Carriage control device of instrument lathe

A technology for instrument lathes and control devices, which is applied in the field of instrument lathes and devices for controlling instrument lathes. It can solve the problems of too fast movement of the carriage, which affects the processing precision and workpiece processing quality, achieves high processing efficiency, improves processing accuracy and processing The effect of speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

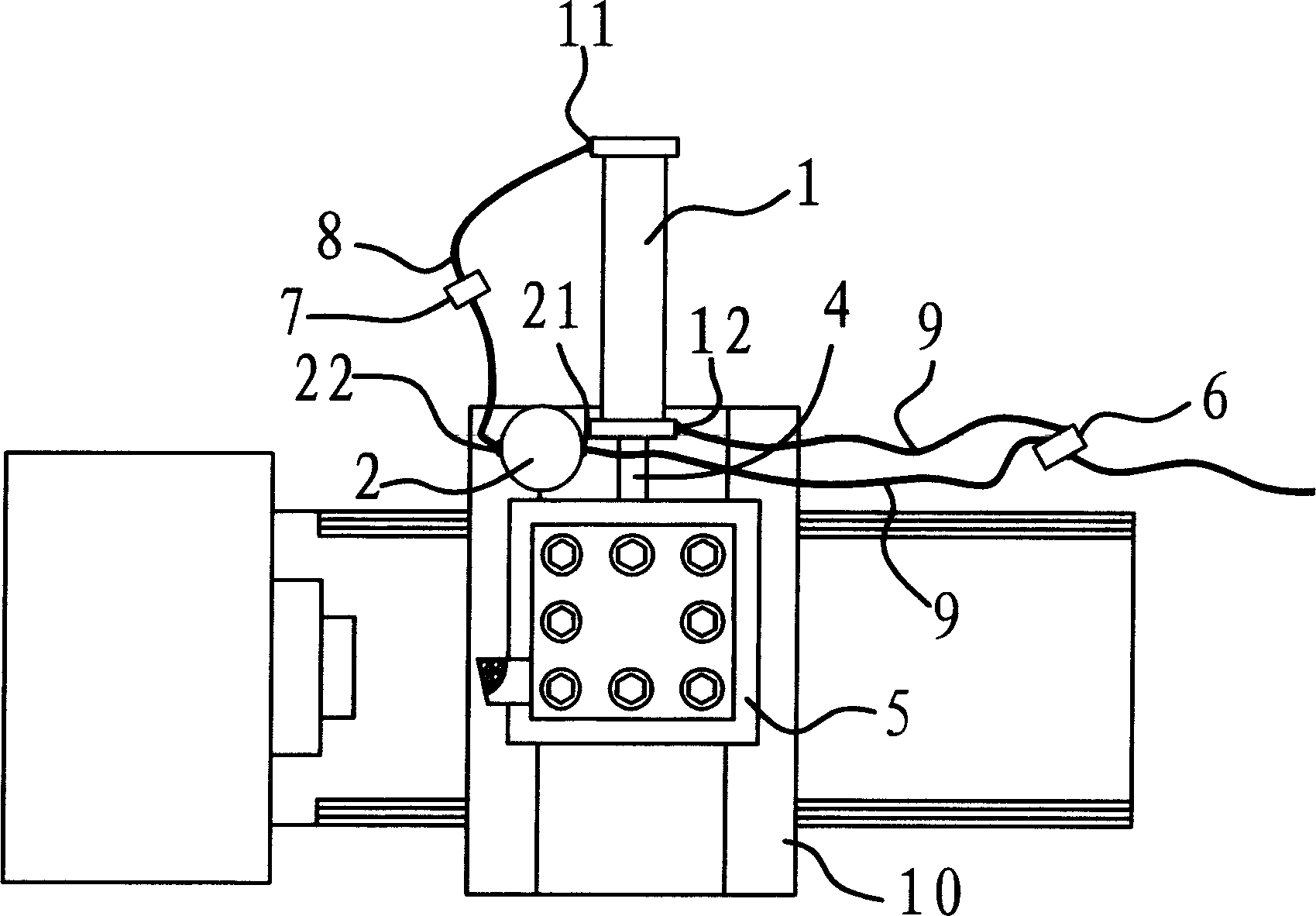

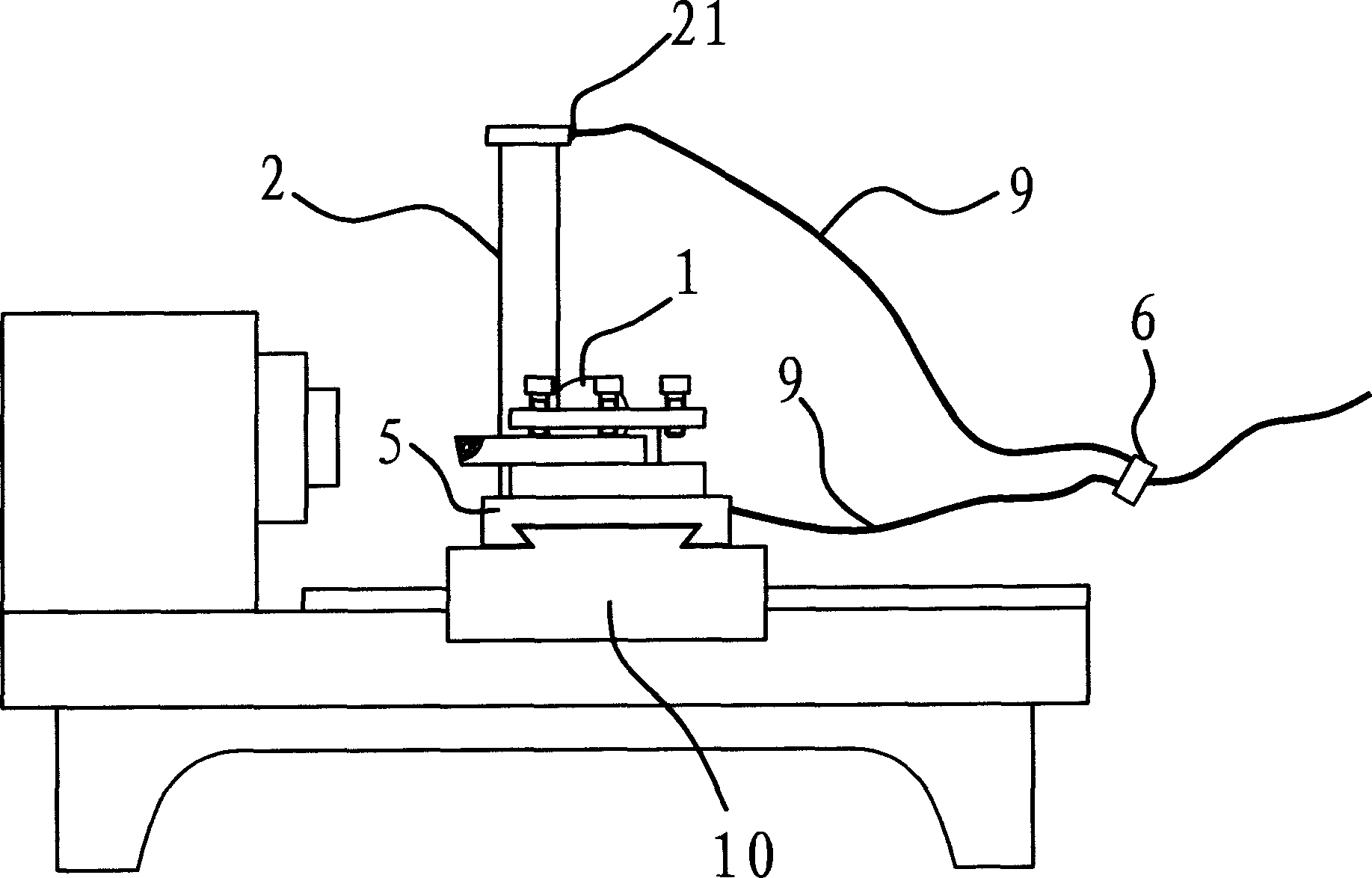

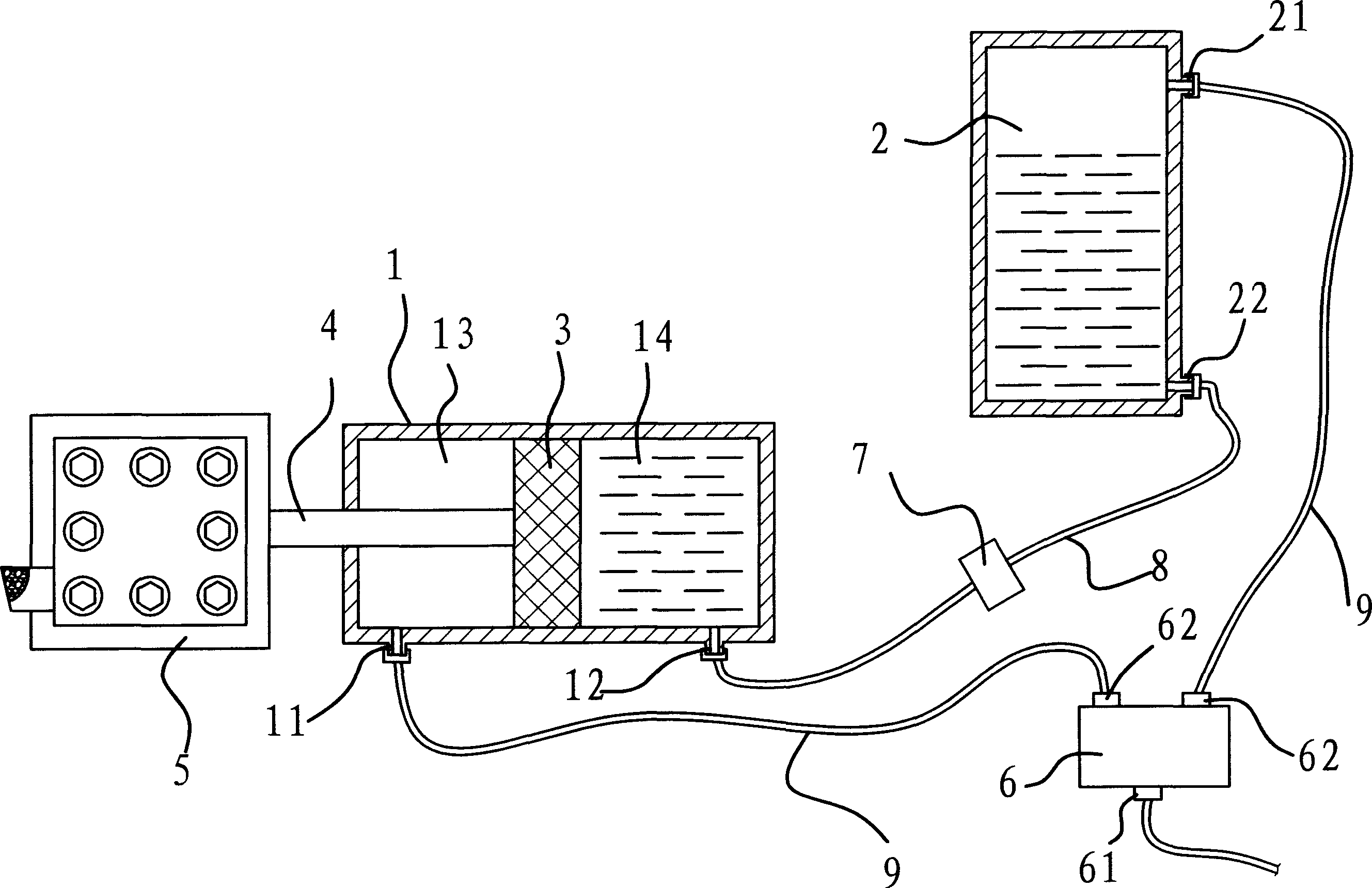

[0016] like figure 1 and figure 2 As shown, the carriage control device of the instrument lathe is set on the bed body of the lathe, which includes a first cylinder 1, a second cylinder 2, a piston 3, a piston rod 4, a throttle valve 6, an oil pipe 8 and an air pipe 9 and other parts. In this embodiment, the outer end of the piston rod 4 is fixedly connected with the small carriage 5 of the instrument lathe. The first cylinder body 1 and the second cylinder body 2 are fixed on the large carriage 10 of the instrument lathe.

[0017] like figure 1 and figure 2 As shown, the first cylinder body 1 is placed horizontally, and a piston 3 that can slide back and forth is arranged in its inner chamber. The piston 3 divides the inner cavity of the first cylinder 1 into a front cavity 13 and a rear cavity 14 . The inner end of the piston rod 4 is fixedly connected with the piston 3, and the outer end stretches out from the first cylinder 1, and is fixedly connected with the smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com