Intelligent negative pressure collector based on negative pressure drainage system

A technology of negative pressure collection and drainage system, which is applied in the direction of waterway system, sewer pipe system, and sewage discharge, etc. It can solve the problems of inability to analyze the cause and location of the fault, consume a lot of time, and reduce the overall efficiency, etc., to achieve stable growth Open the components, facilitate positioning and maintenance, and ensure stable opening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

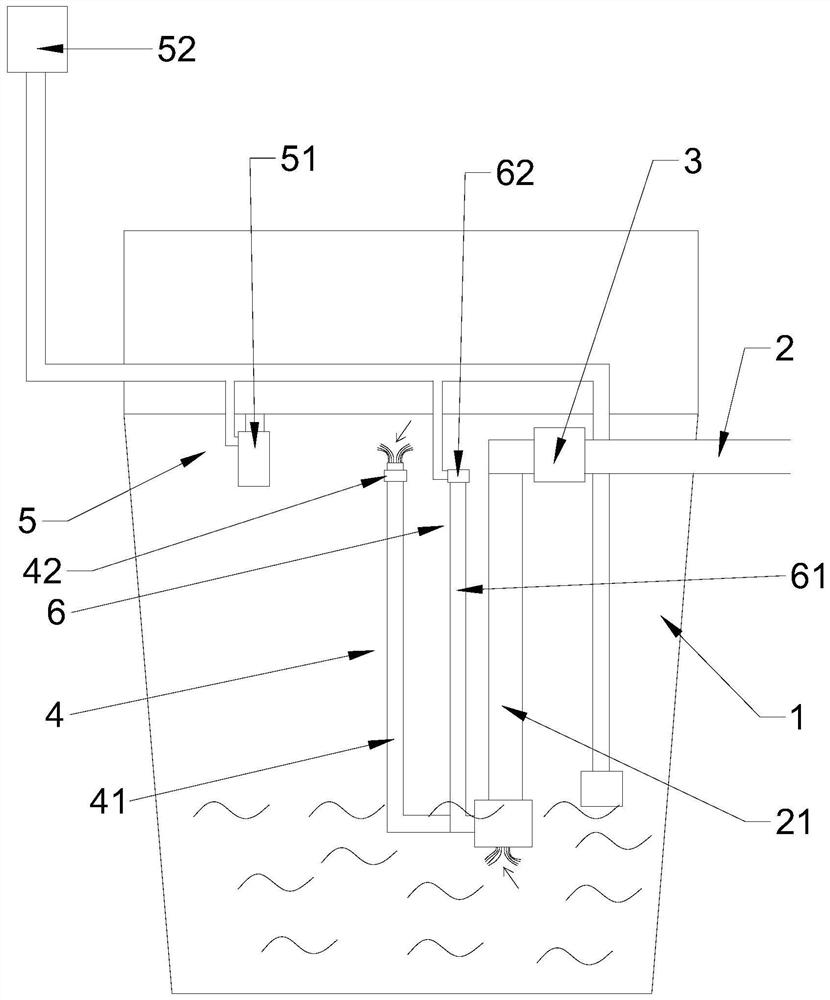

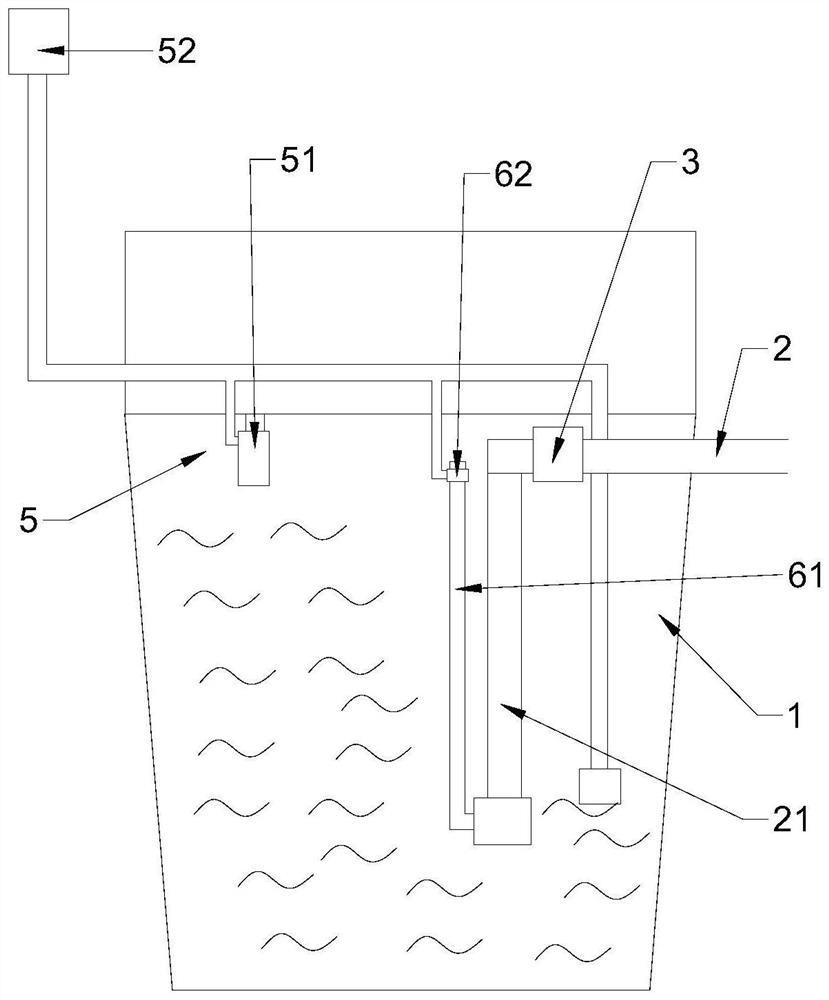

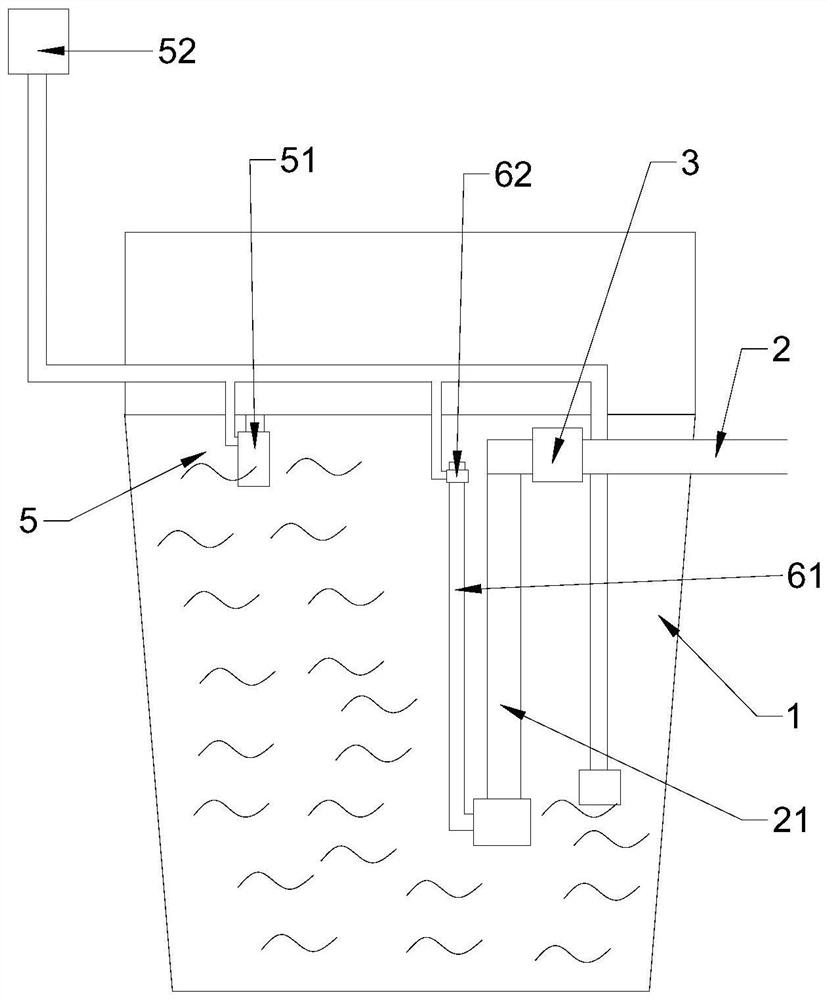

[0025] See attached Figure 1-5 As shown, an intelligent negative pressure collector based on a negative pressure drainage system in this embodiment includes a negative pressure intelligent collector 1, a negative pressure collecting pipe 2 is arranged in the negative pressure intelligent collector 1, and a negative pressure collecting pipe 2 The interface valve 3 is set on the top, and the interface valve 3 can control the on-off of the negative pressure collection pipe 2, and the air intake assembly 4 is arranged on the water absorption section 21 of the negative pressure collection pipe 2, and the air intake assembly 4 can adjust the air in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com