Constant-torque electric EGR (Exhaust Gas Recirculation) valve driving mechanism

A technology of EGR valve and driving mechanism, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of shortening the service life of the EGR valve, the inability of the center rod to move vertically, the axial offset of the rack, etc., and achieve the driving clearance. Reduce, ensure vertical motion, turn on stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

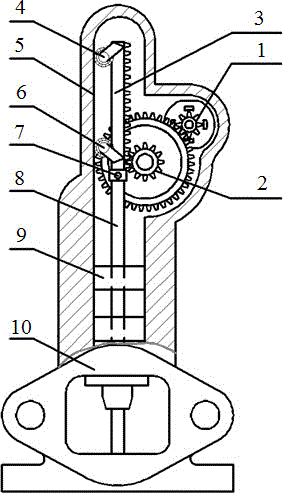

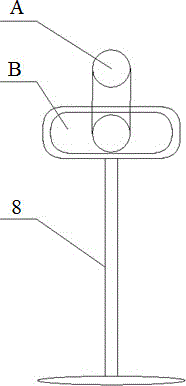

[0019] An electric EGR valve drive mechanism with constant torque, including a motor 1, a reduction mechanism, a drive mechanism and a guide mechanism arranged in the valve body 10, the output shaft of the motor drives the drive mechanism through the reduction mechanism, and further drives the center rod to move up and down, The guiding mechanism is arranged on the valve body and the driving mechanism, and is used to ensure that the driving mechanism can maintain linear motion in the vertical direction, and further ensure that the central rod can perform linear motion in the vertical direction.

[0020] In the present invention, the deceleration mechanism adopts the deceleration gear set 2, and the drive mechanism adopts a vertical drive rack 3, and the drive rack 3 and the motor 1 are meshed through the speed change gear set 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com