Fixed-hole fixed-length continuous shearing method of basic bore system section steel

A technology for making base holes and profiles, which is applied to shearing devices, accessories of shearing machines, metal rolling, etc. Compact structure, small sizing error, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

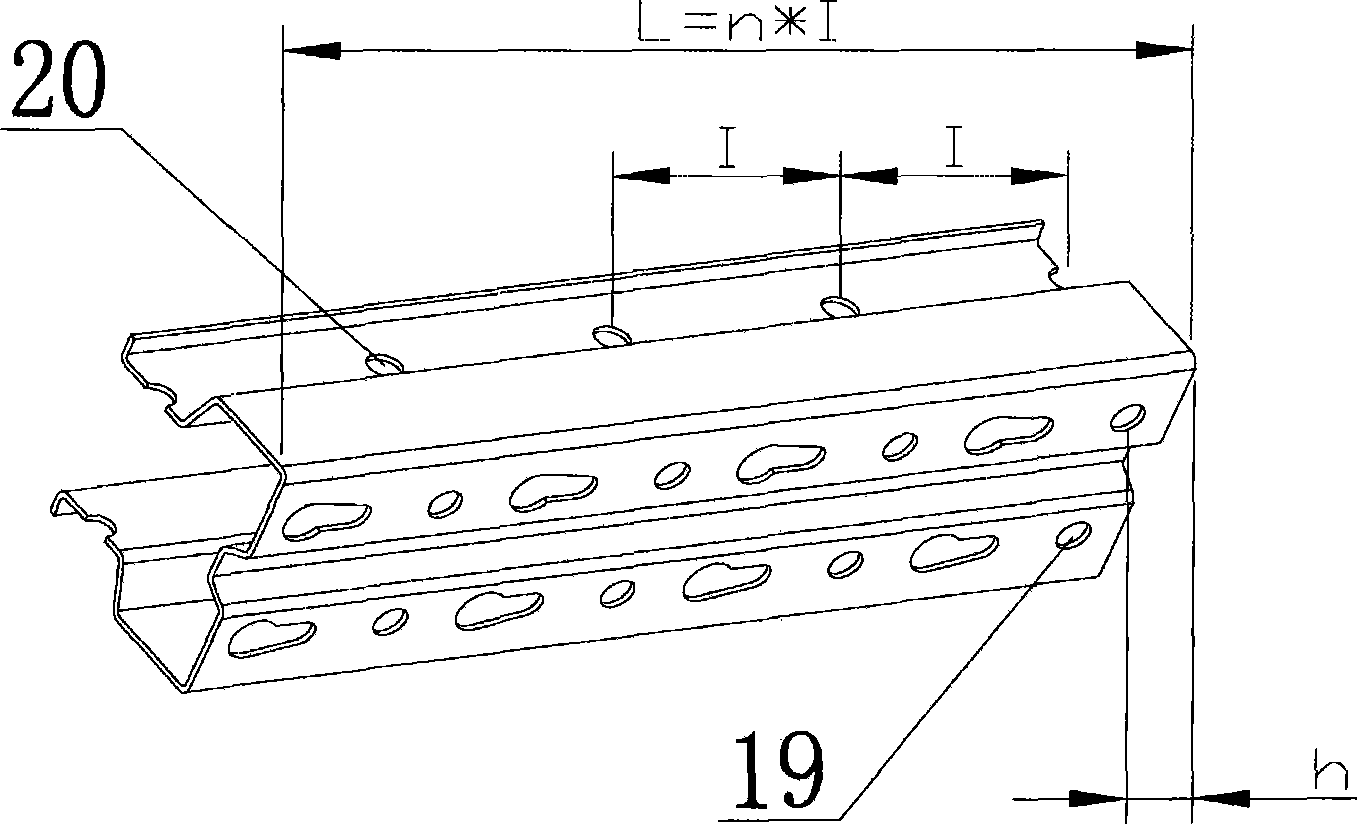

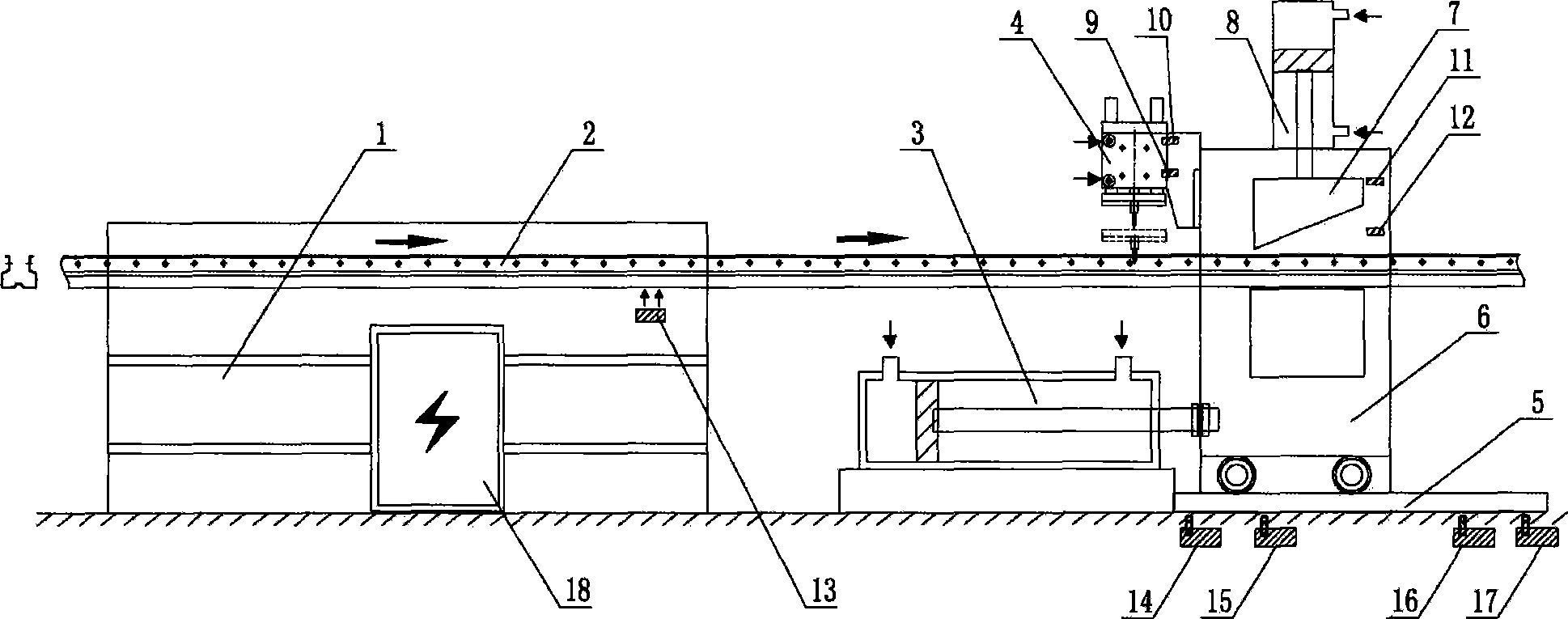

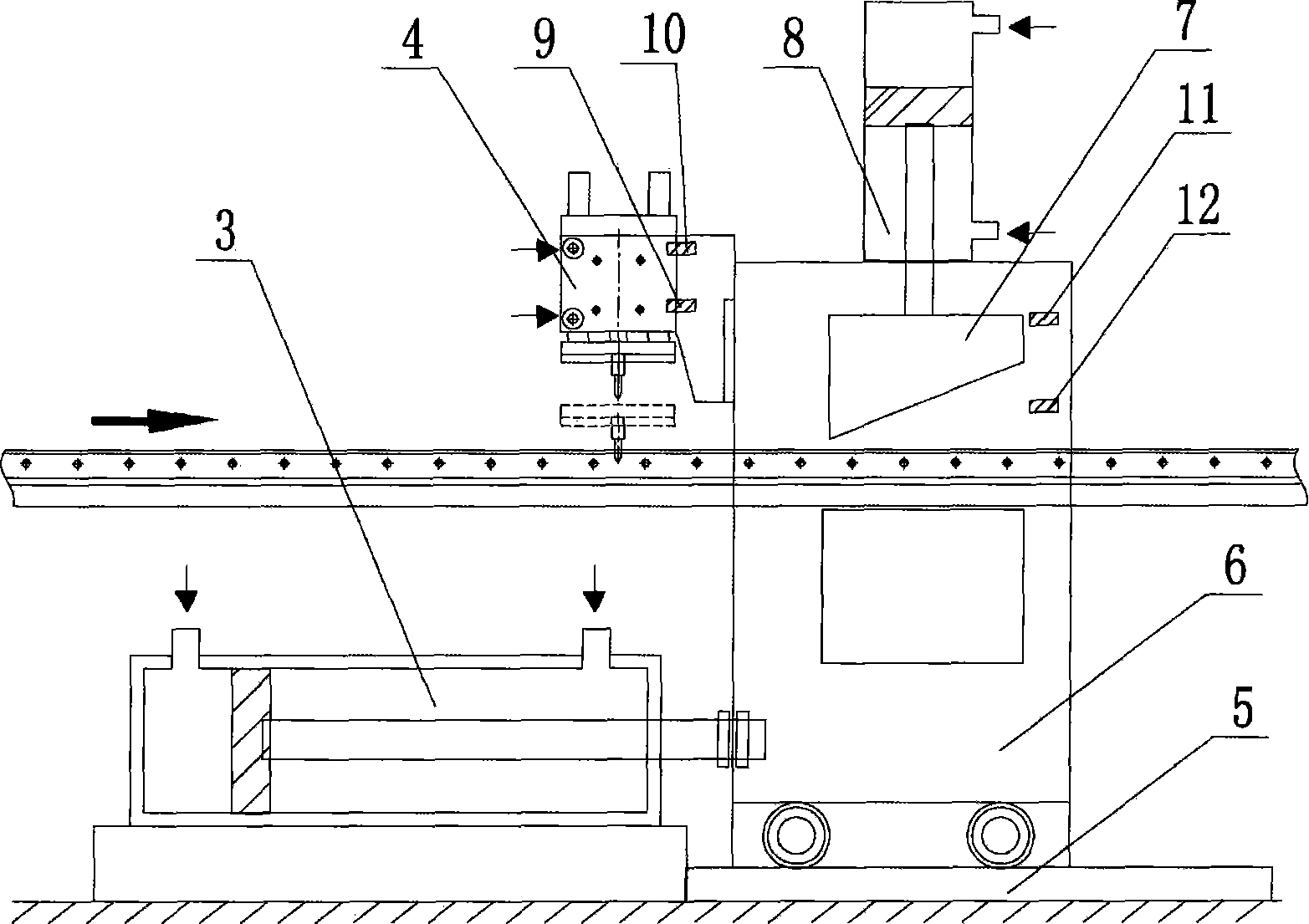

[0017] Such as figure 1 Shown is the structure diagram of the base hole profile shelf column. For the base hole profile, the product not only requires the total length of the profile to be accurate when cutting, but also must ensure that its reference size is also accurate, and must meet its reference size and If the total length is within the tolerance, the cut profile is a qualified product; now combine figure 1 Taking the structure diagram of the shelf column as an example to illustrate, for the base hole profile shelf column, the spacing I of the process holes 20 for each specification product is fixed, as in figure 1 Assuming that I=75mm, the spacing of the entire batch of profile holes is 75mm. This spacing accuracy can be guaranteed by the previous punching process of the production line. In the fixed-length follow-up cutting, as long as the reference size and the number of counted holes are guaranteed, the total length will also be guaranteed. Within the tolerance, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com