Method for exactly calibrating and modifying scanner by using normal scanner in precision measurement

A precision measurement and scanner technology, applied in the fields of instruments, character and pattern recognition, computer parts, etc., can solve problems such as difficult promotion, high price, distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

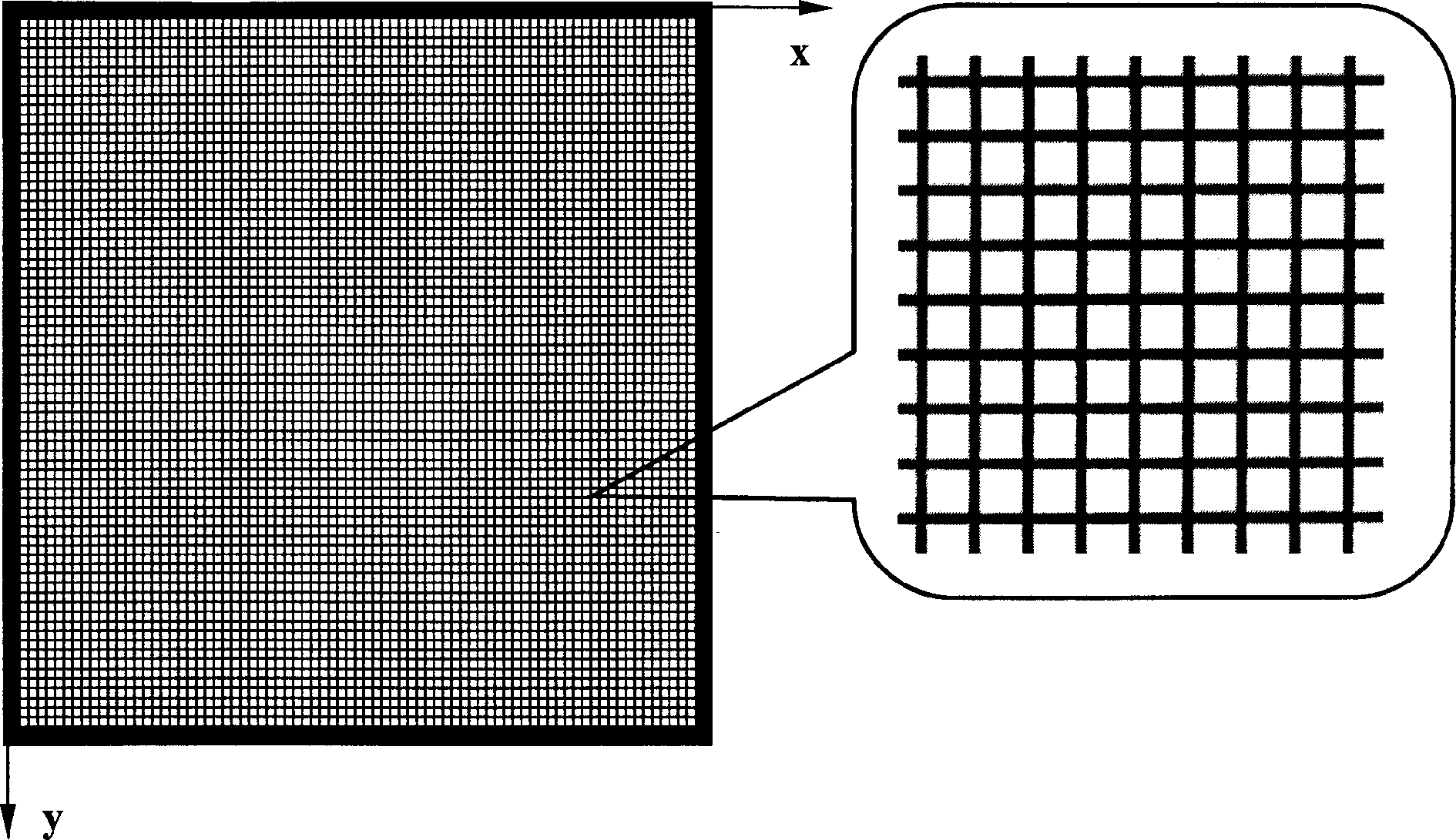

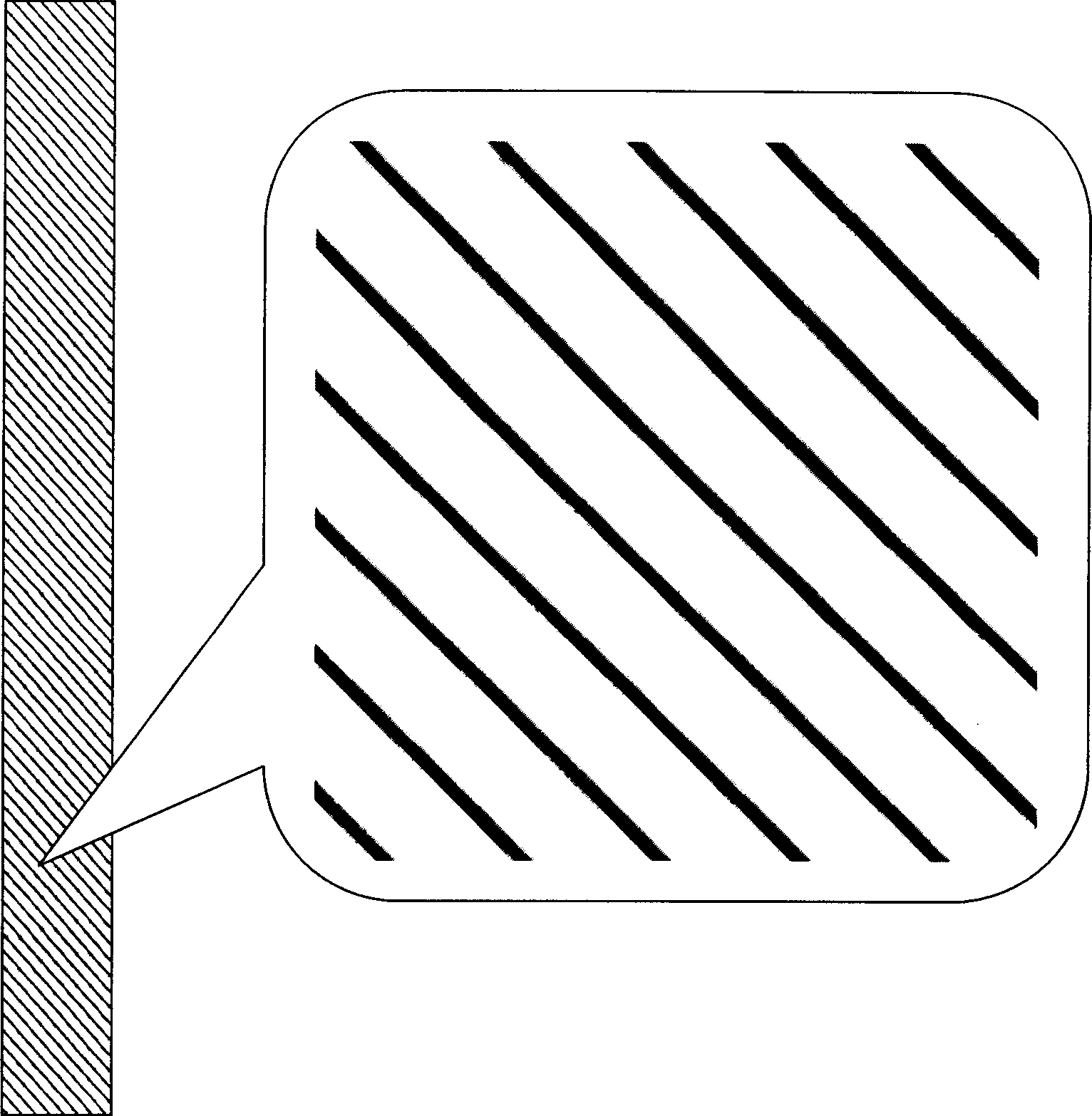

[0137] The measurement system is composed of ordinary flat-bed scanner, electronic computer, precise orthogonal grid and linear grid for calibration (or without linear grid), and application software developed on the basis of this calibration and correction method and digital image processing technology. Implement the described method as follows:

[0138] 1. Press the precision grid and linear grid (negligible) for the image to be tested and calibration Figure 4 or Figure 5 Arranged on the scanning platform;

[0139] 2. Scan the image to be tested and calibrate the precision grid and linear grid (negligible); for the scanned image obtained, selectively perform the following operations (generally applicable calibration and correction sequence):

[0140] 3.1 Calibrate and correct the Y-X error of the scanned image;

[0141] 3.2 Calibrate and correct the X-X error of the scanned image;

[0142] 3.3 Calibrate and correct the X-Y error of the scanned image;

[0143] 3.4 Cali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com