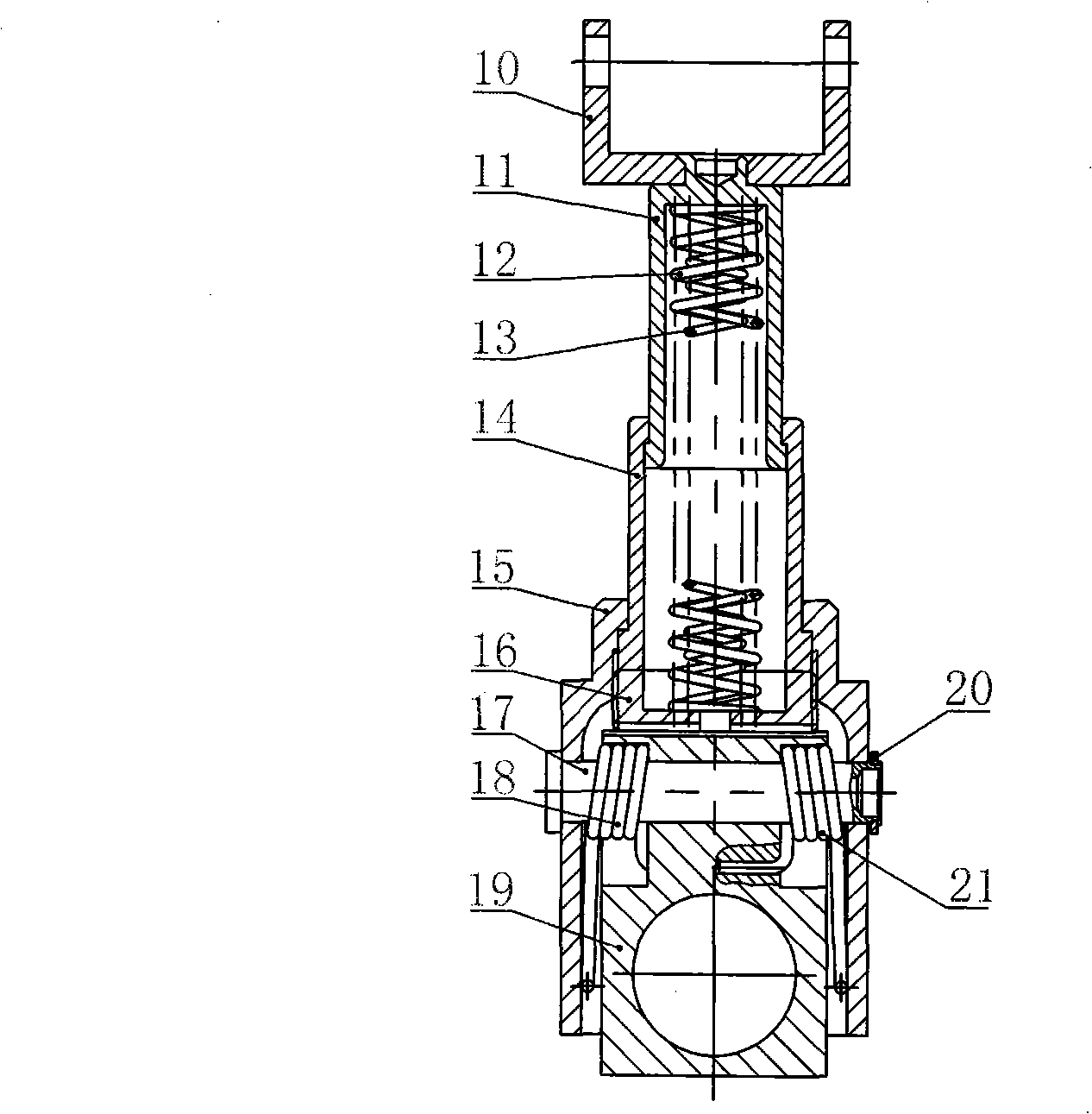

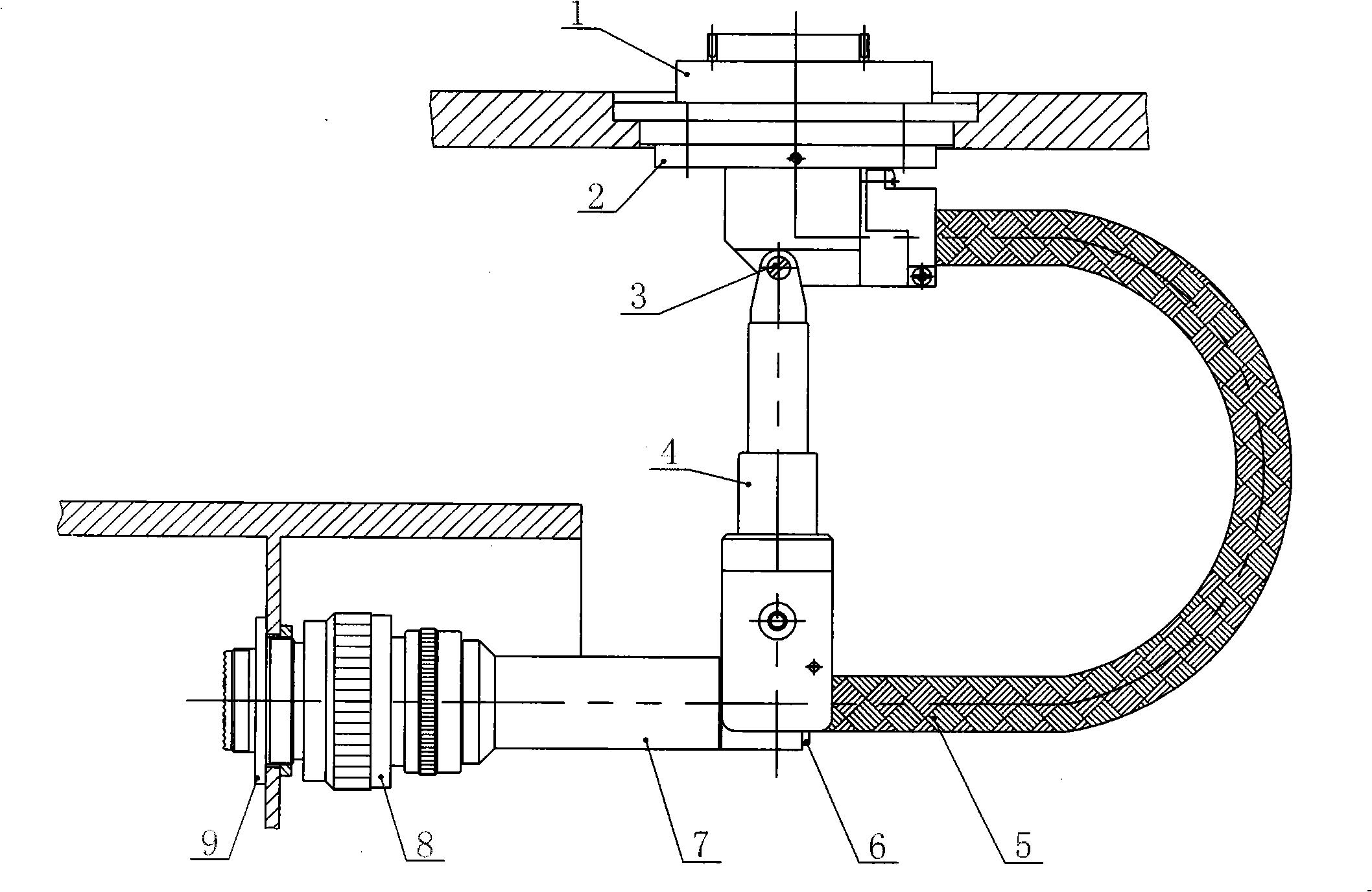

Error compensation separation electric connector

InactiveCN101494347AReduced installation accuracyWith lifting functionCoupling device detailsElectricityElectrical connection

The invention relates to an error compensation separation electric connector, which consists of a separation socket, a separation plug, a rotation pin, a supporting and pulling mechanism, a cable, a tail sleeve, a tail accessory, an adapter plug, and an adapter socket; the separation socket is connected with the adapter plug through the cable; the tail of the adapter plug is connected with the tail accessory; and the supporting and pulling mechanism is installed on the tail accessory through the tail sleeve and connected with the separation plug through the rotation pin to rotate with the rotation pin as a rotating shaft. A vertical separation connector capable of realizing tri-direction large-scale error compensation can lower installation accuracy of the equipment, and has supporting and pulling functions so as to keep the connector in a plugged state; reliable electrical connection is provided; after being started, momentary enforcing separation of the connector can be accomplished.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

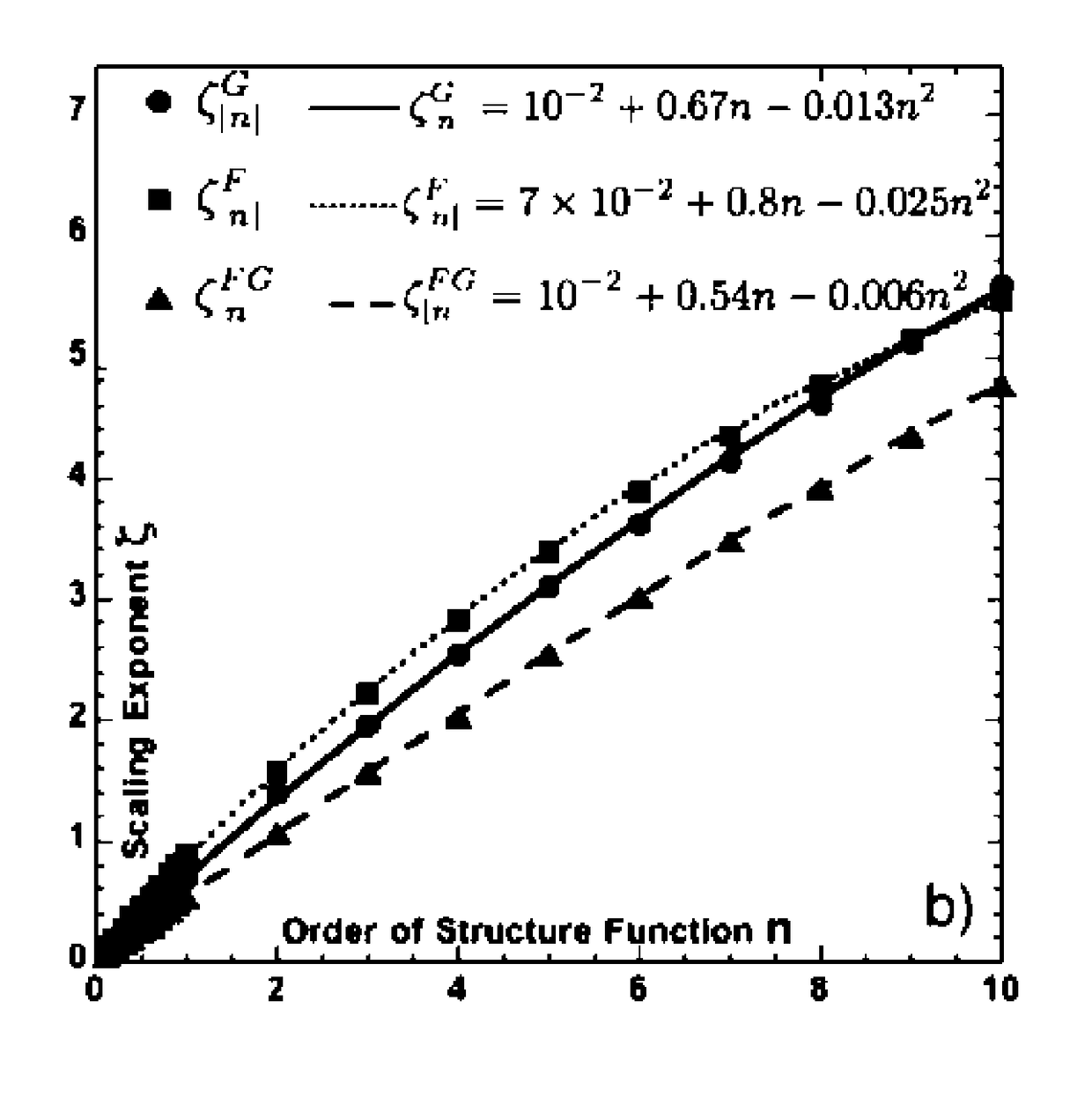

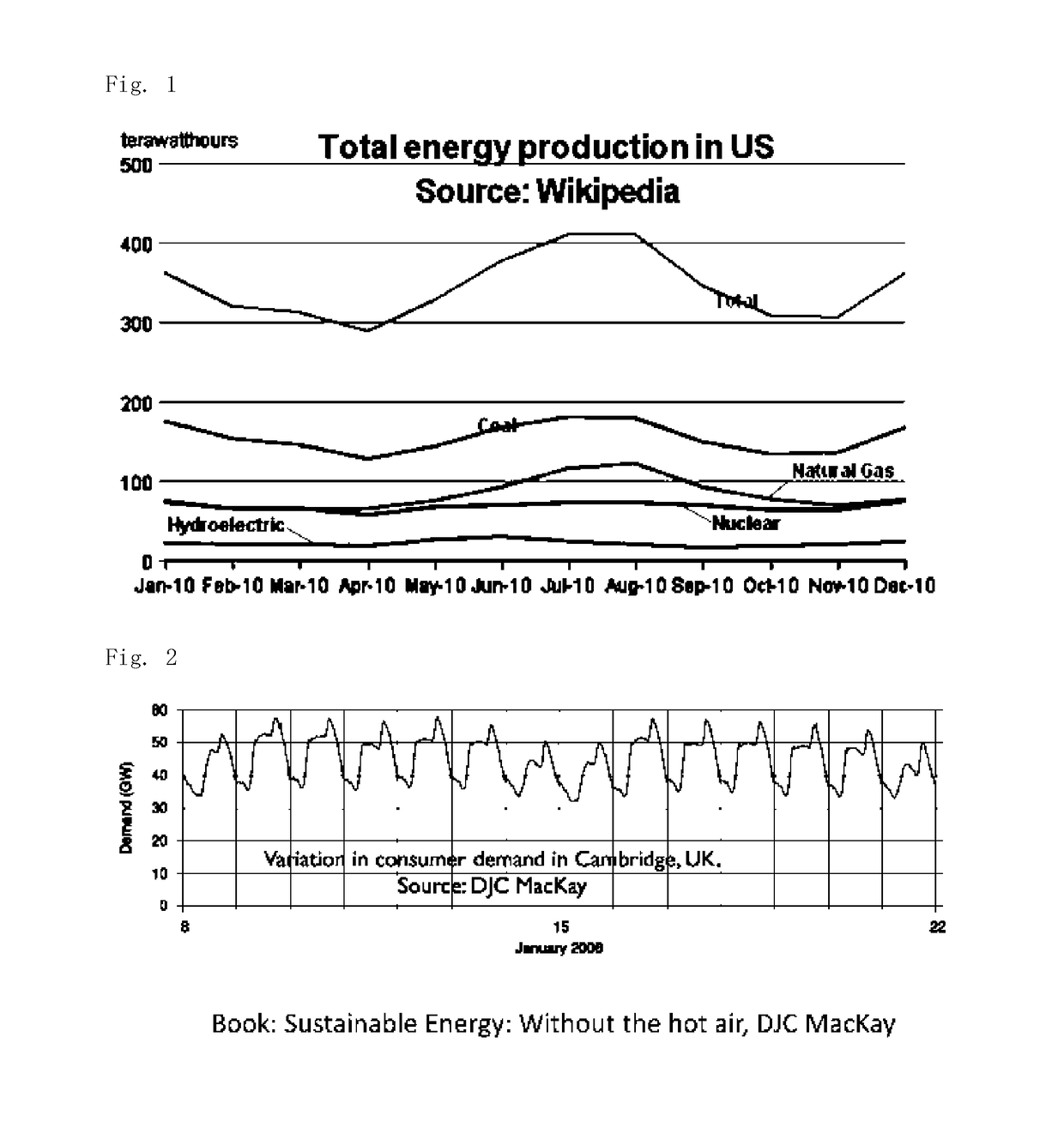

System and method of determining forecast error for renewable energy fluctuations

ActiveUS20180019595A1Reduce scaling errorReduce errorsGeneration forecast in ac networkSimulator controlTemporal correlationTurbine

A system for determining (a) forecast error and / or (b) scaling error for wind power generation is provided, the system utilizing generated and forecast time series for power generation derived from wind and analyzing temporal correlations in the wind fluctuations to quantify: (a) the forecast error defined by deviations between the high frequency components of the forecast and generated time series, and (b) a scaling error defined by a degree that temporal correlations fail to be predicted for an accurate predictor of wind fluctuations. Wind fluctuations may exhibit multi-fractal behavior at the turbine level and / or may be rectified to a fractal structure at the grid level. A memory kernel may be used to reduce the forecast and scaling errors.

Owner:OKINAWA INST OF SCI & TECH SCHOOL

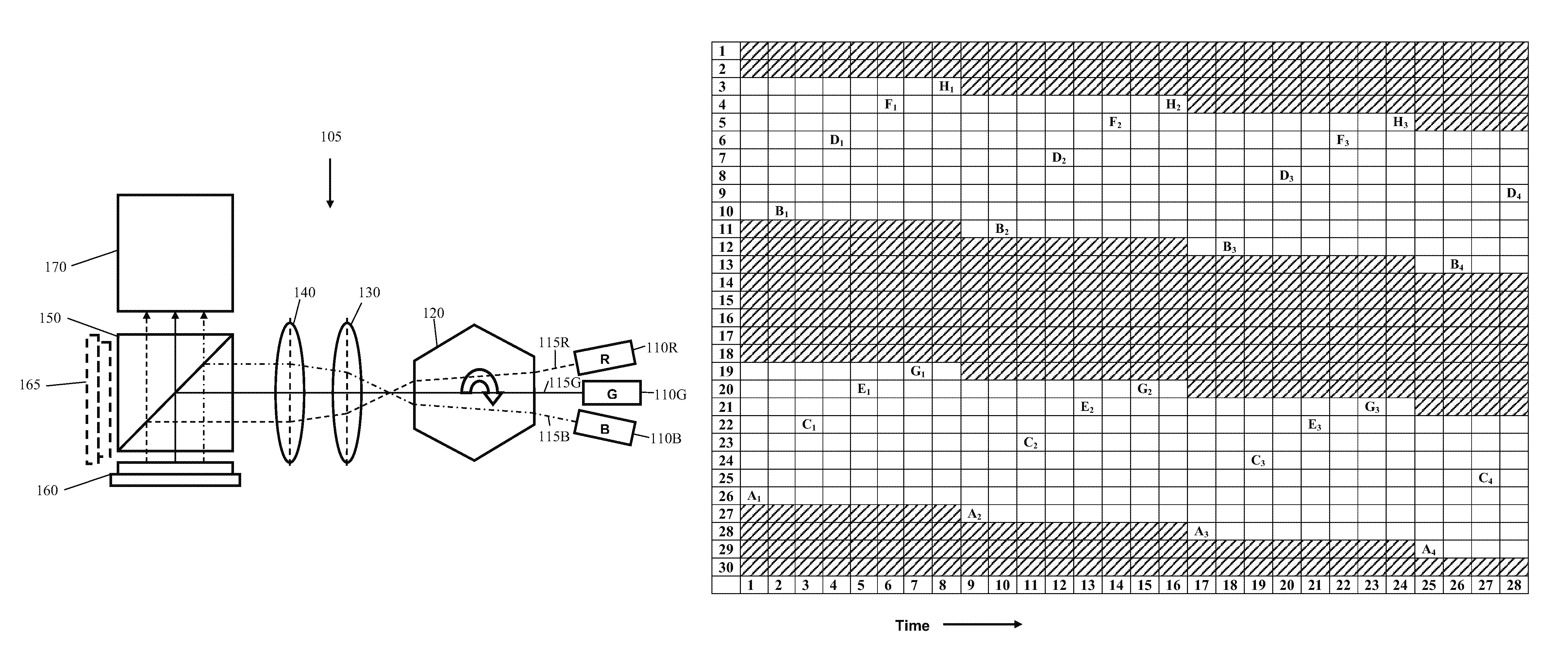

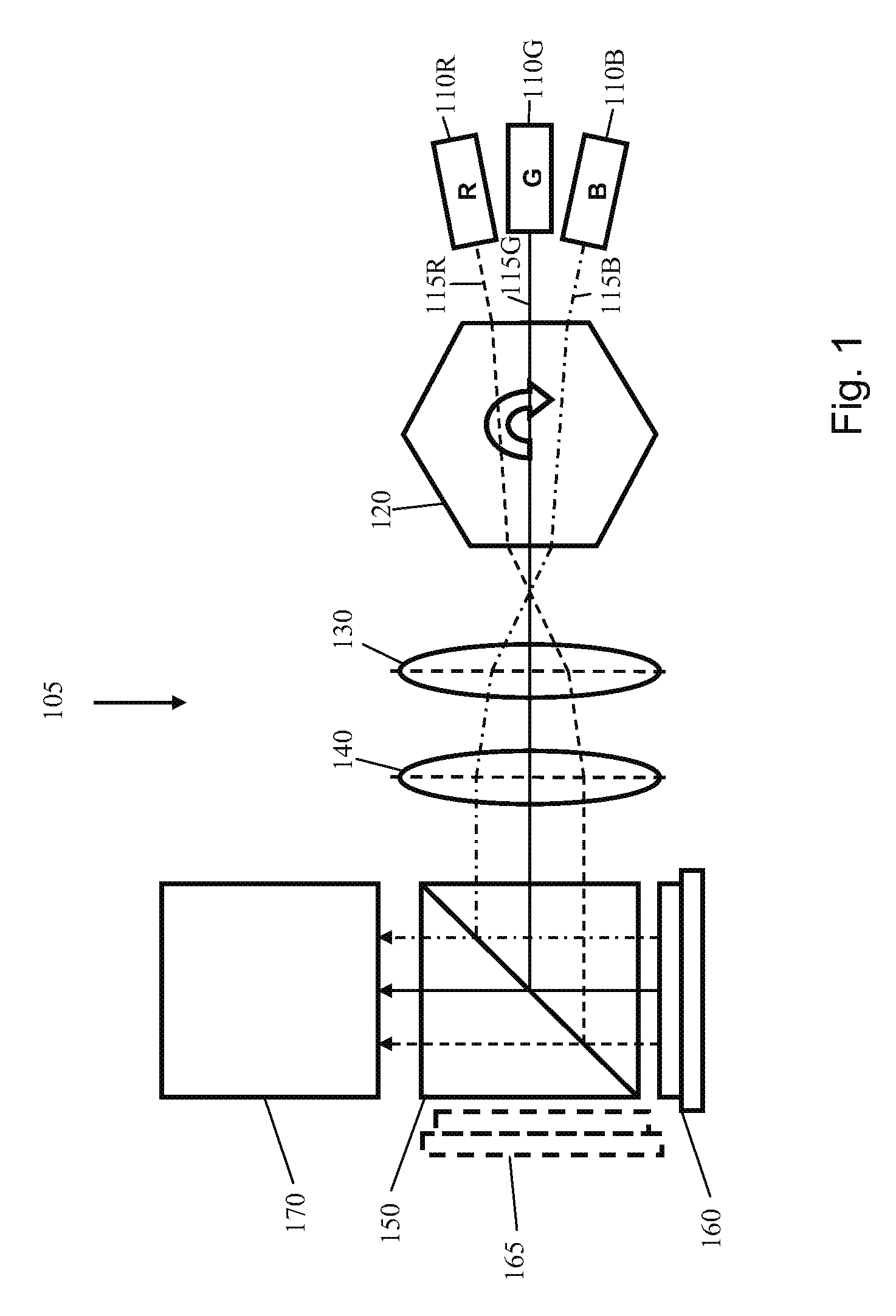

System and method for pulse width modulating a scrolling color display

ActiveUS9406269B2Reducing left-eye and right-eye latencyImprove the display effectCathode-ray tube indicatorsDisplay deviceComputer vision

A method of organizing and ordering pulse width modulation image data is disclosed, so that it may be displayed on the pixels of a scrolling color display. The method includes a method of formatting received image data into a different form suitable for driving a pulse width modulated display and a method of distributing image data across a series of different image modulation segments to minimize flicker and gray scale errors. The method includes means for reducing lateral field effects between adjacent pixels in different data states.

Owner:GOOGLE LLC

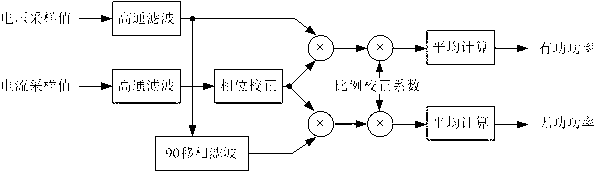

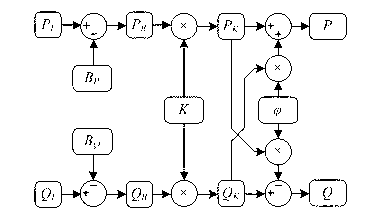

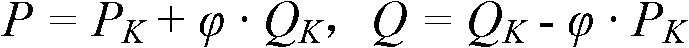

Error compensation method of active powers and reactive powers

ActiveCN102854381ACalibration parameters are accurateHigh compensation accuracyElectric devicesElectric power measurementControl theoryAngular error

The invention relates to an error compensation method of active powers and reactive powers, belonging to the technical field of alternating circuit (AC) parameter measurement. The error compensation method comprises the following steps: performing average computation on sampled active powers and sampled reactive powers to obtain average active power and average reactive power; and performing offset error compensation, proportional error compensation and angle error compensation on the average active power and the average reactive power to obtain final active power output and final reactive power output. An active power offset error setting value, a reactive offset error setting value, a proportional error adjustment coefficient and an angle error adjustment coefficient are obtained by direct correction computation, so that each correction parameter can be computed and set accurately, offset errors caused by common-mode noises are compensated, and the compensation accuracy is high.

Owner:XUJI GRP +3

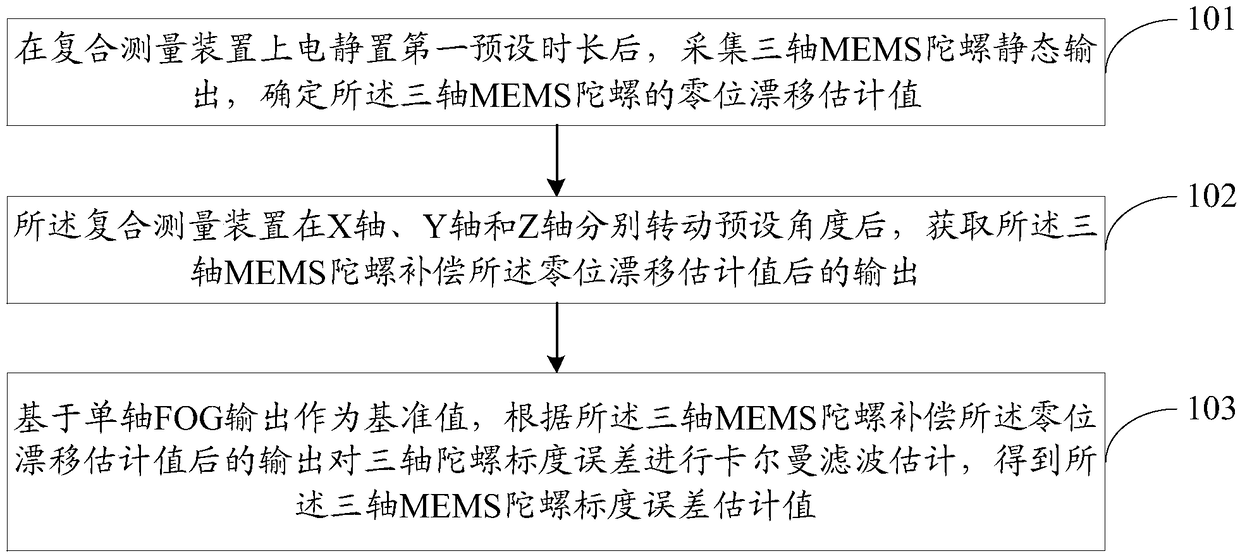

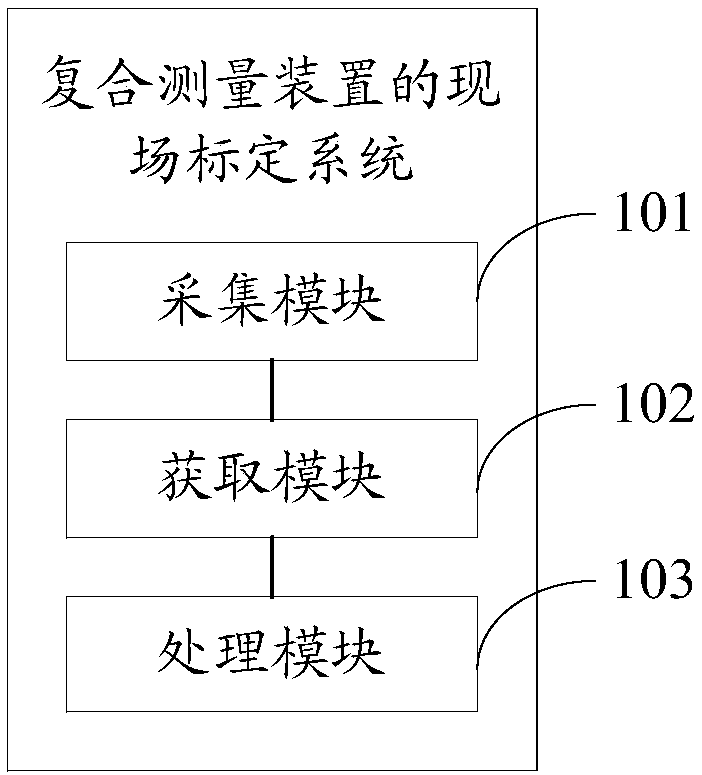

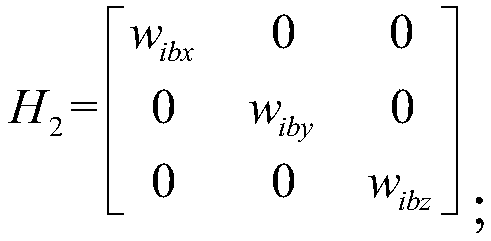

Field calibration method and system for composite measuring device

ActiveCN109186633ASolve the problem of on-site calibrationMeasurement devicesElectricityMeasurement device

The invention provides a field calibration method and system for a composite measuring device. The method comprises the following steps: performing electric standing on the composite measuring devicefor the first preset duration, acquiring static output of a triaxial MEMS (Micro-electromechanical Systems) gyroscope, and determining a zero drift estimated value of the triaxial MEMS gyroscope, wherein the zero drift estimated value is the mean of static output of the triaxial MEMS gyroscope in the second preset duration; respectively rotating the composite measuring device on an axis X, an axisY and an axis Z for preset angles, and acquiring output after the triaxial MEMS gyroscope compensates the zero drift estimated value; and by taking uniaxial FOG output as a reference value, performing Kalman filtering estimation on the triaxial gyroscope scale error according to the output after the triaxial MEMS gyroscope compensates the zero drift estimated value, thereby obtaining the triaxialMEMS gyroscope scale error estimated value. According to the method and system disclosed by the invention, field calibration of the composite measuring device is realized.

Owner:HENGYANG ZHIGU TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com