Electric control selection valve and active bottle control distribution method using the valve

A valve selection, electronic control technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problems of delaying the operation of the fighter, delaying the operation of the fighter, and difficulty in installation, so as to achieve smooth opening and reduce control. The effect of link and control simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

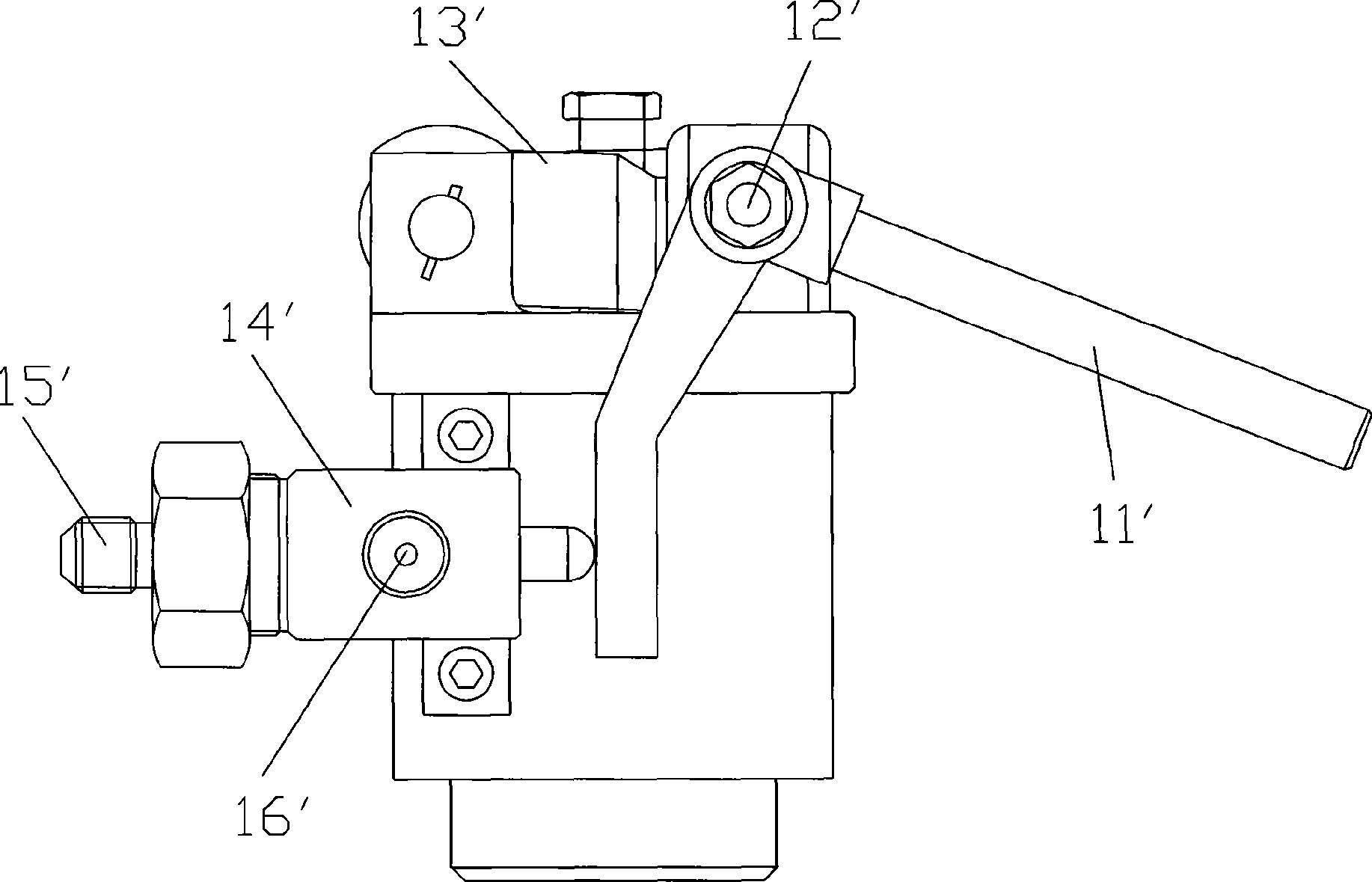

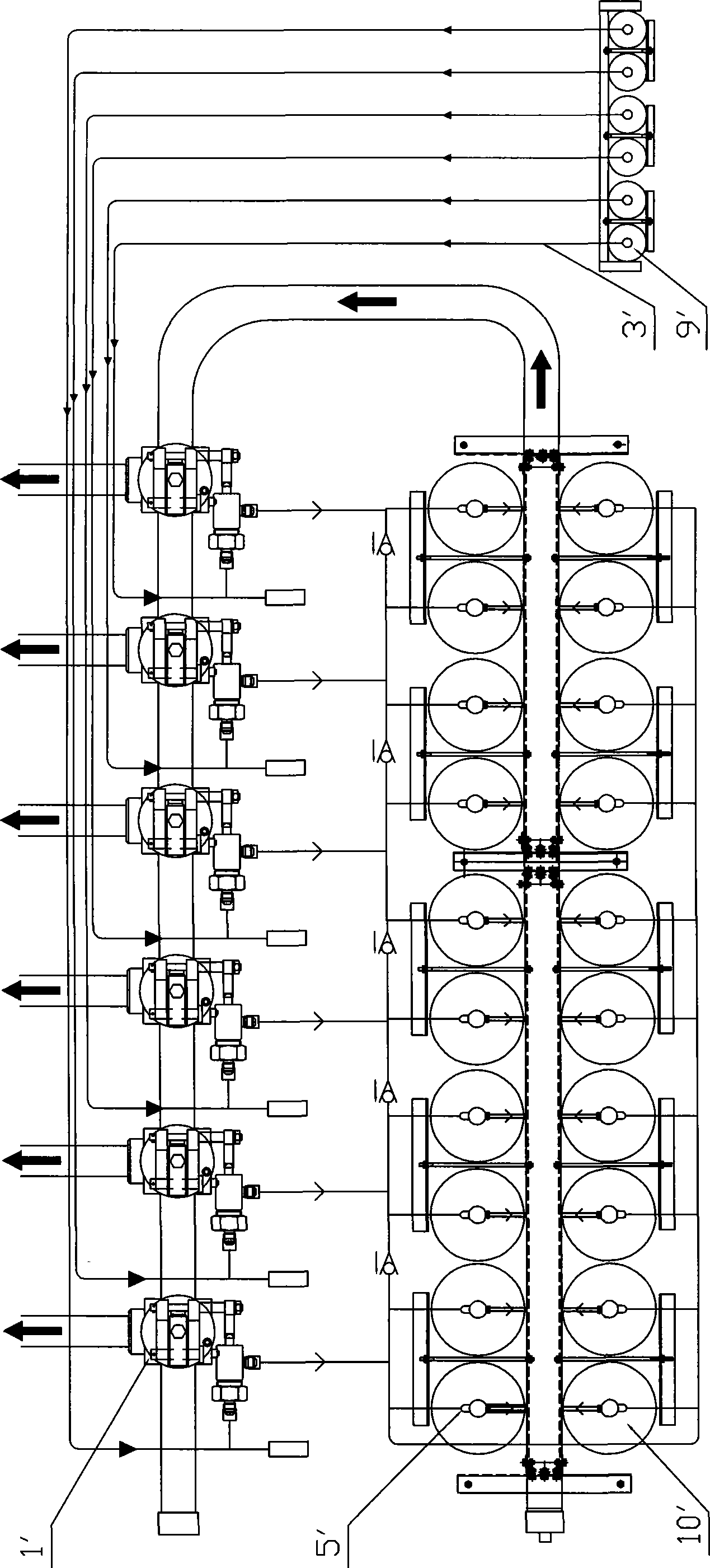

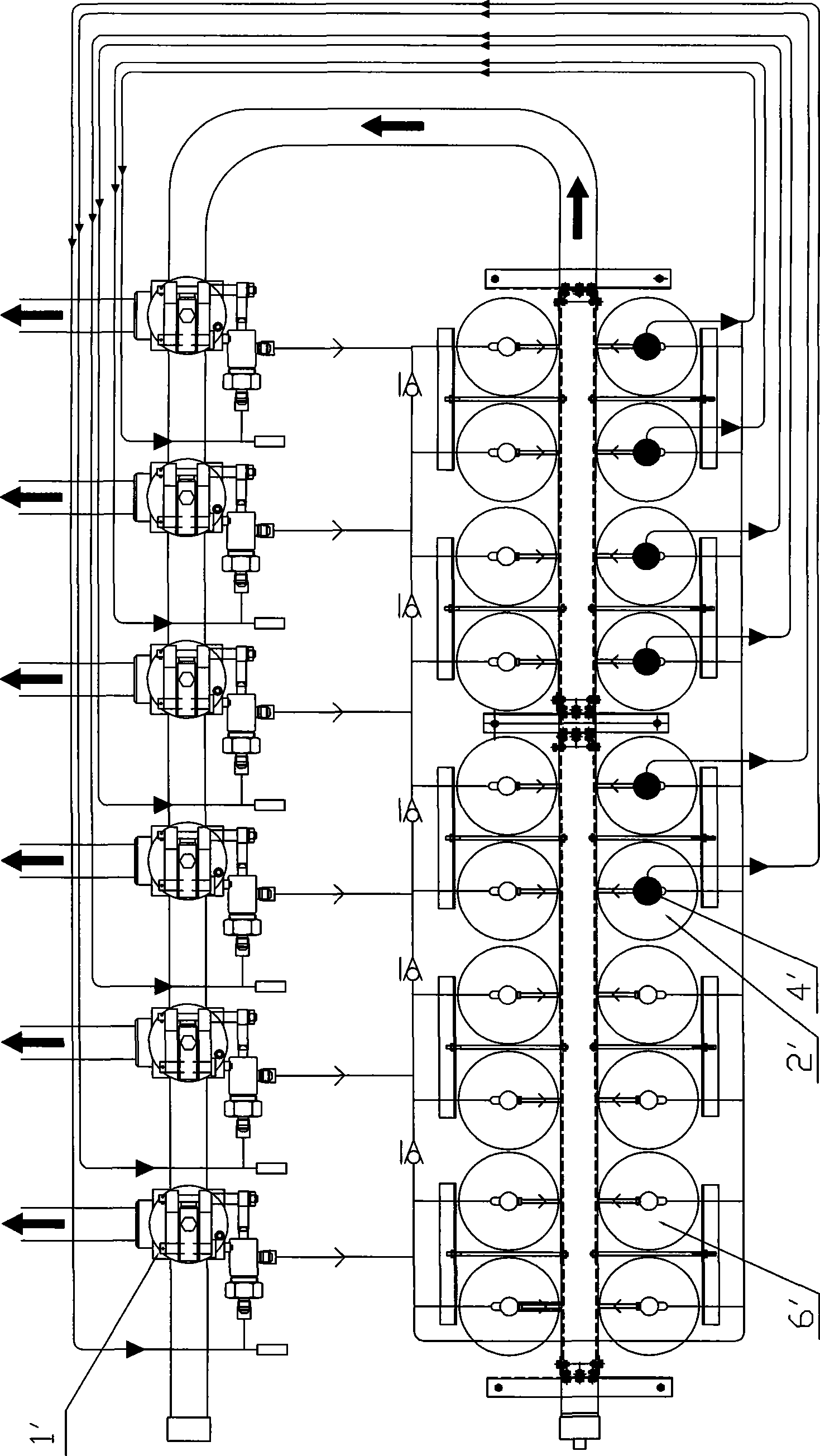

[0026] see Figure 4 and Figure 5 , is composed of the connection between the electric control drive device I and the selector valve II, the electric control drive device I is provided with a metal sealing diaphragm 1, and the metal sealing diaphragm 1 divides the electric control drive device I into an upper space I-1 and a lower space I-2, and the electric control driving device 1 is provided with a driving gas outlet 11. The selector valve II includes a valve body 2, a valve cover 3, a valve stem 4, a piston 7, a cylinder head 6 and a spring 8. The valve body 2 is provided with a total air inlet 13 and a total air outlet 12, a valve cover 3, a valve stem 4 , the piston 7, the cylinder head 6 and the spring 8 are located in the valve body 2, the spring 8, the piston 7, the cylinder head 6, and the valve cover 3 are sequentially set on the valve stem 4, and the valve cover 3 is located at the total air outlet 12, and the cylinder head 6 is fixed in the valve body 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com